Spray Drying Particle Size . Particle formation during spray drying, related to particle size and density. Spray drying process is widely used to produce particulate materials in the pharmaceutical industries, such as porous materials for direct. This strategy is based on mspm methods and follows qbd precepts. Particles were prepared in a laboratory spray dryer from carbohydrates with. Size and density are particle properties, which are crucial for several delivery systems (e.g., powders for inhalation and suspensions for. It is intended to exploit data that are A novel hierarchical strategy to model the spray drying process and predict the particle size of the product is presented. The first one is the atomization of the liquid stream by an appropriate device. The spray dried particles showed a particle size within the range of 5 to 10 micron and different morphologies (e.g. Theoretical and experimental investigations of the particle formation process during spray drying are presented. The spray drying process comprises three major phases.

from www.pharmaexcipients.com

Size and density are particle properties, which are crucial for several delivery systems (e.g., powders for inhalation and suspensions for. The spray drying process comprises three major phases. Theoretical and experimental investigations of the particle formation process during spray drying are presented. A novel hierarchical strategy to model the spray drying process and predict the particle size of the product is presented. This strategy is based on mspm methods and follows qbd precepts. It is intended to exploit data that are The first one is the atomization of the liquid stream by an appropriate device. Spray drying process is widely used to produce particulate materials in the pharmaceutical industries, such as porous materials for direct. Particle formation during spray drying, related to particle size and density. Particles were prepared in a laboratory spray dryer from carbohydrates with.

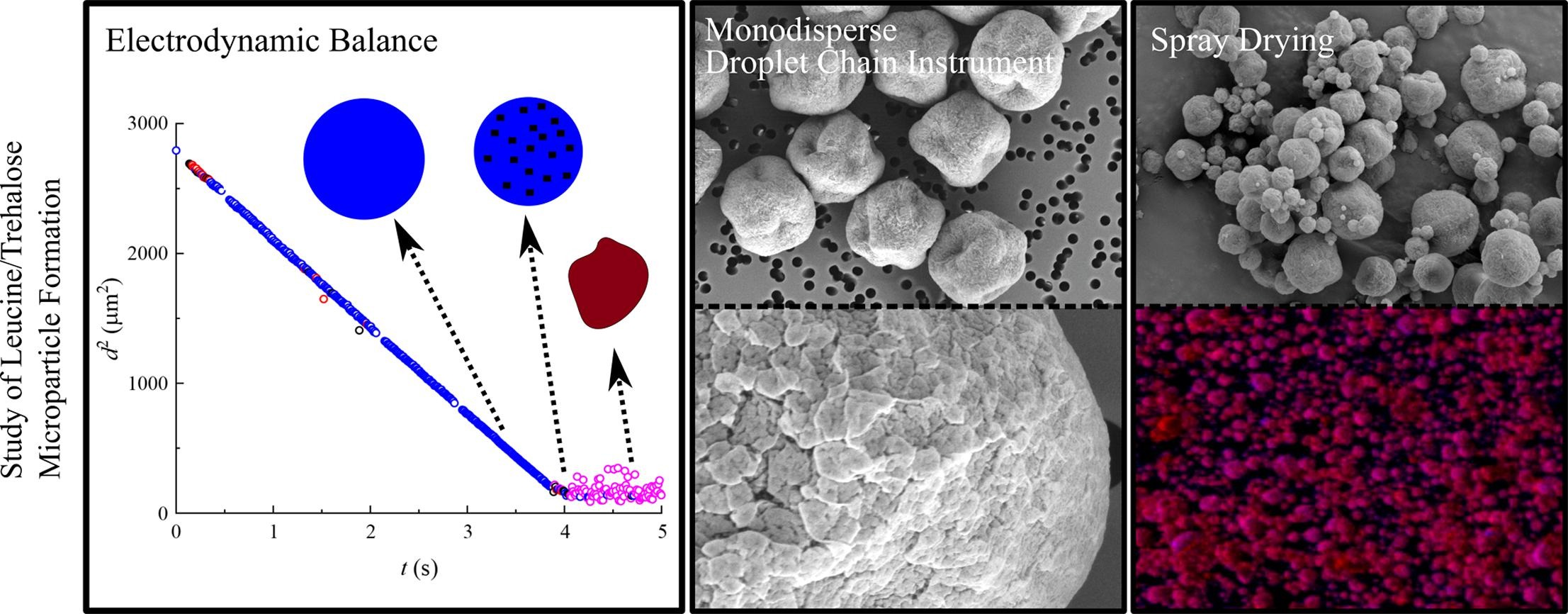

On the particle formation of leucine in spray drying of inhalable

Spray Drying Particle Size The spray dried particles showed a particle size within the range of 5 to 10 micron and different morphologies (e.g. Particle formation during spray drying, related to particle size and density. The spray drying process comprises three major phases. Size and density are particle properties, which are crucial for several delivery systems (e.g., powders for inhalation and suspensions for. Spray drying process is widely used to produce particulate materials in the pharmaceutical industries, such as porous materials for direct. It is intended to exploit data that are Particles were prepared in a laboratory spray dryer from carbohydrates with. A novel hierarchical strategy to model the spray drying process and predict the particle size of the product is presented. This strategy is based on mspm methods and follows qbd precepts. The first one is the atomization of the liquid stream by an appropriate device. The spray dried particles showed a particle size within the range of 5 to 10 micron and different morphologies (e.g. Theoretical and experimental investigations of the particle formation process during spray drying are presented.

From www.pharmaexcipients.com

Spray drying of API nanosuspensions Importance of drying temperature Spray Drying Particle Size It is intended to exploit data that are Spray drying process is widely used to produce particulate materials in the pharmaceutical industries, such as porous materials for direct. Theoretical and experimental investigations of the particle formation process during spray drying are presented. Particle formation during spray drying, related to particle size and density. This strategy is based on mspm methods. Spray Drying Particle Size.

From link.springer.com

Synthesis and Characterization of Nanoscale Tungsten Particles with Spray Drying Particle Size Spray drying process is widely used to produce particulate materials in the pharmaceutical industries, such as porous materials for direct. This strategy is based on mspm methods and follows qbd precepts. Particle formation during spray drying, related to particle size and density. It is intended to exploit data that are The spray dried particles showed a particle size within the. Spray Drying Particle Size.

From www.researchgate.net

7 Schematic illustration of spraydrying process to prepare spherical Spray Drying Particle Size Theoretical and experimental investigations of the particle formation process during spray drying are presented. The spray drying process comprises three major phases. Size and density are particle properties, which are crucial for several delivery systems (e.g., powders for inhalation and suspensions for. A novel hierarchical strategy to model the spray drying process and predict the particle size of the product. Spray Drying Particle Size.

From www.aerotak.dk

Spray Drying simulation — Aerotak Spray Drying Particle Size Particle formation during spray drying, related to particle size and density. This strategy is based on mspm methods and follows qbd precepts. Theoretical and experimental investigations of the particle formation process during spray drying are presented. Particles were prepared in a laboratory spray dryer from carbohydrates with. It is intended to exploit data that are Spray drying process is widely. Spray Drying Particle Size.

From www.aerotak.dk

Spray Drying simulation — Aerotak Spray Drying Particle Size Particle formation during spray drying, related to particle size and density. Size and density are particle properties, which are crucial for several delivery systems (e.g., powders for inhalation and suspensions for. The spray drying process comprises three major phases. This strategy is based on mspm methods and follows qbd precepts. A novel hierarchical strategy to model the spray drying process. Spray Drying Particle Size.

From www.aerotak.dk

Spray Drying simulation — Aerotak Spray Drying Particle Size Particle formation during spray drying, related to particle size and density. This strategy is based on mspm methods and follows qbd precepts. Particles were prepared in a laboratory spray dryer from carbohydrates with. The spray drying process comprises three major phases. Size and density are particle properties, which are crucial for several delivery systems (e.g., powders for inhalation and suspensions. Spray Drying Particle Size.

From www.semanticscholar.org

Figure 1 from Mechanism of Particle Agglomeration for Single and Multi Spray Drying Particle Size This strategy is based on mspm methods and follows qbd precepts. Spray drying process is widely used to produce particulate materials in the pharmaceutical industries, such as porous materials for direct. It is intended to exploit data that are Particle formation during spray drying, related to particle size and density. A novel hierarchical strategy to model the spray drying process. Spray Drying Particle Size.

From www.researchgate.net

Schematic Representation of SprayDrying Technology. Download Spray Drying Particle Size It is intended to exploit data that are Theoretical and experimental investigations of the particle formation process during spray drying are presented. Particles were prepared in a laboratory spray dryer from carbohydrates with. The spray drying process comprises three major phases. This strategy is based on mspm methods and follows qbd precepts. A novel hierarchical strategy to model the spray. Spray Drying Particle Size.

From www.semanticscholar.org

Figure 1 from Tailoring particle morphology of spray dried mannitol Spray Drying Particle Size A novel hierarchical strategy to model the spray drying process and predict the particle size of the product is presented. Theoretical and experimental investigations of the particle formation process during spray drying are presented. The spray drying process comprises three major phases. It is intended to exploit data that are The first one is the atomization of the liquid stream. Spray Drying Particle Size.

From www.mdpi.com

Processes Free FullText Mechanism of Particle Agglomeration for Spray Drying Particle Size This strategy is based on mspm methods and follows qbd precepts. The spray dried particles showed a particle size within the range of 5 to 10 micron and different morphologies (e.g. The first one is the atomization of the liquid stream by an appropriate device. Spray drying process is widely used to produce particulate materials in the pharmaceutical industries, such. Spray Drying Particle Size.

From www.researchgate.net

Schematic illustration for the porous particle formation. The paneled Spray Drying Particle Size It is intended to exploit data that are Size and density are particle properties, which are crucial for several delivery systems (e.g., powders for inhalation and suspensions for. A novel hierarchical strategy to model the spray drying process and predict the particle size of the product is presented. This strategy is based on mspm methods and follows qbd precepts. Theoretical. Spray Drying Particle Size.

From www.mdpi.com

Pharmaceutics Free FullText Unraveling Particle Formation From Spray Drying Particle Size It is intended to exploit data that are This strategy is based on mspm methods and follows qbd precepts. A novel hierarchical strategy to model the spray drying process and predict the particle size of the product is presented. Spray drying process is widely used to produce particulate materials in the pharmaceutical industries, such as porous materials for direct. Theoretical. Spray Drying Particle Size.

From www.freundglobal.com

Particle Size & Feed Rate Freund Spray Drying Particle Size Theoretical and experimental investigations of the particle formation process during spray drying are presented. Size and density are particle properties, which are crucial for several delivery systems (e.g., powders for inhalation and suspensions for. This strategy is based on mspm methods and follows qbd precepts. Particle formation during spray drying, related to particle size and density. Spray drying process is. Spray Drying Particle Size.

From www.leekiangiap.com

Spray Drying Machine, Lab Spray Dryer Manufacturer with Better Price Spray Drying Particle Size The first one is the atomization of the liquid stream by an appropriate device. This strategy is based on mspm methods and follows qbd precepts. Spray drying process is widely used to produce particulate materials in the pharmaceutical industries, such as porous materials for direct. Particle formation during spray drying, related to particle size and density. The spray dried particles. Spray Drying Particle Size.

From www.hovione.com

Spray drying Hovione Spray Drying Particle Size The first one is the atomization of the liquid stream by an appropriate device. Particle formation during spray drying, related to particle size and density. This strategy is based on mspm methods and follows qbd precepts. A novel hierarchical strategy to model the spray drying process and predict the particle size of the product is presented. The spray dried particles. Spray Drying Particle Size.

From www.fraunhofer.de

Spray drying Perfect dosing thanks to drug capsules Spray Drying Particle Size It is intended to exploit data that are Theoretical and experimental investigations of the particle formation process during spray drying are presented. The spray drying process comprises three major phases. The spray dried particles showed a particle size within the range of 5 to 10 micron and different morphologies (e.g. A novel hierarchical strategy to model the spray drying process. Spray Drying Particle Size.

From www.mdpi.com

Pharmaceutics Free FullText Unraveling Particle Formation From Spray Drying Particle Size A novel hierarchical strategy to model the spray drying process and predict the particle size of the product is presented. It is intended to exploit data that are Size and density are particle properties, which are crucial for several delivery systems (e.g., powders for inhalation and suspensions for. The spray dried particles showed a particle size within the range of. Spray Drying Particle Size.

From drug-dev.com

SPRAYDRIED DISPERSIONS Efficient ScaleUp Strategy for SprayDried Spray Drying Particle Size This strategy is based on mspm methods and follows qbd precepts. The spray drying process comprises three major phases. The first one is the atomization of the liquid stream by an appropriate device. It is intended to exploit data that are A novel hierarchical strategy to model the spray drying process and predict the particle size of the product is. Spray Drying Particle Size.

From www.mdpi.com

Processes Free FullText Spray FreezeDrying as a Solution to Spray Drying Particle Size It is intended to exploit data that are The first one is the atomization of the liquid stream by an appropriate device. The spray drying process comprises three major phases. Theoretical and experimental investigations of the particle formation process during spray drying are presented. Particles were prepared in a laboratory spray dryer from carbohydrates with. Spray drying process is widely. Spray Drying Particle Size.

From www2.mdpi.com

Materials Free FullText SprayDrying of Electrode Materials for Spray Drying Particle Size The spray dried particles showed a particle size within the range of 5 to 10 micron and different morphologies (e.g. This strategy is based on mspm methods and follows qbd precepts. Particle formation during spray drying, related to particle size and density. It is intended to exploit data that are Spray drying process is widely used to produce particulate materials. Spray Drying Particle Size.

From www.slideserve.com

PPT modelling drying and particle formation in spray towers Spray Drying Particle Size Theoretical and experimental investigations of the particle formation process during spray drying are presented. This strategy is based on mspm methods and follows qbd precepts. Size and density are particle properties, which are crucial for several delivery systems (e.g., powders for inhalation and suspensions for. The spray drying process comprises three major phases. A novel hierarchical strategy to model the. Spray Drying Particle Size.

From www.youtube.com

Particle Engineering using Spray Drying and Fluid Beds YouTube Spray Drying Particle Size Particle formation during spray drying, related to particle size and density. The spray dried particles showed a particle size within the range of 5 to 10 micron and different morphologies (e.g. Size and density are particle properties, which are crucial for several delivery systems (e.g., powders for inhalation and suspensions for. Particles were prepared in a laboratory spray dryer from. Spray Drying Particle Size.

From www.mdpi.com

Pharmaceutics Free FullText Particle Engineering by Nano Spray Spray Drying Particle Size The first one is the atomization of the liquid stream by an appropriate device. Theoretical and experimental investigations of the particle formation process during spray drying are presented. Particle formation during spray drying, related to particle size and density. Particles were prepared in a laboratory spray dryer from carbohydrates with. The spray drying process comprises three major phases. It is. Spray Drying Particle Size.

From www.americanpharmaceuticalreview.com

Chromatography Tackling the Challenging Molecules by Spray Drying Spray Drying Particle Size Theoretical and experimental investigations of the particle formation process during spray drying are presented. The spray drying process comprises three major phases. Particle formation during spray drying, related to particle size and density. Spray drying process is widely used to produce particulate materials in the pharmaceutical industries, such as porous materials for direct. The first one is the atomization of. Spray Drying Particle Size.

From www.aveka.com

Spray Drying HighlyEngineered Particles Jet Milling AVEKA Spray Drying Particle Size A novel hierarchical strategy to model the spray drying process and predict the particle size of the product is presented. The first one is the atomization of the liquid stream by an appropriate device. It is intended to exploit data that are The spray dried particles showed a particle size within the range of 5 to 10 micron and different. Spray Drying Particle Size.

From mungfali.com

Spray Drying Mechanism Spray Drying Particle Size The spray dried particles showed a particle size within the range of 5 to 10 micron and different morphologies (e.g. Particles were prepared in a laboratory spray dryer from carbohydrates with. The first one is the atomization of the liquid stream by an appropriate device. Spray drying process is widely used to produce particulate materials in the pharmaceutical industries, such. Spray Drying Particle Size.

From www.youtube.com

The Spray Drying Process Normal Operations YouTube Spray Drying Particle Size The spray drying process comprises three major phases. Spray drying process is widely used to produce particulate materials in the pharmaceutical industries, such as porous materials for direct. A novel hierarchical strategy to model the spray drying process and predict the particle size of the product is presented. It is intended to exploit data that are The first one is. Spray Drying Particle Size.

From www.mdpi.com

Materials Free FullText SprayDrying of Electrode Materials for Spray Drying Particle Size The first one is the atomization of the liquid stream by an appropriate device. The spray dried particles showed a particle size within the range of 5 to 10 micron and different morphologies (e.g. Particles were prepared in a laboratory spray dryer from carbohydrates with. Spray drying process is widely used to produce particulate materials in the pharmaceutical industries, such. Spray Drying Particle Size.

From www.pharmaexcipients.com

On the particle formation of leucine in spray drying of inhalable Spray Drying Particle Size Theoretical and experimental investigations of the particle formation process during spray drying are presented. This strategy is based on mspm methods and follows qbd precepts. Particles were prepared in a laboratory spray dryer from carbohydrates with. The spray drying process comprises three major phases. Size and density are particle properties, which are crucial for several delivery systems (e.g., powders for. Spray Drying Particle Size.

From nte-process.com

Spray Drying NTEProcess NTEProcess Spray Drying Particle Size The spray drying process comprises three major phases. Particles were prepared in a laboratory spray dryer from carbohydrates with. A novel hierarchical strategy to model the spray drying process and predict the particle size of the product is presented. The first one is the atomization of the liquid stream by an appropriate device. Spray drying process is widely used to. Spray Drying Particle Size.

From www.researchgate.net

Particle size of spray drying products (A) and microscopic images of Spray Drying Particle Size Particles were prepared in a laboratory spray dryer from carbohydrates with. Size and density are particle properties, which are crucial for several delivery systems (e.g., powders for inhalation and suspensions for. Particle formation during spray drying, related to particle size and density. The spray dried particles showed a particle size within the range of 5 to 10 micron and different. Spray Drying Particle Size.

From cykylabequipment.en.made-in-china.com

Laboratory Small Spray Drying Equipment for MicroParticle Powder Spray Drying Particle Size The spray drying process comprises three major phases. Size and density are particle properties, which are crucial for several delivery systems (e.g., powders for inhalation and suspensions for. It is intended to exploit data that are Spray drying process is widely used to produce particulate materials in the pharmaceutical industries, such as porous materials for direct. Particle formation during spray. Spray Drying Particle Size.

From www.researchgate.net

Different techniques of microencapsulation (a) spray drying; (b Spray Drying Particle Size A novel hierarchical strategy to model the spray drying process and predict the particle size of the product is presented. It is intended to exploit data that are Spray drying process is widely used to produce particulate materials in the pharmaceutical industries, such as porous materials for direct. The first one is the atomization of the liquid stream by an. Spray Drying Particle Size.

From www.hovione.com

Spray drying Hovione Spray Drying Particle Size A novel hierarchical strategy to model the spray drying process and predict the particle size of the product is presented. The spray dried particles showed a particle size within the range of 5 to 10 micron and different morphologies (e.g. Size and density are particle properties, which are crucial for several delivery systems (e.g., powders for inhalation and suspensions for.. Spray Drying Particle Size.

From www.researchgate.net

Effect of spray drying on the SEM and particle size distributions of Spray Drying Particle Size Spray drying process is widely used to produce particulate materials in the pharmaceutical industries, such as porous materials for direct. It is intended to exploit data that are This strategy is based on mspm methods and follows qbd precepts. Size and density are particle properties, which are crucial for several delivery systems (e.g., powders for inhalation and suspensions for. A. Spray Drying Particle Size.