Metal Lathe Cutting Lubricant . Choose cutting fluids with high maximum seizure load (pb value), low surface tension, and proven good performance through cutting tests. Cutting fluids should have a long service life, especially important for machining centers. cutting fluids play crucial roles in metal lathe maintenance and care by lubricating and cooling the workpiece and. Without the oil, the machine can quickly overheat, leading to poor results and even damage. cutting fluids should have excellent lubrication and cleaning performance. way oil for lathe is a particular type of machine tool lubricant that is formulated to withstand extreme pressure and protect against corrosion. Cutting oils reduce friction between the cutting tool and the workpiece. The intense heat generated during metal cutting can have detrimental effects on tool life and workpiece quality. So, it’s important to have a good quality oil on hand when operating a metal lathe. This lubrication minimizes wear on both the tool and the workpiece, leading to extended tool life and improved machining accuracy. the oil not only helps to lubricate the cutting tool but also cools both the tool and the metal being worked on. cutting fluids provide lubrication to the cutting tool and workpiece, which helps to improve the movement of the tool and.

from www.penntoolco.com

cutting fluids should have excellent lubrication and cleaning performance. cutting fluids provide lubrication to the cutting tool and workpiece, which helps to improve the movement of the tool and. way oil for lathe is a particular type of machine tool lubricant that is formulated to withstand extreme pressure and protect against corrosion. The intense heat generated during metal cutting can have detrimental effects on tool life and workpiece quality. Choose cutting fluids with high maximum seizure load (pb value), low surface tension, and proven good performance through cutting tests. cutting fluids play crucial roles in metal lathe maintenance and care by lubricating and cooling the workpiece and. Without the oil, the machine can quickly overheat, leading to poor results and even damage. Cutting fluids should have a long service life, especially important for machining centers. So, it’s important to have a good quality oil on hand when operating a metal lathe. the oil not only helps to lubricate the cutting tool but also cools both the tool and the metal being worked on.

Types of Coolant To Use for a Lathe Machine Penn Tool Co., Inc

Metal Lathe Cutting Lubricant Cutting fluids should have a long service life, especially important for machining centers. Cutting oils reduce friction between the cutting tool and the workpiece. cutting fluids provide lubrication to the cutting tool and workpiece, which helps to improve the movement of the tool and. This lubrication minimizes wear on both the tool and the workpiece, leading to extended tool life and improved machining accuracy. Cutting fluids should have a long service life, especially important for machining centers. way oil for lathe is a particular type of machine tool lubricant that is formulated to withstand extreme pressure and protect against corrosion. Without the oil, the machine can quickly overheat, leading to poor results and even damage. The intense heat generated during metal cutting can have detrimental effects on tool life and workpiece quality. cutting fluids should have excellent lubrication and cleaning performance. the oil not only helps to lubricate the cutting tool but also cools both the tool and the metal being worked on. Choose cutting fluids with high maximum seizure load (pb value), low surface tension, and proven good performance through cutting tests. So, it’s important to have a good quality oil on hand when operating a metal lathe. cutting fluids play crucial roles in metal lathe maintenance and care by lubricating and cooling the workpiece and.

From www.bcl.co.za

Metalworking fluids OilChat37 Blue Chip Lubricants Metal Lathe Cutting Lubricant The intense heat generated during metal cutting can have detrimental effects on tool life and workpiece quality. This lubrication minimizes wear on both the tool and the workpiece, leading to extended tool life and improved machining accuracy. Without the oil, the machine can quickly overheat, leading to poor results and even damage. So, it’s important to have a good quality. Metal Lathe Cutting Lubricant.

From anchorlube.com

Lathe Cutting Tools MustHave Tools For Turning Anchor Lubricants Metal Lathe Cutting Lubricant the oil not only helps to lubricate the cutting tool but also cools both the tool and the metal being worked on. cutting fluids play crucial roles in metal lathe maintenance and care by lubricating and cooling the workpiece and. This lubrication minimizes wear on both the tool and the workpiece, leading to extended tool life and improved. Metal Lathe Cutting Lubricant.

From www.jcgibbons.com

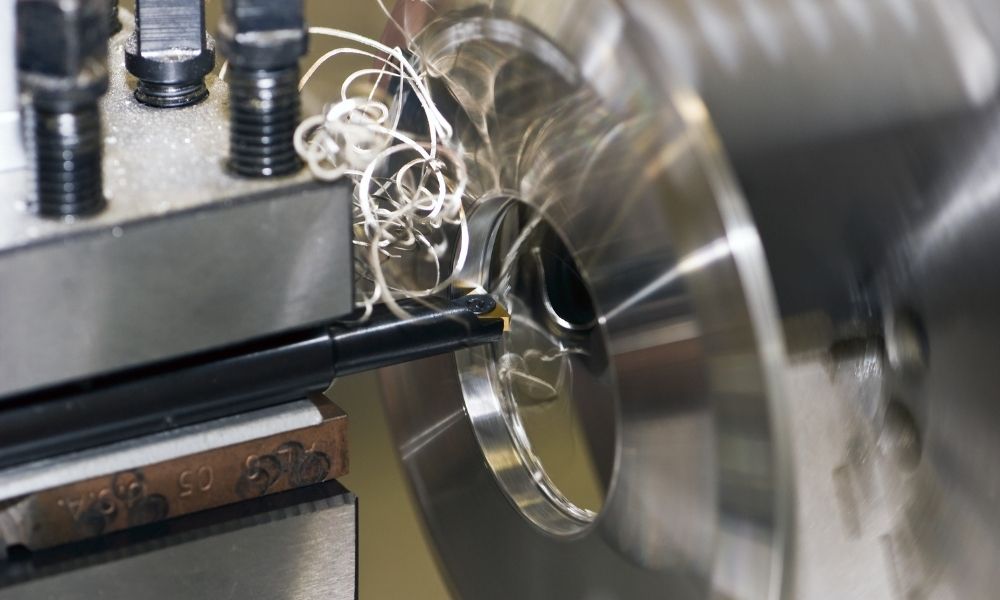

Milling metalworking process. Industrial CNC metal machining by Metal Lathe Cutting Lubricant way oil for lathe is a particular type of machine tool lubricant that is formulated to withstand extreme pressure and protect against corrosion. Without the oil, the machine can quickly overheat, leading to poor results and even damage. cutting fluids provide lubrication to the cutting tool and workpiece, which helps to improve the movement of the tool and.. Metal Lathe Cutting Lubricant.

From doclube.com

Industrial manufacturing lubricants and oils Dennis Oil Company Metal Lathe Cutting Lubricant way oil for lathe is a particular type of machine tool lubricant that is formulated to withstand extreme pressure and protect against corrosion. Choose cutting fluids with high maximum seizure load (pb value), low surface tension, and proven good performance through cutting tests. cutting fluids play crucial roles in metal lathe maintenance and care by lubricating and cooling. Metal Lathe Cutting Lubricant.

From www.precisionmatthews.com

Headstock / Gearbox Oil, ISO 68, Gallon Precision Matthews Machinery Co. Metal Lathe Cutting Lubricant Cutting oils reduce friction between the cutting tool and the workpiece. Cutting fluids should have a long service life, especially important for machining centers. Without the oil, the machine can quickly overheat, leading to poor results and even damage. So, it’s important to have a good quality oil on hand when operating a metal lathe. cutting fluids play crucial. Metal Lathe Cutting Lubricant.

From www.penntoolco.com

Types of Coolant To Use for a Lathe Machine Penn Tool Co., Inc Metal Lathe Cutting Lubricant cutting fluids should have excellent lubrication and cleaning performance. Without the oil, the machine can quickly overheat, leading to poor results and even damage. the oil not only helps to lubricate the cutting tool but also cools both the tool and the metal being worked on. cutting fluids provide lubrication to the cutting tool and workpiece, which. Metal Lathe Cutting Lubricant.

From www.instructables.com

What Is a Mini Metal Lathe and How to Use It for Metalworking 4 Steps Metal Lathe Cutting Lubricant Cutting oils reduce friction between the cutting tool and the workpiece. cutting fluids should have excellent lubrication and cleaning performance. the oil not only helps to lubricate the cutting tool but also cools both the tool and the metal being worked on. Cutting fluids should have a long service life, especially important for machining centers. way oil. Metal Lathe Cutting Lubricant.

From metalprofy.com

Top 5 Best Metal Lathes [June 2024 Review] MetalProfy Metal Lathe Cutting Lubricant Without the oil, the machine can quickly overheat, leading to poor results and even damage. cutting fluids play crucial roles in metal lathe maintenance and care by lubricating and cooling the workpiece and. Cutting oils reduce friction between the cutting tool and the workpiece. So, it’s important to have a good quality oil on hand when operating a metal. Metal Lathe Cutting Lubricant.

From www.youtube.com

Oil I use on my lathe ways YouTube Metal Lathe Cutting Lubricant cutting fluids should have excellent lubrication and cleaning performance. cutting fluids provide lubrication to the cutting tool and workpiece, which helps to improve the movement of the tool and. The intense heat generated during metal cutting can have detrimental effects on tool life and workpiece quality. Cutting fluids should have a long service life, especially important for machining. Metal Lathe Cutting Lubricant.

From www.machinerylubrication.com

Lubrication Basics Machinery Lubrication Metal Lathe Cutting Lubricant cutting fluids provide lubrication to the cutting tool and workpiece, which helps to improve the movement of the tool and. cutting fluids should have excellent lubrication and cleaning performance. Without the oil, the machine can quickly overheat, leading to poor results and even damage. Choose cutting fluids with high maximum seizure load (pb value), low surface tension, and. Metal Lathe Cutting Lubricant.

From liquidtool.com

Utilisation d'un lubrifiant réfrigérant dans l'usinage • LIQUIDTOOL Metal Lathe Cutting Lubricant cutting fluids should have excellent lubrication and cleaning performance. The intense heat generated during metal cutting can have detrimental effects on tool life and workpiece quality. cutting fluids provide lubrication to the cutting tool and workpiece, which helps to improve the movement of the tool and. the oil not only helps to lubricate the cutting tool but. Metal Lathe Cutting Lubricant.

From www.dreamstime.com

CNC Milling Machine Work. Coolant and Lubrication in Gear Metalwork Metal Lathe Cutting Lubricant The intense heat generated during metal cutting can have detrimental effects on tool life and workpiece quality. cutting fluids play crucial roles in metal lathe maintenance and care by lubricating and cooling the workpiece and. way oil for lathe is a particular type of machine tool lubricant that is formulated to withstand extreme pressure and protect against corrosion.. Metal Lathe Cutting Lubricant.

From leblondusa.com

Why, When and How to Replace Lathe Oils, Lubricants and Coolants Metal Lathe Cutting Lubricant This lubrication minimizes wear on both the tool and the workpiece, leading to extended tool life and improved machining accuracy. cutting fluids play crucial roles in metal lathe maintenance and care by lubricating and cooling the workpiece and. The intense heat generated during metal cutting can have detrimental effects on tool life and workpiece quality. Choose cutting fluids with. Metal Lathe Cutting Lubricant.

From khatabook.com

Lubricating Oils Manufacturing Process Extraction Process Metal Lathe Cutting Lubricant So, it’s important to have a good quality oil on hand when operating a metal lathe. cutting fluids provide lubrication to the cutting tool and workpiece, which helps to improve the movement of the tool and. Cutting fluids should have a long service life, especially important for machining centers. This lubrication minimizes wear on both the tool and the. Metal Lathe Cutting Lubricant.

From santmachine.en.made-in-china.com

Precision GapBed Metal Cutting Lathe C0636A China Lathe and Metal Lathe Metal Lathe Cutting Lubricant Without the oil, the machine can quickly overheat, leading to poor results and even damage. The intense heat generated during metal cutting can have detrimental effects on tool life and workpiece quality. way oil for lathe is a particular type of machine tool lubricant that is formulated to withstand extreme pressure and protect against corrosion. Cutting oils reduce friction. Metal Lathe Cutting Lubricant.

From blog.tormach.com

Know Your Cutting Tools How to Use the 5 Main Types of Lathe Tooling Metal Lathe Cutting Lubricant Without the oil, the machine can quickly overheat, leading to poor results and even damage. So, it’s important to have a good quality oil on hand when operating a metal lathe. Cutting fluids should have a long service life, especially important for machining centers. way oil for lathe is a particular type of machine tool lubricant that is formulated. Metal Lathe Cutting Lubricant.

From www.dreamstime.com

Drilling Process Of Metal On Machine Tool Stock Photo Image 39931541 Metal Lathe Cutting Lubricant So, it’s important to have a good quality oil on hand when operating a metal lathe. Cutting fluids should have a long service life, especially important for machining centers. cutting fluids play crucial roles in metal lathe maintenance and care by lubricating and cooling the workpiece and. cutting fluids should have excellent lubrication and cleaning performance. way. Metal Lathe Cutting Lubricant.

From www.hobby-machinist.com

Lathe gearbox lubrication The HobbyMachinist Metal Lathe Cutting Lubricant way oil for lathe is a particular type of machine tool lubricant that is formulated to withstand extreme pressure and protect against corrosion. Choose cutting fluids with high maximum seizure load (pb value), low surface tension, and proven good performance through cutting tests. cutting fluids play crucial roles in metal lathe maintenance and care by lubricating and cooling. Metal Lathe Cutting Lubricant.

From www.hai-lu-oil.com

Synthetic Cutting Fluids TaiwanBased Metalworking Fluid Metal Lathe Cutting Lubricant cutting fluids should have excellent lubrication and cleaning performance. way oil for lathe is a particular type of machine tool lubricant that is formulated to withstand extreme pressure and protect against corrosion. the oil not only helps to lubricate the cutting tool but also cools both the tool and the metal being worked on. Without the oil,. Metal Lathe Cutting Lubricant.

From www.fabricatingandmetalworking.com

Fabricating & Metalworking Metal Lathe Cutting Lubricant Without the oil, the machine can quickly overheat, leading to poor results and even damage. cutting fluids play crucial roles in metal lathe maintenance and care by lubricating and cooling the workpiece and. Choose cutting fluids with high maximum seizure load (pb value), low surface tension, and proven good performance through cutting tests. cutting fluids should have excellent. Metal Lathe Cutting Lubricant.

From www.uslube.com

Industrial Lubricants & Fluids Supplier U.S. Lubricants Metal Lathe Cutting Lubricant Without the oil, the machine can quickly overheat, leading to poor results and even damage. cutting fluids should have excellent lubrication and cleaning performance. cutting fluids play crucial roles in metal lathe maintenance and care by lubricating and cooling the workpiece and. The intense heat generated during metal cutting can have detrimental effects on tool life and workpiece. Metal Lathe Cutting Lubricant.

From www.indiamart.com

Lathe Machine Cutting Oil at best price in Tiruvallur by Ayyan Metal Lathe Cutting Lubricant cutting fluids should have excellent lubrication and cleaning performance. the oil not only helps to lubricate the cutting tool but also cools both the tool and the metal being worked on. Cutting oils reduce friction between the cutting tool and the workpiece. cutting fluids play crucial roles in metal lathe maintenance and care by lubricating and cooling. Metal Lathe Cutting Lubricant.

From www.anyrgb.com

чпу, order, cutting Fluid, manufacturing Engineering, Work Metal Lathe Cutting Lubricant cutting fluids should have excellent lubrication and cleaning performance. This lubrication minimizes wear on both the tool and the workpiece, leading to extended tool life and improved machining accuracy. the oil not only helps to lubricate the cutting tool but also cools both the tool and the metal being worked on. So, it’s important to have a good. Metal Lathe Cutting Lubricant.

From www.youtube.com

Differences between Coolant and Lubricant as Cutting Fluid in Machining Metal Lathe Cutting Lubricant Without the oil, the machine can quickly overheat, leading to poor results and even damage. Cutting oils reduce friction between the cutting tool and the workpiece. the oil not only helps to lubricate the cutting tool but also cools both the tool and the metal being worked on. The intense heat generated during metal cutting can have detrimental effects. Metal Lathe Cutting Lubricant.

From www.amazon.com

HAowosi 10PCS 1/4" Metal Lathe Cutting Tools,C6 Carbide Tip Cutter Metal Lathe Cutting Lubricant Without the oil, the machine can quickly overheat, leading to poor results and even damage. So, it’s important to have a good quality oil on hand when operating a metal lathe. cutting fluids should have excellent lubrication and cleaning performance. This lubrication minimizes wear on both the tool and the workpiece, leading to extended tool life and improved machining. Metal Lathe Cutting Lubricant.

From amtmachine.com

Proper Care and Maintenance of MetalCutting Machinery AMT Machine Tools Metal Lathe Cutting Lubricant Without the oil, the machine can quickly overheat, leading to poor results and even damage. The intense heat generated during metal cutting can have detrimental effects on tool life and workpiece quality. the oil not only helps to lubricate the cutting tool but also cools both the tool and the metal being worked on. So, it’s important to have. Metal Lathe Cutting Lubricant.

From www.midlandslubricants.co.uk

Neat Cutting Oil Midlands Lubricants Ltd Metal Lathe Cutting Lubricant This lubrication minimizes wear on both the tool and the workpiece, leading to extended tool life and improved machining accuracy. Cutting fluids should have a long service life, especially important for machining centers. Cutting oils reduce friction between the cutting tool and the workpiece. cutting fluids provide lubrication to the cutting tool and workpiece, which helps to improve the. Metal Lathe Cutting Lubricant.

From www.warco.co.uk

Slideway Oil Lubricant for Milling Machine & Lathe Slideways Metal Lathe Cutting Lubricant cutting fluids provide lubrication to the cutting tool and workpiece, which helps to improve the movement of the tool and. Choose cutting fluids with high maximum seizure load (pb value), low surface tension, and proven good performance through cutting tests. The intense heat generated during metal cutting can have detrimental effects on tool life and workpiece quality. way. Metal Lathe Cutting Lubricant.

From sedlagencies.com.au

Cutting Oil All You Need To Know! Industrial Sedl Agencies Metal Lathe Cutting Lubricant the oil not only helps to lubricate the cutting tool but also cools both the tool and the metal being worked on. way oil for lathe is a particular type of machine tool lubricant that is formulated to withstand extreme pressure and protect against corrosion. Cutting oils reduce friction between the cutting tool and the workpiece. cutting. Metal Lathe Cutting Lubricant.

From www.youtube.com

Simple Drip Oiler for a Horizontal Bandsaw YouTube Metal Lathe Cutting Lubricant Cutting fluids should have a long service life, especially important for machining centers. Choose cutting fluids with high maximum seizure load (pb value), low surface tension, and proven good performance through cutting tests. Without the oil, the machine can quickly overheat, leading to poor results and even damage. The intense heat generated during metal cutting can have detrimental effects on. Metal Lathe Cutting Lubricant.

From nutechcompany.net

» Metal Working Lubricants Metal Lathe Cutting Lubricant cutting fluids play crucial roles in metal lathe maintenance and care by lubricating and cooling the workpiece and. This lubrication minimizes wear on both the tool and the workpiece, leading to extended tool life and improved machining accuracy. So, it’s important to have a good quality oil on hand when operating a metal lathe. Without the oil, the machine. Metal Lathe Cutting Lubricant.

From www.dreamstime.com

Lathe with Coolant Lubricant System Stock Image Image of engineering Metal Lathe Cutting Lubricant Cutting oils reduce friction between the cutting tool and the workpiece. way oil for lathe is a particular type of machine tool lubricant that is formulated to withstand extreme pressure and protect against corrosion. Cutting fluids should have a long service life, especially important for machining centers. So, it’s important to have a good quality oil on hand when. Metal Lathe Cutting Lubricant.

From www.dajinprecision.com

Best Cutting Fluid for Aluminum in CNC Machining How to Select a Metal Lathe Cutting Lubricant Cutting fluids should have a long service life, especially important for machining centers. So, it’s important to have a good quality oil on hand when operating a metal lathe. cutting fluids provide lubrication to the cutting tool and workpiece, which helps to improve the movement of the tool and. cutting fluids play crucial roles in metal lathe maintenance. Metal Lathe Cutting Lubricant.

From www.warco.co.uk

Neatcut Machine Cutting Oil Best Lubricant Lathes, Milling Machines Metal Lathe Cutting Lubricant Without the oil, the machine can quickly overheat, leading to poor results and even damage. cutting fluids play crucial roles in metal lathe maintenance and care by lubricating and cooling the workpiece and. Cutting fluids should have a long service life, especially important for machining centers. Choose cutting fluids with high maximum seizure load (pb value), low surface tension,. Metal Lathe Cutting Lubricant.

From www.behsankarchemi.com

Cutting oil 10 Behsan Kar Chemi Metal Lathe Cutting Lubricant The intense heat generated during metal cutting can have detrimental effects on tool life and workpiece quality. cutting fluids should have excellent lubrication and cleaning performance. Cutting fluids should have a long service life, especially important for machining centers. This lubrication minimizes wear on both the tool and the workpiece, leading to extended tool life and improved machining accuracy.. Metal Lathe Cutting Lubricant.