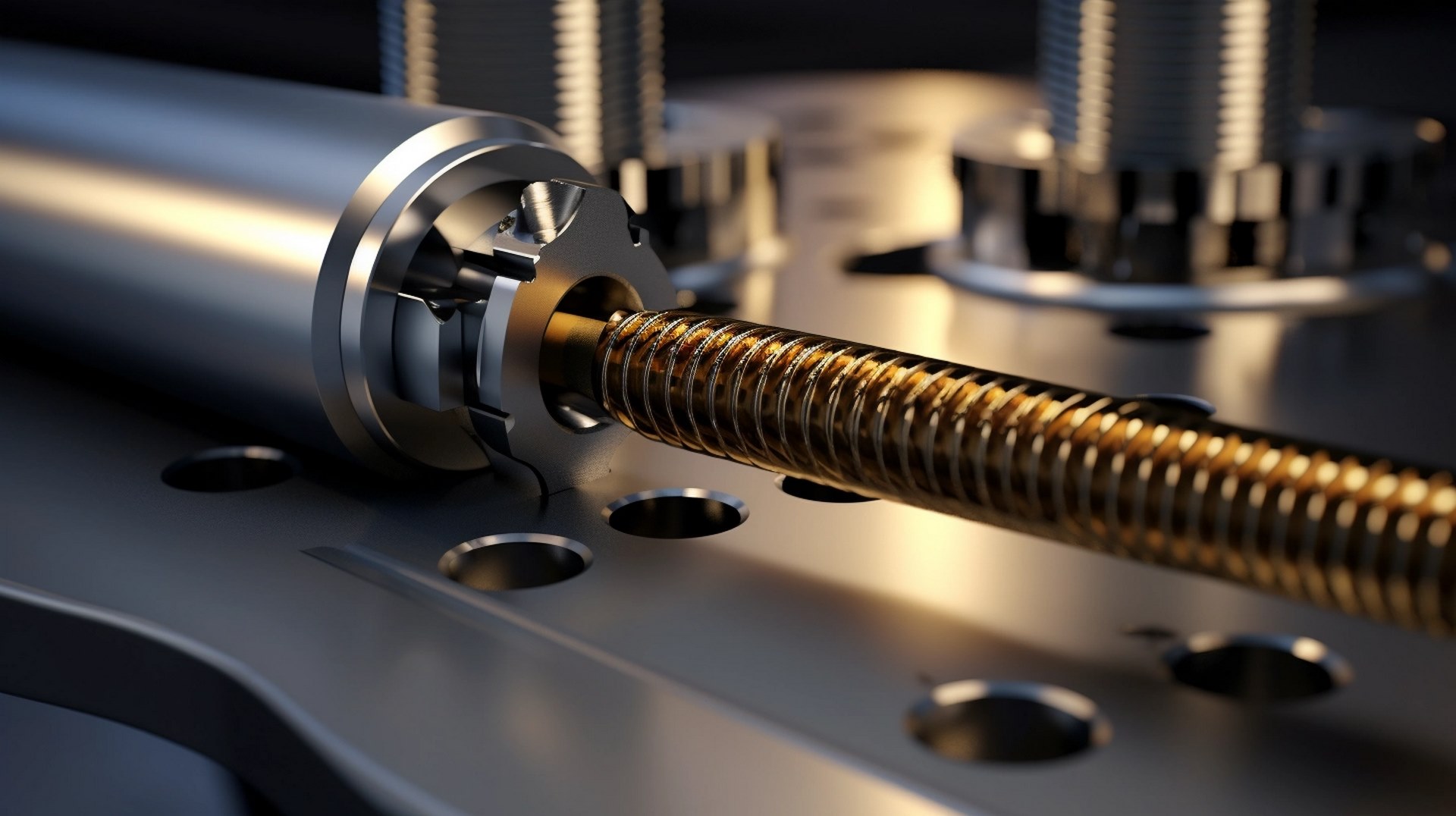

What Is The Purpose Of Thread Rolling . The process is different from. Thread rolling is not a metal cutting process. Thread rolling is commonly used in the production of screws, bolts, and other fasteners, as well as in the automotive and aerospace industries. Alwepo.com, thread rolling is a crucial manufacturing process that plays a significant role in producing threaded components across various industries. As the blank cylinder is. Rolling changes physical properties, hardening and. Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose thread profile is ground into the dies. Thread rolling is a metal forging process that forms threads into the mirror image of a roller die. The fastest, most economical method for producing highly accurate threads, thread rolling allows for higher repeatability,.

from mikehardware.com

Rolling changes physical properties, hardening and. Thread rolling is not a metal cutting process. Thread rolling is commonly used in the production of screws, bolts, and other fasteners, as well as in the automotive and aerospace industries. The fastest, most economical method for producing highly accurate threads, thread rolling allows for higher repeatability,. Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose thread profile is ground into the dies. As the blank cylinder is. The process is different from. Alwepo.com, thread rolling is a crucial manufacturing process that plays a significant role in producing threaded components across various industries. Thread rolling is a metal forging process that forms threads into the mirror image of a roller die.

Thread Rolling Process of Screws The Basics MIKEHARDWARE

What Is The Purpose Of Thread Rolling The process is different from. Alwepo.com, thread rolling is a crucial manufacturing process that plays a significant role in producing threaded components across various industries. The fastest, most economical method for producing highly accurate threads, thread rolling allows for higher repeatability,. As the blank cylinder is. Thread rolling is commonly used in the production of screws, bolts, and other fasteners, as well as in the automotive and aerospace industries. Thread rolling is not a metal cutting process. Rolling changes physical properties, hardening and. Thread rolling is a metal forging process that forms threads into the mirror image of a roller die. Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose thread profile is ground into the dies. The process is different from.

From www.manufacturingguide.com

Thread Rolling Find suppliers, processes & material What Is The Purpose Of Thread Rolling The fastest, most economical method for producing highly accurate threads, thread rolling allows for higher repeatability,. Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose thread profile is ground into the dies. Thread rolling is a metal forging process that forms threads into the mirror image of a roller die.. What Is The Purpose Of Thread Rolling.

From www.indiamart.com

Aluminium Thread Rolling Die at best price in Hyderabad by Laxmi What Is The Purpose Of Thread Rolling As the blank cylinder is. Thread rolling is commonly used in the production of screws, bolts, and other fasteners, as well as in the automotive and aerospace industries. The fastest, most economical method for producing highly accurate threads, thread rolling allows for higher repeatability,. Alwepo.com, thread rolling is a crucial manufacturing process that plays a significant role in producing threaded. What Is The Purpose Of Thread Rolling.

From accu-components.com

Rolled Thread vs Cut Thread The Differences And Benefits Of Each What Is The Purpose Of Thread Rolling Alwepo.com, thread rolling is a crucial manufacturing process that plays a significant role in producing threaded components across various industries. The process is different from. Rolling changes physical properties, hardening and. The fastest, most economical method for producing highly accurate threads, thread rolling allows for higher repeatability,. Thread rolling is a metal forging process that forms threads into the mirror. What Is The Purpose Of Thread Rolling.

From www.slideshare.net

The Basics of Thread Rolling What Is The Purpose Of Thread Rolling The process is different from. Thread rolling is not a metal cutting process. Thread rolling is a metal forging process that forms threads into the mirror image of a roller die. Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose thread profile is ground into the dies. Alwepo.com, thread rolling. What Is The Purpose Of Thread Rolling.

From vesect.com

What Is It? How Does It Work? Process, Types (2022) What Is The Purpose Of Thread Rolling Thread rolling is commonly used in the production of screws, bolts, and other fasteners, as well as in the automotive and aerospace industries. Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose thread profile is ground into the dies. Alwepo.com, thread rolling is a crucial manufacturing process that plays a. What Is The Purpose Of Thread Rolling.

From www.slideshare.net

The Basics of Thread Rolling What Is The Purpose Of Thread Rolling Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose thread profile is ground into the dies. The fastest, most economical method for producing highly accurate threads, thread rolling allows for higher repeatability,. As the blank cylinder is. Thread rolling is commonly used in the production of screws, bolts, and other. What Is The Purpose Of Thread Rolling.

From www.slideshare.net

The Basics of Thread Rolling What Is The Purpose Of Thread Rolling Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose thread profile is ground into the dies. The process is different from. As the blank cylinder is. The fastest, most economical method for producing highly accurate threads, thread rolling allows for higher repeatability,. Thread rolling is a metal forging process that. What Is The Purpose Of Thread Rolling.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types What Is The Purpose Of Thread Rolling Rolling changes physical properties, hardening and. Thread rolling is a metal forging process that forms threads into the mirror image of a roller die. Thread rolling is not a metal cutting process. Alwepo.com, thread rolling is a crucial manufacturing process that plays a significant role in producing threaded components across various industries. The fastest, most economical method for producing highly. What Is The Purpose Of Thread Rolling.

From localrevive.com

What Is It? How Does It Work? Process, Types (2022) What Is The Purpose Of Thread Rolling Rolling changes physical properties, hardening and. Thread rolling is commonly used in the production of screws, bolts, and other fasteners, as well as in the automotive and aerospace industries. The fastest, most economical method for producing highly accurate threads, thread rolling allows for higher repeatability,. The process is different from. Alwepo.com, thread rolling is a crucial manufacturing process that plays. What Is The Purpose Of Thread Rolling.

From www.walmart.com

Plertrvy Clearance 5 Strands Of Rainbow Cotton Handmade Crochet Diy What Is The Purpose Of Thread Rolling Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose thread profile is ground into the dies. As the blank cylinder is. The process is different from. The fastest, most economical method for producing highly accurate threads, thread rolling allows for higher repeatability,. Rolling changes physical properties, hardening and. Thread rolling. What Is The Purpose Of Thread Rolling.

From www.youtube.com

Rolled Threads Unlimited Unified Thread Rolling Example YouTube What Is The Purpose Of Thread Rolling Rolling changes physical properties, hardening and. As the blank cylinder is. Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose thread profile is ground into the dies. Thread rolling is commonly used in the production of screws, bolts, and other fasteners, as well as in the automotive and aerospace industries.. What Is The Purpose Of Thread Rolling.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types What Is The Purpose Of Thread Rolling Thread rolling is not a metal cutting process. As the blank cylinder is. Thread rolling is a metal forging process that forms threads into the mirror image of a roller die. The fastest, most economical method for producing highly accurate threads, thread rolling allows for higher repeatability,. Rolling changes physical properties, hardening and. The process is different from. Thread rolling. What Is The Purpose Of Thread Rolling.

From www.dysoncorp.com

Why Rolled Thread is Preferred for Fasteners What Is The Purpose Of Thread Rolling Thread rolling is a metal forging process that forms threads into the mirror image of a roller die. Thread rolling is commonly used in the production of screws, bolts, and other fasteners, as well as in the automotive and aerospace industries. Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose. What Is The Purpose Of Thread Rolling.

From www.associatedsteel.com

Rolled Threads Associated Steel Corporation What Is The Purpose Of Thread Rolling Thread rolling is commonly used in the production of screws, bolts, and other fasteners, as well as in the automotive and aerospace industries. Alwepo.com, thread rolling is a crucial manufacturing process that plays a significant role in producing threaded components across various industries. Thread rolling is a metal forging process that forms threads into the mirror image of a roller. What Is The Purpose Of Thread Rolling.

From alwepo.com

What Is Thread Rolling? Definition, Types, Process, Machines, And What Is The Purpose Of Thread Rolling The process is different from. Rolling changes physical properties, hardening and. Thread rolling is not a metal cutting process. As the blank cylinder is. The fastest, most economical method for producing highly accurate threads, thread rolling allows for higher repeatability,. Thread rolling is commonly used in the production of screws, bolts, and other fasteners, as well as in the automotive. What Is The Purpose Of Thread Rolling.

From www.rolledthreads.com

How Does the Thread Rolling Process Work? What Is The Purpose Of Thread Rolling Rolling changes physical properties, hardening and. The fastest, most economical method for producing highly accurate threads, thread rolling allows for higher repeatability,. Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose thread profile is ground into the dies. Alwepo.com, thread rolling is a crucial manufacturing process that plays a significant. What Is The Purpose Of Thread Rolling.

From www.accu.co.uk

What Are Thread Rolling Screws And When Should You Use Them? Accu What Is The Purpose Of Thread Rolling As the blank cylinder is. The process is different from. Thread rolling is not a metal cutting process. Alwepo.com, thread rolling is a crucial manufacturing process that plays a significant role in producing threaded components across various industries. The fastest, most economical method for producing highly accurate threads, thread rolling allows for higher repeatability,. Rolling changes physical properties, hardening and.. What Is The Purpose Of Thread Rolling.

From www.wescomachine.com

Thread Rolling WESCO What Is The Purpose Of Thread Rolling As the blank cylinder is. The process is different from. Thread rolling is a metal forging process that forms threads into the mirror image of a roller die. Alwepo.com, thread rolling is a crucial manufacturing process that plays a significant role in producing threaded components across various industries. Rolling changes physical properties, hardening and. Thread rolling is not a metal. What Is The Purpose Of Thread Rolling.

From www.rolledthreads.com

Capabilities Rolled Threads Unlimited What Is The Purpose Of Thread Rolling Rolling changes physical properties, hardening and. Thread rolling is commonly used in the production of screws, bolts, and other fasteners, as well as in the automotive and aerospace industries. Alwepo.com, thread rolling is a crucial manufacturing process that plays a significant role in producing threaded components across various industries. As the blank cylinder is. The process is different from. Thread. What Is The Purpose Of Thread Rolling.

From www.researchgate.net

Cross section of the threads produced by thread rolling and What Is The Purpose Of Thread Rolling Alwepo.com, thread rolling is a crucial manufacturing process that plays a significant role in producing threaded components across various industries. Thread rolling is a metal forging process that forms threads into the mirror image of a roller die. The fastest, most economical method for producing highly accurate threads, thread rolling allows for higher repeatability,. The process is different from. Thread. What Is The Purpose Of Thread Rolling.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types What Is The Purpose Of Thread Rolling The fastest, most economical method for producing highly accurate threads, thread rolling allows for higher repeatability,. Thread rolling is a metal forging process that forms threads into the mirror image of a roller die. Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose thread profile is ground into the dies.. What Is The Purpose Of Thread Rolling.

From www.indiamart.com

Round 23mm Stainless Steel Thread Rolling Die, For Industrial at Rs What Is The Purpose Of Thread Rolling The fastest, most economical method for producing highly accurate threads, thread rolling allows for higher repeatability,. The process is different from. Thread rolling is a metal forging process that forms threads into the mirror image of a roller die. Thread rolling is commonly used in the production of screws, bolts, and other fasteners, as well as in the automotive and. What Is The Purpose Of Thread Rolling.

From mikehardware.com

Thread Rolling Process of Screws The Basics MIKEHARDWARE What Is The Purpose Of Thread Rolling Alwepo.com, thread rolling is a crucial manufacturing process that plays a significant role in producing threaded components across various industries. Thread rolling is a metal forging process that forms threads into the mirror image of a roller die. Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose thread profile is. What Is The Purpose Of Thread Rolling.

From www.jerpbakbayless.com

Guide to MultiStart Threads JerpbakBayless 2, 3, 4 Start Thread Guide What Is The Purpose Of Thread Rolling Thread rolling is a metal forging process that forms threads into the mirror image of a roller die. As the blank cylinder is. Rolling changes physical properties, hardening and. Thread rolling is not a metal cutting process. Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose thread profile is ground. What Is The Purpose Of Thread Rolling.

From www.slideshare.net

The Basics of Thread Rolling What Is The Purpose Of Thread Rolling The fastest, most economical method for producing highly accurate threads, thread rolling allows for higher repeatability,. Thread rolling is commonly used in the production of screws, bolts, and other fasteners, as well as in the automotive and aerospace industries. Rolling changes physical properties, hardening and. The process is different from. Thread rolling is a metal forging process that forms threads. What Is The Purpose Of Thread Rolling.

From www.youtube.com

Thread rolling machine YouTube What Is The Purpose Of Thread Rolling Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose thread profile is ground into the dies. Thread rolling is not a metal cutting process. Thread rolling is a metal forging process that forms threads into the mirror image of a roller die. Alwepo.com, thread rolling is a crucial manufacturing process. What Is The Purpose Of Thread Rolling.

From thegatewaymag.com

Applying Pressure The Benefits of Thread Rolling The Gateway to New What Is The Purpose Of Thread Rolling Rolling changes physical properties, hardening and. Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose thread profile is ground into the dies. As the blank cylinder is. The process is different from. Alwepo.com, thread rolling is a crucial manufacturing process that plays a significant role in producing threaded components across. What Is The Purpose Of Thread Rolling.

From www.indiamart.com

Thread Rolling Machine at Rs 300000 Chennai ID 26720574562 What Is The Purpose Of Thread Rolling The process is different from. Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose thread profile is ground into the dies. Thread rolling is not a metal cutting process. Alwepo.com, thread rolling is a crucial manufacturing process that plays a significant role in producing threaded components across various industries. Rolling. What Is The Purpose Of Thread Rolling.

From vesect.com

What Is It? How Does It Work? Process, Types (2022) What Is The Purpose Of Thread Rolling The process is different from. As the blank cylinder is. The fastest, most economical method for producing highly accurate threads, thread rolling allows for higher repeatability,. Alwepo.com, thread rolling is a crucial manufacturing process that plays a significant role in producing threaded components across various industries. Rolling changes physical properties, hardening and. Thread rolling is commonly used in the production. What Is The Purpose Of Thread Rolling.

From localrevive.com

What Is It? How Does It Work? Process, Types (2022) What Is The Purpose Of Thread Rolling Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose thread profile is ground into the dies. Rolling changes physical properties, hardening and. Thread rolling is not a metal cutting process. Thread rolling is commonly used in the production of screws, bolts, and other fasteners, as well as in the automotive. What Is The Purpose Of Thread Rolling.

From www.researchgate.net

Thread rolling machine and dies Download Scientific Diagram What Is The Purpose Of Thread Rolling The process is different from. Thread rolling is commonly used in the production of screws, bolts, and other fasteners, as well as in the automotive and aerospace industries. Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose thread profile is ground into the dies. Rolling changes physical properties, hardening and.. What Is The Purpose Of Thread Rolling.

From www.atlrod.com

Advantages of Rolled Threads Atlanta Rod and Manufacturing What Is The Purpose Of Thread Rolling Thread rolling is commonly used in the production of screws, bolts, and other fasteners, as well as in the automotive and aerospace industries. As the blank cylinder is. The fastest, most economical method for producing highly accurate threads, thread rolling allows for higher repeatability,. Thread rolling is not a metal cutting process. Thread rolling is a metal forging process that. What Is The Purpose Of Thread Rolling.

From www.youtube.com

5 Solutions to Common Thread Rolling Problems YouTube What Is The Purpose Of Thread Rolling The fastest, most economical method for producing highly accurate threads, thread rolling allows for higher repeatability,. Thread rolling is commonly used in the production of screws, bolts, and other fasteners, as well as in the automotive and aerospace industries. Rolling changes physical properties, hardening and. Thread rolling is not a metal cutting process. As the blank cylinder is. Thread rolling. What Is The Purpose Of Thread Rolling.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types What Is The Purpose Of Thread Rolling Thread rolling is not a metal cutting process. Thread rolling is commonly used in the production of screws, bolts, and other fasteners, as well as in the automotive and aerospace industries. Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose thread profile is ground into the dies. Alwepo.com, thread rolling. What Is The Purpose Of Thread Rolling.

From www.tsamfg.com

ThreadRollingupclose TSA Manufacturing What Is The Purpose Of Thread Rolling Thread rolling is not a metal cutting process. Thread rolling is commonly used in the production of screws, bolts, and other fasteners, as well as in the automotive and aerospace industries. Rolling changes physical properties, hardening and. As the blank cylinder is. The fastest, most economical method for producing highly accurate threads, thread rolling allows for higher repeatability,. The process. What Is The Purpose Of Thread Rolling.