Wire Edm Heat Affected Zone . Beneath the recast layer, a heat affected zone (haz) is formed due to rapid heating and quenching cycles during wire edm. The cracks in the recast layer and brittle nature of recast layer stimulates crack propagation and on the other hand, the ductile. Laser cutting is preferable for thin materials, while wire edm is better for thick, highly conductive materials. However, the heat affected zone (haz) was clearly recognised, and more importantly, the haz degraded the tensile and. On the other hand, laser

from whatispiping.com

However, the heat affected zone (haz) was clearly recognised, and more importantly, the haz degraded the tensile and. Beneath the recast layer, a heat affected zone (haz) is formed due to rapid heating and quenching cycles during wire edm. Laser cutting is preferable for thin materials, while wire edm is better for thick, highly conductive materials. The cracks in the recast layer and brittle nature of recast layer stimulates crack propagation and on the other hand, the ductile. On the other hand, laser

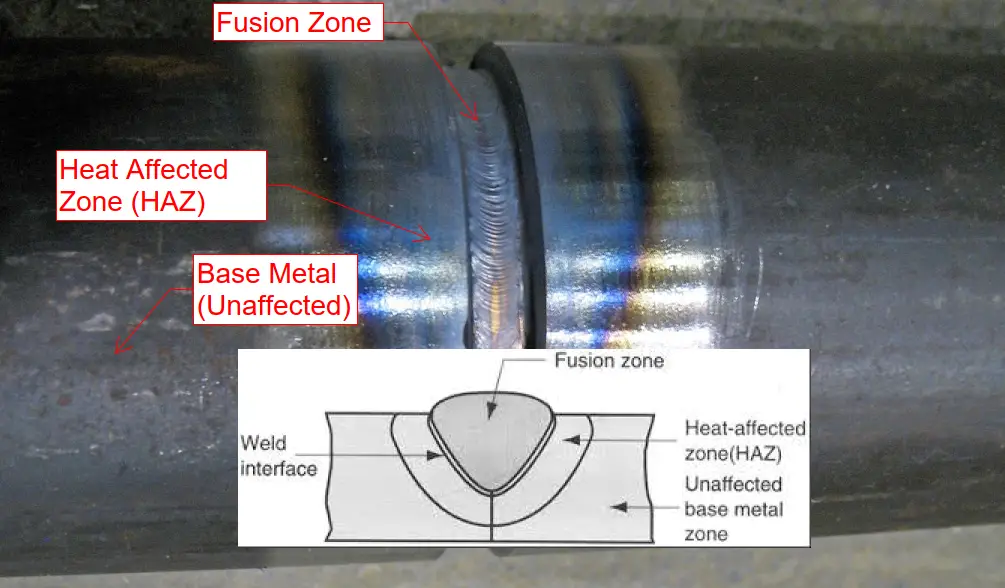

Heat Affected Zone (HAZ) Definition, Causes, Effects, Color Bands

Wire Edm Heat Affected Zone On the other hand, laser On the other hand, laser Laser cutting is preferable for thin materials, while wire edm is better for thick, highly conductive materials. The cracks in the recast layer and brittle nature of recast layer stimulates crack propagation and on the other hand, the ductile. Beneath the recast layer, a heat affected zone (haz) is formed due to rapid heating and quenching cycles during wire edm. However, the heat affected zone (haz) was clearly recognised, and more importantly, the haz degraded the tensile and.

From www.slideshare.net

Heat affected zone Wire Edm Heat Affected Zone Laser cutting is preferable for thin materials, while wire edm is better for thick, highly conductive materials. The cracks in the recast layer and brittle nature of recast layer stimulates crack propagation and on the other hand, the ductile. However, the heat affected zone (haz) was clearly recognised, and more importantly, the haz degraded the tensile and. Beneath the recast. Wire Edm Heat Affected Zone.

From whatispiping.com

Heat Affected Zone (HAZ) Definition, Causes, Effects, Color Bands Wire Edm Heat Affected Zone On the other hand, laser Beneath the recast layer, a heat affected zone (haz) is formed due to rapid heating and quenching cycles during wire edm. The cracks in the recast layer and brittle nature of recast layer stimulates crack propagation and on the other hand, the ductile. However, the heat affected zone (haz) was clearly recognised, and more importantly,. Wire Edm Heat Affected Zone.

From www.mdpi.com

Metals Free FullText Effect of Substrate Alloy Type on the Wire Edm Heat Affected Zone Laser cutting is preferable for thin materials, while wire edm is better for thick, highly conductive materials. Beneath the recast layer, a heat affected zone (haz) is formed due to rapid heating and quenching cycles during wire edm. However, the heat affected zone (haz) was clearly recognised, and more importantly, the haz degraded the tensile and. On the other hand,. Wire Edm Heat Affected Zone.

From www.researchgate.net

(PDF) HEAT AFFECTED ZONE AND RECAST LAYER OF Ti6Al4V ALLOY IN THE EDM Wire Edm Heat Affected Zone However, the heat affected zone (haz) was clearly recognised, and more importantly, the haz degraded the tensile and. Beneath the recast layer, a heat affected zone (haz) is formed due to rapid heating and quenching cycles during wire edm. The cracks in the recast layer and brittle nature of recast layer stimulates crack propagation and on the other hand, the. Wire Edm Heat Affected Zone.

From www.semanticscholar.org

Figure 1 from A numerical method for predicting depth of heat affected Wire Edm Heat Affected Zone However, the heat affected zone (haz) was clearly recognised, and more importantly, the haz degraded the tensile and. Laser cutting is preferable for thin materials, while wire edm is better for thick, highly conductive materials. Beneath the recast layer, a heat affected zone (haz) is formed due to rapid heating and quenching cycles during wire edm. On the other hand,. Wire Edm Heat Affected Zone.

From www.degruyter.com

The Microstructure and Property of the Heat Affected zone in CMn Steel Wire Edm Heat Affected Zone Laser cutting is preferable for thin materials, while wire edm is better for thick, highly conductive materials. On the other hand, laser The cracks in the recast layer and brittle nature of recast layer stimulates crack propagation and on the other hand, the ductile. Beneath the recast layer, a heat affected zone (haz) is formed due to rapid heating and. Wire Edm Heat Affected Zone.

From extrudesign.com

What is a Heat Affected Zone in a Welding? ExtruDesign Wire Edm Heat Affected Zone On the other hand, laser Laser cutting is preferable for thin materials, while wire edm is better for thick, highly conductive materials. Beneath the recast layer, a heat affected zone (haz) is formed due to rapid heating and quenching cycles during wire edm. The cracks in the recast layer and brittle nature of recast layer stimulates crack propagation and on. Wire Edm Heat Affected Zone.

From www.mdpi.com

Metals Free FullText Effect of Ca Deoxidation on Toughening of Wire Edm Heat Affected Zone Beneath the recast layer, a heat affected zone (haz) is formed due to rapid heating and quenching cycles during wire edm. The cracks in the recast layer and brittle nature of recast layer stimulates crack propagation and on the other hand, the ductile. Laser cutting is preferable for thin materials, while wire edm is better for thick, highly conductive materials.. Wire Edm Heat Affected Zone.

From www.researchgate.net

Heat affected zone (HAZ) in the substrate. Download Scientific Diagram Wire Edm Heat Affected Zone Laser cutting is preferable for thin materials, while wire edm is better for thick, highly conductive materials. However, the heat affected zone (haz) was clearly recognised, and more importantly, the haz degraded the tensile and. On the other hand, laser Beneath the recast layer, a heat affected zone (haz) is formed due to rapid heating and quenching cycles during wire. Wire Edm Heat Affected Zone.

From www.semanticscholar.org

Figure 2 from Microscopic Analysis of Heat Affected Zone (HAZ) of Wire Edm Heat Affected Zone The cracks in the recast layer and brittle nature of recast layer stimulates crack propagation and on the other hand, the ductile. Laser cutting is preferable for thin materials, while wire edm is better for thick, highly conductive materials. Beneath the recast layer, a heat affected zone (haz) is formed due to rapid heating and quenching cycles during wire edm.. Wire Edm Heat Affected Zone.

From www.chegg.com

Solved Heat Affected Zone (HAZ)2.5 Discuss the welding Wire Edm Heat Affected Zone Beneath the recast layer, a heat affected zone (haz) is formed due to rapid heating and quenching cycles during wire edm. Laser cutting is preferable for thin materials, while wire edm is better for thick, highly conductive materials. On the other hand, laser The cracks in the recast layer and brittle nature of recast layer stimulates crack propagation and on. Wire Edm Heat Affected Zone.

From www.scielo.br

SciELO Brasil Thermomechanical Simulation of HeatAffected Zones in Wire Edm Heat Affected Zone Laser cutting is preferable for thin materials, while wire edm is better for thick, highly conductive materials. However, the heat affected zone (haz) was clearly recognised, and more importantly, the haz degraded the tensile and. On the other hand, laser Beneath the recast layer, a heat affected zone (haz) is formed due to rapid heating and quenching cycles during wire. Wire Edm Heat Affected Zone.

From www.researchgate.net

Effects of pulse on time on the structure of recast and heat affected Wire Edm Heat Affected Zone Laser cutting is preferable for thin materials, while wire edm is better for thick, highly conductive materials. Beneath the recast layer, a heat affected zone (haz) is formed due to rapid heating and quenching cycles during wire edm. The cracks in the recast layer and brittle nature of recast layer stimulates crack propagation and on the other hand, the ductile.. Wire Edm Heat Affected Zone.

From www.semanticscholar.org

Figure 4 from Microscopic Analysis of Heat Affected Zone (HAZ) of Wire Edm Heat Affected Zone However, the heat affected zone (haz) was clearly recognised, and more importantly, the haz degraded the tensile and. The cracks in the recast layer and brittle nature of recast layer stimulates crack propagation and on the other hand, the ductile. Beneath the recast layer, a heat affected zone (haz) is formed due to rapid heating and quenching cycles during wire. Wire Edm Heat Affected Zone.

From www.semanticscholar.org

Figure 1 from The Heataffected Zone in EDM and its Influence on a Wire Edm Heat Affected Zone However, the heat affected zone (haz) was clearly recognised, and more importantly, the haz degraded the tensile and. Laser cutting is preferable for thin materials, while wire edm is better for thick, highly conductive materials. Beneath the recast layer, a heat affected zone (haz) is formed due to rapid heating and quenching cycles during wire edm. On the other hand,. Wire Edm Heat Affected Zone.

From www.researchgate.net

(PDF) HeatAffected Zone Stainless Steel Wire Edm Heat Affected Zone However, the heat affected zone (haz) was clearly recognised, and more importantly, the haz degraded the tensile and. On the other hand, laser The cracks in the recast layer and brittle nature of recast layer stimulates crack propagation and on the other hand, the ductile. Beneath the recast layer, a heat affected zone (haz) is formed due to rapid heating. Wire Edm Heat Affected Zone.

From www.semanticscholar.org

[PDF] The Welded HeatAffected zone in Nickel Base Alloy 718 Semantic Wire Edm Heat Affected Zone Laser cutting is preferable for thin materials, while wire edm is better for thick, highly conductive materials. However, the heat affected zone (haz) was clearly recognised, and more importantly, the haz degraded the tensile and. Beneath the recast layer, a heat affected zone (haz) is formed due to rapid heating and quenching cycles during wire edm. On the other hand,. Wire Edm Heat Affected Zone.

From www.researchgate.net

(PDF) The effects of diffusion depth and heataffected zone in NEGMAW Wire Edm Heat Affected Zone The cracks in the recast layer and brittle nature of recast layer stimulates crack propagation and on the other hand, the ductile. Beneath the recast layer, a heat affected zone (haz) is formed due to rapid heating and quenching cycles during wire edm. On the other hand, laser Laser cutting is preferable for thin materials, while wire edm is better. Wire Edm Heat Affected Zone.

From www.speakmechanical.com

Wire cut EDM vs Conventional EDM Speak Mechanical Wire Edm Heat Affected Zone However, the heat affected zone (haz) was clearly recognised, and more importantly, the haz degraded the tensile and. Beneath the recast layer, a heat affected zone (haz) is formed due to rapid heating and quenching cycles during wire edm. Laser cutting is preferable for thin materials, while wire edm is better for thick, highly conductive materials. On the other hand,. Wire Edm Heat Affected Zone.

From fedinit.blogspot.com

Definition Of Heat Affected Zone In Welding FEDINIT Wire Edm Heat Affected Zone However, the heat affected zone (haz) was clearly recognised, and more importantly, the haz degraded the tensile and. Beneath the recast layer, a heat affected zone (haz) is formed due to rapid heating and quenching cycles during wire edm. The cracks in the recast layer and brittle nature of recast layer stimulates crack propagation and on the other hand, the. Wire Edm Heat Affected Zone.

From www.researchgate.net

6. Schematic diagram of the heataffected zone regions in a fusion weld Wire Edm Heat Affected Zone However, the heat affected zone (haz) was clearly recognised, and more importantly, the haz degraded the tensile and. On the other hand, laser Beneath the recast layer, a heat affected zone (haz) is formed due to rapid heating and quenching cycles during wire edm. Laser cutting is preferable for thin materials, while wire edm is better for thick, highly conductive. Wire Edm Heat Affected Zone.

From www.researchgate.net

Microstructure of the heat affected zone. Download Scientific Diagram Wire Edm Heat Affected Zone However, the heat affected zone (haz) was clearly recognised, and more importantly, the haz degraded the tensile and. Laser cutting is preferable for thin materials, while wire edm is better for thick, highly conductive materials. On the other hand, laser The cracks in the recast layer and brittle nature of recast layer stimulates crack propagation and on the other hand,. Wire Edm Heat Affected Zone.

From www.researchgate.net

Schematic view of the laser cladding process. Hereon, heat affected Wire Edm Heat Affected Zone The cracks in the recast layer and brittle nature of recast layer stimulates crack propagation and on the other hand, the ductile. Laser cutting is preferable for thin materials, while wire edm is better for thick, highly conductive materials. Beneath the recast layer, a heat affected zone (haz) is formed due to rapid heating and quenching cycles during wire edm.. Wire Edm Heat Affected Zone.

From extrudesign.com

What is a Heat Affected Zone in a Welding? ExtruDesign Wire Edm Heat Affected Zone The cracks in the recast layer and brittle nature of recast layer stimulates crack propagation and on the other hand, the ductile. Laser cutting is preferable for thin materials, while wire edm is better for thick, highly conductive materials. On the other hand, laser Beneath the recast layer, a heat affected zone (haz) is formed due to rapid heating and. Wire Edm Heat Affected Zone.

From www.iqsdirectory.com

Wire EDM Components, Types, Applications, and Advantages Wire Edm Heat Affected Zone However, the heat affected zone (haz) was clearly recognised, and more importantly, the haz degraded the tensile and. Beneath the recast layer, a heat affected zone (haz) is formed due to rapid heating and quenching cycles during wire edm. Laser cutting is preferable for thin materials, while wire edm is better for thick, highly conductive materials. The cracks in the. Wire Edm Heat Affected Zone.

From weldinganswers.com

The Importance of the Heat Affected Zone (HAZ) WELDING ANSWERS Wire Edm Heat Affected Zone However, the heat affected zone (haz) was clearly recognised, and more importantly, the haz degraded the tensile and. Laser cutting is preferable for thin materials, while wire edm is better for thick, highly conductive materials. Beneath the recast layer, a heat affected zone (haz) is formed due to rapid heating and quenching cycles during wire edm. On the other hand,. Wire Edm Heat Affected Zone.

From www.3xpolymer.com

Wire Cut EDM Fluids 3X Polymer® Wire Edm Heat Affected Zone Beneath the recast layer, a heat affected zone (haz) is formed due to rapid heating and quenching cycles during wire edm. However, the heat affected zone (haz) was clearly recognised, and more importantly, the haz degraded the tensile and. The cracks in the recast layer and brittle nature of recast layer stimulates crack propagation and on the other hand, the. Wire Edm Heat Affected Zone.

From www.nist.gov

AM Ti alloy heat affected zone Wire Edm Heat Affected Zone However, the heat affected zone (haz) was clearly recognised, and more importantly, the haz degraded the tensile and. Beneath the recast layer, a heat affected zone (haz) is formed due to rapid heating and quenching cycles during wire edm. Laser cutting is preferable for thin materials, while wire edm is better for thick, highly conductive materials. The cracks in the. Wire Edm Heat Affected Zone.

From www.researchgate.net

Microstructures of the (a) Base substrate, (b) heat affected zone, (c Wire Edm Heat Affected Zone However, the heat affected zone (haz) was clearly recognised, and more importantly, the haz degraded the tensile and. On the other hand, laser The cracks in the recast layer and brittle nature of recast layer stimulates crack propagation and on the other hand, the ductile. Beneath the recast layer, a heat affected zone (haz) is formed due to rapid heating. Wire Edm Heat Affected Zone.

From www.semanticscholar.org

Figure 8 from Effect of heat affected zone on the mechanical properties Wire Edm Heat Affected Zone On the other hand, laser The cracks in the recast layer and brittle nature of recast layer stimulates crack propagation and on the other hand, the ductile. Laser cutting is preferable for thin materials, while wire edm is better for thick, highly conductive materials. However, the heat affected zone (haz) was clearly recognised, and more importantly, the haz degraded the. Wire Edm Heat Affected Zone.

From www.difference.minaprem.com

Difference Between Weld Metal and Heat Affected Zone (HAZ) Wire Edm Heat Affected Zone However, the heat affected zone (haz) was clearly recognised, and more importantly, the haz degraded the tensile and. On the other hand, laser Laser cutting is preferable for thin materials, while wire edm is better for thick, highly conductive materials. The cracks in the recast layer and brittle nature of recast layer stimulates crack propagation and on the other hand,. Wire Edm Heat Affected Zone.

From www.slideshare.net

Heat affected zone Wire Edm Heat Affected Zone On the other hand, laser However, the heat affected zone (haz) was clearly recognised, and more importantly, the haz degraded the tensile and. Laser cutting is preferable for thin materials, while wire edm is better for thick, highly conductive materials. Beneath the recast layer, a heat affected zone (haz) is formed due to rapid heating and quenching cycles during wire. Wire Edm Heat Affected Zone.

From www.researchgate.net

(PDF) Experimental Investigation of Wire EDM Process Parameters on Heat Wire Edm Heat Affected Zone The cracks in the recast layer and brittle nature of recast layer stimulates crack propagation and on the other hand, the ductile. On the other hand, laser Laser cutting is preferable for thin materials, while wire edm is better for thick, highly conductive materials. Beneath the recast layer, a heat affected zone (haz) is formed due to rapid heating and. Wire Edm Heat Affected Zone.

From hexagon.com

EDGECAM Wire EDM Hexagon Wire Edm Heat Affected Zone On the other hand, laser Beneath the recast layer, a heat affected zone (haz) is formed due to rapid heating and quenching cycles during wire edm. Laser cutting is preferable for thin materials, while wire edm is better for thick, highly conductive materials. The cracks in the recast layer and brittle nature of recast layer stimulates crack propagation and on. Wire Edm Heat Affected Zone.

From lubecogreenfluids.com

How EDM Fluids Improve Efficiency and Accuracy in Wire EDM Machining Wire Edm Heat Affected Zone On the other hand, laser Beneath the recast layer, a heat affected zone (haz) is formed due to rapid heating and quenching cycles during wire edm. The cracks in the recast layer and brittle nature of recast layer stimulates crack propagation and on the other hand, the ductile. Laser cutting is preferable for thin materials, while wire edm is better. Wire Edm Heat Affected Zone.