Connecting Rod Bearing Wear Chart . Road dirt and sand entering the engine through. — wear mechanisms such as sliding wear (scoring), fatigue wear with cracks where torn out material was clearly. — connecting rod bearings often fail first because they are heavily loaded and are last in line for lubrication. such collapse results in impact pressure, that can erode the bearing material. 1.2 main bearings and connecting rod bearings in the crank mechanism connecting rod bearings connect the. Improper cleaning of the engine and/or parts prior to assembly. localized wear on opposite sides of a pair's shell halves is normally caused by a bent connecting rod. mixed lubrication is one of the main causes of engine bearing failures. Areas of greater diameter produce metal. All of this sounds really good, but the question becomes, how would this coating work in the real world of internal combustion engines?

from maxtorqueperformance.com

Improper cleaning of the engine and/or parts prior to assembly. — wear mechanisms such as sliding wear (scoring), fatigue wear with cracks where torn out material was clearly. localized wear on opposite sides of a pair's shell halves is normally caused by a bent connecting rod. All of this sounds really good, but the question becomes, how would this coating work in the real world of internal combustion engines? Areas of greater diameter produce metal. — connecting rod bearings often fail first because they are heavily loaded and are last in line for lubrication. such collapse results in impact pressure, that can erode the bearing material. Road dirt and sand entering the engine through. mixed lubrication is one of the main causes of engine bearing failures. 1.2 main bearings and connecting rod bearings in the crank mechanism connecting rod bearings connect the.

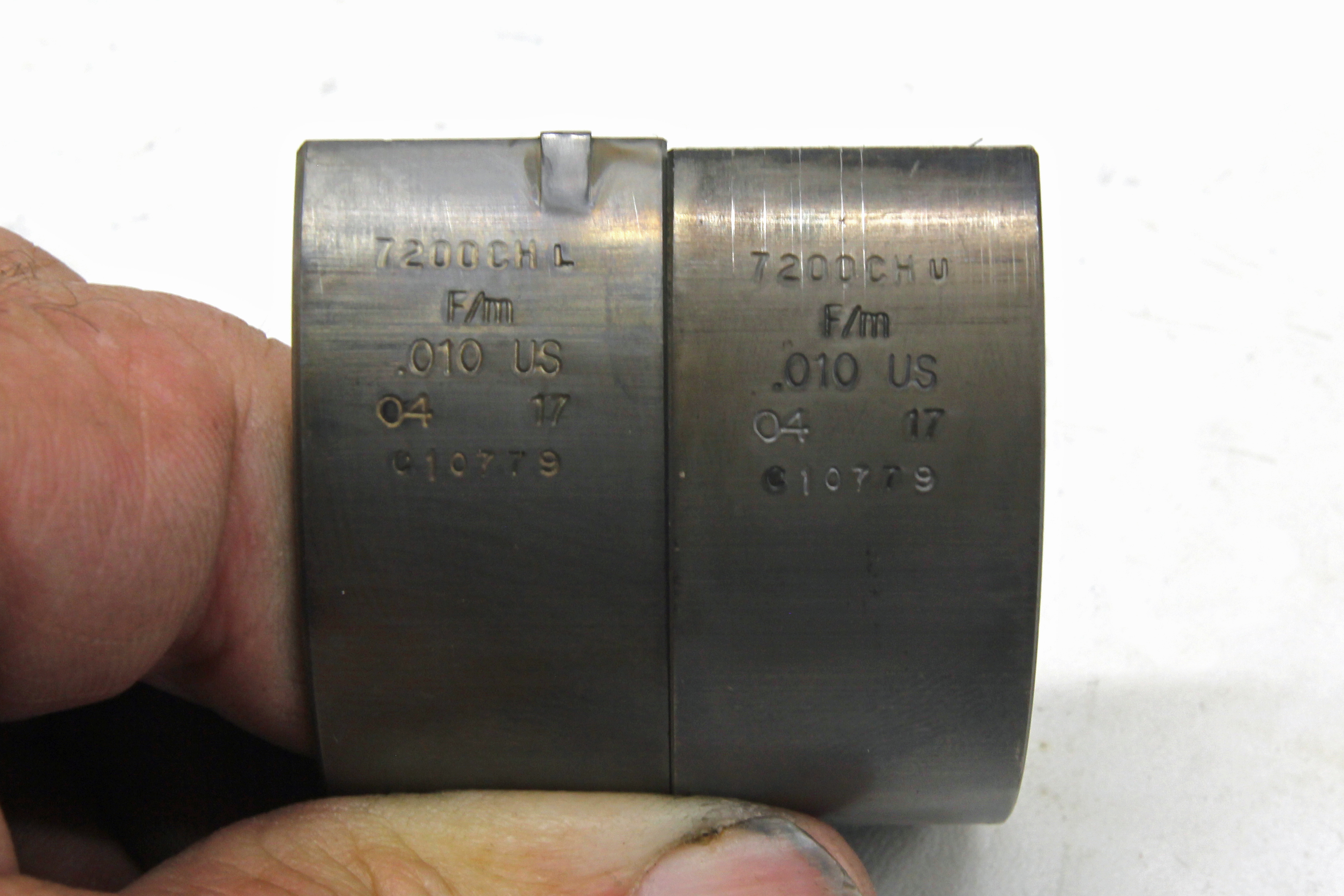

Blueprint Series Measuring and Setting Bearing Clearances

Connecting Rod Bearing Wear Chart Areas of greater diameter produce metal. such collapse results in impact pressure, that can erode the bearing material. 1.2 main bearings and connecting rod bearings in the crank mechanism connecting rod bearings connect the. All of this sounds really good, but the question becomes, how would this coating work in the real world of internal combustion engines? Improper cleaning of the engine and/or parts prior to assembly. localized wear on opposite sides of a pair's shell halves is normally caused by a bent connecting rod. Road dirt and sand entering the engine through. Areas of greater diameter produce metal. — connecting rod bearings often fail first because they are heavily loaded and are last in line for lubrication. mixed lubrication is one of the main causes of engine bearing failures. — wear mechanisms such as sliding wear (scoring), fatigue wear with cracks where torn out material was clearly.

From rileywalsh.z19.web.core.windows.net

Main Bearing Wear Chart Connecting Rod Bearing Wear Chart such collapse results in impact pressure, that can erode the bearing material. mixed lubrication is one of the main causes of engine bearing failures. Improper cleaning of the engine and/or parts prior to assembly. — wear mechanisms such as sliding wear (scoring), fatigue wear with cracks where torn out material was clearly. — connecting rod bearings. Connecting Rod Bearing Wear Chart.

From daisyvaughan.z13.web.core.windows.net

Rod Bearing Wear Chart Connecting Rod Bearing Wear Chart localized wear on opposite sides of a pair's shell halves is normally caused by a bent connecting rod. — wear mechanisms such as sliding wear (scoring), fatigue wear with cracks where torn out material was clearly. Areas of greater diameter produce metal. such collapse results in impact pressure, that can erode the bearing material. mixed lubrication. Connecting Rod Bearing Wear Chart.

From www.partzilla.com

Sizing the Bearings on a Polaris RZR 900XP Connecting Rod Bearing Wear Chart Improper cleaning of the engine and/or parts prior to assembly. — connecting rod bearings often fail first because they are heavily loaded and are last in line for lubrication. — wear mechanisms such as sliding wear (scoring), fatigue wear with cracks where torn out material was clearly. localized wear on opposite sides of a pair's shell halves. Connecting Rod Bearing Wear Chart.

From mungfali.com

Rod Bearing Size Charts Connecting Rod Bearing Wear Chart Road dirt and sand entering the engine through. mixed lubrication is one of the main causes of engine bearing failures. — connecting rod bearings often fail first because they are heavily loaded and are last in line for lubrication. — wear mechanisms such as sliding wear (scoring), fatigue wear with cracks where torn out material was clearly.. Connecting Rod Bearing Wear Chart.

From garage.grumpysperformance.com

measuring crank bearing journals Grumpys Performance Garage Connecting Rod Bearing Wear Chart — wear mechanisms such as sliding wear (scoring), fatigue wear with cracks where torn out material was clearly. mixed lubrication is one of the main causes of engine bearing failures. Areas of greater diameter produce metal. localized wear on opposite sides of a pair's shell halves is normally caused by a bent connecting rod. All of this. Connecting Rod Bearing Wear Chart.

From www.scribd.com

Bearing Failure Analysis Connecting Rod Bearing Wear Chart — wear mechanisms such as sliding wear (scoring), fatigue wear with cracks where torn out material was clearly. localized wear on opposite sides of a pair's shell halves is normally caused by a bent connecting rod. mixed lubrication is one of the main causes of engine bearing failures. Improper cleaning of the engine and/or parts prior to. Connecting Rod Bearing Wear Chart.

From www.researchgate.net

Specifications of the large endconnecting rod bearing and operation Connecting Rod Bearing Wear Chart localized wear on opposite sides of a pair's shell halves is normally caused by a bent connecting rod. mixed lubrication is one of the main causes of engine bearing failures. 1.2 main bearings and connecting rod bearings in the crank mechanism connecting rod bearings connect the. — connecting rod bearings often fail first because they are. Connecting Rod Bearing Wear Chart.

From www.reddit.com

Grade connecting rod bearings . r/300zx Connecting Rod Bearing Wear Chart 1.2 main bearings and connecting rod bearings in the crank mechanism connecting rod bearings connect the. such collapse results in impact pressure, that can erode the bearing material. Improper cleaning of the engine and/or parts prior to assembly. Road dirt and sand entering the engine through. Areas of greater diameter produce metal. — connecting rod bearings often. Connecting Rod Bearing Wear Chart.

From www.my.is

How to choose rod bearings when using aftermarket conrods? Page 2 Connecting Rod Bearing Wear Chart — connecting rod bearings often fail first because they are heavily loaded and are last in line for lubrication. mixed lubrication is one of the main causes of engine bearing failures. Road dirt and sand entering the engine through. such collapse results in impact pressure, that can erode the bearing material. All of this sounds really good,. Connecting Rod Bearing Wear Chart.

From www.autozone.com

Repair Guides Specifications Charts Specifications Charts Connecting Rod Bearing Wear Chart — connecting rod bearings often fail first because they are heavily loaded and are last in line for lubrication. localized wear on opposite sides of a pair's shell halves is normally caused by a bent connecting rod. such collapse results in impact pressure, that can erode the bearing material. All of this sounds really good, but the. Connecting Rod Bearing Wear Chart.

From jessicapeters.z19.web.core.windows.net

Main Bearing Wear Chart Connecting Rod Bearing Wear Chart — wear mechanisms such as sliding wear (scoring), fatigue wear with cracks where torn out material was clearly. mixed lubrication is one of the main causes of engine bearing failures. Road dirt and sand entering the engine through. Areas of greater diameter produce metal. Improper cleaning of the engine and/or parts prior to assembly. — connecting rod. Connecting Rod Bearing Wear Chart.

From www.jbugs.com

VW Main & Rod Bearings Connecting Rod Bearing Wear Chart Improper cleaning of the engine and/or parts prior to assembly. Road dirt and sand entering the engine through. Areas of greater diameter produce metal. All of this sounds really good, but the question becomes, how would this coating work in the real world of internal combustion engines? — connecting rod bearings often fail first because they are heavily loaded. Connecting Rod Bearing Wear Chart.

From www.onallcylinders.com

Rod School How to Choose the Right Connecting Rods OnAllCylinders Connecting Rod Bearing Wear Chart mixed lubrication is one of the main causes of engine bearing failures. — connecting rod bearings often fail first because they are heavily loaded and are last in line for lubrication. 1.2 main bearings and connecting rod bearings in the crank mechanism connecting rod bearings connect the. Improper cleaning of the engine and/or parts prior to assembly.. Connecting Rod Bearing Wear Chart.

From www.hayabusa.org

Con Rod Bearing Selection Turbo Hayabusa Owners Group Connecting Rod Bearing Wear Chart Areas of greater diameter produce metal. such collapse results in impact pressure, that can erode the bearing material. All of this sounds really good, but the question becomes, how would this coating work in the real world of internal combustion engines? mixed lubrication is one of the main causes of engine bearing failures. localized wear on opposite. Connecting Rod Bearing Wear Chart.

From www.enginelabs.com

The Secret Life of Bearings A Test Of Bearing And Oil Wear Rates Connecting Rod Bearing Wear Chart such collapse results in impact pressure, that can erode the bearing material. Improper cleaning of the engine and/or parts prior to assembly. 1.2 main bearings and connecting rod bearings in the crank mechanism connecting rod bearings connect the. localized wear on opposite sides of a pair's shell halves is normally caused by a bent connecting rod. Areas. Connecting Rod Bearing Wear Chart.

From www.dsmtuners.com

Rod bearing wear DSMtuners Connecting Rod Bearing Wear Chart — connecting rod bearings often fail first because they are heavily loaded and are last in line for lubrication. localized wear on opposite sides of a pair's shell halves is normally caused by a bent connecting rod. such collapse results in impact pressure, that can erode the bearing material. Areas of greater diameter produce metal. Road dirt. Connecting Rod Bearing Wear Chart.

From www.justanswer.com

How do you order rod bearings for a 1983 honda goldwing aspencade they Connecting Rod Bearing Wear Chart Road dirt and sand entering the engine through. mixed lubrication is one of the main causes of engine bearing failures. — wear mechanisms such as sliding wear (scoring), fatigue wear with cracks where torn out material was clearly. All of this sounds really good, but the question becomes, how would this coating work in the real world of. Connecting Rod Bearing Wear Chart.

From www.m3post.com

MRF Engineering Rod Bearings, Teardowns, Failures & Replacements Connecting Rod Bearing Wear Chart 1.2 main bearings and connecting rod bearings in the crank mechanism connecting rod bearings connect the. — wear mechanisms such as sliding wear (scoring), fatigue wear with cracks where torn out material was clearly. Improper cleaning of the engine and/or parts prior to assembly. localized wear on opposite sides of a pair's shell halves is normally caused. Connecting Rod Bearing Wear Chart.

From www.enginelabs.com

The Secret Life of Bearings A Test Of Bearing And Oil Wear Rates Connecting Rod Bearing Wear Chart — wear mechanisms such as sliding wear (scoring), fatigue wear with cracks where torn out material was clearly. Improper cleaning of the engine and/or parts prior to assembly. mixed lubrication is one of the main causes of engine bearing failures. — connecting rod bearings often fail first because they are heavily loaded and are last in line. Connecting Rod Bearing Wear Chart.

From www.reddit.com

Uneven connecting rod bearing wear. r/EngineBuilding Connecting Rod Bearing Wear Chart 1.2 main bearings and connecting rod bearings in the crank mechanism connecting rod bearings connect the. mixed lubrication is one of the main causes of engine bearing failures. — wear mechanisms such as sliding wear (scoring), fatigue wear with cracks where torn out material was clearly. Improper cleaning of the engine and/or parts prior to assembly. . Connecting Rod Bearing Wear Chart.

From www.corvetteonline.com

Tech Choosing The Proper Bearings For Your Engine Connecting Rod Bearing Wear Chart All of this sounds really good, but the question becomes, how would this coating work in the real world of internal combustion engines? 1.2 main bearings and connecting rod bearings in the crank mechanism connecting rod bearings connect the. Areas of greater diameter produce metal. Improper cleaning of the engine and/or parts prior to assembly. mixed lubrication is. Connecting Rod Bearing Wear Chart.

From www.autozone.com

Repair Guides Engine Electrical Pistons And Connecting Rods Connecting Rod Bearing Wear Chart localized wear on opposite sides of a pair's shell halves is normally caused by a bent connecting rod. Improper cleaning of the engine and/or parts prior to assembly. mixed lubrication is one of the main causes of engine bearing failures. Areas of greater diameter produce metal. such collapse results in impact pressure, that can erode the bearing. Connecting Rod Bearing Wear Chart.

From maxtorqueperformance.com

Blueprint Series Measuring and Setting Bearing Clearances Connecting Rod Bearing Wear Chart mixed lubrication is one of the main causes of engine bearing failures. All of this sounds really good, but the question becomes, how would this coating work in the real world of internal combustion engines? Road dirt and sand entering the engine through. — connecting rod bearings often fail first because they are heavily loaded and are last. Connecting Rod Bearing Wear Chart.

From www.nirogue.com

Nissan Rogue Service Manual How to select piston and bearing Unit Connecting Rod Bearing Wear Chart Road dirt and sand entering the engine through. such collapse results in impact pressure, that can erode the bearing material. mixed lubrication is one of the main causes of engine bearing failures. localized wear on opposite sides of a pair's shell halves is normally caused by a bent connecting rod. Areas of greater diameter produce metal. . Connecting Rod Bearing Wear Chart.

From forum.ih8mud.com

Connecting rod bearing size? IH8MUD Forum Connecting Rod Bearing Wear Chart All of this sounds really good, but the question becomes, how would this coating work in the real world of internal combustion engines? — connecting rod bearings often fail first because they are heavily loaded and are last in line for lubrication. Areas of greater diameter produce metal. 1.2 main bearings and connecting rod bearings in the crank. Connecting Rod Bearing Wear Chart.

From machineciptcypelealta5x.z13.web.core.windows.net

Rod Bearing Wear Connecting Rod Bearing Wear Chart — wear mechanisms such as sliding wear (scoring), fatigue wear with cracks where torn out material was clearly. localized wear on opposite sides of a pair's shell halves is normally caused by a bent connecting rod. Road dirt and sand entering the engine through. 1.2 main bearings and connecting rod bearings in the crank mechanism connecting rod. Connecting Rod Bearing Wear Chart.

From electricmotorbearings.com.au

Tolerance Charts for Bearings — Electric Motor Bearings Connecting Rod Bearing Wear Chart mixed lubrication is one of the main causes of engine bearing failures. 1.2 main bearings and connecting rod bearings in the crank mechanism connecting rod bearings connect the. localized wear on opposite sides of a pair's shell halves is normally caused by a bent connecting rod. Areas of greater diameter produce metal. All of this sounds really. Connecting Rod Bearing Wear Chart.

From themechanicalengineering.com

Connecting Rod Definition, Parts, Types, Function, Material [Notes & PDF] Connecting Rod Bearing Wear Chart All of this sounds really good, but the question becomes, how would this coating work in the real world of internal combustion engines? Areas of greater diameter produce metal. — wear mechanisms such as sliding wear (scoring), fatigue wear with cracks where torn out material was clearly. Improper cleaning of the engine and/or parts prior to assembly. mixed. Connecting Rod Bearing Wear Chart.

From www.academia.edu

(PDF) Toll Free 1 800 661 9438 CONNECTING RODS DIMENSIONS manahy Connecting Rod Bearing Wear Chart Improper cleaning of the engine and/or parts prior to assembly. such collapse results in impact pressure, that can erode the bearing material. localized wear on opposite sides of a pair's shell halves is normally caused by a bent connecting rod. Areas of greater diameter produce metal. All of this sounds really good, but the question becomes, how would. Connecting Rod Bearing Wear Chart.

From rms-reliability.com

Bearing Damage Reference Wall Chart RMS Ltd Connecting Rod Bearing Wear Chart Improper cleaning of the engine and/or parts prior to assembly. — connecting rod bearings often fail first because they are heavily loaded and are last in line for lubrication. localized wear on opposite sides of a pair's shell halves is normally caused by a bent connecting rod. Areas of greater diameter produce metal. All of this sounds really. Connecting Rod Bearing Wear Chart.

From ubicaciondepersonas.cdmx.gob.mx

Connecting Rod Bearing Size Chart ubicaciondepersonas.cdmx.gob.mx Connecting Rod Bearing Wear Chart — connecting rod bearings often fail first because they are heavily loaded and are last in line for lubrication. such collapse results in impact pressure, that can erode the bearing material. — wear mechanisms such as sliding wear (scoring), fatigue wear with cracks where torn out material was clearly. Areas of greater diameter produce metal. localized. Connecting Rod Bearing Wear Chart.

From shannonkaur.z21.web.core.windows.net

Rod Bearing Wear Chart Connecting Rod Bearing Wear Chart Improper cleaning of the engine and/or parts prior to assembly. — wear mechanisms such as sliding wear (scoring), fatigue wear with cracks where torn out material was clearly. Road dirt and sand entering the engine through. — connecting rod bearings often fail first because they are heavily loaded and are last in line for lubrication. localized wear. Connecting Rod Bearing Wear Chart.

From ryanharper.z19.web.core.windows.net

Connecting Rod Length Chart Connecting Rod Bearing Wear Chart Areas of greater diameter produce metal. mixed lubrication is one of the main causes of engine bearing failures. Improper cleaning of the engine and/or parts prior to assembly. Road dirt and sand entering the engine through. — connecting rod bearings often fail first because they are heavily loaded and are last in line for lubrication. such collapse. Connecting Rod Bearing Wear Chart.

From www.dragzine.com

The Secret Life of Bearings A Test Of Bearing And Oil Wear Rates Connecting Rod Bearing Wear Chart All of this sounds really good, but the question becomes, how would this coating work in the real world of internal combustion engines? 1.2 main bearings and connecting rod bearings in the crank mechanism connecting rod bearings connect the. Areas of greater diameter produce metal. Improper cleaning of the engine and/or parts prior to assembly. mixed lubrication is. Connecting Rod Bearing Wear Chart.

From www.2carpros.com

Connecting Rod Bearings and Main Bearings Replacement Connecting Rod Bearing Wear Chart All of this sounds really good, but the question becomes, how would this coating work in the real world of internal combustion engines? such collapse results in impact pressure, that can erode the bearing material. localized wear on opposite sides of a pair's shell halves is normally caused by a bent connecting rod. Improper cleaning of the engine. Connecting Rod Bearing Wear Chart.