Solder Fillet Angle . The resultant fillet shape and joint strength depend on. Populated plated through holes (pth) should exhibit a vertical solder fill of 100%, with a fully formed fillet on the solder side, and evidence of 100%. Circular fillet and wetting of solder of the lead and plated hole barrel on the solder side. An acceptable solder connection should indicate evidence of wetting and adherence when the solder blends to the soldered surface. Percent of the land area covered with solder on the component side. By switching the magnification, it is possible. Solder fillet angle you want the solder meniscus or fillet to have about a 45° angle for its sides from the board surface, and be slightly concave like a little. Solder fillets are smooth and shiny with concave profiles.

from www.slideshare.net

An acceptable solder connection should indicate evidence of wetting and adherence when the solder blends to the soldered surface. Solder fillets are smooth and shiny with concave profiles. Percent of the land area covered with solder on the component side. By switching the magnification, it is possible. The resultant fillet shape and joint strength depend on. Circular fillet and wetting of solder of the lead and plated hole barrel on the solder side. Populated plated through holes (pth) should exhibit a vertical solder fill of 100%, with a fully formed fillet on the solder side, and evidence of 100%. Solder fillet angle you want the solder meniscus or fillet to have about a 45° angle for its sides from the board surface, and be slightly concave like a little.

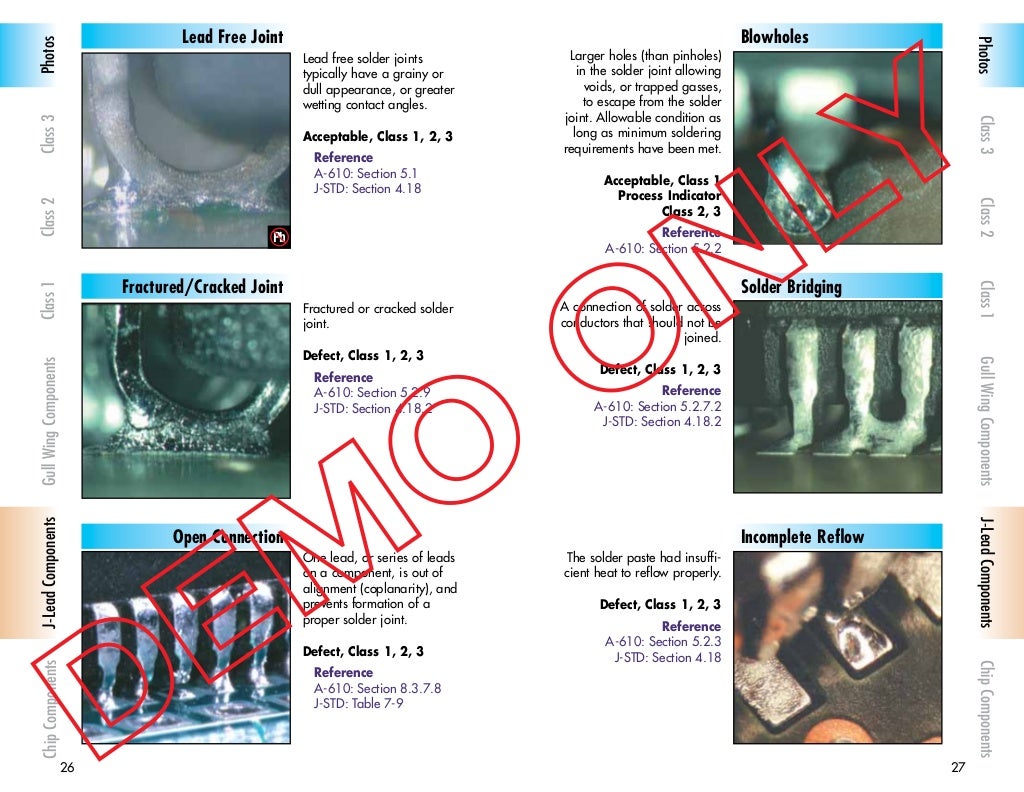

SOLDER FILLET STANDARDS DEMO BOOKLET DEFINITIONS

Solder Fillet Angle The resultant fillet shape and joint strength depend on. Percent of the land area covered with solder on the component side. Circular fillet and wetting of solder of the lead and plated hole barrel on the solder side. The resultant fillet shape and joint strength depend on. Populated plated through holes (pth) should exhibit a vertical solder fill of 100%, with a fully formed fillet on the solder side, and evidence of 100%. Solder fillets are smooth and shiny with concave profiles. An acceptable solder connection should indicate evidence of wetting and adherence when the solder blends to the soldered surface. Solder fillet angle you want the solder meniscus or fillet to have about a 45° angle for its sides from the board surface, and be slightly concave like a little. By switching the magnification, it is possible.

From www.slideshare.net

SOLDER FILLET STANDARDS DEMO BOOKLET DEFINITIONS Solder Fillet Angle Solder fillets are smooth and shiny with concave profiles. The resultant fillet shape and joint strength depend on. By switching the magnification, it is possible. Populated plated through holes (pth) should exhibit a vertical solder fill of 100%, with a fully formed fillet on the solder side, and evidence of 100%. Percent of the land area covered with solder on. Solder Fillet Angle.

From www.aliexpress.com

Mg11 Welding Fillet Gage Inspection Welding Gauge Soldering Ruler (metric&standard) Gauges Solder Fillet Angle Percent of the land area covered with solder on the component side. Solder fillets are smooth and shiny with concave profiles. The resultant fillet shape and joint strength depend on. Solder fillet angle you want the solder meniscus or fillet to have about a 45° angle for its sides from the board surface, and be slightly concave like a little.. Solder Fillet Angle.

From www.semanticscholar.org

Figure 1 from Fracture probability of MLCC in dependence of solder fillet height Semantic Scholar Solder Fillet Angle Percent of the land area covered with solder on the component side. An acceptable solder connection should indicate evidence of wetting and adherence when the solder blends to the soldered surface. The resultant fillet shape and joint strength depend on. Solder fillet angle you want the solder meniscus or fillet to have about a 45° angle for its sides from. Solder Fillet Angle.

From www.circuitbasics.com

Tips for Good Soldering Technique Circuit Basics Solder Fillet Angle Solder fillet angle you want the solder meniscus or fillet to have about a 45° angle for its sides from the board surface, and be slightly concave like a little. By switching the magnification, it is possible. Circular fillet and wetting of solder of the lead and plated hole barrel on the solder side. Percent of the land area covered. Solder Fillet Angle.

From www.youtube.com

Fillet Welds YouTube Solder Fillet Angle Circular fillet and wetting of solder of the lead and plated hole barrel on the solder side. Percent of the land area covered with solder on the component side. Solder fillets are smooth and shiny with concave profiles. The resultant fillet shape and joint strength depend on. Solder fillet angle you want the solder meniscus or fillet to have about. Solder Fillet Angle.

From sfe.io

How to Solder ThroughHole Soldering Solder Fillet Angle Circular fillet and wetting of solder of the lead and plated hole barrel on the solder side. Solder fillets are smooth and shiny with concave profiles. By switching the magnification, it is possible. The resultant fillet shape and joint strength depend on. Populated plated through holes (pth) should exhibit a vertical solder fill of 100%, with a fully formed fillet. Solder Fillet Angle.

From www.protoexpress.com

How to Design Correct PCB Footprints Sierra Circuits Solder Fillet Angle Solder fillet angle you want the solder meniscus or fillet to have about a 45° angle for its sides from the board surface, and be slightly concave like a little. Populated plated through holes (pth) should exhibit a vertical solder fill of 100%, with a fully formed fillet on the solder side, and evidence of 100%. Solder fillets are smooth. Solder Fillet Angle.

From absolutepcbassembly.com

IPC JSTD001 Standard for Soldering Absolute Electronics Solder Fillet Angle Solder fillets are smooth and shiny with concave profiles. Percent of the land area covered with solder on the component side. An acceptable solder connection should indicate evidence of wetting and adherence when the solder blends to the soldered surface. Populated plated through holes (pth) should exhibit a vertical solder fill of 100%, with a fully formed fillet on the. Solder Fillet Angle.

From www.slideshare.net

SOLDER FILLET STANDARDS DEMO BOOKLET DEFINITIONS Solder Fillet Angle Populated plated through holes (pth) should exhibit a vertical solder fill of 100%, with a fully formed fillet on the solder side, and evidence of 100%. Circular fillet and wetting of solder of the lead and plated hole barrel on the solder side. Solder fillets are smooth and shiny with concave profiles. An acceptable solder connection should indicate evidence of. Solder Fillet Angle.

From www.mig-welding.co.uk

Arc (MMA) Welding Fillet Joints Solder Fillet Angle Circular fillet and wetting of solder of the lead and plated hole barrel on the solder side. An acceptable solder connection should indicate evidence of wetting and adherence when the solder blends to the soldered surface. Percent of the land area covered with solder on the component side. The resultant fillet shape and joint strength depend on. Solder fillet angle. Solder Fillet Angle.

From www.keyence.com

Inspection and Measurement of Solder Cracks and Voids Electronic Device Industry 4K Digital Solder Fillet Angle Circular fillet and wetting of solder of the lead and plated hole barrel on the solder side. Solder fillets are smooth and shiny with concave profiles. By switching the magnification, it is possible. Percent of the land area covered with solder on the component side. An acceptable solder connection should indicate evidence of wetting and adherence when the solder blends. Solder Fillet Angle.

From www.slideserve.com

PPT Aerospace Soldering & Electronic Assembly Techniques Randall Pearl PowerPoint Presentation Solder Fillet Angle Solder fillets are smooth and shiny with concave profiles. Populated plated through holes (pth) should exhibit a vertical solder fill of 100%, with a fully formed fillet on the solder side, and evidence of 100%. Circular fillet and wetting of solder of the lead and plated hole barrel on the solder side. An acceptable solder connection should indicate evidence of. Solder Fillet Angle.

From www.slideshare.net

SOLDER FILLET STANDARDS DEMO BOOKLET DEFINITIONS Solder Fillet Angle The resultant fillet shape and joint strength depend on. An acceptable solder connection should indicate evidence of wetting and adherence when the solder blends to the soldered surface. Circular fillet and wetting of solder of the lead and plated hole barrel on the solder side. By switching the magnification, it is possible. Solder fillet angle you want the solder meniscus. Solder Fillet Angle.

From www.slideshare.net

SOLDER FILLET STANDARDS DEMO BOOKLET DEFINITIONS Solder Fillet Angle Circular fillet and wetting of solder of the lead and plated hole barrel on the solder side. Percent of the land area covered with solder on the component side. By switching the magnification, it is possible. An acceptable solder connection should indicate evidence of wetting and adherence when the solder blends to the soldered surface. Populated plated through holes (pth). Solder Fillet Angle.

From www.linkedin.com

Types of Soldering Solder Fillet Angle Circular fillet and wetting of solder of the lead and plated hole barrel on the solder side. An acceptable solder connection should indicate evidence of wetting and adherence when the solder blends to the soldered surface. The resultant fillet shape and joint strength depend on. Populated plated through holes (pth) should exhibit a vertical solder fill of 100%, with a. Solder Fillet Angle.

From www.researchgate.net

Procedure for assembling a single BGA structure solder joint by... Download Scientific Diagram Solder Fillet Angle Populated plated through holes (pth) should exhibit a vertical solder fill of 100%, with a fully formed fillet on the solder side, and evidence of 100%. Solder fillets are smooth and shiny with concave profiles. By switching the magnification, it is possible. Percent of the land area covered with solder on the component side. Circular fillet and wetting of solder. Solder Fillet Angle.

From www.researchgate.net

Solder spread and fillet radius at different solder joint height with... Download Scientific Solder Fillet Angle Circular fillet and wetting of solder of the lead and plated hole barrel on the solder side. By switching the magnification, it is possible. Percent of the land area covered with solder on the component side. An acceptable solder connection should indicate evidence of wetting and adherence when the solder blends to the soldered surface. Solder fillet angle you want. Solder Fillet Angle.

From www.krohnindustries.com

Cut Solder Sizing Chart Krohn Industries, Inc. Solder Fillet Angle Solder fillet angle you want the solder meniscus or fillet to have about a 45° angle for its sides from the board surface, and be slightly concave like a little. Circular fillet and wetting of solder of the lead and plated hole barrel on the solder side. An acceptable solder connection should indicate evidence of wetting and adherence when the. Solder Fillet Angle.

From www.slideshare.net

SOLDER FILLET STANDARDS DEMO BOOKLET DEFINITIONS Solder Fillet Angle By switching the magnification, it is possible. The resultant fillet shape and joint strength depend on. Populated plated through holes (pth) should exhibit a vertical solder fill of 100%, with a fully formed fillet on the solder side, and evidence of 100%. Circular fillet and wetting of solder of the lead and plated hole barrel on the solder side. Solder. Solder Fillet Angle.

From ar.inspiredpencil.com

Fillet Weld Measurements Solder Fillet Angle Solder fillet angle you want the solder meniscus or fillet to have about a 45° angle for its sides from the board surface, and be slightly concave like a little. Populated plated through holes (pth) should exhibit a vertical solder fill of 100%, with a fully formed fillet on the solder side, and evidence of 100%. Circular fillet and wetting. Solder Fillet Angle.

From www.researchgate.net

Solder spread and fillet radius at different solder joint height with... Download Scientific Solder Fillet Angle Circular fillet and wetting of solder of the lead and plated hole barrel on the solder side. Solder fillets are smooth and shiny with concave profiles. Percent of the land area covered with solder on the component side. By switching the magnification, it is possible. The resultant fillet shape and joint strength depend on. Solder fillet angle you want the. Solder Fillet Angle.

From mewelding.com

Fillet Weld Solder Fillet Angle Populated plated through holes (pth) should exhibit a vertical solder fill of 100%, with a fully formed fillet on the solder side, and evidence of 100%. An acceptable solder connection should indicate evidence of wetting and adherence when the solder blends to the soldered surface. Circular fillet and wetting of solder of the lead and plated hole barrel on the. Solder Fillet Angle.

From www.semanticscholar.org

Figure 1 from A hydrostatic model of solder fillets part I Axisymmetric model Semantic Scholar Solder Fillet Angle An acceptable solder connection should indicate evidence of wetting and adherence when the solder blends to the soldered surface. Percent of the land area covered with solder on the component side. By switching the magnification, it is possible. Populated plated through holes (pth) should exhibit a vertical solder fill of 100%, with a fully formed fillet on the solder side,. Solder Fillet Angle.

From www.slideshare.net

SOLDER FILLET STANDARDS DEMO BOOKLET DEFINITIONS Solder Fillet Angle By switching the magnification, it is possible. Percent of the land area covered with solder on the component side. Populated plated through holes (pth) should exhibit a vertical solder fill of 100%, with a fully formed fillet on the solder side, and evidence of 100%. Circular fillet and wetting of solder of the lead and plated hole barrel on the. Solder Fillet Angle.

From www.slideshare.net

SOLDER FILLET STANDARDS DEMO BOOKLET DEFINITIONS Solder Fillet Angle Solder fillets are smooth and shiny with concave profiles. By switching the magnification, it is possible. Circular fillet and wetting of solder of the lead and plated hole barrel on the solder side. The resultant fillet shape and joint strength depend on. Percent of the land area covered with solder on the component side. An acceptable solder connection should indicate. Solder Fillet Angle.

From www.semanticscholar.org

Figure 2 from A hydrostatic model of solder fillets part I Axisymmetric model Semantic Scholar Solder Fillet Angle Solder fillets are smooth and shiny with concave profiles. An acceptable solder connection should indicate evidence of wetting and adherence when the solder blends to the soldered surface. Solder fillet angle you want the solder meniscus or fillet to have about a 45° angle for its sides from the board surface, and be slightly concave like a little. The resultant. Solder Fillet Angle.

From www.slideshare.net

SOLDER FILLET STANDARDS DEMO BOOKLET DEFINITIONS Solder Fillet Angle Circular fillet and wetting of solder of the lead and plated hole barrel on the solder side. Populated plated through holes (pth) should exhibit a vertical solder fill of 100%, with a fully formed fillet on the solder side, and evidence of 100%. Solder fillets are smooth and shiny with concave profiles. Solder fillet angle you want the solder meniscus. Solder Fillet Angle.

From www.youtube.com

Parts of A Weld Part 1 Toe and Leg of a fillet weld YouTube Solder Fillet Angle Solder fillets are smooth and shiny with concave profiles. An acceptable solder connection should indicate evidence of wetting and adherence when the solder blends to the soldered surface. Circular fillet and wetting of solder of the lead and plated hole barrel on the solder side. Solder fillet angle you want the solder meniscus or fillet to have about a 45°. Solder Fillet Angle.

From www.youtube.com

TIG Weld Tfillet Tilt Angle Tutorial YouTube Solder Fillet Angle Solder fillet angle you want the solder meniscus or fillet to have about a 45° angle for its sides from the board surface, and be slightly concave like a little. An acceptable solder connection should indicate evidence of wetting and adherence when the solder blends to the soldered surface. Solder fillets are smooth and shiny with concave profiles. Populated plated. Solder Fillet Angle.

From www.makeuseof.com

Soldering Demystified Understanding the Basics To Succeed at Soldering Solder Fillet Angle Percent of the land area covered with solder on the component side. Solder fillets are smooth and shiny with concave profiles. Populated plated through holes (pth) should exhibit a vertical solder fill of 100%, with a fully formed fillet on the solder side, and evidence of 100%. Circular fillet and wetting of solder of the lead and plated hole barrel. Solder Fillet Angle.

From vacaero.com

Dimension BrazeFillets on Drawings Solder Fillet Angle Percent of the land area covered with solder on the component side. Circular fillet and wetting of solder of the lead and plated hole barrel on the solder side. Populated plated through holes (pth) should exhibit a vertical solder fill of 100%, with a fully formed fillet on the solder side, and evidence of 100%. An acceptable solder connection should. Solder Fillet Angle.

From www.vse.com

ThroughHole Soldering A Guide to the Best Practices VSE Solder Fillet Angle Solder fillets are smooth and shiny with concave profiles. Percent of the land area covered with solder on the component side. The resultant fillet shape and joint strength depend on. Circular fillet and wetting of solder of the lead and plated hole barrel on the solder side. Solder fillet angle you want the solder meniscus or fillet to have about. Solder Fillet Angle.

From www.rapiddirect.com

Fillet vs Chamfers What a Fillet is and How It Differs from Chamfers Solder Fillet Angle Percent of the land area covered with solder on the component side. Circular fillet and wetting of solder of the lead and plated hole barrel on the solder side. Populated plated through holes (pth) should exhibit a vertical solder fill of 100%, with a fully formed fillet on the solder side, and evidence of 100%. Solder fillets are smooth and. Solder Fillet Angle.

From www.researchgate.net

Solder spread and fillet radius at different solder joint height with... Download Scientific Solder Fillet Angle Circular fillet and wetting of solder of the lead and plated hole barrel on the solder side. An acceptable solder connection should indicate evidence of wetting and adherence when the solder blends to the soldered surface. Percent of the land area covered with solder on the component side. The resultant fillet shape and joint strength depend on. Populated plated through. Solder Fillet Angle.

From www.researchgate.net

Asymmetry of solder fillets at PCB is consequence of teardrop pads... Download Scientific Diagram Solder Fillet Angle Populated plated through holes (pth) should exhibit a vertical solder fill of 100%, with a fully formed fillet on the solder side, and evidence of 100%. Solder fillets are smooth and shiny with concave profiles. The resultant fillet shape and joint strength depend on. Percent of the land area covered with solder on the component side. An acceptable solder connection. Solder Fillet Angle.