Boiler Steam Drum Level Calculation . Thermodynamics of pressure and temperature, geometry of the steam drum, and equation of continuity define transmitter calibration. A steam turbine, thus generating electricity. These are the minimum and maximum water levels allowed for safe operation of the boiler. Modern ccs’s can compensate for this density error, but the math behind this compensation is hairy: A test apparatus was constructed in the yarway test lab, shown in figure 7, to measure the level error and gage temperature of various gages. Boiler drum level is a critical measurement necessary to maintain efficient, reliable, and safe operations. Drum level control systems are used extensively throughout the process industries and the utilities to control the level of boiling water contained in. They are measured from the bottom tap of the.

from boilersinfo.com

Modern ccs’s can compensate for this density error, but the math behind this compensation is hairy: Thermodynamics of pressure and temperature, geometry of the steam drum, and equation of continuity define transmitter calibration. They are measured from the bottom tap of the. A test apparatus was constructed in the yarway test lab, shown in figure 7, to measure the level error and gage temperature of various gages. These are the minimum and maximum water levels allowed for safe operation of the boiler. A steam turbine, thus generating electricity. Boiler drum level is a critical measurement necessary to maintain efficient, reliable, and safe operations. Drum level control systems are used extensively throughout the process industries and the utilities to control the level of boiling water contained in.

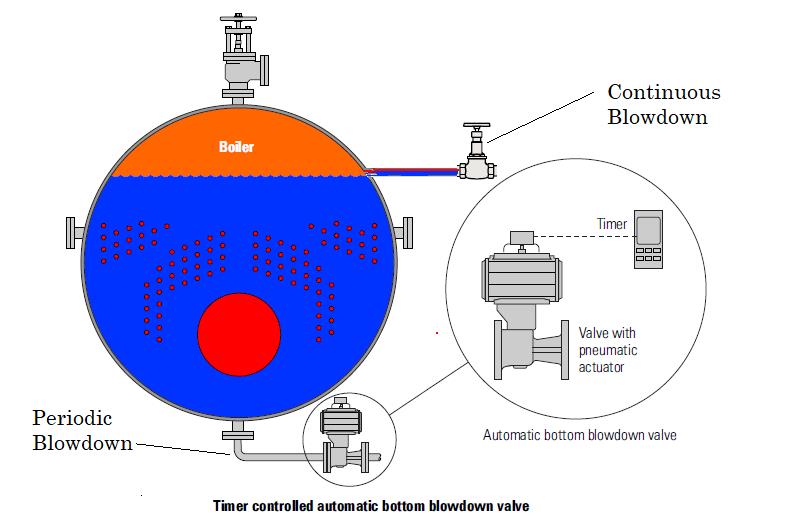

Boiler Blowdown types and Boiler Blowdown calculation

Boiler Steam Drum Level Calculation Thermodynamics of pressure and temperature, geometry of the steam drum, and equation of continuity define transmitter calibration. A steam turbine, thus generating electricity. Drum level control systems are used extensively throughout the process industries and the utilities to control the level of boiling water contained in. Thermodynamics of pressure and temperature, geometry of the steam drum, and equation of continuity define transmitter calibration. They are measured from the bottom tap of the. A test apparatus was constructed in the yarway test lab, shown in figure 7, to measure the level error and gage temperature of various gages. Modern ccs’s can compensate for this density error, but the math behind this compensation is hairy: Boiler drum level is a critical measurement necessary to maintain efficient, reliable, and safe operations. These are the minimum and maximum water levels allowed for safe operation of the boiler.

From www.youtube.com

Boiler Steam Drum YouTube Boiler Steam Drum Level Calculation A test apparatus was constructed in the yarway test lab, shown in figure 7, to measure the level error and gage temperature of various gages. A steam turbine, thus generating electricity. These are the minimum and maximum water levels allowed for safe operation of the boiler. Boiler drum level is a critical measurement necessary to maintain efficient, reliable, and safe. Boiler Steam Drum Level Calculation.

From instrumentationtools.com

Drum Level Compensation and Range Calculation of DP Transmitter Boiler Steam Drum Level Calculation A steam turbine, thus generating electricity. Modern ccs’s can compensate for this density error, but the math behind this compensation is hairy: These are the minimum and maximum water levels allowed for safe operation of the boiler. Drum level control systems are used extensively throughout the process industries and the utilities to control the level of boiling water contained in.. Boiler Steam Drum Level Calculation.

From www.iqsdirectory.com

Water Tube Boilers What is it? Types & Characteristics Boiler Steam Drum Level Calculation Boiler drum level is a critical measurement necessary to maintain efficient, reliable, and safe operations. Thermodynamics of pressure and temperature, geometry of the steam drum, and equation of continuity define transmitter calibration. These are the minimum and maximum water levels allowed for safe operation of the boiler. A steam turbine, thus generating electricity. A test apparatus was constructed in the. Boiler Steam Drum Level Calculation.

From blog.incatools.com

Boiler Steam Drum Level Control Strategies Boiler Steam Drum Level Calculation Thermodynamics of pressure and temperature, geometry of the steam drum, and equation of continuity define transmitter calibration. Drum level control systems are used extensively throughout the process industries and the utilities to control the level of boiling water contained in. Modern ccs’s can compensate for this density error, but the math behind this compensation is hairy: They are measured from. Boiler Steam Drum Level Calculation.

From idpowerstation.blogspot.com

Inside Power Station Steam Drum Level Measurement Boiler Steam Drum Level Calculation A steam turbine, thus generating electricity. Thermodynamics of pressure and temperature, geometry of the steam drum, and equation of continuity define transmitter calibration. A test apparatus was constructed in the yarway test lab, shown in figure 7, to measure the level error and gage temperature of various gages. These are the minimum and maximum water levels allowed for safe operation. Boiler Steam Drum Level Calculation.

From in.pinterest.com

Calculate Differential Pressure Sensed by Level Transmitter Boiler Steam Drum Level Calculation A test apparatus was constructed in the yarway test lab, shown in figure 7, to measure the level error and gage temperature of various gages. Modern ccs’s can compensate for this density error, but the math behind this compensation is hairy: They are measured from the bottom tap of the. These are the minimum and maximum water levels allowed for. Boiler Steam Drum Level Calculation.

From www.icpmag.it

Efficient system for steam drum level measurement ICP Magazine Boiler Steam Drum Level Calculation A steam turbine, thus generating electricity. These are the minimum and maximum water levels allowed for safe operation of the boiler. They are measured from the bottom tap of the. Boiler drum level is a critical measurement necessary to maintain efficient, reliable, and safe operations. Thermodynamics of pressure and temperature, geometry of the steam drum, and equation of continuity define. Boiler Steam Drum Level Calculation.

From instrumentationtools.com

Boiler Drum Level Transmitter calibration Instrumentation Tools Boiler Steam Drum Level Calculation A test apparatus was constructed in the yarway test lab, shown in figure 7, to measure the level error and gage temperature of various gages. A steam turbine, thus generating electricity. They are measured from the bottom tap of the. Boiler drum level is a critical measurement necessary to maintain efficient, reliable, and safe operations. Modern ccs’s can compensate for. Boiler Steam Drum Level Calculation.

From boilersinfo.com

Boiler Blowdown types and Boiler Blowdown calculation Boiler Steam Drum Level Calculation Drum level control systems are used extensively throughout the process industries and the utilities to control the level of boiling water contained in. Modern ccs’s can compensate for this density error, but the math behind this compensation is hairy: A test apparatus was constructed in the yarway test lab, shown in figure 7, to measure the level error and gage. Boiler Steam Drum Level Calculation.

From www.thermodyneboilers.com

Blowdown in Boiler Boiler Blowdown Calculation Formula & Calculator... Boiler Steam Drum Level Calculation Modern ccs’s can compensate for this density error, but the math behind this compensation is hairy: These are the minimum and maximum water levels allowed for safe operation of the boiler. Thermodynamics of pressure and temperature, geometry of the steam drum, and equation of continuity define transmitter calibration. A test apparatus was constructed in the yarway test lab, shown in. Boiler Steam Drum Level Calculation.

From exydazycn.blob.core.windows.net

Level Control System Failure E61 at Elizabeth Lopes blog Boiler Steam Drum Level Calculation A test apparatus was constructed in the yarway test lab, shown in figure 7, to measure the level error and gage temperature of various gages. These are the minimum and maximum water levels allowed for safe operation of the boiler. Thermodynamics of pressure and temperature, geometry of the steam drum, and equation of continuity define transmitter calibration. Modern ccs’s can. Boiler Steam Drum Level Calculation.

From www.pinterest.es

Pin on fred Boiler Steam Drum Level Calculation They are measured from the bottom tap of the. Drum level control systems are used extensively throughout the process industries and the utilities to control the level of boiling water contained in. Thermodynamics of pressure and temperature, geometry of the steam drum, and equation of continuity define transmitter calibration. A test apparatus was constructed in the yarway test lab, shown. Boiler Steam Drum Level Calculation.

From www.mercon-automation.com

Steam drums' guided wave radar water level measurement MERCON Boiler Steam Drum Level Calculation They are measured from the bottom tap of the. Thermodynamics of pressure and temperature, geometry of the steam drum, and equation of continuity define transmitter calibration. Boiler drum level is a critical measurement necessary to maintain efficient, reliable, and safe operations. Modern ccs’s can compensate for this density error, but the math behind this compensation is hairy: Drum level control. Boiler Steam Drum Level Calculation.

From dxotmweuu.blob.core.windows.net

Boiler Steam Drum Level Compensation Formula at Alejandro Odom blog Boiler Steam Drum Level Calculation A test apparatus was constructed in the yarway test lab, shown in figure 7, to measure the level error and gage temperature of various gages. Modern ccs’s can compensate for this density error, but the math behind this compensation is hairy: Drum level control systems are used extensively throughout the process industries and the utilities to control the level of. Boiler Steam Drum Level Calculation.

From boilersinfo.com

Boiler Blowdown types and Boiler Blowdown calculation Boiler Steam Drum Level Calculation Boiler drum level is a critical measurement necessary to maintain efficient, reliable, and safe operations. Thermodynamics of pressure and temperature, geometry of the steam drum, and equation of continuity define transmitter calibration. They are measured from the bottom tap of the. A steam turbine, thus generating electricity. These are the minimum and maximum water levels allowed for safe operation of. Boiler Steam Drum Level Calculation.

From www.youtube.com

Why Three Element method for Boiler Drum Level Control Single Element Boiler Steam Drum Level Calculation A test apparatus was constructed in the yarway test lab, shown in figure 7, to measure the level error and gage temperature of various gages. Modern ccs’s can compensate for this density error, but the math behind this compensation is hairy: They are measured from the bottom tap of the. Boiler drum level is a critical measurement necessary to maintain. Boiler Steam Drum Level Calculation.

From flagames.ru

steam codes Boiler Steam Drum Level Calculation They are measured from the bottom tap of the. A test apparatus was constructed in the yarway test lab, shown in figure 7, to measure the level error and gage temperature of various gages. Modern ccs’s can compensate for this density error, but the math behind this compensation is hairy: Boiler drum level is a critical measurement necessary to maintain. Boiler Steam Drum Level Calculation.

From www.youtube.com

WATER TUBE BOILERSTEAM DRUMWATER OF BOILERS(PART2 Boiler Steam Drum Level Calculation Drum level control systems are used extensively throughout the process industries and the utilities to control the level of boiling water contained in. A steam turbine, thus generating electricity. Thermodynamics of pressure and temperature, geometry of the steam drum, and equation of continuity define transmitter calibration. These are the minimum and maximum water levels allowed for safe operation of the. Boiler Steam Drum Level Calculation.

From www.youtube.com

BOILER DRUM LEVEL NOT MAINTAINED ! HOW TO CONTROL BOILER STEAM DRUM Boiler Steam Drum Level Calculation Modern ccs’s can compensate for this density error, but the math behind this compensation is hairy: A steam turbine, thus generating electricity. Thermodynamics of pressure and temperature, geometry of the steam drum, and equation of continuity define transmitter calibration. Boiler drum level is a critical measurement necessary to maintain efficient, reliable, and safe operations. A test apparatus was constructed in. Boiler Steam Drum Level Calculation.

From chemicalengineeringworld.com

Boiler Drum Level Control Chemical Engineering World Boiler Steam Drum Level Calculation Boiler drum level is a critical measurement necessary to maintain efficient, reliable, and safe operations. Thermodynamics of pressure and temperature, geometry of the steam drum, and equation of continuity define transmitter calibration. Drum level control systems are used extensively throughout the process industries and the utilities to control the level of boiling water contained in. A test apparatus was constructed. Boiler Steam Drum Level Calculation.

From www.vega.com

Steam boiler drum level measurement technology comparison Differential Boiler Steam Drum Level Calculation Modern ccs’s can compensate for this density error, but the math behind this compensation is hairy: Thermodynamics of pressure and temperature, geometry of the steam drum, and equation of continuity define transmitter calibration. A steam turbine, thus generating electricity. Drum level control systems are used extensively throughout the process industries and the utilities to control the level of boiling water. Boiler Steam Drum Level Calculation.

From savree.com

Boiler Steam Drum Explained saVRee Boiler Steam Drum Level Calculation Modern ccs’s can compensate for this density error, but the math behind this compensation is hairy: These are the minimum and maximum water levels allowed for safe operation of the boiler. Thermodynamics of pressure and temperature, geometry of the steam drum, and equation of continuity define transmitter calibration. Drum level control systems are used extensively throughout the process industries and. Boiler Steam Drum Level Calculation.

From www.youtube.com

How to perform Boiler Drum Level Transmitter Calibration YouTube Boiler Steam Drum Level Calculation Thermodynamics of pressure and temperature, geometry of the steam drum, and equation of continuity define transmitter calibration. They are measured from the bottom tap of the. A steam turbine, thus generating electricity. These are the minimum and maximum water levels allowed for safe operation of the boiler. A test apparatus was constructed in the yarway test lab, shown in figure. Boiler Steam Drum Level Calculation.

From www.youtube.com

Foxboro Technical Training IMV31 Boiler Drum Level Configuration Boiler Steam Drum Level Calculation A test apparatus was constructed in the yarway test lab, shown in figure 7, to measure the level error and gage temperature of various gages. Thermodynamics of pressure and temperature, geometry of the steam drum, and equation of continuity define transmitter calibration. They are measured from the bottom tap of the. Boiler drum level is a critical measurement necessary to. Boiler Steam Drum Level Calculation.

From instrumentationtools.com

Commissioning Differential Pressure Transmitter in Boiler Steam Drum Boiler Steam Drum Level Calculation They are measured from the bottom tap of the. Boiler drum level is a critical measurement necessary to maintain efficient, reliable, and safe operations. These are the minimum and maximum water levels allowed for safe operation of the boiler. Modern ccs’s can compensate for this density error, but the math behind this compensation is hairy: A steam turbine, thus generating. Boiler Steam Drum Level Calculation.

From prsync.com

Guided Wave Radar for Tight Boiler Steam Drum Level Control Boiler Steam Drum Level Calculation Boiler drum level is a critical measurement necessary to maintain efficient, reliable, and safe operations. Modern ccs’s can compensate for this density error, but the math behind this compensation is hairy: A steam turbine, thus generating electricity. Drum level control systems are used extensively throughout the process industries and the utilities to control the level of boiling water contained in.. Boiler Steam Drum Level Calculation.

From blog.hitech.in

Electronic Drum Level Indicator Boiler Drum Level Indicator Lavel Gauge Boiler Steam Drum Level Calculation Boiler drum level is a critical measurement necessary to maintain efficient, reliable, and safe operations. These are the minimum and maximum water levels allowed for safe operation of the boiler. They are measured from the bottom tap of the. A test apparatus was constructed in the yarway test lab, shown in figure 7, to measure the level error and gage. Boiler Steam Drum Level Calculation.

From boilersinfo.com

Boiler Steam drum internals and function Boiler Steam Drum Level Calculation Drum level control systems are used extensively throughout the process industries and the utilities to control the level of boiling water contained in. A test apparatus was constructed in the yarway test lab, shown in figure 7, to measure the level error and gage temperature of various gages. A steam turbine, thus generating electricity. These are the minimum and maximum. Boiler Steam Drum Level Calculation.

From www.alibaba.com

Src410 Boiler Steam Drum Level Gauge Meter Buy Boiler Drum Level Boiler Steam Drum Level Calculation A test apparatus was constructed in the yarway test lab, shown in figure 7, to measure the level error and gage temperature of various gages. Boiler drum level is a critical measurement necessary to maintain efficient, reliable, and safe operations. A steam turbine, thus generating electricity. They are measured from the bottom tap of the. Modern ccs’s can compensate for. Boiler Steam Drum Level Calculation.

From tecgcontrol.com

Steam Drum Level Monitoring TECG Control Boiler Steam Drum Level Calculation Boiler drum level is a critical measurement necessary to maintain efficient, reliable, and safe operations. Drum level control systems are used extensively throughout the process industries and the utilities to control the level of boiling water contained in. Modern ccs’s can compensate for this density error, but the math behind this compensation is hairy: They are measured from the bottom. Boiler Steam Drum Level Calculation.

From exocxaufz.blob.core.windows.net

What Causes Low Water Level In Boiler at Todd Moreland blog Boiler Steam Drum Level Calculation These are the minimum and maximum water levels allowed for safe operation of the boiler. Boiler drum level is a critical measurement necessary to maintain efficient, reliable, and safe operations. Drum level control systems are used extensively throughout the process industries and the utilities to control the level of boiling water contained in. A test apparatus was constructed in the. Boiler Steam Drum Level Calculation.

From www.wareinc.com

3Element Steam Drum Level Control WARE Boiler Steam Drum Level Calculation A steam turbine, thus generating electricity. Drum level control systems are used extensively throughout the process industries and the utilities to control the level of boiling water contained in. They are measured from the bottom tap of the. A test apparatus was constructed in the yarway test lab, shown in figure 7, to measure the level error and gage temperature. Boiler Steam Drum Level Calculation.

From savree.com

Boiler Steam Drum Explained saVRee Boiler Steam Drum Level Calculation A test apparatus was constructed in the yarway test lab, shown in figure 7, to measure the level error and gage temperature of various gages. Boiler drum level is a critical measurement necessary to maintain efficient, reliable, and safe operations. A steam turbine, thus generating electricity. Modern ccs’s can compensate for this density error, but the math behind this compensation. Boiler Steam Drum Level Calculation.

From ar.inspiredpencil.com

Boiler Drum Components Boiler Steam Drum Level Calculation Boiler drum level is a critical measurement necessary to maintain efficient, reliable, and safe operations. Thermodynamics of pressure and temperature, geometry of the steam drum, and equation of continuity define transmitter calibration. Modern ccs’s can compensate for this density error, but the math behind this compensation is hairy: A test apparatus was constructed in the yarway test lab, shown in. Boiler Steam Drum Level Calculation.

From powerengineering101.com

How To Determine The Minimum Required Thickness Of A Boiler Drum Boiler Steam Drum Level Calculation Thermodynamics of pressure and temperature, geometry of the steam drum, and equation of continuity define transmitter calibration. A test apparatus was constructed in the yarway test lab, shown in figure 7, to measure the level error and gage temperature of various gages. Drum level control systems are used extensively throughout the process industries and the utilities to control the level. Boiler Steam Drum Level Calculation.