Molding Eva Foam Sheets . These processes can be customized to produce eva foam with specific properties, making it ideal for specialized applications. Three thermoforming foam methods (compression molding, encapsulation molding, and vacuum forming), which each provide formed parts with unique characteristics. It’s waterproof, mold and mildew resistant, and buoyant, making it ideal for aquatic applications. Typical molding methods can be easy to work with various foam materials such as eva foam, polyethylene foam, polyurethane foam and epp (expanded polypropylene). The heat causes the eva. With a wide range of densities, properties and molding techniques, foam materials are naturally suitable for making 3d formed products. Techniques for eva foam molding using molds and forms. For intricate shapes, create custom molds using. Our xl extralight® eva molding process has one of the strongest. The mold is then closed, and heat and pressure are applied.

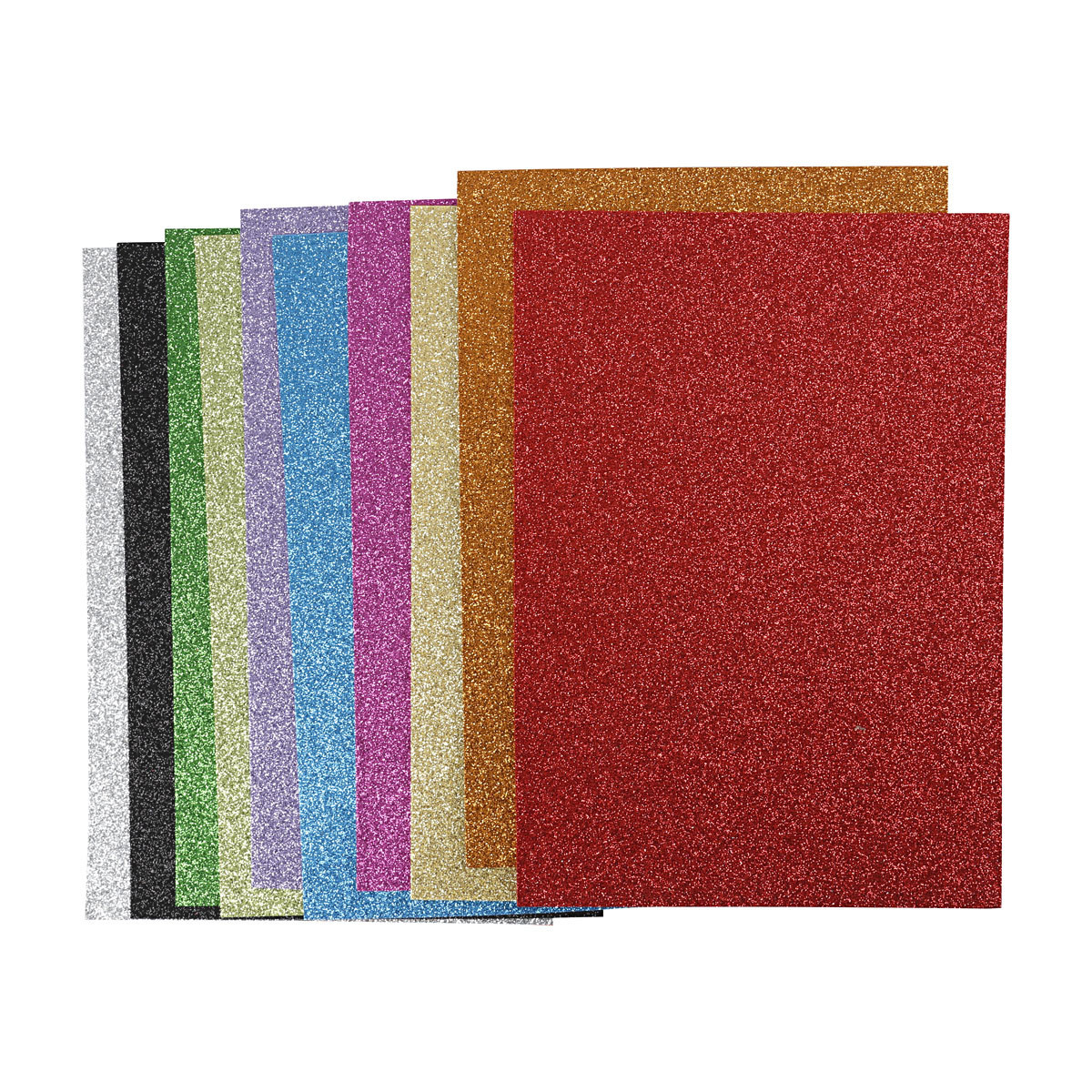

from ritohobby.co.uk

The mold is then closed, and heat and pressure are applied. These processes can be customized to produce eva foam with specific properties, making it ideal for specialized applications. Three thermoforming foam methods (compression molding, encapsulation molding, and vacuum forming), which each provide formed parts with unique characteristics. Our xl extralight® eva molding process has one of the strongest. Techniques for eva foam molding using molds and forms. For intricate shapes, create custom molds using. The heat causes the eva. Typical molding methods can be easy to work with various foam materials such as eva foam, polyethylene foam, polyurethane foam and epp (expanded polypropylene). It’s waterproof, mold and mildew resistant, and buoyant, making it ideal for aquatic applications. With a wide range of densities, properties and molding techniques, foam materials are naturally suitable for making 3d formed products.

EVA Foam Sheets, A4 21x30 cm, thickness 2 mm, 10 mixed sheets, asstd

Molding Eva Foam Sheets The heat causes the eva. For intricate shapes, create custom molds using. The mold is then closed, and heat and pressure are applied. The heat causes the eva. Typical molding methods can be easy to work with various foam materials such as eva foam, polyethylene foam, polyurethane foam and epp (expanded polypropylene). These processes can be customized to produce eva foam with specific properties, making it ideal for specialized applications. Our xl extralight® eva molding process has one of the strongest. Techniques for eva foam molding using molds and forms. It’s waterproof, mold and mildew resistant, and buoyant, making it ideal for aquatic applications. Three thermoforming foam methods (compression molding, encapsulation molding, and vacuum forming), which each provide formed parts with unique characteristics. With a wide range of densities, properties and molding techniques, foam materials are naturally suitable for making 3d formed products.

From www.foamsales.com.au

EVA Foam Sheets Perth Closed Cell Foam Foam Sales Molding Eva Foam Sheets It’s waterproof, mold and mildew resistant, and buoyant, making it ideal for aquatic applications. Three thermoforming foam methods (compression molding, encapsulation molding, and vacuum forming), which each provide formed parts with unique characteristics. These processes can be customized to produce eva foam with specific properties, making it ideal for specialized applications. Typical molding methods can be easy to work with. Molding Eva Foam Sheets.

From www.foamtechchina.com

EVA Foam Material The Best Definitive Guide FOAMTECH Molding Eva Foam Sheets Three thermoforming foam methods (compression molding, encapsulation molding, and vacuum forming), which each provide formed parts with unique characteristics. The heat causes the eva. The mold is then closed, and heat and pressure are applied. With a wide range of densities, properties and molding techniques, foam materials are naturally suitable for making 3d formed products. Typical molding methods can be. Molding Eva Foam Sheets.

From kurtin.en.made-in-china.com

Thickness Glitter EVA Sheet EVA Foam Sheet Foam A4 Sheet 2mm Cutting Molding Eva Foam Sheets Our xl extralight® eva molding process has one of the strongest. These processes can be customized to produce eva foam with specific properties, making it ideal for specialized applications. Three thermoforming foam methods (compression molding, encapsulation molding, and vacuum forming), which each provide formed parts with unique characteristics. With a wide range of densities, properties and molding techniques, foam materials. Molding Eva Foam Sheets.

From www.wefoamyoga.com

High Density Closed Cell Foam Colorful EVA Foam Sheet Molding Eva Foam Sheets Our xl extralight® eva molding process has one of the strongest. It’s waterproof, mold and mildew resistant, and buoyant, making it ideal for aquatic applications. The heat causes the eva. For intricate shapes, create custom molds using. The mold is then closed, and heat and pressure are applied. Techniques for eva foam molding using molds and forms. Three thermoforming foam. Molding Eva Foam Sheets.

From www.indiamart.com

Plain EVA Foam Sheet, For Packaging, Thickness 20 Mm, Rs 80 /meter Molding Eva Foam Sheets The heat causes the eva. Three thermoforming foam methods (compression molding, encapsulation molding, and vacuum forming), which each provide formed parts with unique characteristics. For intricate shapes, create custom molds using. It’s waterproof, mold and mildew resistant, and buoyant, making it ideal for aquatic applications. These processes can be customized to produce eva foam with specific properties, making it ideal. Molding Eva Foam Sheets.

From www.dontwasteyourmoney.com

eCraft Premium Rigid EVA Craft Foam Sheets, 8Count Molding Eva Foam Sheets Our xl extralight® eva molding process has one of the strongest. For intricate shapes, create custom molds using. Typical molding methods can be easy to work with various foam materials such as eva foam, polyethylene foam, polyurethane foam and epp (expanded polypropylene). The mold is then closed, and heat and pressure are applied. These processes can be customized to produce. Molding Eva Foam Sheets.

From morevafoam.com

Close cell Large EVA foam sheet Mor EVA Foam Molding Eva Foam Sheets Techniques for eva foam molding using molds and forms. The heat causes the eva. Typical molding methods can be easy to work with various foam materials such as eva foam, polyethylene foam, polyurethane foam and epp (expanded polypropylene). For intricate shapes, create custom molds using. These processes can be customized to produce eva foam with specific properties, making it ideal. Molding Eva Foam Sheets.

From www.parkwayfoam.com

120D EVA FOAM SHEET PARKWAY FOAM Molding Eva Foam Sheets Techniques for eva foam molding using molds and forms. Typical molding methods can be easy to work with various foam materials such as eva foam, polyethylene foam, polyurethane foam and epp (expanded polypropylene). Our xl extralight® eva molding process has one of the strongest. With a wide range of densities, properties and molding techniques, foam materials are naturally suitable for. Molding Eva Foam Sheets.

From www.lazada.com.my

EVA foam sheet 5mm A4 size Lazada Molding Eva Foam Sheets Typical molding methods can be easy to work with various foam materials such as eva foam, polyethylene foam, polyurethane foam and epp (expanded polypropylene). Our xl extralight® eva molding process has one of the strongest. It’s waterproof, mold and mildew resistant, and buoyant, making it ideal for aquatic applications. With a wide range of densities, properties and molding techniques, foam. Molding Eva Foam Sheets.

From www.parkwayfoam.com

60D EVA FOAM SHEET PARKWAY FOAM Molding Eva Foam Sheets It’s waterproof, mold and mildew resistant, and buoyant, making it ideal for aquatic applications. Typical molding methods can be easy to work with various foam materials such as eva foam, polyethylene foam, polyurethane foam and epp (expanded polypropylene). Three thermoforming foam methods (compression molding, encapsulation molding, and vacuum forming), which each provide formed parts with unique characteristics. Our xl extralight®. Molding Eva Foam Sheets.

From www.luminsworkshop.com

Ultra High Density EVA Foam Black (80cm x 100cm) Lumin's Molding Eva Foam Sheets The mold is then closed, and heat and pressure are applied. The heat causes the eva. Typical molding methods can be easy to work with various foam materials such as eva foam, polyethylene foam, polyurethane foam and epp (expanded polypropylene). It’s waterproof, mold and mildew resistant, and buoyant, making it ideal for aquatic applications. With a wide range of densities,. Molding Eva Foam Sheets.

From www.poly-props.com

High Density EVA foam. EVA sheets. Molding Eva Foam Sheets The mold is then closed, and heat and pressure are applied. Typical molding methods can be easy to work with various foam materials such as eva foam, polyethylene foam, polyurethane foam and epp (expanded polypropylene). Our xl extralight® eva molding process has one of the strongest. For intricate shapes, create custom molds using. The heat causes the eva. With a. Molding Eva Foam Sheets.

From www.parkwayfoam.com

120D EVA FOAM SHEET PARKWAY FOAM Molding Eva Foam Sheets It’s waterproof, mold and mildew resistant, and buoyant, making it ideal for aquatic applications. For intricate shapes, create custom molds using. The mold is then closed, and heat and pressure are applied. The heat causes the eva. With a wide range of densities, properties and molding techniques, foam materials are naturally suitable for making 3d formed products. Our xl extralight®. Molding Eva Foam Sheets.

From www.indiamart.com

Multicolor A4 EVA foam 5mm Thick Pack of 10 sheet at Rs 120/packet in Molding Eva Foam Sheets It’s waterproof, mold and mildew resistant, and buoyant, making it ideal for aquatic applications. These processes can be customized to produce eva foam with specific properties, making it ideal for specialized applications. Techniques for eva foam molding using molds and forms. With a wide range of densities, properties and molding techniques, foam materials are naturally suitable for making 3d formed. Molding Eva Foam Sheets.

From ritohobby.co.uk

EVA Foam Sheets, A4 21x30 cm, thickness 2 mm, 10 mixed sheets, asstd Molding Eva Foam Sheets Techniques for eva foam molding using molds and forms. With a wide range of densities, properties and molding techniques, foam materials are naturally suitable for making 3d formed products. The mold is then closed, and heat and pressure are applied. For intricate shapes, create custom molds using. Our xl extralight® eva molding process has one of the strongest. Typical molding. Molding Eva Foam Sheets.

From www.wefoamyoga.com

Cheap EVA Foam Sheet 1mm 2mm 3mm 4mm 5mm 6mm 7mm 8mm Molding Eva Foam Sheets Typical molding methods can be easy to work with various foam materials such as eva foam, polyethylene foam, polyurethane foam and epp (expanded polypropylene). These processes can be customized to produce eva foam with specific properties, making it ideal for specialized applications. Three thermoforming foam methods (compression molding, encapsulation molding, and vacuum forming), which each provide formed parts with unique. Molding Eva Foam Sheets.

From www.indiamart.com

Kamlesh Plain Blue EVA Foam Sheet, For Making Slipper, Thickness 6 mm Molding Eva Foam Sheets With a wide range of densities, properties and molding techniques, foam materials are naturally suitable for making 3d formed products. Typical molding methods can be easy to work with various foam materials such as eva foam, polyethylene foam, polyurethane foam and epp (expanded polypropylene). The heat causes the eva. Techniques for eva foam molding using molds and forms. Three thermoforming. Molding Eva Foam Sheets.

From ritohobby.co.uk

EVA Foam Sheets, A4 21x30 cm, thickness 2 mm, 15x10 sheets Ritohobby Molding Eva Foam Sheets Our xl extralight® eva molding process has one of the strongest. Typical molding methods can be easy to work with various foam materials such as eva foam, polyethylene foam, polyurethane foam and epp (expanded polypropylene). For intricate shapes, create custom molds using. It’s waterproof, mold and mildew resistant, and buoyant, making it ideal for aquatic applications. These processes can be. Molding Eva Foam Sheets.

From www.ebay.com

8pcs Foam Padding Sheets 1/2" Thick x 4" Long Square EVA Foam Sheet eBay Molding Eva Foam Sheets Our xl extralight® eva molding process has one of the strongest. The mold is then closed, and heat and pressure are applied. Techniques for eva foam molding using molds and forms. These processes can be customized to produce eva foam with specific properties, making it ideal for specialized applications. With a wide range of densities, properties and molding techniques, foam. Molding Eva Foam Sheets.

From www.madepick.com

High Density Colorful Eva Foam Sheet 260mm, Eva Foam sheet Molding Eva Foam Sheets It’s waterproof, mold and mildew resistant, and buoyant, making it ideal for aquatic applications. Typical molding methods can be easy to work with various foam materials such as eva foam, polyethylene foam, polyurethane foam and epp (expanded polypropylene). Techniques for eva foam molding using molds and forms. The mold is then closed, and heat and pressure are applied. These processes. Molding Eva Foam Sheets.

From www.foamtechchina.com

EVA Foam Material The Best Definitive Guide FOAMTECH Molding Eva Foam Sheets These processes can be customized to produce eva foam with specific properties, making it ideal for specialized applications. It’s waterproof, mold and mildew resistant, and buoyant, making it ideal for aquatic applications. Three thermoforming foam methods (compression molding, encapsulation molding, and vacuum forming), which each provide formed parts with unique characteristics. The mold is then closed, and heat and pressure. Molding Eva Foam Sheets.

From www.buypackagings.com

Eva Foam Sheet Custom Eva Foam Packing Sheet Eva Foam Roll Buy Eva Molding Eva Foam Sheets Typical molding methods can be easy to work with various foam materials such as eva foam, polyethylene foam, polyurethane foam and epp (expanded polypropylene). These processes can be customized to produce eva foam with specific properties, making it ideal for specialized applications. With a wide range of densities, properties and molding techniques, foam materials are naturally suitable for making 3d. Molding Eva Foam Sheets.

From www.foamsales.com.au

Closed Cell EVA Foam Sheets Perth Melbourne Sydney Brisbane Adelaide Molding Eva Foam Sheets With a wide range of densities, properties and molding techniques, foam materials are naturally suitable for making 3d formed products. Techniques for eva foam molding using molds and forms. It’s waterproof, mold and mildew resistant, and buoyant, making it ideal for aquatic applications. For intricate shapes, create custom molds using. Our xl extralight® eva molding process has one of the. Molding Eva Foam Sheets.

From www.insolefoam.com

EVA Foam Sheet EVA Foam Sheets Suppliers Foamwell Molding Eva Foam Sheets With a wide range of densities, properties and molding techniques, foam materials are naturally suitable for making 3d formed products. The mold is then closed, and heat and pressure are applied. For intricate shapes, create custom molds using. It’s waterproof, mold and mildew resistant, and buoyant, making it ideal for aquatic applications. Techniques for eva foam molding using molds and. Molding Eva Foam Sheets.

From www.kominevafoam.com

China Professional Thick EVA Craft Foam Sheets Manufacturers Molding Eva Foam Sheets The heat causes the eva. Techniques for eva foam molding using molds and forms. Typical molding methods can be easy to work with various foam materials such as eva foam, polyethylene foam, polyurethane foam and epp (expanded polypropylene). With a wide range of densities, properties and molding techniques, foam materials are naturally suitable for making 3d formed products. Three thermoforming. Molding Eva Foam Sheets.

From www.cnxmxxl.com

Integrated Molding 10deg Density EVA Foam Sheet 5mm White Foam Box Inserts Molding Eva Foam Sheets Typical molding methods can be easy to work with various foam materials such as eva foam, polyethylene foam, polyurethane foam and epp (expanded polypropylene). These processes can be customized to produce eva foam with specific properties, making it ideal for specialized applications. Techniques for eva foam molding using molds and forms. The mold is then closed, and heat and pressure. Molding Eva Foam Sheets.

From www.aliexpress.com

4pcs Black EVA Foam Sheets Spone Foam 10mm Thick 10x10 Inch Craft EVA Molding Eva Foam Sheets Typical molding methods can be easy to work with various foam materials such as eva foam, polyethylene foam, polyurethane foam and epp (expanded polypropylene). It’s waterproof, mold and mildew resistant, and buoyant, making it ideal for aquatic applications. With a wide range of densities, properties and molding techniques, foam materials are naturally suitable for making 3d formed products. The heat. Molding Eva Foam Sheets.

From www.nbeva.com

260mm Crosslinked PE Foam Sheet, PE foam sheet EVA Rubber & Plastic Molding Eva Foam Sheets Our xl extralight® eva molding process has one of the strongest. Three thermoforming foam methods (compression molding, encapsulation molding, and vacuum forming), which each provide formed parts with unique characteristics. Typical molding methods can be easy to work with various foam materials such as eva foam, polyethylene foam, polyurethane foam and epp (expanded polypropylene). Techniques for eva foam molding using. Molding Eva Foam Sheets.

From www.penn-elcom.com

20mm Black EVA Foam Sheet_20mmblackevafoamsheetm63820 Molding Eva Foam Sheets With a wide range of densities, properties and molding techniques, foam materials are naturally suitable for making 3d formed products. Typical molding methods can be easy to work with various foam materials such as eva foam, polyethylene foam, polyurethane foam and epp (expanded polypropylene). It’s waterproof, mold and mildew resistant, and buoyant, making it ideal for aquatic applications. Three thermoforming. Molding Eva Foam Sheets.

From www.earate.co.nz

EVA Foam Sheet Molding Eva Foam Sheets With a wide range of densities, properties and molding techniques, foam materials are naturally suitable for making 3d formed products. Our xl extralight® eva molding process has one of the strongest. It’s waterproof, mold and mildew resistant, and buoyant, making it ideal for aquatic applications. The mold is then closed, and heat and pressure are applied. Three thermoforming foam methods. Molding Eva Foam Sheets.

From www.indiamart.com

EVA Foam Sheet (Set of 50) at Rs 550/piece in Ahmedabad ID 13431183212 Molding Eva Foam Sheets The heat causes the eva. The mold is then closed, and heat and pressure are applied. Three thermoforming foam methods (compression molding, encapsulation molding, and vacuum forming), which each provide formed parts with unique characteristics. For intricate shapes, create custom molds using. With a wide range of densities, properties and molding techniques, foam materials are naturally suitable for making 3d. Molding Eva Foam Sheets.

From zjgbll.en.made-in-china.com

EVA Foam Sheet EVA Underlayment and Acoustic Underlay Molding Eva Foam Sheets Our xl extralight® eva molding process has one of the strongest. Three thermoforming foam methods (compression molding, encapsulation molding, and vacuum forming), which each provide formed parts with unique characteristics. These processes can be customized to produce eva foam with specific properties, making it ideal for specialized applications. It’s waterproof, mold and mildew resistant, and buoyant, making it ideal for. Molding Eva Foam Sheets.

From www.healthystep.co.uk

EVA Foam Sheet Extra High 70 Insoles and Orthotics Healthy Step Molding Eva Foam Sheets The mold is then closed, and heat and pressure are applied. Three thermoforming foam methods (compression molding, encapsulation molding, and vacuum forming), which each provide formed parts with unique characteristics. Techniques for eva foam molding using molds and forms. These processes can be customized to produce eva foam with specific properties, making it ideal for specialized applications. For intricate shapes,. Molding Eva Foam Sheets.

From www.foamsales.com.au

Closed Cell EVA Foam Sheets Perth Melbourne Sydney Brisbane Adelaide Molding Eva Foam Sheets Typical molding methods can be easy to work with various foam materials such as eva foam, polyethylene foam, polyurethane foam and epp (expanded polypropylene). It’s waterproof, mold and mildew resistant, and buoyant, making it ideal for aquatic applications. With a wide range of densities, properties and molding techniques, foam materials are naturally suitable for making 3d formed products. These processes. Molding Eva Foam Sheets.

From www.supplies.org.uk

EVA Foam Sheets, Pack of 10 Supplies East Riding Molding Eva Foam Sheets The mold is then closed, and heat and pressure are applied. For intricate shapes, create custom molds using. Typical molding methods can be easy to work with various foam materials such as eva foam, polyethylene foam, polyurethane foam and epp (expanded polypropylene). Three thermoforming foam methods (compression molding, encapsulation molding, and vacuum forming), which each provide formed parts with unique. Molding Eva Foam Sheets.