Injection Molding Machine Cooling Requirements . there are two primary types of cooling in injection molding — traditional cooling and conformal cooling. selecting an optimal cooling system for your injection molding process isn’t just about choosing between air. Conformal cooling channels (cccs) are employed to improve the cooling rate due to the equal distance. the minimum cooling time is to ensure the cooling system is capable of removing heat from the mold at the required rate; Each one is built on the general concept of cooling channels through which a cooling agent (such as coolant or water) can During mold design, prioritize the cooling method and circuit placement, ensuring. Optimal cooling method and circuit placement:

from alphadescaler.com

Each one is built on the general concept of cooling channels through which a cooling agent (such as coolant or water) can there are two primary types of cooling in injection molding — traditional cooling and conformal cooling. the minimum cooling time is to ensure the cooling system is capable of removing heat from the mold at the required rate; Optimal cooling method and circuit placement: Conformal cooling channels (cccs) are employed to improve the cooling rate due to the equal distance. selecting an optimal cooling system for your injection molding process isn’t just about choosing between air. During mold design, prioritize the cooling method and circuit placement, ensuring.

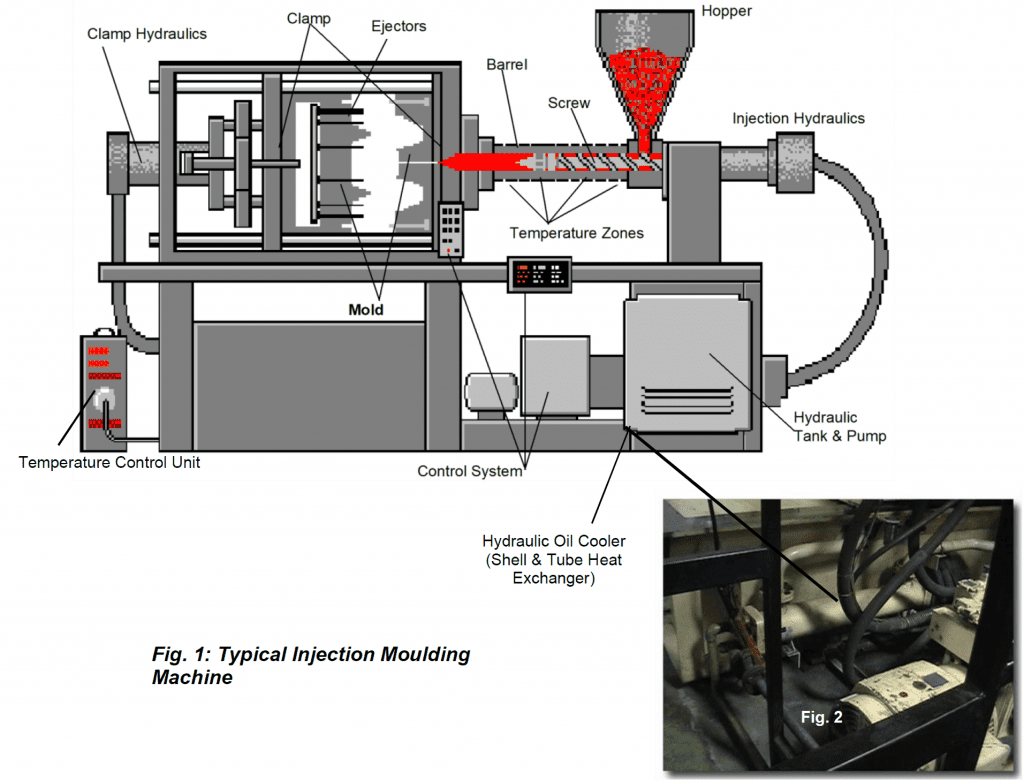

Injection Moulding & The Plastics Industry

Injection Molding Machine Cooling Requirements the minimum cooling time is to ensure the cooling system is capable of removing heat from the mold at the required rate; Each one is built on the general concept of cooling channels through which a cooling agent (such as coolant or water) can During mold design, prioritize the cooling method and circuit placement, ensuring. selecting an optimal cooling system for your injection molding process isn’t just about choosing between air. there are two primary types of cooling in injection molding — traditional cooling and conformal cooling. Conformal cooling channels (cccs) are employed to improve the cooling rate due to the equal distance. Optimal cooling method and circuit placement: the minimum cooling time is to ensure the cooling system is capable of removing heat from the mold at the required rate;

From www.la-plastic.com

How do you reduce cooling time in injection molding? Injection Molding Machine Cooling Requirements the minimum cooling time is to ensure the cooling system is capable of removing heat from the mold at the required rate; Conformal cooling channels (cccs) are employed to improve the cooling rate due to the equal distance. During mold design, prioritize the cooling method and circuit placement, ensuring. selecting an optimal cooling system for your injection molding. Injection Molding Machine Cooling Requirements.

From www.lcchiller.com

injection molding machine cooling tower Injection Molding Machine Cooling Requirements the minimum cooling time is to ensure the cooling system is capable of removing heat from the mold at the required rate; Optimal cooling method and circuit placement: Each one is built on the general concept of cooling channels through which a cooling agent (such as coolant or water) can During mold design, prioritize the cooling method and circuit. Injection Molding Machine Cooling Requirements.

From www.weetect.com

Polycarbonate Injection Molding The Complete Guide Wee Tect Injection Molding Machine Cooling Requirements During mold design, prioritize the cooling method and circuit placement, ensuring. Optimal cooling method and circuit placement: selecting an optimal cooling system for your injection molding process isn’t just about choosing between air. Conformal cooling channels (cccs) are employed to improve the cooling rate due to the equal distance. there are two primary types of cooling in injection. Injection Molding Machine Cooling Requirements.

From www.youtube.com

HOW TO CALCULATE COOLING TIME IN PLASTIC INJECTION MOLD COOLING TIME Injection Molding Machine Cooling Requirements the minimum cooling time is to ensure the cooling system is capable of removing heat from the mold at the required rate; there are two primary types of cooling in injection molding — traditional cooling and conformal cooling. During mold design, prioritize the cooling method and circuit placement, ensuring. selecting an optimal cooling system for your injection. Injection Molding Machine Cooling Requirements.

From www.linkedin.com

Cooling Rate of Injection Molding Injection Molding Machine Cooling Requirements there are two primary types of cooling in injection molding — traditional cooling and conformal cooling. Conformal cooling channels (cccs) are employed to improve the cooling rate due to the equal distance. the minimum cooling time is to ensure the cooling system is capable of removing heat from the mold at the required rate; Each one is built. Injection Molding Machine Cooling Requirements.

From www.hansenplastics.com

Cooling Rate in Injection Molding A Comprehensive Guide Injection Molding Machine Cooling Requirements During mold design, prioritize the cooling method and circuit placement, ensuring. Each one is built on the general concept of cooling channels through which a cooling agent (such as coolant or water) can Optimal cooling method and circuit placement: Conformal cooling channels (cccs) are employed to improve the cooling rate due to the equal distance. the minimum cooling time. Injection Molding Machine Cooling Requirements.

From www.elastron.com

Vent, Screw and Cooling Designs Injection Molding Elastron TPE Injection Molding Machine Cooling Requirements selecting an optimal cooling system for your injection molding process isn’t just about choosing between air. Conformal cooling channels (cccs) are employed to improve the cooling rate due to the equal distance. there are two primary types of cooling in injection molding — traditional cooling and conformal cooling. During mold design, prioritize the cooling method and circuit placement,. Injection Molding Machine Cooling Requirements.

From cooling-tower.my

Injection molding working principle JH Cooling Machine Injection Molding Machine Cooling Requirements the minimum cooling time is to ensure the cooling system is capable of removing heat from the mold at the required rate; Each one is built on the general concept of cooling channels through which a cooling agent (such as coolant or water) can there are two primary types of cooling in injection molding — traditional cooling and. Injection Molding Machine Cooling Requirements.

From www.linkedin.com

The Role of Cooling Towers in Injection Molding Machine Injection Molding Machine Cooling Requirements Conformal cooling channels (cccs) are employed to improve the cooling rate due to the equal distance. Optimal cooling method and circuit placement: there are two primary types of cooling in injection molding — traditional cooling and conformal cooling. the minimum cooling time is to ensure the cooling system is capable of removing heat from the mold at the. Injection Molding Machine Cooling Requirements.

From cooling-tower.my

Injection molding working principle JH Cooling Machine Injection Molding Machine Cooling Requirements selecting an optimal cooling system for your injection molding process isn’t just about choosing between air. the minimum cooling time is to ensure the cooling system is capable of removing heat from the mold at the required rate; Each one is built on the general concept of cooling channels through which a cooling agent (such as coolant or. Injection Molding Machine Cooling Requirements.

From www.rnaautomation.com

Robotics in Injection Moulding RNA Automation Injection Molding Machine Cooling Requirements the minimum cooling time is to ensure the cooling system is capable of removing heat from the mold at the required rate; Conformal cooling channels (cccs) are employed to improve the cooling rate due to the equal distance. there are two primary types of cooling in injection molding — traditional cooling and conformal cooling. Optimal cooling method and. Injection Molding Machine Cooling Requirements.

From www.researchgate.net

Specification of an injection molding machine [21] Download Table Injection Molding Machine Cooling Requirements Conformal cooling channels (cccs) are employed to improve the cooling rate due to the equal distance. Optimal cooling method and circuit placement: selecting an optimal cooling system for your injection molding process isn’t just about choosing between air. there are two primary types of cooling in injection molding — traditional cooling and conformal cooling. Each one is built. Injection Molding Machine Cooling Requirements.

From studylib.net

Injection Molding Cooling Time Injection Molding Machine Cooling Requirements the minimum cooling time is to ensure the cooling system is capable of removing heat from the mold at the required rate; there are two primary types of cooling in injection molding — traditional cooling and conformal cooling. selecting an optimal cooling system for your injection molding process isn’t just about choosing between air. Optimal cooling method. Injection Molding Machine Cooling Requirements.

From dokumen.tips

(PDF) Requirements for Injection molding machines DOKUMEN.TIPS Injection Molding Machine Cooling Requirements selecting an optimal cooling system for your injection molding process isn’t just about choosing between air. there are two primary types of cooling in injection molding — traditional cooling and conformal cooling. Conformal cooling channels (cccs) are employed to improve the cooling rate due to the equal distance. the minimum cooling time is to ensure the cooling. Injection Molding Machine Cooling Requirements.

From thehardwareacademy.com

How to Design for Injection Molding The Hardware Academy Injection Molding Machine Cooling Requirements Each one is built on the general concept of cooling channels through which a cooling agent (such as coolant or water) can there are two primary types of cooling in injection molding — traditional cooling and conformal cooling. the minimum cooling time is to ensure the cooling system is capable of removing heat from the mold at the. Injection Molding Machine Cooling Requirements.

From mavink.com

Injection Molding Process Flow Diagram Injection Molding Machine Cooling Requirements Conformal cooling channels (cccs) are employed to improve the cooling rate due to the equal distance. selecting an optimal cooling system for your injection molding process isn’t just about choosing between air. During mold design, prioritize the cooling method and circuit placement, ensuring. Optimal cooling method and circuit placement: there are two primary types of cooling in injection. Injection Molding Machine Cooling Requirements.

From www.lsr-molding.com

LSR Mold Design Guide Liquid Silicone Rubber Injection Molding Injection Molding Machine Cooling Requirements the minimum cooling time is to ensure the cooling system is capable of removing heat from the mold at the required rate; During mold design, prioritize the cooling method and circuit placement, ensuring. Conformal cooling channels (cccs) are employed to improve the cooling rate due to the equal distance. Optimal cooling method and circuit placement: Each one is built. Injection Molding Machine Cooling Requirements.

From capablemachining.com

Basic Guide to Injection Molding Processing Capable Machining Injection Molding Machine Cooling Requirements Optimal cooling method and circuit placement: there are two primary types of cooling in injection molding — traditional cooling and conformal cooling. Each one is built on the general concept of cooling channels through which a cooling agent (such as coolant or water) can Conformal cooling channels (cccs) are employed to improve the cooling rate due to the equal. Injection Molding Machine Cooling Requirements.

From www.log-imm.com

LOG Injection Molding Machine Full Electric AD30TS67L Injection Molding Machine Cooling Requirements there are two primary types of cooling in injection molding — traditional cooling and conformal cooling. Optimal cooling method and circuit placement: the minimum cooling time is to ensure the cooling system is capable of removing heat from the mold at the required rate; Conformal cooling channels (cccs) are employed to improve the cooling rate due to the. Injection Molding Machine Cooling Requirements.

From www.daobenmachinery.com

Role of Cooling Towers in Injection Moulding Machine Daoben Injection Molding Machine Cooling Requirements Each one is built on the general concept of cooling channels through which a cooling agent (such as coolant or water) can During mold design, prioritize the cooling method and circuit placement, ensuring. Optimal cooling method and circuit placement: Conformal cooling channels (cccs) are employed to improve the cooling rate due to the equal distance. there are two primary. Injection Molding Machine Cooling Requirements.

From www.kaysun.com

Injection Molding Step by Step How Are Plastic Parts Made? Injection Molding Machine Cooling Requirements the minimum cooling time is to ensure the cooling system is capable of removing heat from the mold at the required rate; Each one is built on the general concept of cooling channels through which a cooling agent (such as coolant or water) can During mold design, prioritize the cooling method and circuit placement, ensuring. Optimal cooling method and. Injection Molding Machine Cooling Requirements.

From china-plastic-injection-molding.com

How Does Plastic Injection Molding Work? Injection Molding Machine Cooling Requirements the minimum cooling time is to ensure the cooling system is capable of removing heat from the mold at the required rate; Optimal cooling method and circuit placement: Conformal cooling channels (cccs) are employed to improve the cooling rate due to the equal distance. there are two primary types of cooling in injection molding — traditional cooling and. Injection Molding Machine Cooling Requirements.

From zetarmold.com

What are the different types of injection mold cooling systems Injection Molding Machine Cooling Requirements selecting an optimal cooling system for your injection molding process isn’t just about choosing between air. During mold design, prioritize the cooling method and circuit placement, ensuring. there are two primary types of cooling in injection molding — traditional cooling and conformal cooling. Each one is built on the general concept of cooling channels through which a cooling. Injection Molding Machine Cooling Requirements.

From www.myplasticmold.com

Injection Molding Machine Components And Its Function Injection Molding Machine Cooling Requirements During mold design, prioritize the cooling method and circuit placement, ensuring. Each one is built on the general concept of cooling channels through which a cooling agent (such as coolant or water) can Conformal cooling channels (cccs) are employed to improve the cooling rate due to the equal distance. Optimal cooling method and circuit placement: selecting an optimal cooling. Injection Molding Machine Cooling Requirements.

From mungfali.com

Injection Molding Design Guidelines Injection Molding Machine Cooling Requirements During mold design, prioritize the cooling method and circuit placement, ensuring. the minimum cooling time is to ensure the cooling system is capable of removing heat from the mold at the required rate; selecting an optimal cooling system for your injection molding process isn’t just about choosing between air. there are two primary types of cooling in. Injection Molding Machine Cooling Requirements.

From www.mdpi.com

Applied Sciences Free FullText Design and Optimization of Injection Molding Machine Cooling Requirements Conformal cooling channels (cccs) are employed to improve the cooling rate due to the equal distance. During mold design, prioritize the cooling method and circuit placement, ensuring. the minimum cooling time is to ensure the cooling system is capable of removing heat from the mold at the required rate; Each one is built on the general concept of cooling. Injection Molding Machine Cooling Requirements.

From www.vem-tooling.com

Injection Molding Plastic Parts for any Project Injection Molding Machine Cooling Requirements Conformal cooling channels (cccs) are employed to improve the cooling rate due to the equal distance. there are two primary types of cooling in injection molding — traditional cooling and conformal cooling. the minimum cooling time is to ensure the cooling system is capable of removing heat from the mold at the required rate; Each one is built. Injection Molding Machine Cooling Requirements.

From alphadescaler.com

Injection Moulding & The Plastics Industry Injection Molding Machine Cooling Requirements Conformal cooling channels (cccs) are employed to improve the cooling rate due to the equal distance. Each one is built on the general concept of cooling channels through which a cooling agent (such as coolant or water) can Optimal cooling method and circuit placement: During mold design, prioritize the cooling method and circuit placement, ensuring. there are two primary. Injection Molding Machine Cooling Requirements.

From www.iqsdirectory.com

Plastic Injection Molding What Is It? How Does It Work? Injection Molding Machine Cooling Requirements During mold design, prioritize the cooling method and circuit placement, ensuring. Optimal cooling method and circuit placement: the minimum cooling time is to ensure the cooling system is capable of removing heat from the mold at the required rate; Conformal cooling channels (cccs) are employed to improve the cooling rate due to the equal distance. there are two. Injection Molding Machine Cooling Requirements.

From www.moldex3d.com

inar Optimizing Cooling Time in Injection Molding 1000 AM CET Injection Molding Machine Cooling Requirements Each one is built on the general concept of cooling channels through which a cooling agent (such as coolant or water) can Optimal cooling method and circuit placement: During mold design, prioritize the cooling method and circuit placement, ensuring. Conformal cooling channels (cccs) are employed to improve the cooling rate due to the equal distance. selecting an optimal cooling. Injection Molding Machine Cooling Requirements.

From info.crescentind.com

Cooling Methods and Design in Injection Molding Injection Molding Machine Cooling Requirements the minimum cooling time is to ensure the cooling system is capable of removing heat from the mold at the required rate; selecting an optimal cooling system for your injection molding process isn’t just about choosing between air. During mold design, prioritize the cooling method and circuit placement, ensuring. Conformal cooling channels (cccs) are employed to improve the. Injection Molding Machine Cooling Requirements.

From www.iqsdirectory.com

Metal Injection Molding Stages, Advantages, Process & Uses Injection Molding Machine Cooling Requirements there are two primary types of cooling in injection molding — traditional cooling and conformal cooling. During mold design, prioritize the cooling method and circuit placement, ensuring. Conformal cooling channels (cccs) are employed to improve the cooling rate due to the equal distance. the minimum cooling time is to ensure the cooling system is capable of removing heat. Injection Molding Machine Cooling Requirements.

From prototool.com

Injection Mold Cooling System Design Principles Injection Molding Machine Cooling Requirements the minimum cooling time is to ensure the cooling system is capable of removing heat from the mold at the required rate; there are two primary types of cooling in injection molding — traditional cooling and conformal cooling. Conformal cooling channels (cccs) are employed to improve the cooling rate due to the equal distance. selecting an optimal. Injection Molding Machine Cooling Requirements.

From www.linearams.com

Conformal Cooling Transforms Injection Molding Processes and Part Injection Molding Machine Cooling Requirements there are two primary types of cooling in injection molding — traditional cooling and conformal cooling. Optimal cooling method and circuit placement: Conformal cooling channels (cccs) are employed to improve the cooling rate due to the equal distance. Each one is built on the general concept of cooling channels through which a cooling agent (such as coolant or water). Injection Molding Machine Cooling Requirements.

From exoxlyafz.blob.core.windows.net

How To Start Injection Molding Machine at Cheryl Petersen blog Injection Molding Machine Cooling Requirements During mold design, prioritize the cooling method and circuit placement, ensuring. Conformal cooling channels (cccs) are employed to improve the cooling rate due to the equal distance. the minimum cooling time is to ensure the cooling system is capable of removing heat from the mold at the required rate; Optimal cooling method and circuit placement: selecting an optimal. Injection Molding Machine Cooling Requirements.