Shaping Machine Calculation . Find the machining time required for machining the surface 600 × 800 mm, on a shaping machine. Read more about shaper operation: Shaper machine is a production machine in which the single point cutting tools are attached and the workpiece is fixed and while moving forward the tool cuts the workpiece and in return, there is no cut on the workpiece and used for producing flat and angular surfaces. Various gear shaping processes are listed and then described below : In this process gear tooth are accurately sized and shaped by cutting them by a multipoint cutting tool. Mathematical model for the mechanism was compiled and computer. It is used to remove material, usually metals such as steel or aluminium, to produce a flat surface. Assume, cutting speed as 8 m/min. Operation performed on shaping machine or shaper. In setting up a mechanically operated shaper, the length of cut (in inches) is known, and the cutting speed (in feet per minute) is selected according to the kind of metal being cut. (a) gear cutting by gear shaper. It is then necessary to compute the strokes per minute since that is how the shaper speed is controlled. Gear shaping is one of the gear generating methods. Dynamic analysis of a shaping machine mechanism. Such calculations are beyond the scope of this text.

from www.linquip.com

Assume, cutting speed as 8 m/min. It is used to remove material, usually metals such as steel or aluminium, to produce a flat surface. Dynamic analysis of a shaping machine mechanism. Operation performed on shaping machine or shaper. In this process gear tooth are accurately sized and shaped by cutting them by a multipoint cutting tool. Shaper machine is a production machine in which the single point cutting tools are attached and the workpiece is fixed and while moving forward the tool cuts the workpiece and in return, there is no cut on the workpiece and used for producing flat and angular surfaces. Various gear shaping processes are listed and then described below : (a) gear cutting by gear shaper. Gear shaping is one of the gear generating methods. Read more about shaper operation:

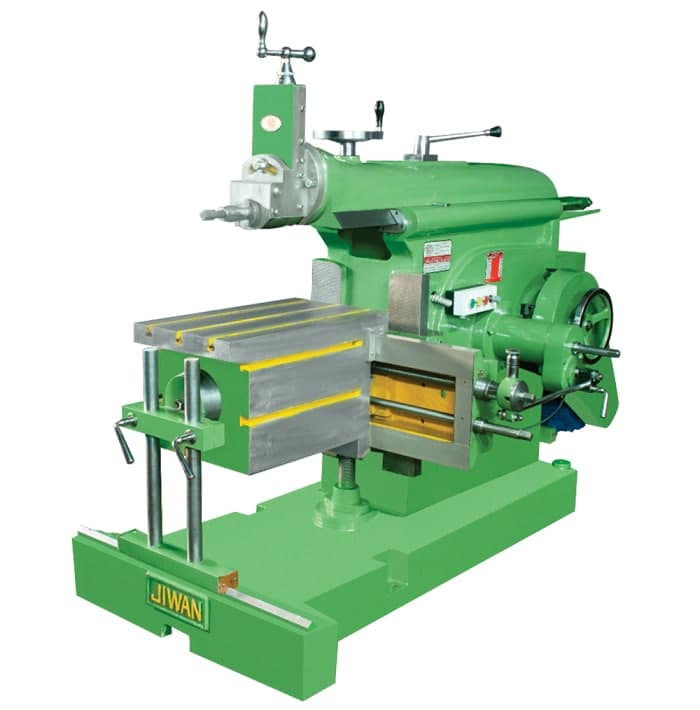

Shaper Machine A Full Explanatory Guide for Buyers Linquip

Shaping Machine Calculation Operation performed on shaping machine or shaper. Assume, cutting speed as 8 m/min. Find the machining time required for machining the surface 600 × 800 mm, on a shaping machine. It is then necessary to compute the strokes per minute since that is how the shaper speed is controlled. In this process gear tooth are accurately sized and shaped by cutting them by a multipoint cutting tool. Read more about shaper operation: Various gear shaping processes are listed and then described below : Shaper machine is a production machine in which the single point cutting tools are attached and the workpiece is fixed and while moving forward the tool cuts the workpiece and in return, there is no cut on the workpiece and used for producing flat and angular surfaces. Gear shaping is one of the gear generating methods. In setting up a mechanically operated shaper, the length of cut (in inches) is known, and the cutting speed (in feet per minute) is selected according to the kind of metal being cut. It is used to remove material, usually metals such as steel or aluminium, to produce a flat surface. Operation performed on shaping machine or shaper. Such calculations are beyond the scope of this text. Dynamic analysis of a shaping machine mechanism. Mathematical model for the mechanism was compiled and computer. (a) gear cutting by gear shaper.

From themechanicalengineering.com

Shaper Machine Definition, Parts, Working, Types, Operation Shaping Machine Calculation Find the machining time required for machining the surface 600 × 800 mm, on a shaping machine. The shaping machine is a simple and yet extremely effective machine. Read more about shaper operation: Shaper machine is a production machine in which the single point cutting tools are attached and the workpiece is fixed and while moving forward the tool cuts. Shaping Machine Calculation.

From learnmech.com

Shaper Machine Types, Parts, Working, Operations, Diagram Shaping Machine Calculation Assume, cutting speed as 8 m/min. In setting up a mechanically operated shaper, the length of cut (in inches) is known, and the cutting speed (in feet per minute) is selected according to the kind of metal being cut. Find the machining time required for machining the surface 600 × 800 mm, on a shaping machine. Various gear shaping processes. Shaping Machine Calculation.

From www.youtube.com

hydraulic shaper machineworking of hydraulic shaper machine Shaping Machine Calculation It is then necessary to compute the strokes per minute since that is how the shaper speed is controlled. In this process gear tooth are accurately sized and shaped by cutting them by a multipoint cutting tool. Various gear shaping processes are listed and then described below : In setting up a mechanically operated shaper, the length of cut (in. Shaping Machine Calculation.

From www.youtube.com

Machining Parameters and Machining time calculation in Shaping Shaping Machine Calculation In this process gear tooth are accurately sized and shaped by cutting them by a multipoint cutting tool. (a) gear cutting by gear shaper. It is used to remove material, usually metals such as steel or aluminium, to produce a flat surface. Shaper machine is a production machine in which the single point cutting tools are attached and the workpiece. Shaping Machine Calculation.

From www.researchgate.net

Shaping Operation B.1. Linkage of Shaper The cutting stroke takes more Shaping Machine Calculation The shaping machine is a simple and yet extremely effective machine. Dynamic analysis of a shaping machine mechanism. In this process gear tooth are accurately sized and shaped by cutting them by a multipoint cutting tool. Find the machining time required for machining the surface 600 × 800 mm, on a shaping machine. Operation performed on shaping machine or shaper.. Shaping Machine Calculation.

From www.youtube.com

6 Different Types of Shaper Machine Operations TheEngineersPost YouTube Shaping Machine Calculation Dynamic analysis of a shaping machine mechanism. Read more about shaper operation: The shaping machine is a simple and yet extremely effective machine. In this process gear tooth are accurately sized and shaped by cutting them by a multipoint cutting tool. Various gear shaping processes are listed and then described below : (a) gear cutting by gear shaper. Such calculations. Shaping Machine Calculation.

From gateformulame.blogspot.com

GATE FORMULA MECHANICAL Lathe & Shaper Formulas Shaping Machine Calculation The shaping machine is a simple and yet extremely effective machine. It is used to remove material, usually metals such as steel or aluminium, to produce a flat surface. Various gear shaping processes are listed and then described below : In setting up a mechanically operated shaper, the length of cut (in inches) is known, and the cutting speed (in. Shaping Machine Calculation.

From pathakmachines.com

Shaper Machine Working Principle, Different Types, Operations, And Shaping Machine Calculation In this process gear tooth are accurately sized and shaped by cutting them by a multipoint cutting tool. Such calculations are beyond the scope of this text. Mathematical model for the mechanism was compiled and computer. It is used to remove material, usually metals such as steel or aluminium, to produce a flat surface. In setting up a mechanically operated. Shaping Machine Calculation.

From guidebytips.com

Shaper Machine Different Types of Shaper Machine [A Detailed Guide] Shaping Machine Calculation Various gear shaping processes are listed and then described below : Gear shaping is one of the gear generating methods. Find the machining time required for machining the surface 600 × 800 mm, on a shaping machine. Mathematical model for the mechanism was compiled and computer. In this process gear tooth are accurately sized and shaped by cutting them by. Shaping Machine Calculation.

From www.theengineerspost.com

6 Different Types of Shaper Machine Operations [Images & PDF] Shaping Machine Calculation In setting up a mechanically operated shaper, the length of cut (in inches) is known, and the cutting speed (in feet per minute) is selected according to the kind of metal being cut. Find the machining time required for machining the surface 600 × 800 mm, on a shaping machine. Assume, cutting speed as 8 m/min. Read more about shaper. Shaping Machine Calculation.

From www.theengineerspost.com

Shaper Machine Types, Parts, Working Principle & Uses [PDF] Shaping Machine Calculation Dynamic analysis of a shaping machine mechanism. Gear shaping is one of the gear generating methods. It is used to remove material, usually metals such as steel or aluminium, to produce a flat surface. The shaping machine is a simple and yet extremely effective machine. Various gear shaping processes are listed and then described below : Mathematical model for the. Shaping Machine Calculation.

From excelmachinetools.co.uk

ESM350 Hydraulic Horizontal Shaper Machine (415v 3Ph) Excel Machine Tools Shaping Machine Calculation Such calculations are beyond the scope of this text. It is used to remove material, usually metals such as steel or aluminium, to produce a flat surface. In this process gear tooth are accurately sized and shaped by cutting them by a multipoint cutting tool. Mathematical model for the mechanism was compiled and computer. (a) gear cutting by gear shaper.. Shaping Machine Calculation.

From www.chegg.com

Solved 2) 33 points) The shaping machine shown below is a Shaping Machine Calculation The shaping machine is a simple and yet extremely effective machine. In setting up a mechanically operated shaper, the length of cut (in inches) is known, and the cutting speed (in feet per minute) is selected according to the kind of metal being cut. Such calculations are beyond the scope of this text. Gear shaping is one of the gear. Shaping Machine Calculation.

From keryengineering.weebly.com

keryengineering Blog Shaping Machine Calculation In setting up a mechanically operated shaper, the length of cut (in inches) is known, and the cutting speed (in feet per minute) is selected according to the kind of metal being cut. Operation performed on shaping machine or shaper. Shaper machine is a production machine in which the single point cutting tools are attached and the workpiece is fixed. Shaping Machine Calculation.

From www.youtube.com

Full Tutorial of Tool Head of Shaping Machine in solidworks with all Shaping Machine Calculation The shaping machine is a simple and yet extremely effective machine. In setting up a mechanically operated shaper, the length of cut (in inches) is known, and the cutting speed (in feet per minute) is selected according to the kind of metal being cut. Dynamic analysis of a shaping machine mechanism. Operation performed on shaping machine or shaper. Shaper machine. Shaping Machine Calculation.

From www.slideshare.net

Both side Shaper machine with calculation.pptx Shaping Machine Calculation Mathematical model for the mechanism was compiled and computer. Operation performed on shaping machine or shaper. Dynamic analysis of a shaping machine mechanism. It is then necessary to compute the strokes per minute since that is how the shaper speed is controlled. Find the machining time required for machining the surface 600 × 800 mm, on a shaping machine. In. Shaping Machine Calculation.

From technologystudent.com

The Shaping Machine Shaping Machine Calculation (a) gear cutting by gear shaper. In this process gear tooth are accurately sized and shaped by cutting them by a multipoint cutting tool. Shaper machine is a production machine in which the single point cutting tools are attached and the workpiece is fixed and while moving forward the tool cuts the workpiece and in return, there is no cut. Shaping Machine Calculation.

From technologystudent.com

The Shaping Machine Shaping Machine Calculation It is used to remove material, usually metals such as steel or aluminium, to produce a flat surface. Dynamic analysis of a shaping machine mechanism. Gear shaping is one of the gear generating methods. Various gear shaping processes are listed and then described below : Read more about shaper operation: Assume, cutting speed as 8 m/min. Find the machining time. Shaping Machine Calculation.

From www.youtube.com

Shaper Machine Machining Time Calculation Deduce the formula of Shaping Machine Calculation The shaping machine is a simple and yet extremely effective machine. Find the machining time required for machining the surface 600 × 800 mm, on a shaping machine. It is used to remove material, usually metals such as steel or aluminium, to produce a flat surface. Gear shaping is one of the gear generating methods. It is then necessary to. Shaping Machine Calculation.

From www.indiamart.com

Shaping Machine, Capacity 12" / 18" / 24" / 30" / 36", ID 8105821648 Shaping Machine Calculation In this process gear tooth are accurately sized and shaped by cutting them by a multipoint cutting tool. In setting up a mechanically operated shaper, the length of cut (in inches) is known, and the cutting speed (in feet per minute) is selected according to the kind of metal being cut. It is used to remove material, usually metals such. Shaping Machine Calculation.

From learnmech.com

Shaper Machine Types, Parts, Working, Operations, Diagram Shaping Machine Calculation It is used to remove material, usually metals such as steel or aluminium, to produce a flat surface. The shaping machine is a simple and yet extremely effective machine. Various gear shaping processes are listed and then described below : Find the machining time required for machining the surface 600 × 800 mm, on a shaping machine. In this process. Shaping Machine Calculation.

From www.semanticscholar.org

Figure 1 from CADBased Calculation of Cutting Force Components in Gear Shaping Machine Calculation In setting up a mechanically operated shaper, the length of cut (in inches) is known, and the cutting speed (in feet per minute) is selected according to the kind of metal being cut. Such calculations are beyond the scope of this text. Find the machining time required for machining the surface 600 × 800 mm, on a shaping machine. Assume,. Shaping Machine Calculation.

From www.youtube.com

Lathe Machining Time Calculation Example Simple Turning YouTube Shaping Machine Calculation Read more about shaper operation: Gear shaping is one of the gear generating methods. The shaping machine is a simple and yet extremely effective machine. It is used to remove material, usually metals such as steel or aluminium, to produce a flat surface. Various gear shaping processes are listed and then described below : Shaper machine is a production machine. Shaping Machine Calculation.

From www.youtube.com

Shaping machine operation YouTube Shaping Machine Calculation In setting up a mechanically operated shaper, the length of cut (in inches) is known, and the cutting speed (in feet per minute) is selected according to the kind of metal being cut. Mathematical model for the mechanism was compiled and computer. In this process gear tooth are accurately sized and shaped by cutting them by a multipoint cutting tool.. Shaping Machine Calculation.

From dizz.com

Shaper Machine Working, Parts, Types, and Operations (With PDF) Shaping Machine Calculation In this process gear tooth are accurately sized and shaped by cutting them by a multipoint cutting tool. (a) gear cutting by gear shaper. Dynamic analysis of a shaping machine mechanism. Gear shaping is one of the gear generating methods. The shaping machine is a simple and yet extremely effective machine. It is used to remove material, usually metals such. Shaping Machine Calculation.

From www.linquip.com

Shaper Machine A Full Explanatory Guide for Buyers Linquip Shaping Machine Calculation Read more about shaper operation: It is then necessary to compute the strokes per minute since that is how the shaper speed is controlled. Shaper machine is a production machine in which the single point cutting tools are attached and the workpiece is fixed and while moving forward the tool cuts the workpiece and in return, there is no cut. Shaping Machine Calculation.

From study4engineers.blogspot.com

STUDY4ENGINEERS Quick return Mechanism of Shaper Shaping Machine Calculation In setting up a mechanically operated shaper, the length of cut (in inches) is known, and the cutting speed (in feet per minute) is selected according to the kind of metal being cut. Such calculations are beyond the scope of this text. In this process gear tooth are accurately sized and shaped by cutting them by a multipoint cutting tool.. Shaping Machine Calculation.

From www.theengineerspost.com

Shaper Machine Types, Parts, Working Principle & Uses [PDF] Shaping Machine Calculation Find the machining time required for machining the surface 600 × 800 mm, on a shaping machine. Shaper machine is a production machine in which the single point cutting tools are attached and the workpiece is fixed and while moving forward the tool cuts the workpiece and in return, there is no cut on the workpiece and used for producing. Shaping Machine Calculation.

From www.studocu.com

Shaping Machine CME 18 notes SHAPING MACHINE Shaper is a Shaping Machine Calculation It is used to remove material, usually metals such as steel or aluminium, to produce a flat surface. Assume, cutting speed as 8 m/min. Shaper machine is a production machine in which the single point cutting tools are attached and the workpiece is fixed and while moving forward the tool cuts the workpiece and in return, there is no cut. Shaping Machine Calculation.

From engineeringlearn.com

Shaper Machine Types and Operation [with Pictures & Complete Details Shaping Machine Calculation Such calculations are beyond the scope of this text. In this process gear tooth are accurately sized and shaped by cutting them by a multipoint cutting tool. (a) gear cutting by gear shaper. Assume, cutting speed as 8 m/min. It is then necessary to compute the strokes per minute since that is how the shaper speed is controlled. Various gear. Shaping Machine Calculation.

From cncwmt.com

BC6050 Mechanical Shaping Machine Shaper Planer From WMTCNC Shaping Machine Calculation Operation performed on shaping machine or shaper. (a) gear cutting by gear shaper. The shaping machine is a simple and yet extremely effective machine. It is used to remove material, usually metals such as steel or aluminium, to produce a flat surface. It is then necessary to compute the strokes per minute since that is how the shaper speed is. Shaping Machine Calculation.

From www.youtube.com

THREAD CUTTING GEAR CALCULATION FORMULA ON LATHE M/C IN हिंदी YouTube Shaping Machine Calculation Such calculations are beyond the scope of this text. (a) gear cutting by gear shaper. Various gear shaping processes are listed and then described below : It is used to remove material, usually metals such as steel or aluminium, to produce a flat surface. Assume, cutting speed as 8 m/min. Find the machining time required for machining the surface 600. Shaping Machine Calculation.

From www.theengineerspost.com

Shaper Machine and 9 Different Types of Shaper Machines Shaping Machine Calculation Shaper machine is a production machine in which the single point cutting tools are attached and the workpiece is fixed and while moving forward the tool cuts the workpiece and in return, there is no cut on the workpiece and used for producing flat and angular surfaces. Such calculations are beyond the scope of this text. In this process gear. Shaping Machine Calculation.

From in.pinterest.com

Shaper Machine Definition, Parts, and Working Shaping Machine Calculation The shaping machine is a simple and yet extremely effective machine. (a) gear cutting by gear shaper. Various gear shaping processes are listed and then described below : In setting up a mechanically operated shaper, the length of cut (in inches) is known, and the cutting speed (in feet per minute) is selected according to the kind of metal being. Shaping Machine Calculation.

From learnmech.com

Shaper Machine Types, Parts, Working, Operations, Diagram Shaping Machine Calculation It is used to remove material, usually metals such as steel or aluminium, to produce a flat surface. It is then necessary to compute the strokes per minute since that is how the shaper speed is controlled. In this process gear tooth are accurately sized and shaped by cutting them by a multipoint cutting tool. Find the machining time required. Shaping Machine Calculation.