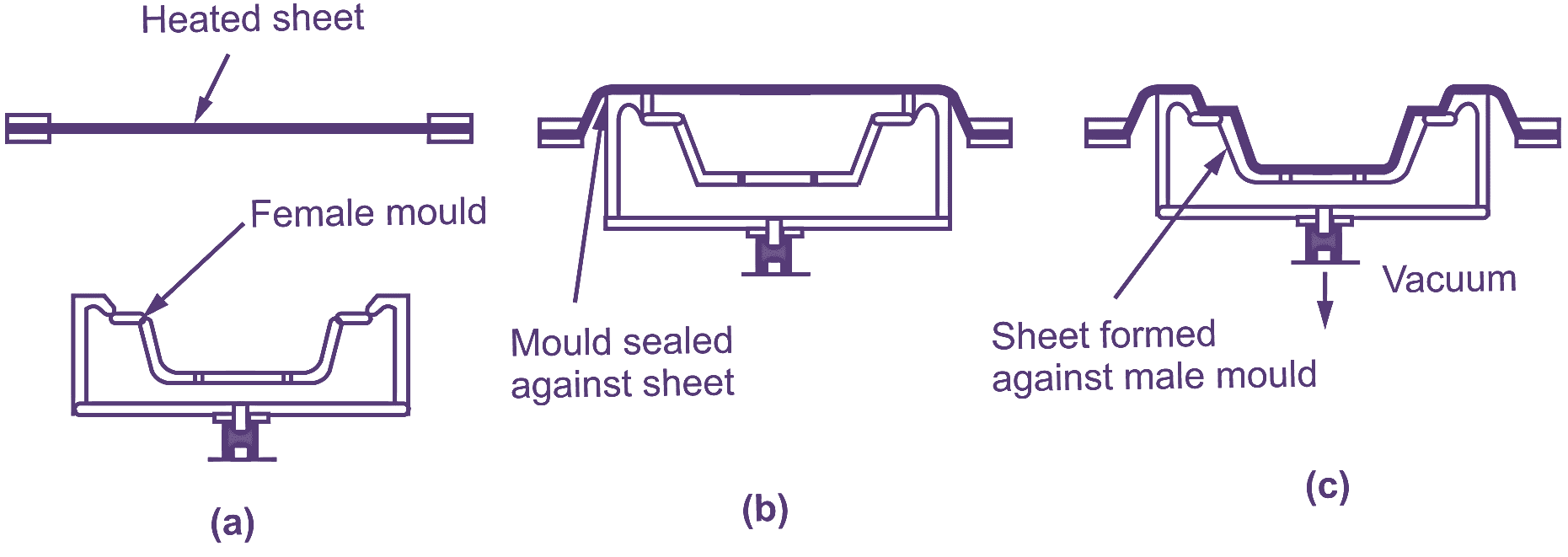

What Is Made From Vacuum Forming . vacuum forming is the simplest method to make repeatable plastic parts economically. vacuum forming is a type of thermoforming process where a plastic sheet is heated until it becomes pliable, then shaped over a mold using vacuum pressure. vacuum forming is a widely used manufacturing process that involves shaping a thermoplastic sheet into a desired form by applying heat and vacuum pressure. This method is favored for its ability to create detailed and large parts efficiently, making it indispensable in various industries. Key materials for vacuum forming include acrylic, polycarbonate, pvc, hips, and petg, each. vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by. Discover how vacuum forming is utilized across industries from automotive to aerospace, offering efficiency and flexibility in product design.

from electricalworkbook.com

vacuum forming is a widely used manufacturing process that involves shaping a thermoplastic sheet into a desired form by applying heat and vacuum pressure. Discover how vacuum forming is utilized across industries from automotive to aerospace, offering efficiency and flexibility in product design. vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by. vacuum forming is a type of thermoforming process where a plastic sheet is heated until it becomes pliable, then shaped over a mold using vacuum pressure. vacuum forming is the simplest method to make repeatable plastic parts economically. Key materials for vacuum forming include acrylic, polycarbonate, pvc, hips, and petg, each. This method is favored for its ability to create detailed and large parts efficiently, making it indispensable in various industries.

What is Vacuum Forming? Process, Applications, Products & Advantages

What Is Made From Vacuum Forming vacuum forming is the simplest method to make repeatable plastic parts economically. vacuum forming is a widely used manufacturing process that involves shaping a thermoplastic sheet into a desired form by applying heat and vacuum pressure. vacuum forming is the simplest method to make repeatable plastic parts economically. Key materials for vacuum forming include acrylic, polycarbonate, pvc, hips, and petg, each. Discover how vacuum forming is utilized across industries from automotive to aerospace, offering efficiency and flexibility in product design. vacuum forming is a type of thermoforming process where a plastic sheet is heated until it becomes pliable, then shaped over a mold using vacuum pressure. vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by. This method is favored for its ability to create detailed and large parts efficiently, making it indispensable in various industries.

From formlabs.com

Introduction to Vacuum Forming What Is Made From Vacuum Forming vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by. This method is favored for its ability to create detailed and large parts efficiently, making it indispensable in various industries. Discover how vacuum forming is utilized across industries from automotive to aerospace, offering efficiency and flexibility in product design. vacuum forming is a widely. What Is Made From Vacuum Forming.

From www.alplastics.ca

VACUUM FORMING What Is Made From Vacuum Forming vacuum forming is the simplest method to make repeatable plastic parts economically. Discover how vacuum forming is utilized across industries from automotive to aerospace, offering efficiency and flexibility in product design. vacuum forming is a widely used manufacturing process that involves shaping a thermoplastic sheet into a desired form by applying heat and vacuum pressure. Key materials for. What Is Made From Vacuum Forming.

From www.youtube.com

Introduction To Vacuum Forming What is vacuum Forming and What Can I What Is Made From Vacuum Forming vacuum forming is a widely used manufacturing process that involves shaping a thermoplastic sheet into a desired form by applying heat and vacuum pressure. This method is favored for its ability to create detailed and large parts efficiently, making it indispensable in various industries. Key materials for vacuum forming include acrylic, polycarbonate, pvc, hips, and petg, each. vacuum. What Is Made From Vacuum Forming.

From craftvac.com

WHAT IS VACUUM FORMING ? What Is Made From Vacuum Forming Discover how vacuum forming is utilized across industries from automotive to aerospace, offering efficiency and flexibility in product design. vacuum forming is a type of thermoforming process where a plastic sheet is heated until it becomes pliable, then shaped over a mold using vacuum pressure. vacuum forming is the simplest method to make repeatable plastic parts economically. . What Is Made From Vacuum Forming.

From www.youtube.com

Prop Shop How to Make a Vacuum Forming Machine YouTube What Is Made From Vacuum Forming vacuum forming is a type of thermoforming process where a plastic sheet is heated until it becomes pliable, then shaped over a mold using vacuum pressure. This method is favored for its ability to create detailed and large parts efficiently, making it indispensable in various industries. vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated. What Is Made From Vacuum Forming.

From www.youtube.com

Vacuum Forming YouTube What Is Made From Vacuum Forming Discover how vacuum forming is utilized across industries from automotive to aerospace, offering efficiency and flexibility in product design. Key materials for vacuum forming include acrylic, polycarbonate, pvc, hips, and petg, each. This method is favored for its ability to create detailed and large parts efficiently, making it indispensable in various industries. vacuum forming, the simplest thermoforming method, uses. What Is Made From Vacuum Forming.

From www.slideshare.net

Vacuum Forming What Is Made From Vacuum Forming vacuum forming is the simplest method to make repeatable plastic parts economically. vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by. vacuum forming is a widely used manufacturing process that involves shaping a thermoplastic sheet into a desired form by applying heat and vacuum pressure. vacuum forming is a type of. What Is Made From Vacuum Forming.

From www.iqsdirectory.com

Vacuum Forming Types, Uses, Features and Benefits What Is Made From Vacuum Forming Key materials for vacuum forming include acrylic, polycarbonate, pvc, hips, and petg, each. vacuum forming is a type of thermoforming process where a plastic sheet is heated until it becomes pliable, then shaped over a mold using vacuum pressure. vacuum forming is a widely used manufacturing process that involves shaping a thermoplastic sheet into a desired form by. What Is Made From Vacuum Forming.

From warringah-plastics.com.au

Industry Leaders in Vacuum Forming in Sydney Warringah Plastics What Is Made From Vacuum Forming vacuum forming is a widely used manufacturing process that involves shaping a thermoplastic sheet into a desired form by applying heat and vacuum pressure. This method is favored for its ability to create detailed and large parts efficiently, making it indispensable in various industries. vacuum forming is the simplest method to make repeatable plastic parts economically. vacuum. What Is Made From Vacuum Forming.

From interform-uk.com

Thermoplastic vacuum forming plastic with Interform Manufacturing What Is Made From Vacuum Forming Discover how vacuum forming is utilized across industries from automotive to aerospace, offering efficiency and flexibility in product design. This method is favored for its ability to create detailed and large parts efficiently, making it indispensable in various industries. vacuum forming is a type of thermoforming process where a plastic sheet is heated until it becomes pliable, then shaped. What Is Made From Vacuum Forming.

From www.youtube.com

What is Vacuum Forming? YouTube What Is Made From Vacuum Forming Key materials for vacuum forming include acrylic, polycarbonate, pvc, hips, and petg, each. vacuum forming is the simplest method to make repeatable plastic parts economically. vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by. vacuum forming is a widely used manufacturing process that involves shaping a thermoplastic sheet into a desired form. What Is Made From Vacuum Forming.

From electricalworkbook.com

What is Vacuum Forming? Process, Applications, Products & Advantages What Is Made From Vacuum Forming Key materials for vacuum forming include acrylic, polycarbonate, pvc, hips, and petg, each. vacuum forming is the simplest method to make repeatable plastic parts economically. This method is favored for its ability to create detailed and large parts efficiently, making it indispensable in various industries. vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic. What Is Made From Vacuum Forming.

From www.petervaldivia.com

Fabrication of Plastics. Tecnología ESO en Ingles What Is Made From Vacuum Forming vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by. This method is favored for its ability to create detailed and large parts efficiently, making it indispensable in various industries. Key materials for vacuum forming include acrylic, polycarbonate, pvc, hips, and petg, each. vacuum forming is a widely used manufacturing process that involves shaping. What Is Made From Vacuum Forming.

From www.hotrod.com

How to build a vacuum forming mold to make your own plastic parts What Is Made From Vacuum Forming Key materials for vacuum forming include acrylic, polycarbonate, pvc, hips, and petg, each. This method is favored for its ability to create detailed and large parts efficiently, making it indispensable in various industries. Discover how vacuum forming is utilized across industries from automotive to aerospace, offering efficiency and flexibility in product design. vacuum forming is a type of thermoforming. What Is Made From Vacuum Forming.

From sites.wit.edu

stepbystep guide to vacuum forming Center for Applied Research What Is Made From Vacuum Forming vacuum forming is a widely used manufacturing process that involves shaping a thermoplastic sheet into a desired form by applying heat and vacuum pressure. Discover how vacuum forming is utilized across industries from automotive to aerospace, offering efficiency and flexibility in product design. Key materials for vacuum forming include acrylic, polycarbonate, pvc, hips, and petg, each. vacuum forming,. What Is Made From Vacuum Forming.

From www.youtube.com

Vacuum Forming Process Working Applications ENGINEERING STUDY What Is Made From Vacuum Forming This method is favored for its ability to create detailed and large parts efficiently, making it indispensable in various industries. Key materials for vacuum forming include acrylic, polycarbonate, pvc, hips, and petg, each. vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by. Discover how vacuum forming is utilized across industries from automotive to aerospace,. What Is Made From Vacuum Forming.

From spottingit.com

The advantages of vacuum forming Spotting IT What Is Made From Vacuum Forming Discover how vacuum forming is utilized across industries from automotive to aerospace, offering efficiency and flexibility in product design. This method is favored for its ability to create detailed and large parts efficiently, making it indispensable in various industries. vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by. vacuum forming is a type. What Is Made From Vacuum Forming.

From electricalworkbook.com

What is Vacuum Forming? Process, Applications, Products & Advantages What Is Made From Vacuum Forming Discover how vacuum forming is utilized across industries from automotive to aerospace, offering efficiency and flexibility in product design. vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by. vacuum forming is the simplest method to make repeatable plastic parts economically. Key materials for vacuum forming include acrylic, polycarbonate, pvc, hips, and petg, each.. What Is Made From Vacuum Forming.

From www.la-plastic.com

What is the Vacuum Forming Process? What Is Made From Vacuum Forming Discover how vacuum forming is utilized across industries from automotive to aerospace, offering efficiency and flexibility in product design. Key materials for vacuum forming include acrylic, polycarbonate, pvc, hips, and petg, each. vacuum forming is the simplest method to make repeatable plastic parts economically. vacuum forming is a type of thermoforming process where a plastic sheet is heated. What Is Made From Vacuum Forming.

From www.youtube.com

Formech explores how vacuum forming is innovating design at Pratt What Is Made From Vacuum Forming vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by. vacuum forming is the simplest method to make repeatable plastic parts economically. Key materials for vacuum forming include acrylic, polycarbonate, pvc, hips, and petg, each. vacuum forming is a type of thermoforming process where a plastic sheet is heated until it becomes pliable,. What Is Made From Vacuum Forming.

From foammolders.com

Vacuum Forming The Processes Foam Molders Uses To Create HighQuality What Is Made From Vacuum Forming Discover how vacuum forming is utilized across industries from automotive to aerospace, offering efficiency and flexibility in product design. vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by. This method is favored for its ability to create detailed and large parts efficiently, making it indispensable in various industries. vacuum forming is the simplest. What Is Made From Vacuum Forming.

From www.youtube.com

Formech 508FS Manual Vacuum Forming Machine YouTube What Is Made From Vacuum Forming Key materials for vacuum forming include acrylic, polycarbonate, pvc, hips, and petg, each. This method is favored for its ability to create detailed and large parts efficiently, making it indispensable in various industries. vacuum forming is a widely used manufacturing process that involves shaping a thermoplastic sheet into a desired form by applying heat and vacuum pressure. vacuum. What Is Made From Vacuum Forming.

From designitforyou.com

WHAT IS VACUUM FORMING What Is Made From Vacuum Forming vacuum forming is a type of thermoforming process where a plastic sheet is heated until it becomes pliable, then shaped over a mold using vacuum pressure. vacuum forming is the simplest method to make repeatable plastic parts economically. This method is favored for its ability to create detailed and large parts efficiently, making it indispensable in various industries.. What Is Made From Vacuum Forming.

From plastifaboftexas.com

Vacuum Forming / Thermoforming Plastic Sheet Fabrication Manufacturing What Is Made From Vacuum Forming This method is favored for its ability to create detailed and large parts efficiently, making it indispensable in various industries. vacuum forming is a type of thermoforming process where a plastic sheet is heated until it becomes pliable, then shaped over a mold using vacuum pressure. vacuum forming is a widely used manufacturing process that involves shaping a. What Is Made From Vacuum Forming.

From phase-2.org

What are the benefits of vacuum forming? Move to a new phase What Is Made From Vacuum Forming vacuum forming is a widely used manufacturing process that involves shaping a thermoplastic sheet into a desired form by applying heat and vacuum pressure. Key materials for vacuum forming include acrylic, polycarbonate, pvc, hips, and petg, each. vacuum forming is the simplest method to make repeatable plastic parts economically. vacuum forming is a type of thermoforming process. What Is Made From Vacuum Forming.

From www.youtube.com

How To Vacuum Form in 3 Easy Steps YouTube What Is Made From Vacuum Forming vacuum forming is the simplest method to make repeatable plastic parts economically. This method is favored for its ability to create detailed and large parts efficiently, making it indispensable in various industries. vacuum forming is a widely used manufacturing process that involves shaping a thermoplastic sheet into a desired form by applying heat and vacuum pressure. Key materials. What Is Made From Vacuum Forming.

From truediy.net

What products are made using vacuum forming? What Is Made From Vacuum Forming Key materials for vacuum forming include acrylic, polycarbonate, pvc, hips, and petg, each. vacuum forming is the simplest method to make repeatable plastic parts economically. vacuum forming is a widely used manufacturing process that involves shaping a thermoplastic sheet into a desired form by applying heat and vacuum pressure. vacuum forming, the simplest thermoforming method, uses vacuum. What Is Made From Vacuum Forming.

From www.madearia.com

Vacuum Forming Process, Materials & Benefit Aria Manufacturing Limited What Is Made From Vacuum Forming vacuum forming is the simplest method to make repeatable plastic parts economically. Key materials for vacuum forming include acrylic, polycarbonate, pvc, hips, and petg, each. Discover how vacuum forming is utilized across industries from automotive to aerospace, offering efficiency and flexibility in product design. This method is favored for its ability to create detailed and large parts efficiently, making. What Is Made From Vacuum Forming.

From www.slideshare.net

Vacuum forming What Is Made From Vacuum Forming vacuum forming is the simplest method to make repeatable plastic parts economically. vacuum forming is a widely used manufacturing process that involves shaping a thermoplastic sheet into a desired form by applying heat and vacuum pressure. vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by. This method is favored for its ability. What Is Made From Vacuum Forming.

From schoutengroup.com

Vacuum forming Schouten Group What Is Made From Vacuum Forming This method is favored for its ability to create detailed and large parts efficiently, making it indispensable in various industries. vacuum forming is the simplest method to make repeatable plastic parts economically. Key materials for vacuum forming include acrylic, polycarbonate, pvc, hips, and petg, each. Discover how vacuum forming is utilized across industries from automotive to aerospace, offering efficiency. What Is Made From Vacuum Forming.

From electricalworkbook.com

What is Vacuum Forming? Process, Applications, Products & Advantages What Is Made From Vacuum Forming This method is favored for its ability to create detailed and large parts efficiently, making it indispensable in various industries. vacuum forming is a widely used manufacturing process that involves shaping a thermoplastic sheet into a desired form by applying heat and vacuum pressure. vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by.. What Is Made From Vacuum Forming.

From www.youtube.com

Vacuum forming 01 main process YouTube What Is Made From Vacuum Forming vacuum forming is the simplest method to make repeatable plastic parts economically. vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by. vacuum forming is a type of thermoforming process where a plastic sheet is heated until it becomes pliable, then shaped over a mold using vacuum pressure. Key materials for vacuum forming. What Is Made From Vacuum Forming.

From www.vacforming.uk.com

What Is Vacuum Forming? Process And The Practical Uses What Is Made From Vacuum Forming vacuum forming is the simplest method to make repeatable plastic parts economically. Key materials for vacuum forming include acrylic, polycarbonate, pvc, hips, and petg, each. vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by. vacuum forming is a widely used manufacturing process that involves shaping a thermoplastic sheet into a desired form. What Is Made From Vacuum Forming.

From www.plas-tech.co.uk

Vac Forming The Advantages of Vacuum Forming What Is Made From Vacuum Forming vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by. vacuum forming is a type of thermoforming process where a plastic sheet is heated until it becomes pliable, then shaped over a mold using vacuum pressure. Discover how vacuum forming is utilized across industries from automotive to aerospace, offering efficiency and flexibility in product. What Is Made From Vacuum Forming.

From www.brayplastics.co.uk

What is Vacuum Forming? Bray Plastics What Is Made From Vacuum Forming Key materials for vacuum forming include acrylic, polycarbonate, pvc, hips, and petg, each. vacuum forming is a widely used manufacturing process that involves shaping a thermoplastic sheet into a desired form by applying heat and vacuum pressure. vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by. Discover how vacuum forming is utilized across. What Is Made From Vacuum Forming.