Lathe Cutting Angle . (a) end cutting edge angle. Setting the tool lathe cut angle is an essential step in achieving accurate and efficient machining on a lathe. It affects the effectiveness of the cutting action and chip. This page give rake and relief angles for turning various materials with high speed steel tool bits. (b) side clearance relief angle. (b) side cutting edge angle. The tool has a 2° side cutting edge angle and a 34° end cutting edge angle that can be accommodated in the space between the end of the work and 60° dead center leaving a clearance of 2° on both sides. Grinds for production shops should consult a specialist. When both a relief and a. From the geometry of cutting tool the various cutting tool angles are: Clearance or relief angle (γ): High speed steel (hss) angles shown are good for hobbyists; (a) end clearance relief angle. The cut angle directly affects the chip formation, tool life, and. The cutting angle of a lathe tool refers to the angle at which the tool bit is positioned in relation to the workpiece during turning operations on a lathe.

from www.themachinedesign.com

It affects the effectiveness of the cutting action and chip. Setting the tool lathe cut angle is an essential step in achieving accurate and efficient machining on a lathe. (b) side clearance relief angle. From the geometry of cutting tool the various cutting tool angles are: The tool has a 2° side cutting edge angle and a 34° end cutting edge angle that can be accommodated in the space between the end of the work and 60° dead center leaving a clearance of 2° on both sides. (a) end clearance relief angle. Grinds for production shops should consult a specialist. The cut angle directly affects the chip formation, tool life, and. High speed steel (hss) angles shown are good for hobbyists; (b) side cutting edge angle.

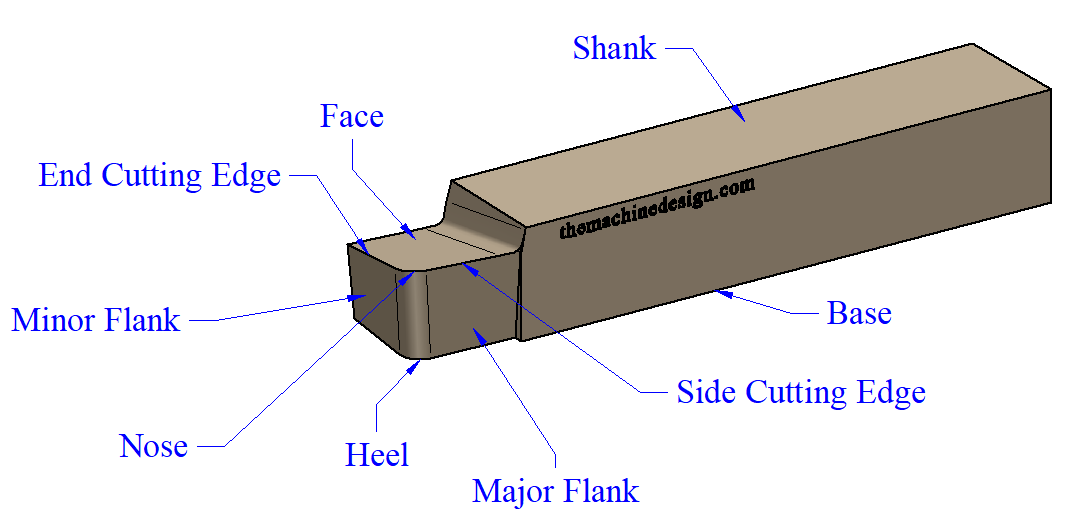

Single Point Cutting Tool Nomenclature, Geometry The Machine Design

Lathe Cutting Angle Grinds for production shops should consult a specialist. This angle plays a crucial role in. The tool has a 2° side cutting edge angle and a 34° end cutting edge angle that can be accommodated in the space between the end of the work and 60° dead center leaving a clearance of 2° on both sides. Clearance or relief angle (γ): Grinds for production shops should consult a specialist. (b) side cutting edge angle. This page give rake and relief angles for turning various materials with high speed steel tool bits. Setting the tool lathe cut angle is an essential step in achieving accurate and efficient machining on a lathe. When both a relief and a. From the geometry of cutting tool the various cutting tool angles are: High speed steel (hss) angles shown are good for hobbyists; It affects the effectiveness of the cutting action and chip. (a) end clearance relief angle. The cutting angle of a lathe tool refers to the angle at which the tool bit is positioned in relation to the workpiece during turning operations on a lathe. The cutting edge angle, also known as the included angle, is the angle between the two cutting edges of the tool. (b) side clearance relief angle.

From brunei.desertcart.com

Buy VEVOR Indexable Carbide Lathe Tools 1/2" Metal Lathe Cutting Tools Lathe Cutting Angle The cutting edge angle, also known as the included angle, is the angle between the two cutting edges of the tool. (b) side clearance relief angle. High speed steel (hss) angles shown are good for hobbyists; This page give rake and relief angles for turning various materials with high speed steel tool bits. It affects the effectiveness of the cutting. Lathe Cutting Angle.

From celshmqd.blob.core.windows.net

Cutting Angles On A Lathe at Elaine Ramirez blog Lathe Cutting Angle High speed steel (hss) angles shown are good for hobbyists; From the geometry of cutting tool the various cutting tool angles are: The tool has a 2° side cutting edge angle and a 34° end cutting edge angle that can be accommodated in the space between the end of the work and 60° dead center leaving a clearance of 2°. Lathe Cutting Angle.

From www.cobanengineering.com

Back Rake, Side Rake, Rake angle, wedge angle and flank angles,the Lathe Cutting Angle This page give rake and relief angles for turning various materials with high speed steel tool bits. (a) end cutting edge angle. When both a relief and a. The cut angle directly affects the chip formation, tool life, and. (b) side clearance relief angle. Clearance or relief angle (γ): High speed steel (hss) angles shown are good for hobbyists; Setting. Lathe Cutting Angle.

From www.youtube.com

Setting the Lathe compound to precision angles YouTube Lathe Cutting Angle Grinds for production shops should consult a specialist. This angle plays a crucial role in. (b) side cutting edge angle. Setting the tool lathe cut angle is an essential step in achieving accurate and efficient machining on a lathe. From the geometry of cutting tool the various cutting tool angles are: The cut angle directly affects the chip formation, tool. Lathe Cutting Angle.

From www.minaprem.com

Concept of Positive Rake, Negative Rake and Zero Rake Angle Lathe Cutting Angle The cutting angle of a lathe tool refers to the angle at which the tool bit is positioned in relation to the workpiece during turning operations on a lathe. This angle plays a crucial role in. It affects the effectiveness of the cutting action and chip. From the geometry of cutting tool the various cutting tool angles are: High speed. Lathe Cutting Angle.

From hmaking.com

LatheCutting Tools A Comprehensive Guide Custom High Precision CNC Lathe Cutting Angle High speed steel (hss) angles shown are good for hobbyists; (b) side clearance relief angle. The cutting angle of a lathe tool refers to the angle at which the tool bit is positioned in relation to the workpiece during turning operations on a lathe. (a) end clearance relief angle. (a) end cutting edge angle. It affects the effectiveness of the. Lathe Cutting Angle.

From www.pinterest.com

Youthful arraigned wood turning techniques get more arraigned Lathe Cutting Angle From the geometry of cutting tool the various cutting tool angles are: The tool has a 2° side cutting edge angle and a 34° end cutting edge angle that can be accommodated in the space between the end of the work and 60° dead center leaving a clearance of 2° on both sides. (a) end clearance relief angle. (b) side. Lathe Cutting Angle.

From www.mech4study.com

Single Point Cutting Tool Nomenclature, Angle,Geometry and Signature Lathe Cutting Angle It affects the effectiveness of the cutting action and chip. The cut angle directly affects the chip formation, tool life, and. When both a relief and a. High speed steel (hss) angles shown are good for hobbyists; The tool has a 2° side cutting edge angle and a 34° end cutting edge angle that can be accommodated in the space. Lathe Cutting Angle.

From mech31.blogspot.com

THIRD YEAR MECHANICAL JNTUH Single Point Cutting Tool Terminology Lathe Cutting Angle When both a relief and a. High speed steel (hss) angles shown are good for hobbyists; (a) end cutting edge angle. The tool has a 2° side cutting edge angle and a 34° end cutting edge angle that can be accommodated in the space between the end of the work and 60° dead center leaving a clearance of 2° on. Lathe Cutting Angle.

From www.theengineerspost.com

Lathe Cutting Tools A Guide to Lathe machine Tools with PDF Lathe Cutting Angle (a) end cutting edge angle. High speed steel (hss) angles shown are good for hobbyists; The cutting angle of a lathe tool refers to the angle at which the tool bit is positioned in relation to the workpiece during turning operations on a lathe. (b) side clearance relief angle. Clearance or relief angle (γ): It affects the effectiveness of the. Lathe Cutting Angle.

From www.difference.minaprem.com

Difference Between Rake Angle and Clearance Angle Lathe Cutting Angle When both a relief and a. From the geometry of cutting tool the various cutting tool angles are: (a) end clearance relief angle. (a) end cutting edge angle. This angle plays a crucial role in. (b) side cutting edge angle. The tool has a 2° side cutting edge angle and a 34° end cutting edge angle that can be accommodated. Lathe Cutting Angle.

From www.smartlathe.com

Components Of A Lathe Cutting Tool Lathe Cutting Angle Setting the tool lathe cut angle is an essential step in achieving accurate and efficient machining on a lathe. From the geometry of cutting tool the various cutting tool angles are: Grinds for production shops should consult a specialist. This angle plays a crucial role in. (a) end cutting edge angle. When both a relief and a. It affects the. Lathe Cutting Angle.

From answer2questn.blogspot.com

Questions Answers About the Lathe Introduction of Centre Lathe Lathe Cutting Angle Grinds for production shops should consult a specialist. Setting the tool lathe cut angle is an essential step in achieving accurate and efficient machining on a lathe. High speed steel (hss) angles shown are good for hobbyists; The cut angle directly affects the chip formation, tool life, and. The cutting edge angle, also known as the included angle, is the. Lathe Cutting Angle.

From celshmqd.blob.core.windows.net

Cutting Angles On A Lathe at Elaine Ramirez blog Lathe Cutting Angle The cutting edge angle, also known as the included angle, is the angle between the two cutting edges of the tool. From the geometry of cutting tool the various cutting tool angles are: High speed steel (hss) angles shown are good for hobbyists; This page give rake and relief angles for turning various materials with high speed steel tool bits.. Lathe Cutting Angle.

From toolnotes.com

Lathe Tools and Toolholders ToolNotes Lathe Cutting Angle The cut angle directly affects the chip formation, tool life, and. The cutting angle of a lathe tool refers to the angle at which the tool bit is positioned in relation to the workpiece during turning operations on a lathe. It affects the effectiveness of the cutting action and chip. The tool has a 2° side cutting edge angle and. Lathe Cutting Angle.

From thehuts-eastbourne.co.uk

Best tool angle for lathe cutting (February 2024) Lathe Cutting Angle (a) end cutting edge angle. Clearance or relief angle (γ): Grinds for production shops should consult a specialist. High speed steel (hss) angles shown are good for hobbyists; The cutting edge angle, also known as the included angle, is the angle between the two cutting edges of the tool. It affects the effectiveness of the cutting action and chip. Setting. Lathe Cutting Angle.

From learnmechanical.com

Single Point Cutting Tool Definition, Types, Geometry, Nomenclature Lathe Cutting Angle Grinds for production shops should consult a specialist. The cut angle directly affects the chip formation, tool life, and. The cutting edge angle, also known as the included angle, is the angle between the two cutting edges of the tool. When both a relief and a. This page give rake and relief angles for turning various materials with high speed. Lathe Cutting Angle.

From www.pinterest.de

Tom's Techniques Reference Bisiklet tasarımı Lathe Cutting Angle The cutting angle of a lathe tool refers to the angle at which the tool bit is positioned in relation to the workpiece during turning operations on a lathe. The cutting edge angle, also known as the included angle, is the angle between the two cutting edges of the tool. The cut angle directly affects the chip formation, tool life,. Lathe Cutting Angle.

From ecoreprap.com

Types of Lathe Tools Used in CNC Turning EcoReprap Lathe Cutting Angle When both a relief and a. Clearance or relief angle (γ): This angle plays a crucial role in. (b) side clearance relief angle. It affects the effectiveness of the cutting action and chip. High speed steel (hss) angles shown are good for hobbyists; The cut angle directly affects the chip formation, tool life, and. The tool has a 2° side. Lathe Cutting Angle.

From www.ukocarbide.com

How to choose a suitable corner radius for CNC turning inserts? Lathe Cutting Angle Grinds for production shops should consult a specialist. Setting the tool lathe cut angle is an essential step in achieving accurate and efficient machining on a lathe. It affects the effectiveness of the cutting action and chip. The cut angle directly affects the chip formation, tool life, and. (b) side clearance relief angle. This angle plays a crucial role in.. Lathe Cutting Angle.

From s3.amazonaws.com

Wood Huston, Wood Lathe Cutting Tool Angles, wooden furniture building Lathe Cutting Angle Grinds for production shops should consult a specialist. The cut angle directly affects the chip formation, tool life, and. (a) end cutting edge angle. The cutting angle of a lathe tool refers to the angle at which the tool bit is positioned in relation to the workpiece during turning operations on a lathe. The cutting edge angle, also known as. Lathe Cutting Angle.

From www.pinterest.com

Tom's Techniques Reference Metal working tools, Machine shop Lathe Cutting Angle Grinds for production shops should consult a specialist. From the geometry of cutting tool the various cutting tool angles are: (a) end cutting edge angle. The cut angle directly affects the chip formation, tool life, and. (b) side clearance relief angle. The tool has a 2° side cutting edge angle and a 34° end cutting edge angle that can be. Lathe Cutting Angle.

From ibls.org

Lathe Tool Setup IBLS Lathe Cutting Angle (b) side cutting edge angle. Setting the tool lathe cut angle is an essential step in achieving accurate and efficient machining on a lathe. When both a relief and a. High speed steel (hss) angles shown are good for hobbyists; (a) end clearance relief angle. The cut angle directly affects the chip formation, tool life, and. This angle plays a. Lathe Cutting Angle.

From www.themachinedesign.com

Single Point Cutting Tool Nomenclature, Geometry The Machine Design Lathe Cutting Angle (b) side cutting edge angle. Clearance or relief angle (γ): This page give rake and relief angles for turning various materials with high speed steel tool bits. (a) end clearance relief angle. Setting the tool lathe cut angle is an essential step in achieving accurate and efficient machining on a lathe. (a) end cutting edge angle. When both a relief. Lathe Cutting Angle.

From huanatools.com

Positive Angle Inserts VS Negative Angle Inserts Huana Tools Lathe Cutting Angle Clearance or relief angle (γ): This angle plays a crucial role in. High speed steel (hss) angles shown are good for hobbyists; From the geometry of cutting tool the various cutting tool angles are: The cutting angle of a lathe tool refers to the angle at which the tool bit is positioned in relation to the workpiece during turning operations. Lathe Cutting Angle.

From www.youtube.com

Single Point Cutting Tool Nomenclature, Tool Signature, Side Rake Lathe Cutting Angle Clearance or relief angle (γ): The tool has a 2° side cutting edge angle and a 34° end cutting edge angle that can be accommodated in the space between the end of the work and 60° dead center leaving a clearance of 2° on both sides. (a) end clearance relief angle. This page give rake and relief angles for turning. Lathe Cutting Angle.

From www.machinemfg.com

Lathe Cutting Tool Angles Selection Principle MachineMFG Lathe Cutting Angle (a) end clearance relief angle. It affects the effectiveness of the cutting action and chip. The cutting edge angle, also known as the included angle, is the angle between the two cutting edges of the tool. From the geometry of cutting tool the various cutting tool angles are: (a) end cutting edge angle. Setting the tool lathe cut angle is. Lathe Cutting Angle.

From gadgetbuilder.com

Lathe Bit Sharpening Lathe Cutting Angle (b) side cutting edge angle. This page give rake and relief angles for turning various materials with high speed steel tool bits. High speed steel (hss) angles shown are good for hobbyists; It affects the effectiveness of the cutting action and chip. (a) end cutting edge angle. The tool has a 2° side cutting edge angle and a 34° end. Lathe Cutting Angle.

From toolnotes.com

Lathe Tools and Toolholders ToolNotes Lathe Cutting Angle When both a relief and a. This page give rake and relief angles for turning various materials with high speed steel tool bits. This angle plays a crucial role in. The cut angle directly affects the chip formation, tool life, and. (a) end cutting edge angle. High speed steel (hss) angles shown are good for hobbyists; (b) side cutting edge. Lathe Cutting Angle.

From www.researchgate.net

Geometry of singlepoint cutting tool Download Scientific Diagram Lathe Cutting Angle (b) side clearance relief angle. (a) end clearance relief angle. When both a relief and a. It affects the effectiveness of the cutting action and chip. High speed steel (hss) angles shown are good for hobbyists; The tool has a 2° side cutting edge angle and a 34° end cutting edge angle that can be accommodated in the space between. Lathe Cutting Angle.

From www.machinemfg.com

Lathe Cutting Tool Angles Selection Principle MachineMFG Lathe Cutting Angle From the geometry of cutting tool the various cutting tool angles are: Clearance or relief angle (γ): The tool has a 2° side cutting edge angle and a 34° end cutting edge angle that can be accommodated in the space between the end of the work and 60° dead center leaving a clearance of 2° on both sides. (a) end. Lathe Cutting Angle.

From www.mech4study.com

Single Point Cutting Tool Nomenclature, Angle,Geometry and Signature Lathe Cutting Angle (a) end cutting edge angle. The tool has a 2° side cutting edge angle and a 34° end cutting edge angle that can be accommodated in the space between the end of the work and 60° dead center leaving a clearance of 2° on both sides. From the geometry of cutting tool the various cutting tool angles are: This angle. Lathe Cutting Angle.

From housegrail.com

11 Different Types of Lathe Tools (With Pictures) House Grail Lathe Cutting Angle This angle plays a crucial role in. High speed steel (hss) angles shown are good for hobbyists; Grinds for production shops should consult a specialist. When both a relief and a. Clearance or relief angle (γ): (b) side clearance relief angle. Setting the tool lathe cut angle is an essential step in achieving accurate and efficient machining on a lathe.. Lathe Cutting Angle.

From sharpeninghandbook.info

Sharpening Handbook Lathe Cutting Angle High speed steel (hss) angles shown are good for hobbyists; (b) side cutting edge angle. This page give rake and relief angles for turning various materials with high speed steel tool bits. Grinds for production shops should consult a specialist. The cutting edge angle, also known as the included angle, is the angle between the two cutting edges of the. Lathe Cutting Angle.

From www.mechanicalbooster.com

Single Point Cutting Tool Geometry, Angles, Nomenclature and Signature Lathe Cutting Angle From the geometry of cutting tool the various cutting tool angles are: The tool has a 2° side cutting edge angle and a 34° end cutting edge angle that can be accommodated in the space between the end of the work and 60° dead center leaving a clearance of 2° on both sides. The cut angle directly affects the chip. Lathe Cutting Angle.