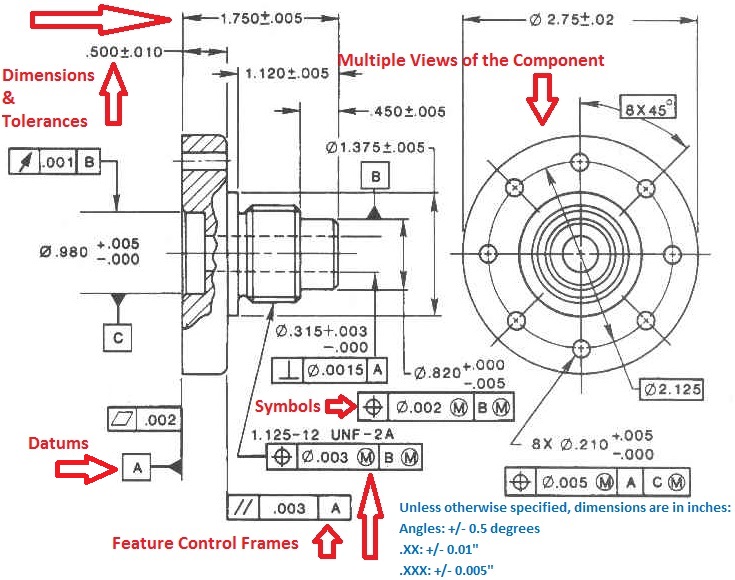

Dimension Inspection Tolerance . numerical value of a dimension expressed in a specific unit and indicated on drawings with lines and relevant symbols. a brief introduction to dimensional inspection so, gd&t is used for specification… but how do we measure to ensure manufacturing. a tolerance dimension is a dimension used if a feature’s size needs to be called out or to specify the location or. by understanding the role of basic dimensions in inspection reports and accurately reporting deviations from tolerance. the basic dimension sets the perfect position of the tolerance zone of a feature, while the geometric tolerance defines the tolerance zone size. as engineering progressed and parts became more complicated, a new method of implementing tolerances was created;

from getdrawings.com

numerical value of a dimension expressed in a specific unit and indicated on drawings with lines and relevant symbols. by understanding the role of basic dimensions in inspection reports and accurately reporting deviations from tolerance. a tolerance dimension is a dimension used if a feature’s size needs to be called out or to specify the location or. as engineering progressed and parts became more complicated, a new method of implementing tolerances was created; a brief introduction to dimensional inspection so, gd&t is used for specification… but how do we measure to ensure manufacturing. the basic dimension sets the perfect position of the tolerance zone of a feature, while the geometric tolerance defines the tolerance zone size.

Types Of Tolerance In Engineering Drawing at GetDrawings Free download

Dimension Inspection Tolerance numerical value of a dimension expressed in a specific unit and indicated on drawings with lines and relevant symbols. by understanding the role of basic dimensions in inspection reports and accurately reporting deviations from tolerance. a brief introduction to dimensional inspection so, gd&t is used for specification… but how do we measure to ensure manufacturing. as engineering progressed and parts became more complicated, a new method of implementing tolerances was created; the basic dimension sets the perfect position of the tolerance zone of a feature, while the geometric tolerance defines the tolerance zone size. a tolerance dimension is a dimension used if a feature’s size needs to be called out or to specify the location or. numerical value of a dimension expressed in a specific unit and indicated on drawings with lines and relevant symbols.

From ar.inspiredpencil.com

Geometric Tolerance Chart Dimension Inspection Tolerance numerical value of a dimension expressed in a specific unit and indicated on drawings with lines and relevant symbols. a tolerance dimension is a dimension used if a feature’s size needs to be called out or to specify the location or. the basic dimension sets the perfect position of the tolerance zone of a feature, while the. Dimension Inspection Tolerance.

From www.gom.com

Gestion simple des tolérances de cotation ISO GOM Inspect Dimension Inspection Tolerance a tolerance dimension is a dimension used if a feature’s size needs to be called out or to specify the location or. by understanding the role of basic dimensions in inspection reports and accurately reporting deviations from tolerance. as engineering progressed and parts became more complicated, a new method of implementing tolerances was created; the basic. Dimension Inspection Tolerance.

From www.gdandtbasics.com

Position Tolerance vs “True Position” GD&T Basics Dimension Inspection Tolerance the basic dimension sets the perfect position of the tolerance zone of a feature, while the geometric tolerance defines the tolerance zone size. a tolerance dimension is a dimension used if a feature’s size needs to be called out or to specify the location or. by understanding the role of basic dimensions in inspection reports and accurately. Dimension Inspection Tolerance.

From www.semianalysis.com

Embracing Chaos The Imperfect Art of Semiconductor Manufacturing And Dimension Inspection Tolerance numerical value of a dimension expressed in a specific unit and indicated on drawings with lines and relevant symbols. a tolerance dimension is a dimension used if a feature’s size needs to be called out or to specify the location or. by understanding the role of basic dimensions in inspection reports and accurately reporting deviations from tolerance.. Dimension Inspection Tolerance.

From www.smlease.com

GD&T Basics Introduction to Geometric Dimension and Tolerance Dimension Inspection Tolerance as engineering progressed and parts became more complicated, a new method of implementing tolerances was created; numerical value of a dimension expressed in a specific unit and indicated on drawings with lines and relevant symbols. a brief introduction to dimensional inspection so, gd&t is used for specification… but how do we measure to ensure manufacturing. a. Dimension Inspection Tolerance.

From www.engineeringessentials.com

Dimension Choice Dimension Inspection Tolerance by understanding the role of basic dimensions in inspection reports and accurately reporting deviations from tolerance. numerical value of a dimension expressed in a specific unit and indicated on drawings with lines and relevant symbols. a brief introduction to dimensional inspection so, gd&t is used for specification… but how do we measure to ensure manufacturing. a. Dimension Inspection Tolerance.

From www.myxxgirl.com

Dimensional Tolerances Ws Stahl My XXX Hot Girl Dimension Inspection Tolerance numerical value of a dimension expressed in a specific unit and indicated on drawings with lines and relevant symbols. as engineering progressed and parts became more complicated, a new method of implementing tolerances was created; the basic dimension sets the perfect position of the tolerance zone of a feature, while the geometric tolerance defines the tolerance zone. Dimension Inspection Tolerance.

From dokumen.tips

(PDF) Forming Sepa General tolerances ISO 2768 · PDF fileGeneral Dimension Inspection Tolerance a tolerance dimension is a dimension used if a feature’s size needs to be called out or to specify the location or. by understanding the role of basic dimensions in inspection reports and accurately reporting deviations from tolerance. the basic dimension sets the perfect position of the tolerance zone of a feature, while the geometric tolerance defines. Dimension Inspection Tolerance.

From getdrawings.com

Types Of Tolerance In Engineering Drawing at GetDrawings Free download Dimension Inspection Tolerance the basic dimension sets the perfect position of the tolerance zone of a feature, while the geometric tolerance defines the tolerance zone size. numerical value of a dimension expressed in a specific unit and indicated on drawings with lines and relevant symbols. by understanding the role of basic dimensions in inspection reports and accurately reporting deviations from. Dimension Inspection Tolerance.

From www.scribd.com

general tolerances Engineering Tolerance Metalworking Dimension Inspection Tolerance as engineering progressed and parts became more complicated, a new method of implementing tolerances was created; by understanding the role of basic dimensions in inspection reports and accurately reporting deviations from tolerance. numerical value of a dimension expressed in a specific unit and indicated on drawings with lines and relevant symbols. the basic dimension sets the. Dimension Inspection Tolerance.

From www.pinterest.co.kr

Drawing with tolerances Geometric tolerancing, Technical drawing Dimension Inspection Tolerance as engineering progressed and parts became more complicated, a new method of implementing tolerances was created; numerical value of a dimension expressed in a specific unit and indicated on drawings with lines and relevant symbols. a tolerance dimension is a dimension used if a feature’s size needs to be called out or to specify the location or.. Dimension Inspection Tolerance.

From slideplayer.com

Dimension Guidelines NOTE Students will need a highlighter ppt download Dimension Inspection Tolerance as engineering progressed and parts became more complicated, a new method of implementing tolerances was created; a brief introduction to dimensional inspection so, gd&t is used for specification… but how do we measure to ensure manufacturing. numerical value of a dimension expressed in a specific unit and indicated on drawings with lines and relevant symbols. the. Dimension Inspection Tolerance.

From dxoapvfhf.blob.core.windows.net

Clevis Pin Tolerance at Jeffrey Overcash blog Dimension Inspection Tolerance by understanding the role of basic dimensions in inspection reports and accurately reporting deviations from tolerance. as engineering progressed and parts became more complicated, a new method of implementing tolerances was created; a brief introduction to dimensional inspection so, gd&t is used for specification… but how do we measure to ensure manufacturing. a tolerance dimension is. Dimension Inspection Tolerance.

From dxopykbzn.blob.core.windows.net

Ring Gauge Tolerance Calculator at Cecil Alvarez blog Dimension Inspection Tolerance a tolerance dimension is a dimension used if a feature’s size needs to be called out or to specify the location or. numerical value of a dimension expressed in a specific unit and indicated on drawings with lines and relevant symbols. by understanding the role of basic dimensions in inspection reports and accurately reporting deviations from tolerance.. Dimension Inspection Tolerance.

From fractory.com

Guide to CNC Machining Tolerances Fractory Dimension Inspection Tolerance a brief introduction to dimensional inspection so, gd&t is used for specification… but how do we measure to ensure manufacturing. numerical value of a dimension expressed in a specific unit and indicated on drawings with lines and relevant symbols. by understanding the role of basic dimensions in inspection reports and accurately reporting deviations from tolerance. as. Dimension Inspection Tolerance.

From www.youtube.com

Examples of Determining the Tolerance on an Engineering Drawing? ED Dimension Inspection Tolerance as engineering progressed and parts became more complicated, a new method of implementing tolerances was created; a brief introduction to dimensional inspection so, gd&t is used for specification… but how do we measure to ensure manufacturing. by understanding the role of basic dimensions in inspection reports and accurately reporting deviations from tolerance. a tolerance dimension is. Dimension Inspection Tolerance.

From www.manufacturinget.org

Geometric Dimensioning and Tolerancing Dimension Inspection Tolerance as engineering progressed and parts became more complicated, a new method of implementing tolerances was created; a tolerance dimension is a dimension used if a feature’s size needs to be called out or to specify the location or. by understanding the role of basic dimensions in inspection reports and accurately reporting deviations from tolerance. the basic. Dimension Inspection Tolerance.

From www.pinterest.com

Quiz Question 9 Answers Technical drawing, Geometric tolerancing Dimension Inspection Tolerance numerical value of a dimension expressed in a specific unit and indicated on drawings with lines and relevant symbols. a tolerance dimension is a dimension used if a feature’s size needs to be called out or to specify the location or. by understanding the role of basic dimensions in inspection reports and accurately reporting deviations from tolerance.. Dimension Inspection Tolerance.

From puckettsectirepas.blogspot.com

Limits Fits And Tolerances Mcq Puckett Sectirepas Dimension Inspection Tolerance the basic dimension sets the perfect position of the tolerance zone of a feature, while the geometric tolerance defines the tolerance zone size. as engineering progressed and parts became more complicated, a new method of implementing tolerances was created; by understanding the role of basic dimensions in inspection reports and accurately reporting deviations from tolerance. numerical. Dimension Inspection Tolerance.

From www.numerade.com

SOLVED Make a rough sketch of a functional gauge to inspect the center Dimension Inspection Tolerance a tolerance dimension is a dimension used if a feature’s size needs to be called out or to specify the location or. numerical value of a dimension expressed in a specific unit and indicated on drawings with lines and relevant symbols. a brief introduction to dimensional inspection so, gd&t is used for specification… but how do we. Dimension Inspection Tolerance.

From www.inpaspages.com

Dimensional inspection Report Dimension Inspection Tolerance a brief introduction to dimensional inspection so, gd&t is used for specification… but how do we measure to ensure manufacturing. a tolerance dimension is a dimension used if a feature’s size needs to be called out or to specify the location or. as engineering progressed and parts became more complicated, a new method of implementing tolerances was. Dimension Inspection Tolerance.

From www.innova-systems.co.uk

How to use OCR with Smart Extract in SOLIDWORKS Inspection Innova Systems Dimension Inspection Tolerance numerical value of a dimension expressed in a specific unit and indicated on drawings with lines and relevant symbols. a tolerance dimension is a dimension used if a feature’s size needs to be called out or to specify the location or. as engineering progressed and parts became more complicated, a new method of implementing tolerances was created;. Dimension Inspection Tolerance.

From slideplayer.com

Introduction to Dimensioning ppt download Dimension Inspection Tolerance a brief introduction to dimensional inspection so, gd&t is used for specification… but how do we measure to ensure manufacturing. the basic dimension sets the perfect position of the tolerance zone of a feature, while the geometric tolerance defines the tolerance zone size. numerical value of a dimension expressed in a specific unit and indicated on drawings. Dimension Inspection Tolerance.

From e1304.blogspot.com

ENGR1304 Chapter 7 Tolerances Dimension Inspection Tolerance a tolerance dimension is a dimension used if a feature’s size needs to be called out or to specify the location or. a brief introduction to dimensional inspection so, gd&t is used for specification… but how do we measure to ensure manufacturing. the basic dimension sets the perfect position of the tolerance zone of a feature, while. Dimension Inspection Tolerance.

From www.designtechacademy.com

Design Tech Academy (1)Geometric Dimensioning and Tolerancing (GD&T Dimension Inspection Tolerance a brief introduction to dimensional inspection so, gd&t is used for specification… but how do we measure to ensure manufacturing. a tolerance dimension is a dimension used if a feature’s size needs to be called out or to specify the location or. by understanding the role of basic dimensions in inspection reports and accurately reporting deviations from. Dimension Inspection Tolerance.

From www.smlease.com

GD&T Basics Introduction to Geometric Dimension and Tolerance Dimension Inspection Tolerance as engineering progressed and parts became more complicated, a new method of implementing tolerances was created; a brief introduction to dimensional inspection so, gd&t is used for specification… but how do we measure to ensure manufacturing. by understanding the role of basic dimensions in inspection reports and accurately reporting deviations from tolerance. the basic dimension sets. Dimension Inspection Tolerance.

From www.3dhubs.com

How to prepare a technical drawing for CNC machining 3D Hubs Dimension Inspection Tolerance as engineering progressed and parts became more complicated, a new method of implementing tolerances was created; a tolerance dimension is a dimension used if a feature’s size needs to be called out or to specify the location or. by understanding the role of basic dimensions in inspection reports and accurately reporting deviations from tolerance. a brief. Dimension Inspection Tolerance.

From werk24.io

Tolerances IT Grades, General Tolerances Dimension Inspection Tolerance a brief introduction to dimensional inspection so, gd&t is used for specification… but how do we measure to ensure manufacturing. by understanding the role of basic dimensions in inspection reports and accurately reporting deviations from tolerance. numerical value of a dimension expressed in a specific unit and indicated on drawings with lines and relevant symbols. the. Dimension Inspection Tolerance.

From leehinte1940.blogspot.com

How to Read Profile Tolerances on a Sheet Metal Part Lee Hinte1940 Dimension Inspection Tolerance a brief introduction to dimensional inspection so, gd&t is used for specification… but how do we measure to ensure manufacturing. numerical value of a dimension expressed in a specific unit and indicated on drawings with lines and relevant symbols. a tolerance dimension is a dimension used if a feature’s size needs to be called out or to. Dimension Inspection Tolerance.

From ar.inspiredpencil.com

Geometric Tolerance Chart Dimension Inspection Tolerance the basic dimension sets the perfect position of the tolerance zone of a feature, while the geometric tolerance defines the tolerance zone size. a tolerance dimension is a dimension used if a feature’s size needs to be called out or to specify the location or. a brief introduction to dimensional inspection so, gd&t is used for specification…. Dimension Inspection Tolerance.

From www.gdandtbasics.com

Position Tolerance and Basic Dimensions GD&T Basics Dimension Inspection Tolerance the basic dimension sets the perfect position of the tolerance zone of a feature, while the geometric tolerance defines the tolerance zone size. as engineering progressed and parts became more complicated, a new method of implementing tolerances was created; a brief introduction to dimensional inspection so, gd&t is used for specification… but how do we measure to. Dimension Inspection Tolerance.

From www.youtube.com

Tolerance Evaluations Tutorial GOM Inspect YouTube Dimension Inspection Tolerance a tolerance dimension is a dimension used if a feature’s size needs to be called out or to specify the location or. as engineering progressed and parts became more complicated, a new method of implementing tolerances was created; numerical value of a dimension expressed in a specific unit and indicated on drawings with lines and relevant symbols.. Dimension Inspection Tolerance.

From paintingvalley.com

Types Of Tolerance In Engineering Drawing at Dimension Inspection Tolerance by understanding the role of basic dimensions in inspection reports and accurately reporting deviations from tolerance. numerical value of a dimension expressed in a specific unit and indicated on drawings with lines and relevant symbols. a brief introduction to dimensional inspection so, gd&t is used for specification… but how do we measure to ensure manufacturing. as. Dimension Inspection Tolerance.

From sandysconcept.blogspot.com

Sheet Metal Tolerance Standards Welding Tolerance Standards Dimension Inspection Tolerance a tolerance dimension is a dimension used if a feature’s size needs to be called out or to specify the location or. by understanding the role of basic dimensions in inspection reports and accurately reporting deviations from tolerance. a brief introduction to dimensional inspection so, gd&t is used for specification… but how do we measure to ensure. Dimension Inspection Tolerance.

From www.cqeacademy.com

Engineering Drawings & GD&T For the Quality Engineer Dimension Inspection Tolerance as engineering progressed and parts became more complicated, a new method of implementing tolerances was created; a tolerance dimension is a dimension used if a feature’s size needs to be called out or to specify the location or. by understanding the role of basic dimensions in inspection reports and accurately reporting deviations from tolerance. numerical value. Dimension Inspection Tolerance.