Woven Garments Costing Sheet . In the previous article, i have discussed how to make a costing sheet for knit garments. Normally senior merchandisers make a costing sheet in garment buying houses. Techpacker helps you create a neat, organized, cost sheet that keeps track of all the expenses and that you can also save for your records. It involves calculating all the expenses involved in making the garment, including the cost of materials, labor, overhead, and any other associated expenses, to arrive at the total cost of production. Understanding how to accurately calculate the cost of manufacturing a garment is essential for designers, manufacturers, and fashion brands. Let’s come to learn how to calculate woven fabric costing and knitted fabric costing. The allocation of the cost depends upon multiple variables. Garment costing is the process of determining the cost of producing a garment or apparel product. Now i will give a typical example of the preparation of a costing sheet for woven garments. To make an accurate costing of order, today i will discuss the method of garments costing for the woven bottom. It is quite useful and handy to understand the percentage share of cost for each constituent of the apparel supply chain, including material used. An ideal cost sheet should be simple, yet comprehensive enough that it holds all of the necessary information about the garment you’re producing. A garment costing sheet is used to trace the all costing components. An industry that manufactures woven fabrics received an order for the development of fabric based on the following description with a 30,000 metre order quantity. A cost sheet for fashion is a detailed breakdown of all the expenses associated with producing a garment.

from apparelcareer.blogspot.com

Normally senior merchandisers make a costing sheet in garment buying houses. An industry that manufactures woven fabrics received an order for the development of fabric based on the following description with a 30,000 metre order quantity. An ideal cost sheet should be simple, yet comprehensive enough that it holds all of the necessary information about the garment you’re producing. The allocation of the cost depends upon multiple variables. Understanding how to accurately calculate the cost of manufacturing a garment is essential for designers, manufacturers, and fashion brands. Garment costing is the process of determining the cost of producing a garment or apparel product. It is quite useful and handy to understand the percentage share of cost for each constituent of the apparel supply chain, including material used. Techpacker helps you create a neat, organized, cost sheet that keeps track of all the expenses and that you can also save for your records. To make an accurate costing of order, today i will discuss the method of garments costing for the woven bottom. Calculate woven fabric costing example 1:

How to Calculate Garment Costing and Pricing Apparel Career

Woven Garments Costing Sheet In the previous article, i have discussed how to make a costing sheet for knit garments. It involves calculating all the expenses involved in making the garment, including the cost of materials, labor, overhead, and any other associated expenses, to arrive at the total cost of production. Calculate woven fabric costing example 1: A cost sheet for fashion is a detailed breakdown of all the expenses associated with producing a garment. It is quite useful and handy to understand the percentage share of cost for each constituent of the apparel supply chain, including material used. Let’s come to learn how to calculate woven fabric costing and knitted fabric costing. Techpacker helps you create a neat, organized, cost sheet that keeps track of all the expenses and that you can also save for your records. Now i will give a typical example of the preparation of a costing sheet for woven garments. A garment costing sheet is used to trace the all costing components. An industry that manufactures woven fabrics received an order for the development of fabric based on the following description with a 30,000 metre order quantity. Garment costing is the process of determining the cost of producing a garment or apparel product. An ideal cost sheet should be simple, yet comprehensive enough that it holds all of the necessary information about the garment you’re producing. Normally senior merchandisers make a costing sheet in garment buying houses. Understanding how to accurately calculate the cost of manufacturing a garment is essential for designers, manufacturers, and fashion brands. The allocation of the cost depends upon multiple variables. To make an accurate costing of order, today i will discuss the method of garments costing for the woven bottom.

From apparel-merchandising.com

ApparelMerchandising Costing Format Woven Garments Costing Sheet An ideal cost sheet should be simple, yet comprehensive enough that it holds all of the necessary information about the garment you’re producing. It is quite useful and handy to understand the percentage share of cost for each constituent of the apparel supply chain, including material used. In the previous article, i have discussed how to make a costing sheet. Woven Garments Costing Sheet.

From textilelearner.net

How to Make Garment Costing Sheet Textile Learner Woven Garments Costing Sheet Let’s come to learn how to calculate woven fabric costing and knitted fabric costing. To make an accurate costing of order, today i will discuss the method of garments costing for the woven bottom. A cost sheet for fashion is a detailed breakdown of all the expenses associated with producing a garment. It involves calculating all the expenses involved in. Woven Garments Costing Sheet.

From textileaid.blogspot.com

Textile Fiber, Yarn Spinning, Woven and Knit Fabric, Dyeing, Garments Woven Garments Costing Sheet Normally senior merchandisers make a costing sheet in garment buying houses. A garment costing sheet is used to trace the all costing components. It is quite useful and handy to understand the percentage share of cost for each constituent of the apparel supply chain, including material used. Now i will give a typical example of the preparation of a costing. Woven Garments Costing Sheet.

From www.scribd.com

Garment Costing Sheet PDF Textiles Yarn Woven Garments Costing Sheet It involves calculating all the expenses involved in making the garment, including the cost of materials, labor, overhead, and any other associated expenses, to arrive at the total cost of production. Understanding how to accurately calculate the cost of manufacturing a garment is essential for designers, manufacturers, and fashion brands. In the previous article, i have discussed how to make. Woven Garments Costing Sheet.

From www.slideshare.net

Costing of woven fabrics Woven Garments Costing Sheet Calculate woven fabric costing example 1: To make an accurate costing of order, today i will discuss the method of garments costing for the woven bottom. Normally senior merchandisers make a costing sheet in garment buying houses. Now i will give a typical example of the preparation of a costing sheet for woven garments. It involves calculating all the expenses. Woven Garments Costing Sheet.

From www.technologygmt.com

Learn How to Create a Garment Costing Sheet? Woven Garments Costing Sheet A garment costing sheet is used to trace the all costing components. It involves calculating all the expenses involved in making the garment, including the cost of materials, labor, overhead, and any other associated expenses, to arrive at the total cost of production. A cost sheet for fashion is a detailed breakdown of all the expenses associated with producing a. Woven Garments Costing Sheet.

From www.scribd.com

Woven Pant Garments Costing PDF Clothing Waist Woven Garments Costing Sheet A cost sheet for fashion is a detailed breakdown of all the expenses associated with producing a garment. In the previous article, i have discussed how to make a costing sheet for knit garments. The allocation of the cost depends upon multiple variables. It involves calculating all the expenses involved in making the garment, including the cost of materials, labor,. Woven Garments Costing Sheet.

From www.scribd.com

Garment Costing Sheet PDF Knitting Textiles Woven Garments Costing Sheet An industry that manufactures woven fabrics received an order for the development of fabric based on the following description with a 30,000 metre order quantity. Techpacker helps you create a neat, organized, cost sheet that keeps track of all the expenses and that you can also save for your records. An ideal cost sheet should be simple, yet comprehensive enough. Woven Garments Costing Sheet.

From www.scribd.com

Garments Cost Sheet PDF Textiles Weaving Woven Garments Costing Sheet Calculate woven fabric costing example 1: Understanding how to accurately calculate the cost of manufacturing a garment is essential for designers, manufacturers, and fashion brands. It involves calculating all the expenses involved in making the garment, including the cost of materials, labor, overhead, and any other associated expenses, to arrive at the total cost of production. In the previous article,. Woven Garments Costing Sheet.

From textileaid.blogspot.com

Textile Fiber, Yarn Spinning, Woven and Knit Fabric, Dyeing, Garments Woven Garments Costing Sheet The allocation of the cost depends upon multiple variables. To make an accurate costing of order, today i will discuss the method of garments costing for the woven bottom. Let’s come to learn how to calculate woven fabric costing and knitted fabric costing. It is quite useful and handy to understand the percentage share of cost for each constituent of. Woven Garments Costing Sheet.

From apparelcareer.blogspot.com

How to Calculate Garment Costing and Pricing Apparel Career Woven Garments Costing Sheet A garment costing sheet is used to trace the all costing components. Understanding how to accurately calculate the cost of manufacturing a garment is essential for designers, manufacturers, and fashion brands. The allocation of the cost depends upon multiple variables. An industry that manufactures woven fabrics received an order for the development of fabric based on the following description with. Woven Garments Costing Sheet.

From textilelearner.net

How to Make Garment Costing Sheet Textile Learner Woven Garments Costing Sheet An ideal cost sheet should be simple, yet comprehensive enough that it holds all of the necessary information about the garment you’re producing. It involves calculating all the expenses involved in making the garment, including the cost of materials, labor, overhead, and any other associated expenses, to arrive at the total cost of production. Let’s come to learn how to. Woven Garments Costing Sheet.

From www.garmentsolution.in

Garment Costing Excel Template (Format 2) Costing in Garment Indust Woven Garments Costing Sheet An ideal cost sheet should be simple, yet comprehensive enough that it holds all of the necessary information about the garment you’re producing. It is quite useful and handy to understand the percentage share of cost for each constituent of the apparel supply chain, including material used. A cost sheet for fashion is a detailed breakdown of all the expenses. Woven Garments Costing Sheet.

From textiletutorials.com

How To Do Garment Costing Considering All Factors? Woven Garments Costing Sheet Calculate woven fabric costing example 1: A cost sheet for fashion is a detailed breakdown of all the expenses associated with producing a garment. Normally senior merchandisers make a costing sheet in garment buying houses. The allocation of the cost depends upon multiple variables. Now i will give a typical example of the preparation of a costing sheet for woven. Woven Garments Costing Sheet.

From printables.ula.edu.pe

Free Garment Cost Sheet Template Free Templates Printable Woven Garments Costing Sheet Calculate woven fabric costing example 1: Normally senior merchandisers make a costing sheet in garment buying houses. Let’s come to learn how to calculate woven fabric costing and knitted fabric costing. A garment costing sheet is used to trace the all costing components. To make an accurate costing of order, today i will discuss the method of garments costing for. Woven Garments Costing Sheet.

From ordnur.com

Costing Sheet of Garments Manufacturing ORDNUR Woven Garments Costing Sheet Normally senior merchandisers make a costing sheet in garment buying houses. Techpacker helps you create a neat, organized, cost sheet that keeps track of all the expenses and that you can also save for your records. An industry that manufactures woven fabrics received an order for the development of fabric based on the following description with a 30,000 metre order. Woven Garments Costing Sheet.

From ordnur.com

Costing Sheet of Garments Manufacturing ORDNUR Woven Garments Costing Sheet An industry that manufactures woven fabrics received an order for the development of fabric based on the following description with a 30,000 metre order quantity. A cost sheet for fashion is a detailed breakdown of all the expenses associated with producing a garment. Normally senior merchandisers make a costing sheet in garment buying houses. It involves calculating all the expenses. Woven Garments Costing Sheet.

From www.scribd.com

Cost Sheet for Woven Fabric Weaving Loom Woven Garments Costing Sheet It involves calculating all the expenses involved in making the garment, including the cost of materials, labor, overhead, and any other associated expenses, to arrive at the total cost of production. An ideal cost sheet should be simple, yet comprehensive enough that it holds all of the necessary information about the garment you’re producing. An industry that manufactures woven fabrics. Woven Garments Costing Sheet.

From www.technologygmt.com

Learn How to Create a Garment Costing Sheet? Woven Garments Costing Sheet Garment costing is the process of determining the cost of producing a garment or apparel product. An industry that manufactures woven fabrics received an order for the development of fabric based on the following description with a 30,000 metre order quantity. A garment costing sheet is used to trace the all costing components. An ideal cost sheet should be simple,. Woven Garments Costing Sheet.

From ordnur.com

Costing Sheet of Garments Manufacturing ORDNUR Woven Garments Costing Sheet An ideal cost sheet should be simple, yet comprehensive enough that it holds all of the necessary information about the garment you’re producing. The allocation of the cost depends upon multiple variables. In the previous article, i have discussed how to make a costing sheet for knit garments. Now i will give a typical example of the preparation of a. Woven Garments Costing Sheet.

From www.etsy.com

Garment Costing Sheet Template Excel Cost Sheet Template for Apparel Woven Garments Costing Sheet To make an accurate costing of order, today i will discuss the method of garments costing for the woven bottom. Now i will give a typical example of the preparation of a costing sheet for woven garments. Understanding how to accurately calculate the cost of manufacturing a garment is essential for designers, manufacturers, and fashion brands. A cost sheet for. Woven Garments Costing Sheet.

From www.template.net

Garment Costing Sheet Template in Excel, Google Sheets Download Woven Garments Costing Sheet Let’s come to learn how to calculate woven fabric costing and knitted fabric costing. Garment costing is the process of determining the cost of producing a garment or apparel product. Understanding how to accurately calculate the cost of manufacturing a garment is essential for designers, manufacturers, and fashion brands. The allocation of the cost depends upon multiple variables. An industry. Woven Garments Costing Sheet.

From www.scribd.com

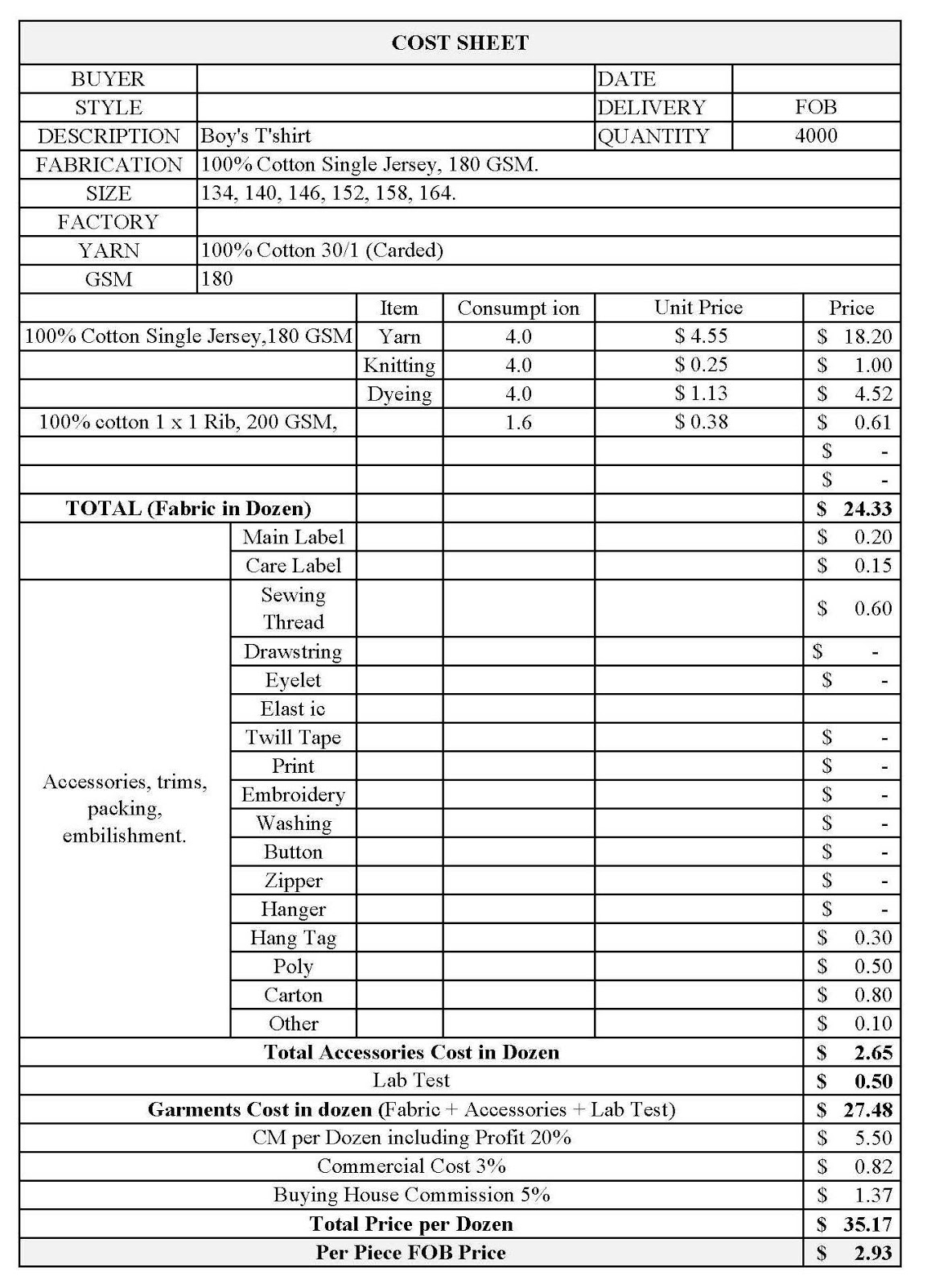

Costing Sheet Preparation For Knit Garments PDF Knitting Textiles Woven Garments Costing Sheet To make an accurate costing of order, today i will discuss the method of garments costing for the woven bottom. The allocation of the cost depends upon multiple variables. An industry that manufactures woven fabrics received an order for the development of fabric based on the following description with a 30,000 metre order quantity. A cost sheet for fashion is. Woven Garments Costing Sheet.

From techallusa.blogspot.com

Techtunes Costing Format of Garments Woven Garments Costing Sheet Normally senior merchandisers make a costing sheet in garment buying houses. It involves calculating all the expenses involved in making the garment, including the cost of materials, labor, overhead, and any other associated expenses, to arrive at the total cost of production. Understanding how to accurately calculate the cost of manufacturing a garment is essential for designers, manufacturers, and fashion. Woven Garments Costing Sheet.

From www.technologygmt.com

Learn How to Create a Garment Costing Sheet? Woven Garments Costing Sheet An ideal cost sheet should be simple, yet comprehensive enough that it holds all of the necessary information about the garment you’re producing. It is quite useful and handy to understand the percentage share of cost for each constituent of the apparel supply chain, including material used. Garment costing is the process of determining the cost of producing a garment. Woven Garments Costing Sheet.

From www.scribd.com

Garment Sample Costing Sheet by OCS PDF Dyeing Textiles Woven Garments Costing Sheet It is quite useful and handy to understand the percentage share of cost for each constituent of the apparel supply chain, including material used. To make an accurate costing of order, today i will discuss the method of garments costing for the woven bottom. A garment costing sheet is used to trace the all costing components. The allocation of the. Woven Garments Costing Sheet.

From www.scribd.com

Costing Sheet For Woven Shirt PDF Shirt Textiles Woven Garments Costing Sheet Techpacker helps you create a neat, organized, cost sheet that keeps track of all the expenses and that you can also save for your records. The allocation of the cost depends upon multiple variables. To make an accurate costing of order, today i will discuss the method of garments costing for the woven bottom. A garment costing sheet is used. Woven Garments Costing Sheet.

From www.onlineclothingstudy.com

Garment Costing Sheet Woven Garments Costing Sheet In the previous article, i have discussed how to make a costing sheet for knit garments. Calculate woven fabric costing example 1: Understanding how to accurately calculate the cost of manufacturing a garment is essential for designers, manufacturers, and fashion brands. An industry that manufactures woven fabrics received an order for the development of fabric based on the following description. Woven Garments Costing Sheet.

From www.youtube.com

Garments Costing Sheet in Excel Episode 41 YouTube Woven Garments Costing Sheet Understanding how to accurately calculate the cost of manufacturing a garment is essential for designers, manufacturers, and fashion brands. Techpacker helps you create a neat, organized, cost sheet that keeps track of all the expenses and that you can also save for your records. A garment costing sheet is used to trace the all costing components. A cost sheet for. Woven Garments Costing Sheet.

From www.scribd.com

Costing sheet preparation for knit Garments PDF Textiles Knitting Woven Garments Costing Sheet An ideal cost sheet should be simple, yet comprehensive enough that it holds all of the necessary information about the garment you’re producing. It is quite useful and handy to understand the percentage share of cost for each constituent of the apparel supply chain, including material used. Garment costing is the process of determining the cost of producing a garment. Woven Garments Costing Sheet.

From garmentsolution.in

GARMENT COSTING SHEET EXCEL TEMPLATE GARMENT SOLUTIONS Woven Garments Costing Sheet Understanding how to accurately calculate the cost of manufacturing a garment is essential for designers, manufacturers, and fashion brands. To make an accurate costing of order, today i will discuss the method of garments costing for the woven bottom. Normally senior merchandisers make a costing sheet in garment buying houses. The allocation of the cost depends upon multiple variables. An. Woven Garments Costing Sheet.

From www.scribd.com

Method of Garments Costing For Woven Long Sleeve Shirt (Factory Costing Woven Garments Costing Sheet Calculate woven fabric costing example 1: In the previous article, i have discussed how to make a costing sheet for knit garments. Understanding how to accurately calculate the cost of manufacturing a garment is essential for designers, manufacturers, and fashion brands. It is quite useful and handy to understand the percentage share of cost for each constituent of the apparel. Woven Garments Costing Sheet.

From www.researchgate.net

(PDF) Complete Garment Costing with Major Cost Breakdown Woven Garments Costing Sheet In the previous article, i have discussed how to make a costing sheet for knit garments. Garment costing is the process of determining the cost of producing a garment or apparel product. An ideal cost sheet should be simple, yet comprehensive enough that it holds all of the necessary information about the garment you’re producing. Understanding how to accurately calculate. Woven Garments Costing Sheet.

From fiber2myfashion.com

Knit Fabric Costing FIBER2MYFASHION Woven Garments Costing Sheet A cost sheet for fashion is a detailed breakdown of all the expenses associated with producing a garment. Calculate woven fabric costing example 1: An industry that manufactures woven fabrics received an order for the development of fabric based on the following description with a 30,000 metre order quantity. A garment costing sheet is used to trace the all costing. Woven Garments Costing Sheet.

From www.scribd.com

Costing Sheet of Knit Garment Knitting Textiles Woven Garments Costing Sheet An ideal cost sheet should be simple, yet comprehensive enough that it holds all of the necessary information about the garment you’re producing. Techpacker helps you create a neat, organized, cost sheet that keeps track of all the expenses and that you can also save for your records. Now i will give a typical example of the preparation of a. Woven Garments Costing Sheet.