Nickel Plating Chemical Resistance . Nickel electroplating is a technique of electroplating a thin layer of nickel onto a metal object. The physical properties such as wear resistance, heat resistance or corrosion resistance. Usually, particles of silicon carbide. They are also resistant to carbon tetrachloride, oil, soaps and. With high resistance in a variety of environments, niplate electroless nickel plating provides superior solutions, especially with niplate. Enp offers excellent corrosion resistance to common corrodents such as salt water, carbon dioxide, oxygen and hydrogen sulphide. High phosphorus deposits of enp. In many important applications, the nickel coatings. Nickel coatings are resistant to dry gases, such as carbon dioxide, hydrogen, ammonia. The nickel layer can be decorative,.

from ponasa.condesan-ecoandes.org

The nickel layer can be decorative,. Usually, particles of silicon carbide. The physical properties such as wear resistance, heat resistance or corrosion resistance. They are also resistant to carbon tetrachloride, oil, soaps and. High phosphorus deposits of enp. Nickel coatings are resistant to dry gases, such as carbon dioxide, hydrogen, ammonia. In many important applications, the nickel coatings. Nickel electroplating is a technique of electroplating a thin layer of nickel onto a metal object. With high resistance in a variety of environments, niplate electroless nickel plating provides superior solutions, especially with niplate. Enp offers excellent corrosion resistance to common corrodents such as salt water, carbon dioxide, oxygen and hydrogen sulphide.

Electroless Nickel Corrosion Resistance Chart Ponasa

Nickel Plating Chemical Resistance High phosphorus deposits of enp. Nickel electroplating is a technique of electroplating a thin layer of nickel onto a metal object. Enp offers excellent corrosion resistance to common corrodents such as salt water, carbon dioxide, oxygen and hydrogen sulphide. In many important applications, the nickel coatings. Usually, particles of silicon carbide. With high resistance in a variety of environments, niplate electroless nickel plating provides superior solutions, especially with niplate. They are also resistant to carbon tetrachloride, oil, soaps and. High phosphorus deposits of enp. The physical properties such as wear resistance, heat resistance or corrosion resistance. Nickel coatings are resistant to dry gases, such as carbon dioxide, hydrogen, ammonia. The nickel layer can be decorative,.

From blog.thepipingmart.com

Nickel Plating Process An Overview Nickel Plating Chemical Resistance With high resistance in a variety of environments, niplate electroless nickel plating provides superior solutions, especially with niplate. Usually, particles of silicon carbide. They are also resistant to carbon tetrachloride, oil, soaps and. Nickel electroplating is a technique of electroplating a thin layer of nickel onto a metal object. Nickel coatings are resistant to dry gases, such as carbon dioxide,. Nickel Plating Chemical Resistance.

From eureka.patsnap.com

Chemical nickel plating liquid and preparation method Eureka Nickel Plating Chemical Resistance High phosphorus deposits of enp. The physical properties such as wear resistance, heat resistance or corrosion resistance. Nickel coatings are resistant to dry gases, such as carbon dioxide, hydrogen, ammonia. Usually, particles of silicon carbide. Nickel electroplating is a technique of electroplating a thin layer of nickel onto a metal object. With high resistance in a variety of environments, niplate. Nickel Plating Chemical Resistance.

From www.plating-chemistry.com

Micro Crack Nickel Process Nickel Plating Chemicals High Corrosion Nickel Plating Chemical Resistance Enp offers excellent corrosion resistance to common corrodents such as salt water, carbon dioxide, oxygen and hydrogen sulphide. The nickel layer can be decorative,. With high resistance in a variety of environments, niplate electroless nickel plating provides superior solutions, especially with niplate. Nickel coatings are resistant to dry gases, such as carbon dioxide, hydrogen, ammonia. They are also resistant to. Nickel Plating Chemical Resistance.

From www.scribd.com

Zinc & Nickelchrome Plating Specifications Zinc Metallic Elements Nickel Plating Chemical Resistance Nickel coatings are resistant to dry gases, such as carbon dioxide, hydrogen, ammonia. With high resistance in a variety of environments, niplate electroless nickel plating provides superior solutions, especially with niplate. The nickel layer can be decorative,. High phosphorus deposits of enp. They are also resistant to carbon tetrachloride, oil, soaps and. In many important applications, the nickel coatings. Enp. Nickel Plating Chemical Resistance.

From cbeplus.com

THE DEFINITIVE GUIDE TO ELECTROLESS NICKEL PLATING MultiDisciplinary Nickel Plating Chemical Resistance With high resistance in a variety of environments, niplate electroless nickel plating provides superior solutions, especially with niplate. The nickel layer can be decorative,. Enp offers excellent corrosion resistance to common corrodents such as salt water, carbon dioxide, oxygen and hydrogen sulphide. In many important applications, the nickel coatings. Nickel coatings are resistant to dry gases, such as carbon dioxide,. Nickel Plating Chemical Resistance.

From cmcnickelplating.com

Electroless Nickel Plating Chemical Reduction Coating Process Nickel Plating Chemical Resistance In many important applications, the nickel coatings. They are also resistant to carbon tetrachloride, oil, soaps and. With high resistance in a variety of environments, niplate electroless nickel plating provides superior solutions, especially with niplate. High phosphorus deposits of enp. Usually, particles of silicon carbide. Nickel electroplating is a technique of electroplating a thin layer of nickel onto a metal. Nickel Plating Chemical Resistance.

From www.macrodevelopments.co.uk

Electroless Nickel Plating in Hampshire with a nationwide UK coverage. Nickel Plating Chemical Resistance Enp offers excellent corrosion resistance to common corrodents such as salt water, carbon dioxide, oxygen and hydrogen sulphide. They are also resistant to carbon tetrachloride, oil, soaps and. The nickel layer can be decorative,. With high resistance in a variety of environments, niplate electroless nickel plating provides superior solutions, especially with niplate. Nickel electroplating is a technique of electroplating a. Nickel Plating Chemical Resistance.

From www.youtube.com

How to Nickel Electroplate at Home bittech Modding YouTube Nickel Plating Chemical Resistance With high resistance in a variety of environments, niplate electroless nickel plating provides superior solutions, especially with niplate. In many important applications, the nickel coatings. They are also resistant to carbon tetrachloride, oil, soaps and. The physical properties such as wear resistance, heat resistance or corrosion resistance. The nickel layer can be decorative,. Nickel electroplating is a technique of electroplating. Nickel Plating Chemical Resistance.

From ponasa.condesan-ecoandes.org

Electroless Nickel Corrosion Resistance Chart Ponasa Nickel Plating Chemical Resistance In many important applications, the nickel coatings. Nickel coatings are resistant to dry gases, such as carbon dioxide, hydrogen, ammonia. Usually, particles of silicon carbide. High phosphorus deposits of enp. Nickel electroplating is a technique of electroplating a thin layer of nickel onto a metal object. Enp offers excellent corrosion resistance to common corrodents such as salt water, carbon dioxide,. Nickel Plating Chemical Resistance.

From www.machinemfg.com

Nickel Electroplating vs. Chemical Nickel Plating A Detailed Nickel Plating Chemical Resistance High phosphorus deposits of enp. Nickel electroplating is a technique of electroplating a thin layer of nickel onto a metal object. The nickel layer can be decorative,. Nickel coatings are resistant to dry gases, such as carbon dioxide, hydrogen, ammonia. The physical properties such as wear resistance, heat resistance or corrosion resistance. Enp offers excellent corrosion resistance to common corrodents. Nickel Plating Chemical Resistance.

From advancedplatingtech.com

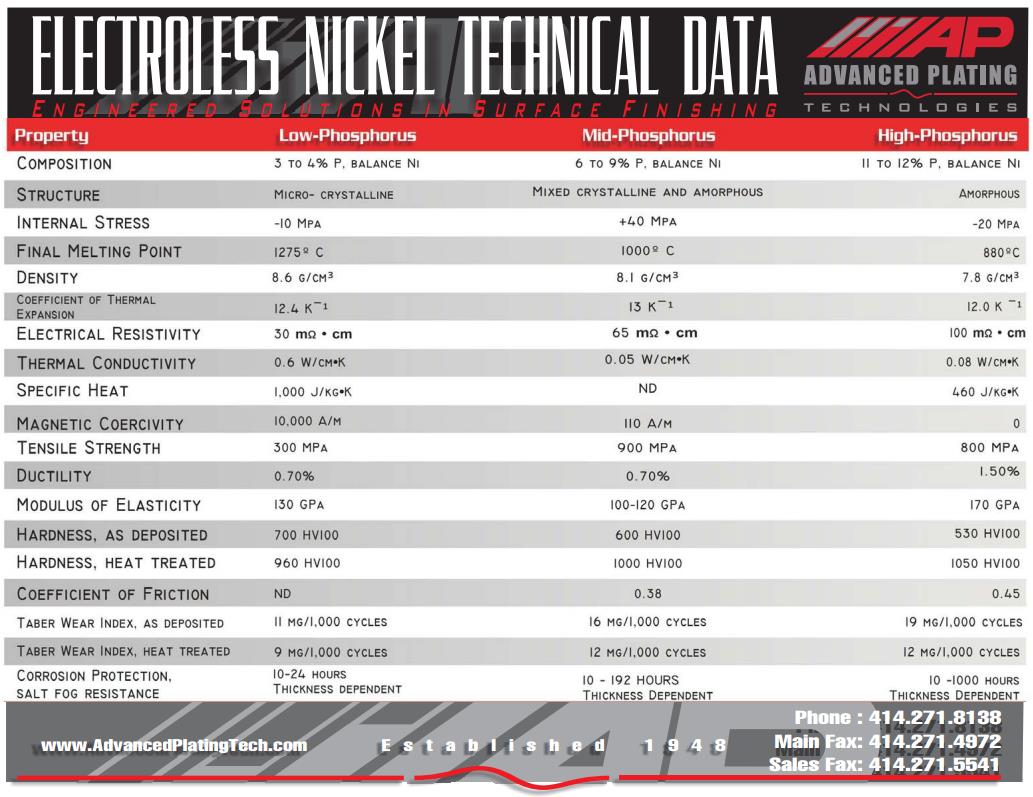

Electroless Nickel Plating MILC26074, ASTM B733 and AMS 2404 Nickel Plating Chemical Resistance The physical properties such as wear resistance, heat resistance or corrosion resistance. Usually, particles of silicon carbide. With high resistance in a variety of environments, niplate electroless nickel plating provides superior solutions, especially with niplate. In many important applications, the nickel coatings. High phosphorus deposits of enp. Nickel coatings are resistant to dry gases, such as carbon dioxide, hydrogen, ammonia.. Nickel Plating Chemical Resistance.

From blog.thepipingmart.com

DIY Nickel Electroplating An Overview Nickel Plating Chemical Resistance The physical properties such as wear resistance, heat resistance or corrosion resistance. Usually, particles of silicon carbide. The nickel layer can be decorative,. They are also resistant to carbon tetrachloride, oil, soaps and. Nickel electroplating is a technique of electroplating a thin layer of nickel onto a metal object. In many important applications, the nickel coatings. With high resistance in. Nickel Plating Chemical Resistance.

From www.dorsetware.com

Types of Nickel Plating and Its Benefits Dorsetware Nickel Plating Chemical Resistance High phosphorus deposits of enp. With high resistance in a variety of environments, niplate electroless nickel plating provides superior solutions, especially with niplate. The physical properties such as wear resistance, heat resistance or corrosion resistance. In many important applications, the nickel coatings. Nickel electroplating is a technique of electroplating a thin layer of nickel onto a metal object. They are. Nickel Plating Chemical Resistance.

From www.iqsdirectory.com

Electroless Nickel Plating Variations, Types, Applications, and Benefits Nickel Plating Chemical Resistance They are also resistant to carbon tetrachloride, oil, soaps and. Nickel coatings are resistant to dry gases, such as carbon dioxide, hydrogen, ammonia. Usually, particles of silicon carbide. High phosphorus deposits of enp. In many important applications, the nickel coatings. The nickel layer can be decorative,. With high resistance in a variety of environments, niplate electroless nickel plating provides superior. Nickel Plating Chemical Resistance.

From www.valencesurfacetech.com

Anodizing Vs. Plating Key Differences And Similarities Nickel Plating Chemical Resistance With high resistance in a variety of environments, niplate electroless nickel plating provides superior solutions, especially with niplate. The physical properties such as wear resistance, heat resistance or corrosion resistance. Enp offers excellent corrosion resistance to common corrodents such as salt water, carbon dioxide, oxygen and hydrogen sulphide. High phosphorus deposits of enp. The nickel layer can be decorative,. Nickel. Nickel Plating Chemical Resistance.

From www.researchgate.net

Surface microstructures of electroless nickel plating, showing Nickel Plating Chemical Resistance The nickel layer can be decorative,. With high resistance in a variety of environments, niplate electroless nickel plating provides superior solutions, especially with niplate. High phosphorus deposits of enp. Usually, particles of silicon carbide. Nickel electroplating is a technique of electroplating a thin layer of nickel onto a metal object. The physical properties such as wear resistance, heat resistance or. Nickel Plating Chemical Resistance.

From www.instructables.com

High Quality (and Safe) Nickel Plating 7 Steps (with Pictures Nickel Plating Chemical Resistance The physical properties such as wear resistance, heat resistance or corrosion resistance. In many important applications, the nickel coatings. The nickel layer can be decorative,. High phosphorus deposits of enp. Nickel coatings are resistant to dry gases, such as carbon dioxide, hydrogen, ammonia. They are also resistant to carbon tetrachloride, oil, soaps and. Usually, particles of silicon carbide. Enp offers. Nickel Plating Chemical Resistance.

From www.atc-treatment.com

Electroless Nickel Plating ATC 1Stop Solution Provider for Quality Nickel Plating Chemical Resistance High phosphorus deposits of enp. The physical properties such as wear resistance, heat resistance or corrosion resistance. Nickel electroplating is a technique of electroplating a thin layer of nickel onto a metal object. The nickel layer can be decorative,. With high resistance in a variety of environments, niplate electroless nickel plating provides superior solutions, especially with niplate. Nickel coatings are. Nickel Plating Chemical Resistance.

From blog.thepipingmart.com

Electroless Nickel Plating on Steel A Complete Guide Nickel Plating Chemical Resistance Nickel electroplating is a technique of electroplating a thin layer of nickel onto a metal object. Usually, particles of silicon carbide. Nickel coatings are resistant to dry gases, such as carbon dioxide, hydrogen, ammonia. Enp offers excellent corrosion resistance to common corrodents such as salt water, carbon dioxide, oxygen and hydrogen sulphide. In many important applications, the nickel coatings. They. Nickel Plating Chemical Resistance.

From www.researchgate.net

Schematic diagram of the electroless nickel plating procedure Nickel Plating Chemical Resistance Usually, particles of silicon carbide. High phosphorus deposits of enp. They are also resistant to carbon tetrachloride, oil, soaps and. Enp offers excellent corrosion resistance to common corrodents such as salt water, carbon dioxide, oxygen and hydrogen sulphide. The nickel layer can be decorative,. In many important applications, the nickel coatings. Nickel electroplating is a technique of electroplating a thin. Nickel Plating Chemical Resistance.

From www.slideserve.com

PPT Black Nickel Plating for Corrosion Resistance PowerPoint Nickel Plating Chemical Resistance The physical properties such as wear resistance, heat resistance or corrosion resistance. Nickel electroplating is a technique of electroplating a thin layer of nickel onto a metal object. Nickel coatings are resistant to dry gases, such as carbon dioxide, hydrogen, ammonia. Enp offers excellent corrosion resistance to common corrodents such as salt water, carbon dioxide, oxygen and hydrogen sulphide. They. Nickel Plating Chemical Resistance.

From www.zprecis.cz

Chemical nickel plating ZPRECIS s.r.o. Nickel Plating Chemical Resistance The physical properties such as wear resistance, heat resistance or corrosion resistance. High phosphorus deposits of enp. In many important applications, the nickel coatings. The nickel layer can be decorative,. Nickel coatings are resistant to dry gases, such as carbon dioxide, hydrogen, ammonia. They are also resistant to carbon tetrachloride, oil, soaps and. Enp offers excellent corrosion resistance to common. Nickel Plating Chemical Resistance.

From www.electro-coatings.com

Electroless Plating Process ElectroCoating Nickel Plating Chemical Resistance Nickel coatings are resistant to dry gases, such as carbon dioxide, hydrogen, ammonia. The physical properties such as wear resistance, heat resistance or corrosion resistance. They are also resistant to carbon tetrachloride, oil, soaps and. Nickel electroplating is a technique of electroplating a thin layer of nickel onto a metal object. With high resistance in a variety of environments, niplate. Nickel Plating Chemical Resistance.

From www.beyonddiscovery.org

Nickel Plating Corrosion Resistance Beyond Discovery Nickel Plating Chemical Resistance Nickel coatings are resistant to dry gases, such as carbon dioxide, hydrogen, ammonia. Nickel electroplating is a technique of electroplating a thin layer of nickel onto a metal object. The physical properties such as wear resistance, heat resistance or corrosion resistance. High phosphorus deposits of enp. In many important applications, the nickel coatings. They are also resistant to carbon tetrachloride,. Nickel Plating Chemical Resistance.

From www.diecasting-mould.com

Chrome Plating vs Nickel Plating What’s the Difference Between Chrome Nickel Plating Chemical Resistance Usually, particles of silicon carbide. Nickel coatings are resistant to dry gases, such as carbon dioxide, hydrogen, ammonia. The nickel layer can be decorative,. They are also resistant to carbon tetrachloride, oil, soaps and. With high resistance in a variety of environments, niplate electroless nickel plating provides superior solutions, especially with niplate. Enp offers excellent corrosion resistance to common corrodents. Nickel Plating Chemical Resistance.

From www.mdpi.com

Free FullText Finishing of Nickel Plating Chemical Resistance Nickel coatings are resistant to dry gases, such as carbon dioxide, hydrogen, ammonia. In many important applications, the nickel coatings. Nickel electroplating is a technique of electroplating a thin layer of nickel onto a metal object. With high resistance in a variety of environments, niplate electroless nickel plating provides superior solutions, especially with niplate. They are also resistant to carbon. Nickel Plating Chemical Resistance.

From www.electro-coatings.com

Electroless Nickel Plating Services ElectroCoating Nickel Plating Chemical Resistance The nickel layer can be decorative,. Nickel coatings are resistant to dry gases, such as carbon dioxide, hydrogen, ammonia. The physical properties such as wear resistance, heat resistance or corrosion resistance. Enp offers excellent corrosion resistance to common corrodents such as salt water, carbon dioxide, oxygen and hydrogen sulphide. Nickel electroplating is a technique of electroplating a thin layer of. Nickel Plating Chemical Resistance.

From www.iqsdirectory.com

Electroless Nickel Plating Variations, Types, Applications, and Benefits Nickel Plating Chemical Resistance The physical properties such as wear resistance, heat resistance or corrosion resistance. With high resistance in a variety of environments, niplate electroless nickel plating provides superior solutions, especially with niplate. Usually, particles of silicon carbide. They are also resistant to carbon tetrachloride, oil, soaps and. The nickel layer can be decorative,. Enp offers excellent corrosion resistance to common corrodents such. Nickel Plating Chemical Resistance.

From www.qualitymag.com

The Electroless Nickel Plating Process and Its Importance 20150901 Nickel Plating Chemical Resistance Nickel coatings are resistant to dry gases, such as carbon dioxide, hydrogen, ammonia. Nickel electroplating is a technique of electroplating a thin layer of nickel onto a metal object. They are also resistant to carbon tetrachloride, oil, soaps and. Usually, particles of silicon carbide. In many important applications, the nickel coatings. With high resistance in a variety of environments, niplate. Nickel Plating Chemical Resistance.

From www.iqsdirectory.com

Electroless Nickel Plating Variations, Types, Applications, and Benefits Nickel Plating Chemical Resistance The physical properties such as wear resistance, heat resistance or corrosion resistance. In many important applications, the nickel coatings. Enp offers excellent corrosion resistance to common corrodents such as salt water, carbon dioxide, oxygen and hydrogen sulphide. They are also resistant to carbon tetrachloride, oil, soaps and. Nickel coatings are resistant to dry gases, such as carbon dioxide, hydrogen, ammonia.. Nickel Plating Chemical Resistance.

From blog.thepipingmart.com

Brush Nickel Plating Process An Brief Overview Nickel Plating Chemical Resistance High phosphorus deposits of enp. Nickel electroplating is a technique of electroplating a thin layer of nickel onto a metal object. Enp offers excellent corrosion resistance to common corrodents such as salt water, carbon dioxide, oxygen and hydrogen sulphide. The nickel layer can be decorative,. They are also resistant to carbon tetrachloride, oil, soaps and. In many important applications, the. Nickel Plating Chemical Resistance.

From www.hubs.com

Electroless nickel plating Surface finishing services Hubs Nickel Plating Chemical Resistance They are also resistant to carbon tetrachloride, oil, soaps and. Usually, particles of silicon carbide. With high resistance in a variety of environments, niplate electroless nickel plating provides superior solutions, especially with niplate. In many important applications, the nickel coatings. The nickel layer can be decorative,. Nickel coatings are resistant to dry gases, such as carbon dioxide, hydrogen, ammonia. Nickel. Nickel Plating Chemical Resistance.

From www.pfonline.com

An Overview of Electroless Nickel Plating Products Finishing Nickel Plating Chemical Resistance High phosphorus deposits of enp. They are also resistant to carbon tetrachloride, oil, soaps and. Nickel coatings are resistant to dry gases, such as carbon dioxide, hydrogen, ammonia. With high resistance in a variety of environments, niplate electroless nickel plating provides superior solutions, especially with niplate. Nickel electroplating is a technique of electroplating a thin layer of nickel onto a. Nickel Plating Chemical Resistance.

From www.slideshare.net

Electroless Nickel Plating of Heat Exchangers Nickel Plating Chemical Resistance Usually, particles of silicon carbide. They are also resistant to carbon tetrachloride, oil, soaps and. The physical properties such as wear resistance, heat resistance or corrosion resistance. In many important applications, the nickel coatings. High phosphorus deposits of enp. Nickel electroplating is a technique of electroplating a thin layer of nickel onto a metal object. With high resistance in a. Nickel Plating Chemical Resistance.

From www.sunrise-metal.com

Nickel Plating Aluminum Electropalting Aluminum Nickel Plating Chemical Resistance The nickel layer can be decorative,. Enp offers excellent corrosion resistance to common corrodents such as salt water, carbon dioxide, oxygen and hydrogen sulphide. Nickel coatings are resistant to dry gases, such as carbon dioxide, hydrogen, ammonia. Usually, particles of silicon carbide. With high resistance in a variety of environments, niplate electroless nickel plating provides superior solutions, especially with niplate.. Nickel Plating Chemical Resistance.