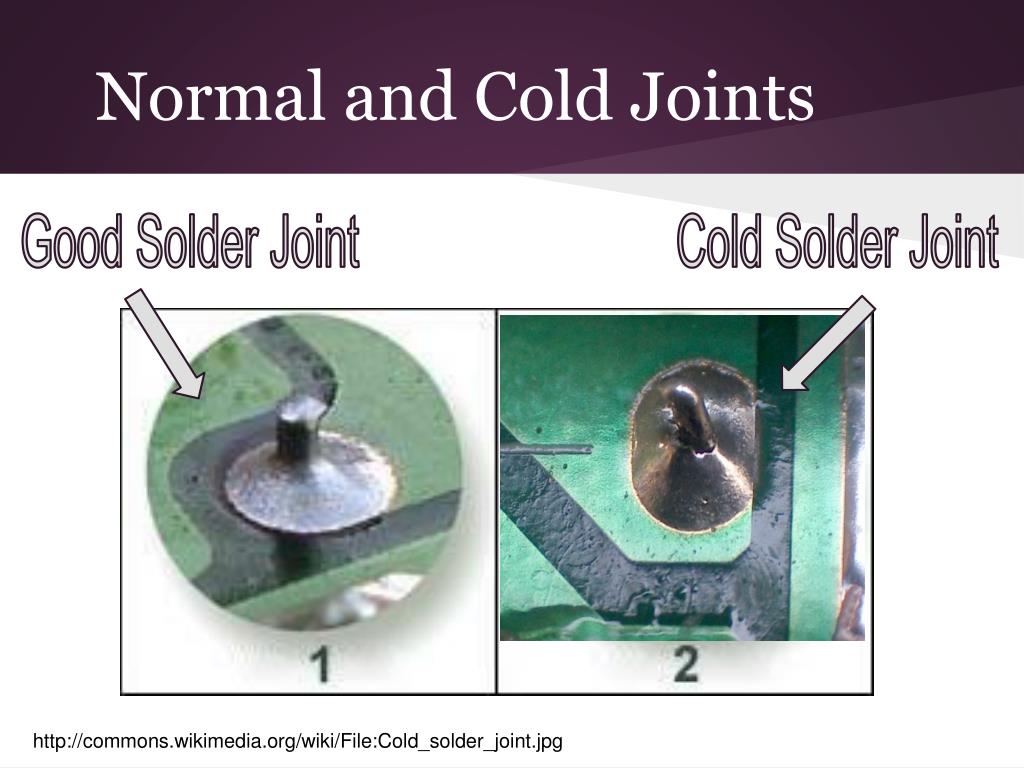

Cold Solder Joint Vs Good Solder Joint . a cold solder junction appears uneven and dull in contrast to a good solder joint, which is smooth and bright, resulting. This defect presents a high chance for the solder joint to crack and eventually fail. a cold solder joint occurs when a joint is not properly heated to allow the solder to flow into the joint, or the joint is moved while. cold solder joints often appear dull, grainy, or rough compared to properly formed solder joints, which are typically shiny and smooth. Characteristics of cold solder joints include a rough surface area, rigidity, and a generally uneven appearance. A cold joint forms when the solder does not melt and flow properly onto the surfaces of the metal components being joined. Cold joints are weak and prone to mechanical failure and electrical problems. while both are soldering issues, a cold joint refers to a solder connection where the solder didn't correctly melt and flow,. This can happen for a number of reasons, such as using too little heat, not applying heat evenly, or not applying heat for long enough. a cold solder joint ensues when a solder does not melt completely, as required to form a proper joint. a cold solder joint is a type of electrical connection where the soldered joint has not been properly heated and didn’t melt completely.

from www.slideserve.com

This defect presents a high chance for the solder joint to crack and eventually fail. a cold solder joint ensues when a solder does not melt completely, as required to form a proper joint. This can happen for a number of reasons, such as using too little heat, not applying heat evenly, or not applying heat for long enough. cold solder joints often appear dull, grainy, or rough compared to properly formed solder joints, which are typically shiny and smooth. a cold solder joint occurs when a joint is not properly heated to allow the solder to flow into the joint, or the joint is moved while. Cold joints are weak and prone to mechanical failure and electrical problems. a cold solder junction appears uneven and dull in contrast to a good solder joint, which is smooth and bright, resulting. a cold solder joint is a type of electrical connection where the soldered joint has not been properly heated and didn’t melt completely. Characteristics of cold solder joints include a rough surface area, rigidity, and a generally uneven appearance. while both are soldering issues, a cold joint refers to a solder connection where the solder didn't correctly melt and flow,.

PPT Soldering PowerPoint Presentation, free download ID1877634

Cold Solder Joint Vs Good Solder Joint A cold joint forms when the solder does not melt and flow properly onto the surfaces of the metal components being joined. cold solder joints often appear dull, grainy, or rough compared to properly formed solder joints, which are typically shiny and smooth. a cold solder junction appears uneven and dull in contrast to a good solder joint, which is smooth and bright, resulting. Characteristics of cold solder joints include a rough surface area, rigidity, and a generally uneven appearance. A cold joint forms when the solder does not melt and flow properly onto the surfaces of the metal components being joined. while both are soldering issues, a cold joint refers to a solder connection where the solder didn't correctly melt and flow,. a cold solder joint is a type of electrical connection where the soldered joint has not been properly heated and didn’t melt completely. a cold solder joint occurs when a joint is not properly heated to allow the solder to flow into the joint, or the joint is moved while. a cold solder joint ensues when a solder does not melt completely, as required to form a proper joint. This can happen for a number of reasons, such as using too little heat, not applying heat evenly, or not applying heat for long enough. This defect presents a high chance for the solder joint to crack and eventually fail. Cold joints are weak and prone to mechanical failure and electrical problems.

From www.pcbamakers.com

How to detect cold solder joints? PCBA Makers Cold Solder Joint Vs Good Solder Joint cold solder joints often appear dull, grainy, or rough compared to properly formed solder joints, which are typically shiny and smooth. This can happen for a number of reasons, such as using too little heat, not applying heat evenly, or not applying heat for long enough. a cold solder joint ensues when a solder does not melt completely,. Cold Solder Joint Vs Good Solder Joint.

From www.slideserve.com

PPT Soldering PowerPoint Presentation, free download ID1877634 Cold Solder Joint Vs Good Solder Joint Cold joints are weak and prone to mechanical failure and electrical problems. a cold solder joint ensues when a solder does not melt completely, as required to form a proper joint. cold solder joints often appear dull, grainy, or rough compared to properly formed solder joints, which are typically shiny and smooth. This defect presents a high chance. Cold Solder Joint Vs Good Solder Joint.

From www.pcbaservices.com

What Is A Cold Solder Joint? Understanding The Basics Cold Solder Joint Vs Good Solder Joint This can happen for a number of reasons, such as using too little heat, not applying heat evenly, or not applying heat for long enough. a cold solder joint ensues when a solder does not melt completely, as required to form a proper joint. a cold solder junction appears uneven and dull in contrast to a good solder. Cold Solder Joint Vs Good Solder Joint.

From www.pcbaaa.com

Understanding solder joint basics and techniques IBE Electronics Cold Solder Joint Vs Good Solder Joint a cold solder junction appears uneven and dull in contrast to a good solder joint, which is smooth and bright, resulting. cold solder joints often appear dull, grainy, or rough compared to properly formed solder joints, which are typically shiny and smooth. while both are soldering issues, a cold joint refers to a solder connection where the. Cold Solder Joint Vs Good Solder Joint.

From electronicshacks.com

What Is a Cold Solder Joint? ElectronicsHacks Cold Solder Joint Vs Good Solder Joint a cold solder joint is a type of electrical connection where the soldered joint has not been properly heated and didn’t melt completely. This can happen for a number of reasons, such as using too little heat, not applying heat evenly, or not applying heat for long enough. a cold solder joint ensues when a solder does not. Cold Solder Joint Vs Good Solder Joint.

From llllllll.co

Soldering q's Tech lines Cold Solder Joint Vs Good Solder Joint This can happen for a number of reasons, such as using too little heat, not applying heat evenly, or not applying heat for long enough. cold solder joints often appear dull, grainy, or rough compared to properly formed solder joints, which are typically shiny and smooth. Characteristics of cold solder joints include a rough surface area, rigidity, and a. Cold Solder Joint Vs Good Solder Joint.

From www.nextpcb.com

Cold Solder Joint Everything You Need Cold Solder Joint Vs Good Solder Joint This can happen for a number of reasons, such as using too little heat, not applying heat evenly, or not applying heat for long enough. A cold joint forms when the solder does not melt and flow properly onto the surfaces of the metal components being joined. cold solder joints often appear dull, grainy, or rough compared to properly. Cold Solder Joint Vs Good Solder Joint.

From www.slideserve.com

PPT Soldering PowerPoint Presentation, free download ID2490508 Cold Solder Joint Vs Good Solder Joint Characteristics of cold solder joints include a rough surface area, rigidity, and a generally uneven appearance. a cold solder joint ensues when a solder does not melt completely, as required to form a proper joint. cold solder joints often appear dull, grainy, or rough compared to properly formed solder joints, which are typically shiny and smooth. a. Cold Solder Joint Vs Good Solder Joint.

From www.electronicsandyou.com

Cold Solder Joint Symptoms, Prevent, Repair and Fix Cold Solder Joint Cold Solder Joint Vs Good Solder Joint This defect presents a high chance for the solder joint to crack and eventually fail. This can happen for a number of reasons, such as using too little heat, not applying heat evenly, or not applying heat for long enough. Cold joints are weak and prone to mechanical failure and electrical problems. a cold solder joint is a type. Cold Solder Joint Vs Good Solder Joint.

From giowbccze.blob.core.windows.net

Cold Solder Joint Explain at Joseph Nieves blog Cold Solder Joint Vs Good Solder Joint cold solder joints often appear dull, grainy, or rough compared to properly formed solder joints, which are typically shiny and smooth. Cold joints are weak and prone to mechanical failure and electrical problems. Characteristics of cold solder joints include a rough surface area, rigidity, and a generally uneven appearance. a cold solder junction appears uneven and dull in. Cold Solder Joint Vs Good Solder Joint.

From vinatronic.com

Cold Solder How To Identify and Prevent Vinatronic inc. Cold Solder Joint Vs Good Solder Joint a cold solder joint is a type of electrical connection where the soldered joint has not been properly heated and didn’t melt completely. Cold joints are weak and prone to mechanical failure and electrical problems. This defect presents a high chance for the solder joint to crack and eventually fail. a cold solder joint occurs when a joint. Cold Solder Joint Vs Good Solder Joint.

From www.electronicsandyou.com

Cold Solder Joint Symptoms, Prevent, Repair and Fix Cold Solder Joint Cold Solder Joint Vs Good Solder Joint Cold joints are weak and prone to mechanical failure and electrical problems. This can happen for a number of reasons, such as using too little heat, not applying heat evenly, or not applying heat for long enough. a cold solder joint ensues when a solder does not melt completely, as required to form a proper joint. a cold. Cold Solder Joint Vs Good Solder Joint.

From morepcb.com

How to Solder Wire on Circuit Board Mastering the Basics MorePCB Cold Solder Joint Vs Good Solder Joint cold solder joints often appear dull, grainy, or rough compared to properly formed solder joints, which are typically shiny and smooth. Cold joints are weak and prone to mechanical failure and electrical problems. This defect presents a high chance for the solder joint to crack and eventually fail. This can happen for a number of reasons, such as using. Cold Solder Joint Vs Good Solder Joint.

From www.pcbaaa.com

Cold solder joints Unraveling the hazards, causes, detection, repair Cold Solder Joint Vs Good Solder Joint cold solder joints often appear dull, grainy, or rough compared to properly formed solder joints, which are typically shiny and smooth. Cold joints are weak and prone to mechanical failure and electrical problems. Characteristics of cold solder joints include a rough surface area, rigidity, and a generally uneven appearance. This defect presents a high chance for the solder joint. Cold Solder Joint Vs Good Solder Joint.

From www.electronicsandyou.com

Cold Solder Joint Symptoms, Prevent, Repair and Fix Cold Solder Joint Cold Solder Joint Vs Good Solder Joint cold solder joints often appear dull, grainy, or rough compared to properly formed solder joints, which are typically shiny and smooth. Characteristics of cold solder joints include a rough surface area, rigidity, and a generally uneven appearance. This can happen for a number of reasons, such as using too little heat, not applying heat evenly, or not applying heat. Cold Solder Joint Vs Good Solder Joint.

From www.youtube.com

How to repair cold solder joint YouTube Cold Solder Joint Vs Good Solder Joint This can happen for a number of reasons, such as using too little heat, not applying heat evenly, or not applying heat for long enough. Cold joints are weak and prone to mechanical failure and electrical problems. A cold joint forms when the solder does not melt and flow properly onto the surfaces of the metal components being joined. . Cold Solder Joint Vs Good Solder Joint.

From www.pcba-manufacturers.com

Understanding Cold Solder Joints Causes, Identification and Solutions Cold Solder Joint Vs Good Solder Joint while both are soldering issues, a cold joint refers to a solder connection where the solder didn't correctly melt and flow,. a cold solder joint is a type of electrical connection where the soldered joint has not been properly heated and didn’t melt completely. Characteristics of cold solder joints include a rough surface area, rigidity, and a generally. Cold Solder Joint Vs Good Solder Joint.

From www.slideserve.com

PPT Soldering PowerPoint Presentation, free download ID1877634 Cold Solder Joint Vs Good Solder Joint Characteristics of cold solder joints include a rough surface area, rigidity, and a generally uneven appearance. a cold solder joint ensues when a solder does not melt completely, as required to form a proper joint. Cold joints are weak and prone to mechanical failure and electrical problems. A cold joint forms when the solder does not melt and flow. Cold Solder Joint Vs Good Solder Joint.

From absolutepcbassembly.com

Cold Solder Joint Definitive Guide to Soldering Absolute Cold Solder Joint Vs Good Solder Joint a cold solder joint ensues when a solder does not melt completely, as required to form a proper joint. A cold joint forms when the solder does not melt and flow properly onto the surfaces of the metal components being joined. Characteristics of cold solder joints include a rough surface area, rigidity, and a generally uneven appearance. This defect. Cold Solder Joint Vs Good Solder Joint.

From www.slideserve.com

PPT Soldering & Desoldering PowerPoint Presentation, free download Cold Solder Joint Vs Good Solder Joint This can happen for a number of reasons, such as using too little heat, not applying heat evenly, or not applying heat for long enough. while both are soldering issues, a cold joint refers to a solder connection where the solder didn't correctly melt and flow,. a cold solder joint ensues when a solder does not melt completely,. Cold Solder Joint Vs Good Solder Joint.

From www.theengineeringknowledge.com

What is a Cold Solder Joint and How Can You Prevent it? 2023 Guide Cold Solder Joint Vs Good Solder Joint A cold joint forms when the solder does not melt and flow properly onto the surfaces of the metal components being joined. This can happen for a number of reasons, such as using too little heat, not applying heat evenly, or not applying heat for long enough. Characteristics of cold solder joints include a rough surface area, rigidity, and a. Cold Solder Joint Vs Good Solder Joint.

From www.circuitbasics.com

Tips for Good Soldering Technique Circuit Basics Cold Solder Joint Vs Good Solder Joint A cold joint forms when the solder does not melt and flow properly onto the surfaces of the metal components being joined. a cold solder junction appears uneven and dull in contrast to a good solder joint, which is smooth and bright, resulting. Characteristics of cold solder joints include a rough surface area, rigidity, and a generally uneven appearance.. Cold Solder Joint Vs Good Solder Joint.

From www.vrogue.co

What Is A Cold Solder Joint Electronicshacks vrogue.co Cold Solder Joint Vs Good Solder Joint a cold solder joint occurs when a joint is not properly heated to allow the solder to flow into the joint, or the joint is moved while. while both are soldering issues, a cold joint refers to a solder connection where the solder didn't correctly melt and flow,. This defect presents a high chance for the solder joint. Cold Solder Joint Vs Good Solder Joint.

From www.youtube.com

Cold Solder Joint The Definitive Guide To Soldering YouTube Cold Solder Joint Vs Good Solder Joint This can happen for a number of reasons, such as using too little heat, not applying heat evenly, or not applying heat for long enough. A cold joint forms when the solder does not melt and flow properly onto the surfaces of the metal components being joined. cold solder joints often appear dull, grainy, or rough compared to properly. Cold Solder Joint Vs Good Solder Joint.

From www.youtube.com

Soldering Soldering types Solder Specifications Good vs. Bad Cold Solder Joint Vs Good Solder Joint while both are soldering issues, a cold joint refers to a solder connection where the solder didn't correctly melt and flow,. cold solder joints often appear dull, grainy, or rough compared to properly formed solder joints, which are typically shiny and smooth. a cold solder joint ensues when a solder does not melt completely, as required to. Cold Solder Joint Vs Good Solder Joint.

From www.slideserve.com

PPT Soldering PowerPoint Presentation, free download ID1877634 Cold Solder Joint Vs Good Solder Joint A cold joint forms when the solder does not melt and flow properly onto the surfaces of the metal components being joined. while both are soldering issues, a cold joint refers to a solder connection where the solder didn't correctly melt and flow,. This can happen for a number of reasons, such as using too little heat, not applying. Cold Solder Joint Vs Good Solder Joint.

From giojcsdfs.blob.core.windows.net

Soldering Wire Tips at Janyce Gallegos blog Cold Solder Joint Vs Good Solder Joint a cold solder junction appears uneven and dull in contrast to a good solder joint, which is smooth and bright, resulting. a cold solder joint is a type of electrical connection where the soldered joint has not been properly heated and didn’t melt completely. This can happen for a number of reasons, such as using too little heat,. Cold Solder Joint Vs Good Solder Joint.

From www.electronicsandyou.com

Cold Solder Joint Symptoms, Prevent, Repair and Fix Cold Solder Joint Cold Solder Joint Vs Good Solder Joint Cold joints are weak and prone to mechanical failure and electrical problems. a cold solder junction appears uneven and dull in contrast to a good solder joint, which is smooth and bright, resulting. This defect presents a high chance for the solder joint to crack and eventually fail. while both are soldering issues, a cold joint refers to. Cold Solder Joint Vs Good Solder Joint.

From www.slideserve.com

PPT Soldering 101 PowerPoint Presentation, free download ID4107653 Cold Solder Joint Vs Good Solder Joint while both are soldering issues, a cold joint refers to a solder connection where the solder didn't correctly melt and flow,. a cold solder joint occurs when a joint is not properly heated to allow the solder to flow into the joint, or the joint is moved while. A cold joint forms when the solder does not melt. Cold Solder Joint Vs Good Solder Joint.

From www.electronicsandyou.com

Cold Solder Joint Symptoms, Prevent, Repair and Fix Cold Solder Joint Cold Solder Joint Vs Good Solder Joint This defect presents a high chance for the solder joint to crack and eventually fail. while both are soldering issues, a cold joint refers to a solder connection where the solder didn't correctly melt and flow,. Characteristics of cold solder joints include a rough surface area, rigidity, and a generally uneven appearance. a cold solder joint ensues when. Cold Solder Joint Vs Good Solder Joint.

From www.electronicsandyou.com

Cold Solder Joint Symptoms, Prevent, Repair and Fix Cold Solder Joint Cold Solder Joint Vs Good Solder Joint cold solder joints often appear dull, grainy, or rough compared to properly formed solder joints, which are typically shiny and smooth. a cold solder joint is a type of electrical connection where the soldered joint has not been properly heated and didn’t melt completely. while both are soldering issues, a cold joint refers to a solder connection. Cold Solder Joint Vs Good Solder Joint.

From www.pcba-manufacturers.com

Understanding Cold Solder Joints Causes, Identification and Solutions Cold Solder Joint Vs Good Solder Joint This can happen for a number of reasons, such as using too little heat, not applying heat evenly, or not applying heat for long enough. A cold joint forms when the solder does not melt and flow properly onto the surfaces of the metal components being joined. a cold solder joint is a type of electrical connection where the. Cold Solder Joint Vs Good Solder Joint.

From www.pcba-manufacturers.com

Understanding Cold Solder Joints Causes, Identification and Solutions Cold Solder Joint Vs Good Solder Joint This can happen for a number of reasons, such as using too little heat, not applying heat evenly, or not applying heat for long enough. Cold joints are weak and prone to mechanical failure and electrical problems. a cold solder junction appears uneven and dull in contrast to a good solder joint, which is smooth and bright, resulting. Characteristics. Cold Solder Joint Vs Good Solder Joint.

From www.nextpcb.com

Cold Solder Joint Everything You Need Cold Solder Joint Vs Good Solder Joint while both are soldering issues, a cold joint refers to a solder connection where the solder didn't correctly melt and flow,. a cold solder joint is a type of electrical connection where the soldered joint has not been properly heated and didn’t melt completely. a cold solder joint ensues when a solder does not melt completely, as. Cold Solder Joint Vs Good Solder Joint.

From www.vrogue.co

What Is A Cold Solder Joint Electronicshacks vrogue.co Cold Solder Joint Vs Good Solder Joint This defect presents a high chance for the solder joint to crack and eventually fail. A cold joint forms when the solder does not melt and flow properly onto the surfaces of the metal components being joined. Characteristics of cold solder joints include a rough surface area, rigidity, and a generally uneven appearance. a cold solder joint ensues when. Cold Solder Joint Vs Good Solder Joint.