Abs 3D Printing Material Properties . Abs, which stands for acrylonitrile butadiene styrene, is one of the most commonly used 3d printing filaments. The proportions can vary from 15% to 35%. This material was one of the first plastics to be used with industrial 3d printers. Abs is a polymer of acrylonitrile and styrene in the presence of polybutadiene. Many years later, abs is still a. Abs is an ideal material for structural applications where impact resistance, strength, and. Abs is a low cost engineering plastic that is easy to machine and 3d print. Abs is a terpolymer made by polymerizing styrene and acrylonitrile in the presence of polybutadiene. Abs (acrylonitrile butadiene styrene) has a long history in the 3d printing world. It’s used to create plastic parts that have to be. By altering the composition of these compounds, the properties of abs can be modified to improve its toughness, heat and impact resistance. Explore everything you need to know about abs 3d printing filament with bambu lab's comprehensive guide. The general composition is 20% acrylonitrile, 25% butadiene and 55% styrene. It is opaque, offers smooth and matte surfaces and can be treated with acetone to make it shiny.

from juggerbot3d.com

The proportions can vary from 15% to 35%. Explore everything you need to know about abs 3d printing filament with bambu lab's comprehensive guide. By altering the composition of these compounds, the properties of abs can be modified to improve its toughness, heat and impact resistance. Abs is a terpolymer made by polymerizing styrene and acrylonitrile in the presence of polybutadiene. The general composition is 20% acrylonitrile, 25% butadiene and 55% styrene. It’s used to create plastic parts that have to be. Abs is an ideal material for structural applications where impact resistance, strength, and. Abs, which stands for acrylonitrile butadiene styrene, is one of the most commonly used 3d printing filaments. Abs (acrylonitrile butadiene styrene) has a long history in the 3d printing world. Abs is a polymer of acrylonitrile and styrene in the presence of polybutadiene.

Acrylonitrile butadiene styrene (ABS) Filament Review

Abs 3D Printing Material Properties Abs (acrylonitrile butadiene styrene) has a long history in the 3d printing world. It is opaque, offers smooth and matte surfaces and can be treated with acetone to make it shiny. Abs is a terpolymer made by polymerizing styrene and acrylonitrile in the presence of polybutadiene. Many years later, abs is still a. Abs (acrylonitrile butadiene styrene) has a long history in the 3d printing world. Abs, which stands for acrylonitrile butadiene styrene, is one of the most commonly used 3d printing filaments. The proportions can vary from 15% to 35%. Explore everything you need to know about abs 3d printing filament with bambu lab's comprehensive guide. The general composition is 20% acrylonitrile, 25% butadiene and 55% styrene. This material was one of the first plastics to be used with industrial 3d printers. Abs is an ideal material for structural applications where impact resistance, strength, and. By altering the composition of these compounds, the properties of abs can be modified to improve its toughness, heat and impact resistance. It’s used to create plastic parts that have to be. Abs is a polymer of acrylonitrile and styrene in the presence of polybutadiene. Abs is a low cost engineering plastic that is easy to machine and 3d print.

From nesolution.com.au

3D Printing with ABS Filament NEsolution Abs 3D Printing Material Properties The general composition is 20% acrylonitrile, 25% butadiene and 55% styrene. The proportions can vary from 15% to 35%. Abs, which stands for acrylonitrile butadiene styrene, is one of the most commonly used 3d printing filaments. It’s used to create plastic parts that have to be. It is opaque, offers smooth and matte surfaces and can be treated with acetone. Abs 3D Printing Material Properties.

From www.youtube.com

Features of ABS 3D Printing Filament Material Properties Series YouTube Abs 3D Printing Material Properties Abs is a polymer of acrylonitrile and styrene in the presence of polybutadiene. It is opaque, offers smooth and matte surfaces and can be treated with acetone to make it shiny. Abs, which stands for acrylonitrile butadiene styrene, is one of the most commonly used 3d printing filaments. This material was one of the first plastics to be used with. Abs 3D Printing Material Properties.

From 3d2go.com.ph

3D Printing Service Guide ABS vs. PLA Filaments 3D2GO Philippines Abs 3D Printing Material Properties It is opaque, offers smooth and matte surfaces and can be treated with acetone to make it shiny. This material was one of the first plastics to be used with industrial 3d printers. Abs is a terpolymer made by polymerizing styrene and acrylonitrile in the presence of polybutadiene. Abs (acrylonitrile butadiene styrene) has a long history in the 3d printing. Abs 3D Printing Material Properties.

From www.directindustry.com

ABS 3D printing resin ABS Flex White Envisiontec white / industrial Abs 3D Printing Material Properties Abs (acrylonitrile butadiene styrene) has a long history in the 3d printing world. This material was one of the first plastics to be used with industrial 3d printers. The proportions can vary from 15% to 35%. The general composition is 20% acrylonitrile, 25% butadiene and 55% styrene. Explore everything you need to know about abs 3d printing filament with bambu. Abs 3D Printing Material Properties.

From www.makerbot.com

Everything you need to know about ABS 3D printing MakerBot Abs 3D Printing Material Properties It’s used to create plastic parts that have to be. By altering the composition of these compounds, the properties of abs can be modified to improve its toughness, heat and impact resistance. The proportions can vary from 15% to 35%. Abs is a low cost engineering plastic that is easy to machine and 3d print. Abs is a polymer of. Abs 3D Printing Material Properties.

From toponew.en.made-in-china.com

PCABS 3D Printing Material China Engineering Plastic Pellets and PC Abs 3D Printing Material Properties Abs is an ideal material for structural applications where impact resistance, strength, and. Many years later, abs is still a. Abs is a low cost engineering plastic that is easy to machine and 3d print. This material was one of the first plastics to be used with industrial 3d printers. Abs is a polymer of acrylonitrile and styrene in the. Abs 3D Printing Material Properties.

From facfox.com

3D Printed Injection Mold With Polyjet Digital ABS FacFox Docs Abs 3D Printing Material Properties Abs is a low cost engineering plastic that is easy to machine and 3d print. It is opaque, offers smooth and matte surfaces and can be treated with acetone to make it shiny. The general composition is 20% acrylonitrile, 25% butadiene and 55% styrene. Abs is a terpolymer made by polymerizing styrene and acrylonitrile in the presence of polybutadiene. This. Abs 3D Printing Material Properties.

From solevant.com

What is ABS 3D Printing and How Does It Work? Abs 3D Printing Material Properties Abs, which stands for acrylonitrile butadiene styrene, is one of the most commonly used 3d printing filaments. Abs is a terpolymer made by polymerizing styrene and acrylonitrile in the presence of polybutadiene. The general composition is 20% acrylonitrile, 25% butadiene and 55% styrene. Abs (acrylonitrile butadiene styrene) has a long history in the 3d printing world. Many years later, abs. Abs 3D Printing Material Properties.

From 3dprint.com

Filabot Launches Incredible New 3D Printing Filaments Graphite Abs 3D Printing Material Properties Abs is a terpolymer made by polymerizing styrene and acrylonitrile in the presence of polybutadiene. Many years later, abs is still a. The general composition is 20% acrylonitrile, 25% butadiene and 55% styrene. Abs (acrylonitrile butadiene styrene) has a long history in the 3d printing world. Abs is a low cost engineering plastic that is easy to machine and 3d. Abs 3D Printing Material Properties.

From juggerbot3d.com

Acrylonitrile butadiene styrene (ABS) Filament Review Abs 3D Printing Material Properties Many years later, abs is still a. It is opaque, offers smooth and matte surfaces and can be treated with acetone to make it shiny. Abs is an ideal material for structural applications where impact resistance, strength, and. By altering the composition of these compounds, the properties of abs can be modified to improve its toughness, heat and impact resistance.. Abs 3D Printing Material Properties.

From a3dxyz.com

ABS A3DXYZ 3D Printers & 3D printing Services in India Abs 3D Printing Material Properties It’s used to create plastic parts that have to be. Abs is a low cost engineering plastic that is easy to machine and 3d print. Abs (acrylonitrile butadiene styrene) has a long history in the 3d printing world. Abs, which stands for acrylonitrile butadiene styrene, is one of the most commonly used 3d printing filaments. Abs is an ideal material. Abs 3D Printing Material Properties.

From www.wevolver.com

ASA vs ABS Finding the right 3D printing filament Abs 3D Printing Material Properties Abs is an ideal material for structural applications where impact resistance, strength, and. By altering the composition of these compounds, the properties of abs can be modified to improve its toughness, heat and impact resistance. Abs is a polymer of acrylonitrile and styrene in the presence of polybutadiene. Many years later, abs is still a. It’s used to create plastic. Abs 3D Printing Material Properties.

From all3dp.com

The Best ABS 3D Printers All3DP Abs 3D Printing Material Properties Abs (acrylonitrile butadiene styrene) has a long history in the 3d printing world. The proportions can vary from 15% to 35%. By altering the composition of these compounds, the properties of abs can be modified to improve its toughness, heat and impact resistance. Abs is a polymer of acrylonitrile and styrene in the presence of polybutadiene. Many years later, abs. Abs 3D Printing Material Properties.

From airwolf3d.com

4 Steps to a Glossy ABS 3D Printed Part Abs 3D Printing Material Properties This material was one of the first plastics to be used with industrial 3d printers. Abs, which stands for acrylonitrile butadiene styrene, is one of the most commonly used 3d printing filaments. It is opaque, offers smooth and matte surfaces and can be treated with acetone to make it shiny. Explore everything you need to know about abs 3d printing. Abs 3D Printing Material Properties.

From vektorus.ru

Печать ABS пластиком Температура печати ABS как печатать 3d Abs 3D Printing Material Properties The proportions can vary from 15% to 35%. By altering the composition of these compounds, the properties of abs can be modified to improve its toughness, heat and impact resistance. Abs is an ideal material for structural applications where impact resistance, strength, and. It’s used to create plastic parts that have to be. Abs is a terpolymer made by polymerizing. Abs 3D Printing Material Properties.

From www.pinterest.com

Free 3D printing filament comparison guide for education. 3d printing Abs 3D Printing Material Properties Abs is a terpolymer made by polymerizing styrene and acrylonitrile in the presence of polybutadiene. The proportions can vary from 15% to 35%. Abs is an ideal material for structural applications where impact resistance, strength, and. Abs is a low cost engineering plastic that is easy to machine and 3d print. Abs is a polymer of acrylonitrile and styrene in. Abs 3D Printing Material Properties.

From www.filamentive.com

Filamentive 3D Printer Filament Material Guide for 3D Printing Abs 3D Printing Material Properties Abs is a polymer of acrylonitrile and styrene in the presence of polybutadiene. Abs is an ideal material for structural applications where impact resistance, strength, and. The proportions can vary from 15% to 35%. Abs is a terpolymer made by polymerizing styrene and acrylonitrile in the presence of polybutadiene. By altering the composition of these compounds, the properties of abs. Abs 3D Printing Material Properties.

From robots.net

What Is Abs In 3D Printing Abs 3D Printing Material Properties The general composition is 20% acrylonitrile, 25% butadiene and 55% styrene. It is opaque, offers smooth and matte surfaces and can be treated with acetone to make it shiny. Abs (acrylonitrile butadiene styrene) has a long history in the 3d printing world. By altering the composition of these compounds, the properties of abs can be modified to improve its toughness,. Abs 3D Printing Material Properties.

From 3dprintersuperstore.com.au

ABS Black 500g 3D Printer Superstore Abs 3D Printing Material Properties Abs (acrylonitrile butadiene styrene) has a long history in the 3d printing world. Abs is an ideal material for structural applications where impact resistance, strength, and. By altering the composition of these compounds, the properties of abs can be modified to improve its toughness, heat and impact resistance. It is opaque, offers smooth and matte surfaces and can be treated. Abs 3D Printing Material Properties.

From www.3dnatives.com

PLA vs ABS, ¿qué material de impresión 3D elegir? 3Dnatives Abs 3D Printing Material Properties It is opaque, offers smooth and matte surfaces and can be treated with acetone to make it shiny. By altering the composition of these compounds, the properties of abs can be modified to improve its toughness, heat and impact resistance. The proportions can vary from 15% to 35%. The general composition is 20% acrylonitrile, 25% butadiene and 55% styrene. Abs. Abs 3D Printing Material Properties.

From www.liqcreate.com

Comparing properties of FDM, SLS and resin 3Dprinting plastics Abs 3D Printing Material Properties Abs is an ideal material for structural applications where impact resistance, strength, and. Abs is a terpolymer made by polymerizing styrene and acrylonitrile in the presence of polybutadiene. It’s used to create plastic parts that have to be. The general composition is 20% acrylonitrile, 25% butadiene and 55% styrene. Many years later, abs is still a. Abs (acrylonitrile butadiene styrene). Abs 3D Printing Material Properties.

From www.simplify3d.com

Ultimate Materials Guide Tips for 3D Printing with ABS Abs 3D Printing Material Properties Abs is an ideal material for structural applications where impact resistance, strength, and. It is opaque, offers smooth and matte surfaces and can be treated with acetone to make it shiny. Abs is a polymer of acrylonitrile and styrene in the presence of polybutadiene. Abs is a terpolymer made by polymerizing styrene and acrylonitrile in the presence of polybutadiene. The. Abs 3D Printing Material Properties.

From www.allthat3d.com

PLA vs ABS Filament Plastic Strength, Flexibility Compared! Which Is Abs 3D Printing Material Properties It’s used to create plastic parts that have to be. Abs, which stands for acrylonitrile butadiene styrene, is one of the most commonly used 3d printing filaments. Abs is a low cost engineering plastic that is easy to machine and 3d print. Abs (acrylonitrile butadiene styrene) has a long history in the 3d printing world. It is opaque, offers smooth. Abs 3D Printing Material Properties.

From www.linkedin.com

PLA vs ABS How to choose a 3D printing material? Abs 3D Printing Material Properties It’s used to create plastic parts that have to be. Abs is a low cost engineering plastic that is easy to machine and 3d print. The proportions can vary from 15% to 35%. It is opaque, offers smooth and matte surfaces and can be treated with acetone to make it shiny. This material was one of the first plastics to. Abs 3D Printing Material Properties.

From www.3dnatives.com

ABS for 3D Printing All You Need to Know 3Dnatives Abs 3D Printing Material Properties It’s used to create plastic parts that have to be. Abs is a terpolymer made by polymerizing styrene and acrylonitrile in the presence of polybutadiene. Abs (acrylonitrile butadiene styrene) has a long history in the 3d printing world. Abs is an ideal material for structural applications where impact resistance, strength, and. Abs, which stands for acrylonitrile butadiene styrene, is one. Abs 3D Printing Material Properties.

From www.amtekcompany.com

New Material for Stratasys Fortus 380mc and 450mc Machines Abs 3D Printing Material Properties Abs, which stands for acrylonitrile butadiene styrene, is one of the most commonly used 3d printing filaments. Abs is an ideal material for structural applications where impact resistance, strength, and. The general composition is 20% acrylonitrile, 25% butadiene and 55% styrene. Many years later, abs is still a. The proportions can vary from 15% to 35%. Abs is a polymer. Abs 3D Printing Material Properties.

From 3dprintingindustry.com

Greek researchers determine the effect of recycling on ABS filament Abs 3D Printing Material Properties Abs, which stands for acrylonitrile butadiene styrene, is one of the most commonly used 3d printing filaments. Abs (acrylonitrile butadiene styrene) has a long history in the 3d printing world. It’s used to create plastic parts that have to be. This material was one of the first plastics to be used with industrial 3d printers. The general composition is 20%. Abs 3D Printing Material Properties.

From www.xometry.com

All About ABS 3D Printing Filament Materials, Properties, Definition Abs 3D Printing Material Properties Abs (acrylonitrile butadiene styrene) has a long history in the 3d printing world. Abs is an ideal material for structural applications where impact resistance, strength, and. This material was one of the first plastics to be used with industrial 3d printers. It is opaque, offers smooth and matte surfaces and can be treated with acetone to make it shiny. Abs,. Abs 3D Printing Material Properties.

From www.filamentive.com

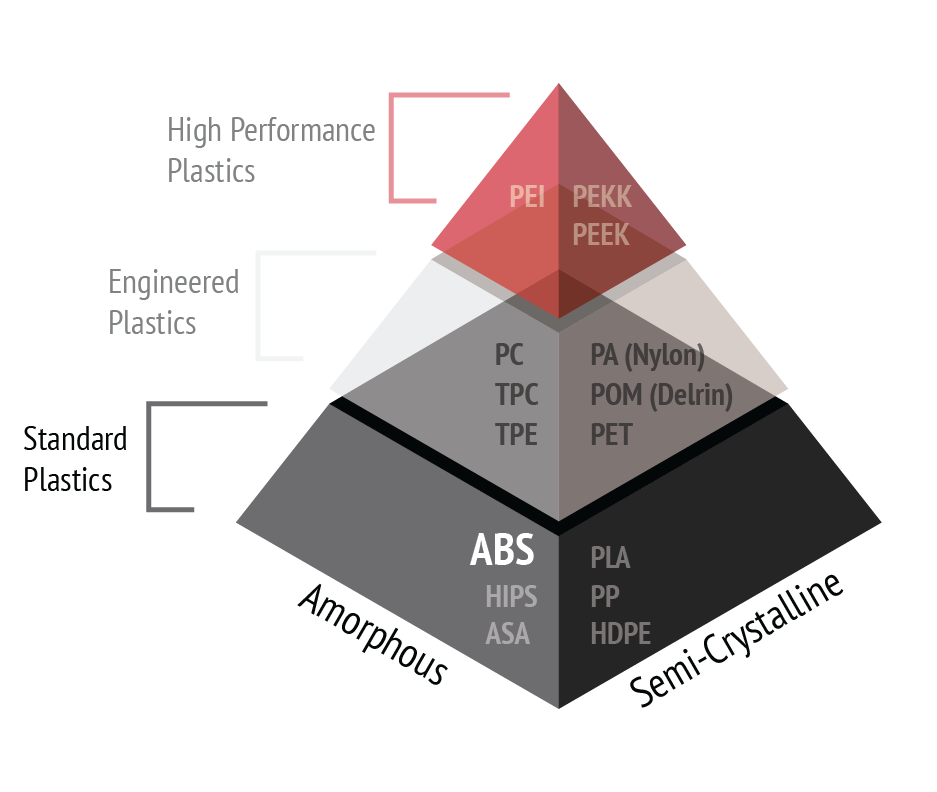

PEEK vs PEKK vs PPSU vs Ultem 3D Printing Filament Abs 3D Printing Material Properties Abs is a polymer of acrylonitrile and styrene in the presence of polybutadiene. Abs is a low cost engineering plastic that is easy to machine and 3d print. It’s used to create plastic parts that have to be. The general composition is 20% acrylonitrile, 25% butadiene and 55% styrene. Explore everything you need to know about abs 3d printing filament. Abs 3D Printing Material Properties.

From www.ibsproduces.com

FDM 3D Printing materials compared Blog IBS Print Abs 3D Printing Material Properties By altering the composition of these compounds, the properties of abs can be modified to improve its toughness, heat and impact resistance. This material was one of the first plastics to be used with industrial 3d printers. Many years later, abs is still a. The general composition is 20% acrylonitrile, 25% butadiene and 55% styrene. It’s used to create plastic. Abs 3D Printing Material Properties.

From www.geeetech.com

ABS vs PLA Everything You Need To Know About The Two Most Popular 3D Abs 3D Printing Material Properties Many years later, abs is still a. It is opaque, offers smooth and matte surfaces and can be treated with acetone to make it shiny. By altering the composition of these compounds, the properties of abs can be modified to improve its toughness, heat and impact resistance. Abs is an ideal material for structural applications where impact resistance, strength, and.. Abs 3D Printing Material Properties.

From www.obico.io

3D Printing ABS All You Need To Know Obico Knowledge Base Abs 3D Printing Material Properties Abs (acrylonitrile butadiene styrene) has a long history in the 3d printing world. This material was one of the first plastics to be used with industrial 3d printers. Abs is a terpolymer made by polymerizing styrene and acrylonitrile in the presence of polybutadiene. It is opaque, offers smooth and matte surfaces and can be treated with acetone to make it. Abs 3D Printing Material Properties.

From e-make.co

Application of ABS material in 3D printing Emake Abs 3D Printing Material Properties It is opaque, offers smooth and matte surfaces and can be treated with acetone to make it shiny. Abs is a low cost engineering plastic that is easy to machine and 3d print. Abs (acrylonitrile butadiene styrene) has a long history in the 3d printing world. Abs, which stands for acrylonitrile butadiene styrene, is one of the most commonly used. Abs 3D Printing Material Properties.

From www.zmorph3d.com

ABS 3D Printing Materials Overview Zmorph S.A. Abs 3D Printing Material Properties Explore everything you need to know about abs 3d printing filament with bambu lab's comprehensive guide. The general composition is 20% acrylonitrile, 25% butadiene and 55% styrene. It’s used to create plastic parts that have to be. Abs (acrylonitrile butadiene styrene) has a long history in the 3d printing world. Abs is a terpolymer made by polymerizing styrene and acrylonitrile. Abs 3D Printing Material Properties.

From 3dscanexpert.com

PLA vs ABS which 3D printing material should you use? 3D Scan Expert Abs 3D Printing Material Properties The proportions can vary from 15% to 35%. Abs is a polymer of acrylonitrile and styrene in the presence of polybutadiene. The general composition is 20% acrylonitrile, 25% butadiene and 55% styrene. Explore everything you need to know about abs 3d printing filament with bambu lab's comprehensive guide. By altering the composition of these compounds, the properties of abs can. Abs 3D Printing Material Properties.