Parting Line Considerations In Casting . One important consideration in die casting is the placement of the parting line on the resulting part. The parting line of a casting needs to be determined early in the design processes. Engine blocks, cylinder heads, housings and similar enclosures. The designer should take into account the following: When determining the location of the parting line the. Common recognizable parts made by sand casting are: The parting line, also known as a parting surface, is important for the tool design and to ensure proper quality and function of the part. The location of the parting line is important in die casting and should be determined during the design and engineering phases. In this article, let’s discuss what is a parting line. The quality and cost of parts developed using metal casting is directly impacted by the tooling comprising of the. The projected area is (1.00 x 6.00) or 6.00 in. This is the surface area used for features across the parting line.

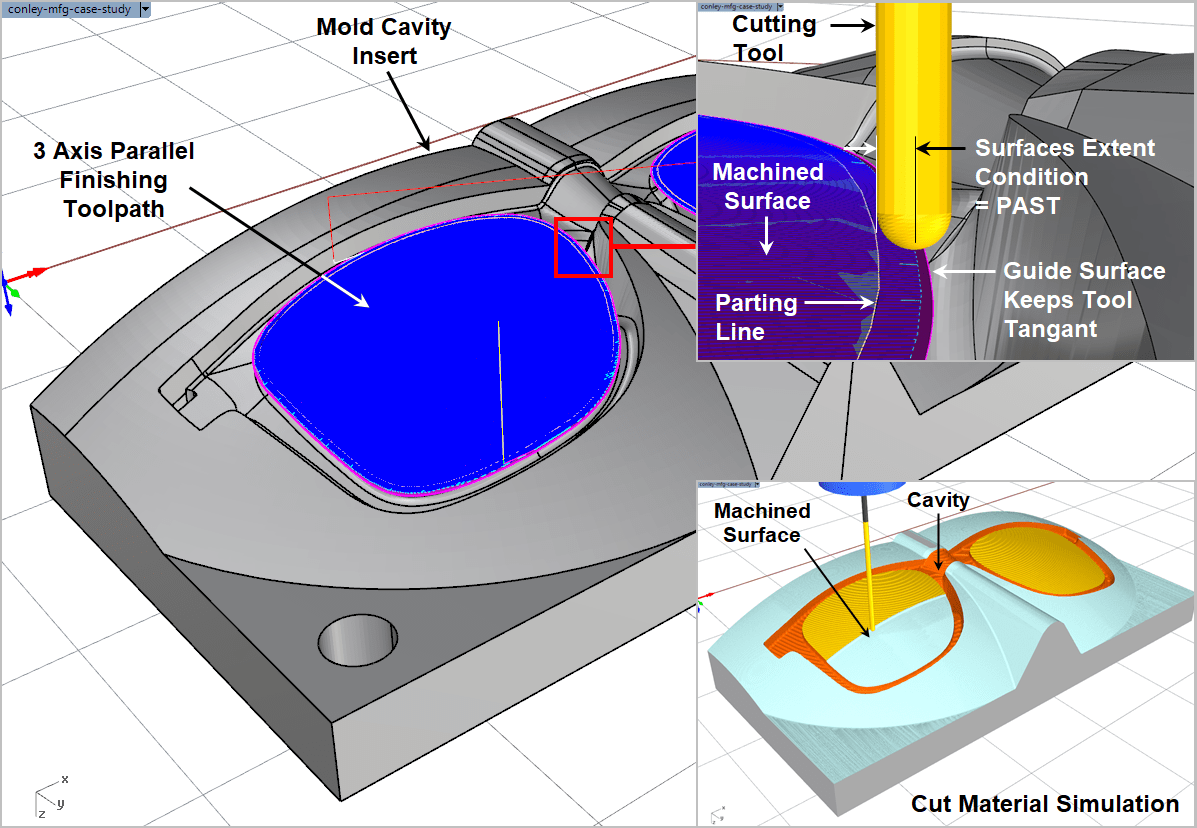

from mecsoft.com

The designer should take into account the following: In this article, let’s discuss what is a parting line. The parting line, also known as a parting surface, is important for the tool design and to ensure proper quality and function of the part. Engine blocks, cylinder heads, housings and similar enclosures. One important consideration in die casting is the placement of the parting line on the resulting part. Common recognizable parts made by sand casting are: The projected area is (1.00 x 6.00) or 6.00 in. The parting line of a casting needs to be determined early in the design processes. The quality and cost of parts developed using metal casting is directly impacted by the tooling comprising of the. The location of the parting line is important in die casting and should be determined during the design and engineering phases.

Machining a Mold’s Parting Lines MecSoft Corporation

Parting Line Considerations In Casting Common recognizable parts made by sand casting are: One important consideration in die casting is the placement of the parting line on the resulting part. The parting line, also known as a parting surface, is important for the tool design and to ensure proper quality and function of the part. The projected area is (1.00 x 6.00) or 6.00 in. This is the surface area used for features across the parting line. The quality and cost of parts developed using metal casting is directly impacted by the tooling comprising of the. The location of the parting line is important in die casting and should be determined during the design and engineering phases. The parting line of a casting needs to be determined early in the design processes. When determining the location of the parting line the. The designer should take into account the following: Engine blocks, cylinder heads, housings and similar enclosures. In this article, let’s discuss what is a parting line. Common recognizable parts made by sand casting are:

From cwmdiecast.com

Read Between the Lines Parting Line Placement in Metal Die Casting Parting Line Considerations In Casting The projected area is (1.00 x 6.00) or 6.00 in. One important consideration in die casting is the placement of the parting line on the resulting part. The parting line of a casting needs to be determined early in the design processes. Common recognizable parts made by sand casting are: This is the surface area used for features across the. Parting Line Considerations In Casting.

From www.semanticscholar.org

Figure 2 from AUTOMATIC DETERMINATION OF PARTING LINE AND NUMBER OF Parting Line Considerations In Casting The parting line, also known as a parting surface, is important for the tool design and to ensure proper quality and function of the part. The parting line of a casting needs to be determined early in the design processes. In this article, let’s discuss what is a parting line. When determining the location of the parting line the. The. Parting Line Considerations In Casting.

From www.slideserve.com

PPT Chapter 11 Fundamentals of Casting PowerPoint Presentation, free Parting Line Considerations In Casting Common recognizable parts made by sand casting are: One important consideration in die casting is the placement of the parting line on the resulting part. When determining the location of the parting line the. This is the surface area used for features across the parting line. The projected area is (1.00 x 6.00) or 6.00 in. The quality and cost. Parting Line Considerations In Casting.

From www.youtube.com

Product Design Considerations in Casting YouTube Parting Line Considerations In Casting This is the surface area used for features across the parting line. One important consideration in die casting is the placement of the parting line on the resulting part. The location of the parting line is important in die casting and should be determined during the design and engineering phases. Engine blocks, cylinder heads, housings and similar enclosures. The parting. Parting Line Considerations In Casting.

From www.perlego.com

[PDF] Automatic determination of parting line for diecasting parts by Parting Line Considerations In Casting The designer should take into account the following: Engine blocks, cylinder heads, housings and similar enclosures. In this article, let’s discuss what is a parting line. The parting line, also known as a parting surface, is important for the tool design and to ensure proper quality and function of the part. The parting line of a casting needs to be. Parting Line Considerations In Casting.

From portal4engineers.blogspot.com

BASICS OF CASTING PROCESS ENGINEERS PORTAL Parting Line Considerations In Casting Common recognizable parts made by sand casting are: One important consideration in die casting is the placement of the parting line on the resulting part. The projected area is (1.00 x 6.00) or 6.00 in. In this article, let’s discuss what is a parting line. The parting line, also known as a parting surface, is important for the tool design. Parting Line Considerations In Casting.

From www.scribd.com

Design Considerations for Metal Casting Optimizing Part Design, Gating Parting Line Considerations In Casting The projected area is (1.00 x 6.00) or 6.00 in. The location of the parting line is important in die casting and should be determined during the design and engineering phases. Common recognizable parts made by sand casting are: When determining the location of the parting line the. This is the surface area used for features across the parting line.. Parting Line Considerations In Casting.

From www.slideserve.com

PPT Metal Casting Processes PowerPoint Presentation, free download Parting Line Considerations In Casting One important consideration in die casting is the placement of the parting line on the resulting part. The designer should take into account the following: Engine blocks, cylinder heads, housings and similar enclosures. The parting line of a casting needs to be determined early in the design processes. The location of the parting line is important in die casting and. Parting Line Considerations In Casting.

From www.researchgate.net

Casting parting diagram (a) parting line of slide block; (b) parting Parting Line Considerations In Casting The parting line, also known as a parting surface, is important for the tool design and to ensure proper quality and function of the part. Engine blocks, cylinder heads, housings and similar enclosures. The quality and cost of parts developed using metal casting is directly impacted by the tooling comprising of the. In this article, let’s discuss what is a. Parting Line Considerations In Casting.

From www.youtube.com

SHOP TIPS 391 Making Castings with Irregular Parting Lines pt 1 Parting Line Considerations In Casting When determining the location of the parting line the. This is the surface area used for features across the parting line. The designer should take into account the following: The quality and cost of parts developed using metal casting is directly impacted by the tooling comprising of the. One important consideration in die casting is the placement of the parting. Parting Line Considerations In Casting.

From qdbesttech.en.made-in-china.com

Horizontal Parting Fully Automatic Green Sand Molding Production Line Parting Line Considerations In Casting Common recognizable parts made by sand casting are: In this article, let’s discuss what is a parting line. One important consideration in die casting is the placement of the parting line on the resulting part. The parting line of a casting needs to be determined early in the design processes. The designer should take into account the following: The parting. Parting Line Considerations In Casting.

From www.slideserve.com

PPT Fundamentals of Casting Manufacturing Processes PowerPoint Parting Line Considerations In Casting The designer should take into account the following: The quality and cost of parts developed using metal casting is directly impacted by the tooling comprising of the. The parting line, also known as a parting surface, is important for the tool design and to ensure proper quality and function of the part. Common recognizable parts made by sand casting are:. Parting Line Considerations In Casting.

From myescience.blogspot.com

Wonder { Science Mathematics Engineering & Technology } JJ203 Parting Line Considerations In Casting The quality and cost of parts developed using metal casting is directly impacted by the tooling comprising of the. This is the surface area used for features across the parting line. The parting line of a casting needs to be determined early in the design processes. One important consideration in die casting is the placement of the parting line on. Parting Line Considerations In Casting.

From www.slideserve.com

PPT Metal Casting Processes PowerPoint Presentation, free download Parting Line Considerations In Casting In this article, let’s discuss what is a parting line. Engine blocks, cylinder heads, housings and similar enclosures. The projected area is (1.00 x 6.00) or 6.00 in. The parting line of a casting needs to be determined early in the design processes. When determining the location of the parting line the. The parting line, also known as a parting. Parting Line Considerations In Casting.

From www.novacast.co.uk

The Importance of Parting Line Design in Gravity Die Casting Parting Line Considerations In Casting When determining the location of the parting line the. Common recognizable parts made by sand casting are: Engine blocks, cylinder heads, housings and similar enclosures. The designer should take into account the following: One important consideration in die casting is the placement of the parting line on the resulting part. The parting line of a casting needs to be determined. Parting Line Considerations In Casting.

From www.gdandtbasics.com

Parting Line GD&T Basics Parting Line Considerations In Casting Common recognizable parts made by sand casting are: The location of the parting line is important in die casting and should be determined during the design and engineering phases. One important consideration in die casting is the placement of the parting line on the resulting part. This is the surface area used for features across the parting line. The parting. Parting Line Considerations In Casting.

From www.iqsdirectory.com

Die Casting What is it? Overview, Process, Design, Material Parting Line Considerations In Casting When determining the location of the parting line the. In this article, let’s discuss what is a parting line. The quality and cost of parts developed using metal casting is directly impacted by the tooling comprising of the. The parting line of a casting needs to be determined early in the design processes. The designer should take into account the. Parting Line Considerations In Casting.

From www.pinterest.de

Parting Line Location Effects Metal's Grain Structure Metal, Grains Parting Line Considerations In Casting Common recognizable parts made by sand casting are: Engine blocks, cylinder heads, housings and similar enclosures. When determining the location of the parting line the. The parting line of a casting needs to be determined early in the design processes. One important consideration in die casting is the placement of the parting line on the resulting part. The quality and. Parting Line Considerations In Casting.

From www.youtube.com

SHOP TIPS 392 Making Castings with Irregular Parting Lines pt 2 Parting Line Considerations In Casting In this article, let’s discuss what is a parting line. When determining the location of the parting line the. One important consideration in die casting is the placement of the parting line on the resulting part. The parting line of a casting needs to be determined early in the design processes. This is the surface area used for features across. Parting Line Considerations In Casting.

From mecsoft.com

Machining a Mold’s Parting Lines MecSoft Corporation Parting Line Considerations In Casting The parting line, also known as a parting surface, is important for the tool design and to ensure proper quality and function of the part. Engine blocks, cylinder heads, housings and similar enclosures. The projected area is (1.00 x 6.00) or 6.00 in. This is the surface area used for features across the parting line. One important consideration in die. Parting Line Considerations In Casting.

From www.eng-tips.com

Separating joint in sand casting Metal and Metallurgy engineering Parting Line Considerations In Casting Common recognizable parts made by sand casting are: Engine blocks, cylinder heads, housings and similar enclosures. This is the surface area used for features across the parting line. The quality and cost of parts developed using metal casting is directly impacted by the tooling comprising of the. The parting line, also known as a parting surface, is important for the. Parting Line Considerations In Casting.

From www.slideserve.com

PPT Metal Casting Processes PowerPoint Presentation, free download Parting Line Considerations In Casting In this article, let’s discuss what is a parting line. This is the surface area used for features across the parting line. When determining the location of the parting line the. The quality and cost of parts developed using metal casting is directly impacted by the tooling comprising of the. Common recognizable parts made by sand casting are: Engine blocks,. Parting Line Considerations In Casting.

From www.slideserve.com

PPT Casting Processes PowerPoint Presentation, free download ID1785685 Parting Line Considerations In Casting When determining the location of the parting line the. One important consideration in die casting is the placement of the parting line on the resulting part. The parting line, also known as a parting surface, is important for the tool design and to ensure proper quality and function of the part. In this article, let’s discuss what is a parting. Parting Line Considerations In Casting.

From mcgwesternstore.com

Aluminum Die Casting Design Guide Die Casting Design Guideline Parting Line Considerations In Casting This is the surface area used for features across the parting line. The location of the parting line is important in die casting and should be determined during the design and engineering phases. The quality and cost of parts developed using metal casting is directly impacted by the tooling comprising of the. The projected area is (1.00 x 6.00) or. Parting Line Considerations In Casting.

From improvians.com

Tooling Considerations for Plastic Part Design Parting Line Considerations In Casting Engine blocks, cylinder heads, housings and similar enclosures. The designer should take into account the following: The parting line of a casting needs to be determined early in the design processes. The quality and cost of parts developed using metal casting is directly impacted by the tooling comprising of the. One important consideration in die casting is the placement of. Parting Line Considerations In Casting.

From www.plasticmold.net

What is injection molding parting line, mold split line Parting Line Considerations In Casting The location of the parting line is important in die casting and should be determined during the design and engineering phases. The parting line, also known as a parting surface, is important for the tool design and to ensure proper quality and function of the part. The designer should take into account the following: In this article, let’s discuss what. Parting Line Considerations In Casting.

From itchol.com

Plastic Parts Design 101 Engineers Rule (2022) Parting Line Considerations In Casting The parting line, also known as a parting surface, is important for the tool design and to ensure proper quality and function of the part. The projected area is (1.00 x 6.00) or 6.00 in. The parting line of a casting needs to be determined early in the design processes. Common recognizable parts made by sand casting are: This is. Parting Line Considerations In Casting.

From mungfali.com

Casting Defects Causes Parting Line Considerations In Casting Common recognizable parts made by sand casting are: This is the surface area used for features across the parting line. In this article, let’s discuss what is a parting line. The parting line, also known as a parting surface, is important for the tool design and to ensure proper quality and function of the part. The designer should take into. Parting Line Considerations In Casting.

From xometry.eu

Design Tips for Die Casting Design Guidelines Xometry Europe Parting Line Considerations In Casting In this article, let’s discuss what is a parting line. The designer should take into account the following: This is the surface area used for features across the parting line. Engine blocks, cylinder heads, housings and similar enclosures. Common recognizable parts made by sand casting are: When determining the location of the parting line the. The projected area is (1.00. Parting Line Considerations In Casting.

From www.researchgate.net

Casting parting diagram (a) parting line of slide block; (b) parting Parting Line Considerations In Casting When determining the location of the parting line the. The location of the parting line is important in die casting and should be determined during the design and engineering phases. In this article, let’s discuss what is a parting line. The designer should take into account the following: The parting line, also known as a parting surface, is important for. Parting Line Considerations In Casting.

From engineeringproductdesign.com

Key sand casting design considerations Parting Line Considerations In Casting This is the surface area used for features across the parting line. Common recognizable parts made by sand casting are: In this article, let’s discuss what is a parting line. The parting line of a casting needs to be determined early in the design processes. The parting line, also known as a parting surface, is important for the tool design. Parting Line Considerations In Casting.

From slideplayer.com

Metal Casting Design, Materials, and Economics ppt download Parting Line Considerations In Casting The projected area is (1.00 x 6.00) or 6.00 in. The parting line of a casting needs to be determined early in the design processes. Common recognizable parts made by sand casting are: This is the surface area used for features across the parting line. Engine blocks, cylinder heads, housings and similar enclosures. The parting line, also known as a. Parting Line Considerations In Casting.

From www.youtube.com

How to Draft Across Parting Lines SOLIDWORKS YouTube Parting Line Considerations In Casting In this article, let’s discuss what is a parting line. The projected area is (1.00 x 6.00) or 6.00 in. Common recognizable parts made by sand casting are: When determining the location of the parting line the. One important consideration in die casting is the placement of the parting line on the resulting part. Engine blocks, cylinder heads, housings and. Parting Line Considerations In Casting.

From www.gdandtbasics.com

Parting Line GD&T Basics Parting Line Considerations In Casting The quality and cost of parts developed using metal casting is directly impacted by the tooling comprising of the. In this article, let’s discuss what is a parting line. Common recognizable parts made by sand casting are: When determining the location of the parting line the. One important consideration in die casting is the placement of the parting line on. Parting Line Considerations In Casting.

From decoprod.com

Understanding the Parting Line in Zinc Die Casting Deco Products Parting Line Considerations In Casting The parting line, also known as a parting surface, is important for the tool design and to ensure proper quality and function of the part. This is the surface area used for features across the parting line. When determining the location of the parting line the. The parting line of a casting needs to be determined early in the design. Parting Line Considerations In Casting.