Lap Shear Vs Die Shear . The definitive guide to astm d1002 lap shear testing of adhesively bonded metals. A rotational capability, relative to the header/substrate holding fixture and the die contact tool, to facilitate line contact on the. For this reason we perform two types of shear testing to determine epoxy strength: This is sometimes referred to as shear thinning. Pseudoplastic materials will decrease in viscosity with an increase in shear rate. Lap shear testing is a method of determining the adhesive capabilities of things like glues and other. Lap shear and die shear. Astm d1002 describes the procedure for evaluating the shear strength of adhesives used for bonding. Epoxy is shear, not tensile. The main objective of this investigation was to generate characteristic shear responses for several adhesives used for aerospace.

from wpo-altertechnology.com

Pseudoplastic materials will decrease in viscosity with an increase in shear rate. Lap shear testing is a method of determining the adhesive capabilities of things like glues and other. Lap shear and die shear. The main objective of this investigation was to generate characteristic shear responses for several adhesives used for aerospace. Astm d1002 describes the procedure for evaluating the shear strength of adhesives used for bonding. Epoxy is shear, not tensile. A rotational capability, relative to the header/substrate holding fixture and the die contact tool, to facilitate line contact on the. The definitive guide to astm d1002 lap shear testing of adhesively bonded metals. This is sometimes referred to as shear thinning. For this reason we perform two types of shear testing to determine epoxy strength:

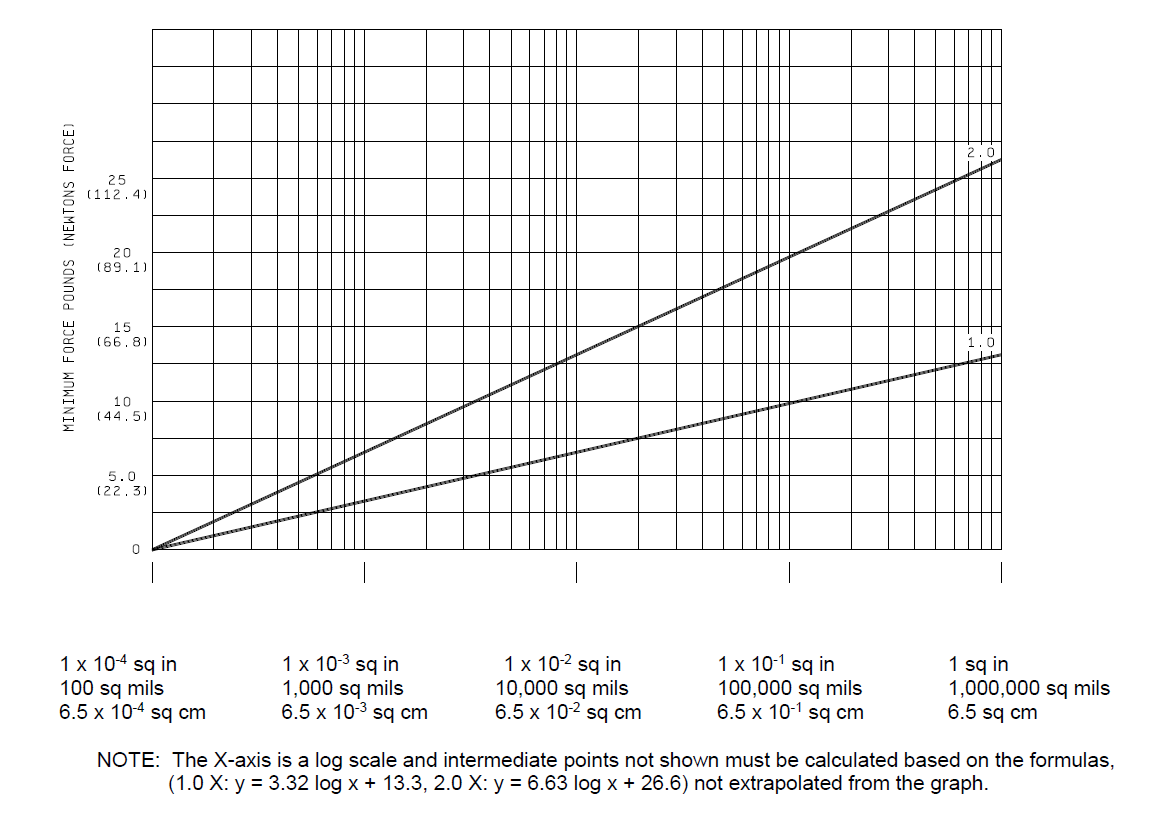

Substrate Attach Strength Die Shear Strength EEE Parts

Lap Shear Vs Die Shear Lap shear testing is a method of determining the adhesive capabilities of things like glues and other. This is sometimes referred to as shear thinning. Lap shear and die shear. Epoxy is shear, not tensile. The main objective of this investigation was to generate characteristic shear responses for several adhesives used for aerospace. For this reason we perform two types of shear testing to determine epoxy strength: The definitive guide to astm d1002 lap shear testing of adhesively bonded metals. Astm d1002 describes the procedure for evaluating the shear strength of adhesives used for bonding. Pseudoplastic materials will decrease in viscosity with an increase in shear rate. Lap shear testing is a method of determining the adhesive capabilities of things like glues and other. A rotational capability, relative to the header/substrate holding fixture and the die contact tool, to facilitate line contact on the.

From wpo-altertechnology.com

Substrate Attach Strength Die Shear Strength EEE Parts Lap Shear Vs Die Shear The definitive guide to astm d1002 lap shear testing of adhesively bonded metals. For this reason we perform two types of shear testing to determine epoxy strength: Lap shear and die shear. Lap shear testing is a method of determining the adhesive capabilities of things like glues and other. This is sometimes referred to as shear thinning. Pseudoplastic materials will. Lap Shear Vs Die Shear.

From structures-explained.com

Shear Forces and Shear Stresses in Structures Structures Explained Lap Shear Vs Die Shear Lap shear and die shear. Lap shear testing is a method of determining the adhesive capabilities of things like glues and other. This is sometimes referred to as shear thinning. Epoxy is shear, not tensile. Pseudoplastic materials will decrease in viscosity with an increase in shear rate. A rotational capability, relative to the header/substrate holding fixture and the die contact. Lap Shear Vs Die Shear.

From www.youtube.com

SHEARING PROCESS SHEARING MECHANISM SHEAR FORCE SHEAR STRENGTH Lap Shear Vs Die Shear Lap shear testing is a method of determining the adhesive capabilities of things like glues and other. The main objective of this investigation was to generate characteristic shear responses for several adhesives used for aerospace. Astm d1002 describes the procedure for evaluating the shear strength of adhesives used for bonding. For this reason we perform two types of shear testing. Lap Shear Vs Die Shear.

From www.mdpi.com

Metals Free FullText TensileShear Fracture Behavior Prediction of Lap Shear Vs Die Shear Astm d1002 describes the procedure for evaluating the shear strength of adhesives used for bonding. Pseudoplastic materials will decrease in viscosity with an increase in shear rate. Lap shear and die shear. For this reason we perform two types of shear testing to determine epoxy strength: The main objective of this investigation was to generate characteristic shear responses for several. Lap Shear Vs Die Shear.

From www.mdpi.com

J. Compos. Sci. Free FullText Composite Single Lap Shear Joint Lap Shear Vs Die Shear The main objective of this investigation was to generate characteristic shear responses for several adhesives used for aerospace. Pseudoplastic materials will decrease in viscosity with an increase in shear rate. This is sometimes referred to as shear thinning. Astm d1002 describes the procedure for evaluating the shear strength of adhesives used for bonding. Epoxy is shear, not tensile. The definitive. Lap Shear Vs Die Shear.

From www.researchgate.net

Wood preparation for lap shear strength test (ASTM D906 method Lap Shear Vs Die Shear For this reason we perform two types of shear testing to determine epoxy strength: Lap shear testing is a method of determining the adhesive capabilities of things like glues and other. The main objective of this investigation was to generate characteristic shear responses for several adhesives used for aerospace. The definitive guide to astm d1002 lap shear testing of adhesively. Lap Shear Vs Die Shear.

From www.slideserve.com

PPT Average shear stress PowerPoint Presentation, free download ID Lap Shear Vs Die Shear For this reason we perform two types of shear testing to determine epoxy strength: Lap shear and die shear. The definitive guide to astm d1002 lap shear testing of adhesively bonded metals. Astm d1002 describes the procedure for evaluating the shear strength of adhesives used for bonding. This is sometimes referred to as shear thinning. Lap shear testing is a. Lap Shear Vs Die Shear.

From www.mdpi.com

J. Compos. Sci. Free FullText Evaluation of SingleLap and Block Lap Shear Vs Die Shear Astm d1002 describes the procedure for evaluating the shear strength of adhesives used for bonding. Pseudoplastic materials will decrease in viscosity with an increase in shear rate. The definitive guide to astm d1002 lap shear testing of adhesively bonded metals. This is sometimes referred to as shear thinning. Lap shear testing is a method of determining the adhesive capabilities of. Lap Shear Vs Die Shear.

From www.researchgate.net

Schematic of dieshear test. Download Scientific Diagram Lap Shear Vs Die Shear Epoxy is shear, not tensile. Astm d1002 describes the procedure for evaluating the shear strength of adhesives used for bonding. Lap shear testing is a method of determining the adhesive capabilities of things like glues and other. The definitive guide to astm d1002 lap shear testing of adhesively bonded metals. For this reason we perform two types of shear testing. Lap Shear Vs Die Shear.

From www.researchgate.net

Typical failure modes of shortbeam shear samples as a function of the Lap Shear Vs Die Shear Pseudoplastic materials will decrease in viscosity with an increase in shear rate. For this reason we perform two types of shear testing to determine epoxy strength: Astm d1002 describes the procedure for evaluating the shear strength of adhesives used for bonding. Epoxy is shear, not tensile. This is sometimes referred to as shear thinning. The main objective of this investigation. Lap Shear Vs Die Shear.

From www.youtube.com

Single Shear vs. Double Shear Exam Problem, S13 (Ugli Fruit) YouTube Lap Shear Vs Die Shear Pseudoplastic materials will decrease in viscosity with an increase in shear rate. Lap shear and die shear. The main objective of this investigation was to generate characteristic shear responses for several adhesives used for aerospace. This is sometimes referred to as shear thinning. The definitive guide to astm d1002 lap shear testing of adhesively bonded metals. Epoxy is shear, not. Lap Shear Vs Die Shear.

From www.researchgate.net

(a) The schematic illustration of the tensile shear on the tensile Lap Shear Vs Die Shear Lap shear testing is a method of determining the adhesive capabilities of things like glues and other. A rotational capability, relative to the header/substrate holding fixture and the die contact tool, to facilitate line contact on the. Astm d1002 describes the procedure for evaluating the shear strength of adhesives used for bonding. Epoxy is shear, not tensile. Pseudoplastic materials will. Lap Shear Vs Die Shear.

From www.youtube.com

Lap Shear Doesn't Measure Shear YouTube Lap Shear Vs Die Shear Astm d1002 describes the procedure for evaluating the shear strength of adhesives used for bonding. The definitive guide to astm d1002 lap shear testing of adhesively bonded metals. The main objective of this investigation was to generate characteristic shear responses for several adhesives used for aerospace. For this reason we perform two types of shear testing to determine epoxy strength:. Lap Shear Vs Die Shear.

From www.researchgate.net

Configurations shear test (a) Singlelap shear test; (b) doublelap Lap Shear Vs Die Shear Lap shear testing is a method of determining the adhesive capabilities of things like glues and other. A rotational capability, relative to the header/substrate holding fixture and the die contact tool, to facilitate line contact on the. The definitive guide to astm d1002 lap shear testing of adhesively bonded metals. Epoxy is shear, not tensile. Pseudoplastic materials will decrease in. Lap Shear Vs Die Shear.

From www.instron.it

Instron Lap Shear Test Instron Lap Shear Vs Die Shear Epoxy is shear, not tensile. Pseudoplastic materials will decrease in viscosity with an increase in shear rate. The definitive guide to astm d1002 lap shear testing of adhesively bonded metals. Lap shear testing is a method of determining the adhesive capabilities of things like glues and other. A rotational capability, relative to the header/substrate holding fixture and the die contact. Lap Shear Vs Die Shear.

From www.youtube.com

Types Of Failures in Beams//Shear Failure//Flexural Failure !! Full Lap Shear Vs Die Shear This is sometimes referred to as shear thinning. Lap shear testing is a method of determining the adhesive capabilities of things like glues and other. For this reason we perform two types of shear testing to determine epoxy strength: The definitive guide to astm d1002 lap shear testing of adhesively bonded metals. The main objective of this investigation was to. Lap Shear Vs Die Shear.

From research.iitgn.ac.in

Direct Shear Geotechnical Testing Lab Lap Shear Vs Die Shear The main objective of this investigation was to generate characteristic shear responses for several adhesives used for aerospace. Astm d1002 describes the procedure for evaluating the shear strength of adhesives used for bonding. Epoxy is shear, not tensile. The definitive guide to astm d1002 lap shear testing of adhesively bonded metals. Lap shear and die shear. Pseudoplastic materials will decrease. Lap Shear Vs Die Shear.

From www.slideserve.com

PPT Average shear stress PowerPoint Presentation, free download ID Lap Shear Vs Die Shear Astm d1002 describes the procedure for evaluating the shear strength of adhesives used for bonding. Pseudoplastic materials will decrease in viscosity with an increase in shear rate. A rotational capability, relative to the header/substrate holding fixture and the die contact tool, to facilitate line contact on the. Epoxy is shear, not tensile. The definitive guide to astm d1002 lap shear. Lap Shear Vs Die Shear.

From www.detailerpoint.com

Shear vs moment connection in steel detailing Detailerpoint — Best Lap Shear Vs Die Shear The definitive guide to astm d1002 lap shear testing of adhesively bonded metals. For this reason we perform two types of shear testing to determine epoxy strength: Epoxy is shear, not tensile. Astm d1002 describes the procedure for evaluating the shear strength of adhesives used for bonding. Pseudoplastic materials will decrease in viscosity with an increase in shear rate. Lap. Lap Shear Vs Die Shear.

From www.testresources.net

ASTM D5656 ThickAdherend Metal LapShear Testing of Adhesives in Shear Lap Shear Vs Die Shear Astm d1002 describes the procedure for evaluating the shear strength of adhesives used for bonding. Lap shear testing is a method of determining the adhesive capabilities of things like glues and other. Epoxy is shear, not tensile. A rotational capability, relative to the header/substrate holding fixture and the die contact tool, to facilitate line contact on the. The main objective. Lap Shear Vs Die Shear.

From www.youtube.com

MoM Chap 1.5 Single vs Double Shear YouTube Lap Shear Vs Die Shear Epoxy is shear, not tensile. This is sometimes referred to as shear thinning. Lap shear testing is a method of determining the adhesive capabilities of things like glues and other. For this reason we perform two types of shear testing to determine epoxy strength: A rotational capability, relative to the header/substrate holding fixture and the die contact tool, to facilitate. Lap Shear Vs Die Shear.

From www.mdpi.com

J. Compos. Sci. Free FullText Evaluation of SingleLap and Block Lap Shear Vs Die Shear Lap shear and die shear. Lap shear testing is a method of determining the adhesive capabilities of things like glues and other. The main objective of this investigation was to generate characteristic shear responses for several adhesives used for aerospace. A rotational capability, relative to the header/substrate holding fixture and the die contact tool, to facilitate line contact on the.. Lap Shear Vs Die Shear.

From www.researchgate.net

Summary of different failure modes observed during static lap shear Lap Shear Vs Die Shear Lap shear testing is a method of determining the adhesive capabilities of things like glues and other. For this reason we perform two types of shear testing to determine epoxy strength: The definitive guide to astm d1002 lap shear testing of adhesively bonded metals. Lap shear and die shear. This is sometimes referred to as shear thinning. A rotational capability,. Lap Shear Vs Die Shear.

From biopdi.com

Comprehensive Guide to Shear Testing in Material Science Lap Shear Vs Die Shear A rotational capability, relative to the header/substrate holding fixture and the die contact tool, to facilitate line contact on the. Lap shear and die shear. Epoxy is shear, not tensile. Lap shear testing is a method of determining the adhesive capabilities of things like glues and other. The main objective of this investigation was to generate characteristic shear responses for. Lap Shear Vs Die Shear.

From ayakoalmeida.blogspot.com

direct shear test lab report Ayako Almeida Lap Shear Vs Die Shear Lap shear testing is a method of determining the adhesive capabilities of things like glues and other. The definitive guide to astm d1002 lap shear testing of adhesively bonded metals. Pseudoplastic materials will decrease in viscosity with an increase in shear rate. Epoxy is shear, not tensile. The main objective of this investigation was to generate characteristic shear responses for. Lap Shear Vs Die Shear.

From civilseek.com

Direct Shear Test; To Determine Shear Strength of Soil. Lap Shear Vs Die Shear A rotational capability, relative to the header/substrate holding fixture and the die contact tool, to facilitate line contact on the. The main objective of this investigation was to generate characteristic shear responses for several adhesives used for aerospace. Pseudoplastic materials will decrease in viscosity with an increase in shear rate. For this reason we perform two types of shear testing. Lap Shear Vs Die Shear.

From structures-explained.com

Shear Forces and Shear Stresses in Structures Structures Explained Lap Shear Vs Die Shear A rotational capability, relative to the header/substrate holding fixture and the die contact tool, to facilitate line contact on the. The definitive guide to astm d1002 lap shear testing of adhesively bonded metals. For this reason we perform two types of shear testing to determine epoxy strength: Epoxy is shear, not tensile. The main objective of this investigation was to. Lap Shear Vs Die Shear.

From www.mdpi.com

J. Compos. Sci. Free FullText Evaluation of SingleLap and Block Lap Shear Vs Die Shear Lap shear testing is a method of determining the adhesive capabilities of things like glues and other. A rotational capability, relative to the header/substrate holding fixture and the die contact tool, to facilitate line contact on the. Pseudoplastic materials will decrease in viscosity with an increase in shear rate. This is sometimes referred to as shear thinning. For this reason. Lap Shear Vs Die Shear.

From www.researchgate.net

Lapshear and crosstension specimens Download Scientific Diagram Lap Shear Vs Die Shear This is sometimes referred to as shear thinning. For this reason we perform two types of shear testing to determine epoxy strength: Lap shear testing is a method of determining the adhesive capabilities of things like glues and other. The definitive guide to astm d1002 lap shear testing of adhesively bonded metals. Lap shear and die shear. A rotational capability,. Lap Shear Vs Die Shear.

From www.youtube.com

Shear Force and Bending Moment_Part 1_Concept of Shear YouTube Lap Shear Vs Die Shear Lap shear testing is a method of determining the adhesive capabilities of things like glues and other. The main objective of this investigation was to generate characteristic shear responses for several adhesives used for aerospace. This is sometimes referred to as shear thinning. Pseudoplastic materials will decrease in viscosity with an increase in shear rate. A rotational capability, relative to. Lap Shear Vs Die Shear.

From www.researchgate.net

Traditional doublelap shear test setup Download Scientific Diagram Lap Shear Vs Die Shear A rotational capability, relative to the header/substrate holding fixture and the die contact tool, to facilitate line contact on the. The definitive guide to astm d1002 lap shear testing of adhesively bonded metals. This is sometimes referred to as shear thinning. For this reason we perform two types of shear testing to determine epoxy strength: Astm d1002 describes the procedure. Lap Shear Vs Die Shear.

From engineerexcel.com

Double Shear Loading Strength Analysis for Engineers EngineerExcel Lap Shear Vs Die Shear Epoxy is shear, not tensile. Pseudoplastic materials will decrease in viscosity with an increase in shear rate. A rotational capability, relative to the header/substrate holding fixture and the die contact tool, to facilitate line contact on the. For this reason we perform two types of shear testing to determine epoxy strength: Astm d1002 describes the procedure for evaluating the shear. Lap Shear Vs Die Shear.

From www.semanticscholar.org

Figure 2 from Pin Failure in Shear vs. Bending for a Double Shear Joint Lap Shear Vs Die Shear Astm d1002 describes the procedure for evaluating the shear strength of adhesives used for bonding. Lap shear and die shear. The definitive guide to astm d1002 lap shear testing of adhesively bonded metals. Lap shear testing is a method of determining the adhesive capabilities of things like glues and other. The main objective of this investigation was to generate characteristic. Lap Shear Vs Die Shear.

From structures-explained.com

Shear Forces and Shear Stresses in Structures Structures Explained Lap Shear Vs Die Shear For this reason we perform two types of shear testing to determine epoxy strength: Lap shear and die shear. Astm d1002 describes the procedure for evaluating the shear strength of adhesives used for bonding. The main objective of this investigation was to generate characteristic shear responses for several adhesives used for aerospace. Lap shear testing is a method of determining. Lap Shear Vs Die Shear.

From barkmanoil.com

Single Shear Vs Double Shear? Top Answer Update Lap Shear Vs Die Shear Pseudoplastic materials will decrease in viscosity with an increase in shear rate. A rotational capability, relative to the header/substrate holding fixture and the die contact tool, to facilitate line contact on the. Astm d1002 describes the procedure for evaluating the shear strength of adhesives used for bonding. The definitive guide to astm d1002 lap shear testing of adhesively bonded metals.. Lap Shear Vs Die Shear.