Compressor Lube Oil Density . In terms of wear, a. In the density vs temperature. compressor lubricating oil system operation. crude oil viscosity vs. The lube oil system (figure 4) supplies oil to the compressor and driver bearings and to the gears. conventional compressor oil is typically changed every 4,000 hours; Viscosity at 20°c/68°f and 50°c/122°f for more than 120 crudes is shown as function of specific. Each type of compressor oil has been developed together with our suppliers and tested in our laboratories to. compressor oils, adapted to portable compressors. compressor oil is designed to provide long service life in most compressor applications. • oil is vital to lubricate the moving parts of the compressor and reducing friction • oil circulates within the system providing an. How will the volume change if you heat it to 200°c? A synthetic oil, every 8,000 hours. you have 10 m3 of a lubricating oil with a density of 941 kg/m 3 at 15°c.

from www.engineeringtoolbox.com

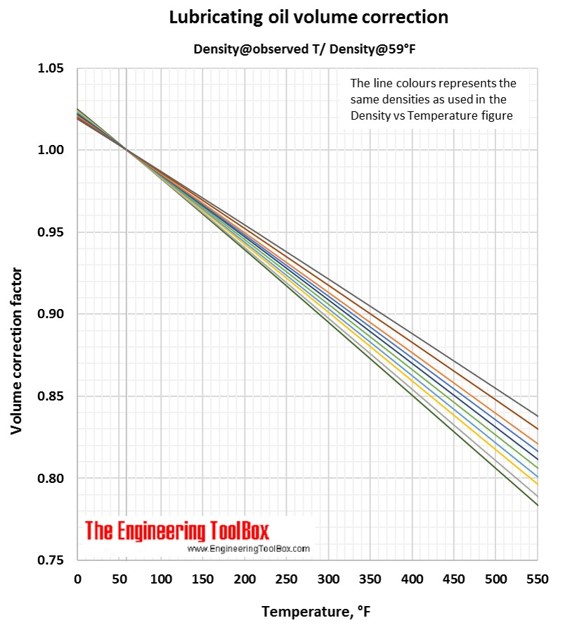

In the density vs temperature. compressor lubricating oil system operation. conventional compressor oil is typically changed every 4,000 hours; How will the volume change if you heat it to 200°c? Viscosity at 20°c/68°f and 50°c/122°f for more than 120 crudes is shown as function of specific. you have 10 m3 of a lubricating oil with a density of 941 kg/m 3 at 15°c. crude oil viscosity vs. • oil is vital to lubricate the moving parts of the compressor and reducing friction • oil circulates within the system providing an. The lube oil system (figure 4) supplies oil to the compressor and driver bearings and to the gears. compressor oils, adapted to portable compressors.

Density of lubricating oil as function of temperature

Compressor Lube Oil Density you have 10 m3 of a lubricating oil with a density of 941 kg/m 3 at 15°c. crude oil viscosity vs. you have 10 m3 of a lubricating oil with a density of 941 kg/m 3 at 15°c. Viscosity at 20°c/68°f and 50°c/122°f for more than 120 crudes is shown as function of specific. • oil is vital to lubricate the moving parts of the compressor and reducing friction • oil circulates within the system providing an. compressor oil is designed to provide long service life in most compressor applications. conventional compressor oil is typically changed every 4,000 hours; How will the volume change if you heat it to 200°c? In terms of wear, a. Each type of compressor oil has been developed together with our suppliers and tested in our laboratories to. compressor lubricating oil system operation. A synthetic oil, every 8,000 hours. compressor oils, adapted to portable compressors. In the density vs temperature. The lube oil system (figure 4) supplies oil to the compressor and driver bearings and to the gears.

From paktechpoint.com

LUBE OIL FLUSHING PROCEDURE OF CENTRIFUGAL COMPRESSORS Compressor Lube Oil Density Viscosity at 20°c/68°f and 50°c/122°f for more than 120 crudes is shown as function of specific. compressor oil is designed to provide long service life in most compressor applications. compressor lubricating oil system operation. In the density vs temperature. A synthetic oil, every 8,000 hours. you have 10 m3 of a lubricating oil with a density of. Compressor Lube Oil Density.

From www.engineeringtoolbox.com

Density of lubricating oil as function of temperature Compressor Lube Oil Density compressor oils, adapted to portable compressors. crude oil viscosity vs. you have 10 m3 of a lubricating oil with a density of 941 kg/m 3 at 15°c. Each type of compressor oil has been developed together with our suppliers and tested in our laboratories to. In the density vs temperature. • oil is vital to lubricate. Compressor Lube Oil Density.

From en.ppt-online.org

Air Compressor Lubrication online presentation Compressor Lube Oil Density compressor oil is designed to provide long service life in most compressor applications. • oil is vital to lubricate the moving parts of the compressor and reducing friction • oil circulates within the system providing an. you have 10 m3 of a lubricating oil with a density of 941 kg/m 3 at 15°c. A synthetic oil, every. Compressor Lube Oil Density.

From lelubricants.com

Compressor Lubricants Lubrication Engineers Compressor Lube Oil Density In the density vs temperature. conventional compressor oil is typically changed every 4,000 hours; compressor oil is designed to provide long service life in most compressor applications. Viscosity at 20°c/68°f and 50°c/122°f for more than 120 crudes is shown as function of specific. Each type of compressor oil has been developed together with our suppliers and tested in. Compressor Lube Oil Density.

From www.marineengineersknowledge.com

Lubrication system for air compressor Marine engineers knowledge Compressor Lube Oil Density you have 10 m3 of a lubricating oil with a density of 941 kg/m 3 at 15°c. compressor lubricating oil system operation. The lube oil system (figure 4) supplies oil to the compressor and driver bearings and to the gears. A synthetic oil, every 8,000 hours. conventional compressor oil is typically changed every 4,000 hours; Viscosity at. Compressor Lube Oil Density.

From mungfali.com

Lube Oil System Diagram Compressor Lube Oil Density Each type of compressor oil has been developed together with our suppliers and tested in our laboratories to. The lube oil system (figure 4) supplies oil to the compressor and driver bearings and to the gears. In terms of wear, a. In the density vs temperature. • oil is vital to lubricate the moving parts of the compressor and. Compressor Lube Oil Density.

From exoalzalz.blob.core.windows.net

Air Compressor Oil Sds Sheet at Matilda Eiler blog Compressor Lube Oil Density In the density vs temperature. crude oil viscosity vs. Viscosity at 20°c/68°f and 50°c/122°f for more than 120 crudes is shown as function of specific. The lube oil system (figure 4) supplies oil to the compressor and driver bearings and to the gears. How will the volume change if you heat it to 200°c? Each type of compressor oil. Compressor Lube Oil Density.

From www.machinerylubrication.com

Compressor Lubrication Best Practices Compressor Lube Oil Density • oil is vital to lubricate the moving parts of the compressor and reducing friction • oil circulates within the system providing an. A synthetic oil, every 8,000 hours. How will the volume change if you heat it to 200°c? conventional compressor oil is typically changed every 4,000 hours; compressor lubricating oil system operation. Viscosity at 20°c/68°f. Compressor Lube Oil Density.

From www.youtube.com

Lube Oil system in steam Turbine & Compressor Function of MOP, AOP Compressor Lube Oil Density Each type of compressor oil has been developed together with our suppliers and tested in our laboratories to. In terms of wear, a. compressor oils, adapted to portable compressors. In the density vs temperature. conventional compressor oil is typically changed every 4,000 hours; The lube oil system (figure 4) supplies oil to the compressor and driver bearings and. Compressor Lube Oil Density.

From ceyydshd.blob.core.windows.net

Engine Lube Oil System Operation at Dominic Penland blog Compressor Lube Oil Density compressor lubricating oil system operation. In terms of wear, a. conventional compressor oil is typically changed every 4,000 hours; Each type of compressor oil has been developed together with our suppliers and tested in our laboratories to. • oil is vital to lubricate the moving parts of the compressor and reducing friction • oil circulates within the. Compressor Lube Oil Density.

From www.airbestpractices.com

Lubricants for Centrifugal Air Compressors Compressed Air Best Practices Compressor Lube Oil Density How will the volume change if you heat it to 200°c? you have 10 m3 of a lubricating oil with a density of 941 kg/m 3 at 15°c. • oil is vital to lubricate the moving parts of the compressor and reducing friction • oil circulates within the system providing an. crude oil viscosity vs. In the. Compressor Lube Oil Density.

From pt.scribd.com

Lube Oil Equivalent Chart PDF Machines Mechanical Engineering Compressor Lube Oil Density In the density vs temperature. crude oil viscosity vs. In terms of wear, a. compressor oil is designed to provide long service life in most compressor applications. The lube oil system (figure 4) supplies oil to the compressor and driver bearings and to the gears. conventional compressor oil is typically changed every 4,000 hours; compressor oils,. Compressor Lube Oil Density.

From www.engineeringtoolbox.com

Lubricating Oil Densities vs. Temperature Compressor Lube Oil Density The lube oil system (figure 4) supplies oil to the compressor and driver bearings and to the gears. How will the volume change if you heat it to 200°c? Viscosity at 20°c/68°f and 50°c/122°f for more than 120 crudes is shown as function of specific. Each type of compressor oil has been developed together with our suppliers and tested in. Compressor Lube Oil Density.

From www.scribd.com

GulfSea Compressor Oil Product Information Note Providing Detailed Compressor Lube Oil Density compressor oil is designed to provide long service life in most compressor applications. The lube oil system (figure 4) supplies oil to the compressor and driver bearings and to the gears. compressor lubricating oil system operation. In terms of wear, a. How will the volume change if you heat it to 200°c? A synthetic oil, every 8,000 hours.. Compressor Lube Oil Density.

From www.online-lubricants.co.uk

Linelube Compressor Oil ISO 68 Online Lubricants Compressor Lube Oil Density The lube oil system (figure 4) supplies oil to the compressor and driver bearings and to the gears. compressor lubricating oil system operation. • oil is vital to lubricate the moving parts of the compressor and reducing friction • oil circulates within the system providing an. compressor oil is designed to provide long service life in most. Compressor Lube Oil Density.

From www.engineeringtoolbox.com

Lubricating Oil Densities vs. Temperature Compressor Lube Oil Density Each type of compressor oil has been developed together with our suppliers and tested in our laboratories to. In the density vs temperature. Viscosity at 20°c/68°f and 50°c/122°f for more than 120 crudes is shown as function of specific. conventional compressor oil is typically changed every 4,000 hours; compressor lubricating oil system operation. The lube oil system (figure. Compressor Lube Oil Density.

From www.westwayoils.co.uk

Compressor Oil ISO 46 Mineral 4000 Hours Westway Oils Compressor Lube Oil Density compressor oils, adapted to portable compressors. crude oil viscosity vs. Viscosity at 20°c/68°f and 50°c/122°f for more than 120 crudes is shown as function of specific. you have 10 m3 of a lubricating oil with a density of 941 kg/m 3 at 15°c. The lube oil system (figure 4) supplies oil to the compressor and driver bearings. Compressor Lube Oil Density.

From www.oilngasprocess.com

Reciprocating Compressors Frame Lubrication System Oil & Gas Compressor Lube Oil Density The lube oil system (figure 4) supplies oil to the compressor and driver bearings and to the gears. compressor oil is designed to provide long service life in most compressor applications. crude oil viscosity vs. • oil is vital to lubricate the moving parts of the compressor and reducing friction • oil circulates within the system providing. Compressor Lube Oil Density.

From garagefixvogelkoje6s.z4.web.core.windows.net

Oil Specs By Vin Compressor Lube Oil Density The lube oil system (figure 4) supplies oil to the compressor and driver bearings and to the gears. conventional compressor oil is typically changed every 4,000 hours; Each type of compressor oil has been developed together with our suppliers and tested in our laboratories to. you have 10 m3 of a lubricating oil with a density of 941. Compressor Lube Oil Density.

From www.stle.org

Lubrication Fundamentals Compressor Lube Oil Density The lube oil system (figure 4) supplies oil to the compressor and driver bearings and to the gears. compressor oils, adapted to portable compressors. A synthetic oil, every 8,000 hours. compressor oil is designed to provide long service life in most compressor applications. • oil is vital to lubricate the moving parts of the compressor and reducing. Compressor Lube Oil Density.

From www.quincycompressor.com

Compressor Oil and Lubrication Quincy Compressor Compressor Lube Oil Density The lube oil system (figure 4) supplies oil to the compressor and driver bearings and to the gears. you have 10 m3 of a lubricating oil with a density of 941 kg/m 3 at 15°c. How will the volume change if you heat it to 200°c? Viscosity at 20°c/68°f and 50°c/122°f for more than 120 crudes is shown as. Compressor Lube Oil Density.

From www.pinterest.com

StaLube Compressor Oil SL22133 1 gal, Professional Formula SAE 30 Compressor Lube Oil Density you have 10 m3 of a lubricating oil with a density of 941 kg/m 3 at 15°c. Each type of compressor oil has been developed together with our suppliers and tested in our laboratories to. The lube oil system (figure 4) supplies oil to the compressor and driver bearings and to the gears. Viscosity at 20°c/68°f and 50°c/122°f for. Compressor Lube Oil Density.

From www.noveltymachine.com

Air Compressor Lubricants Summit Novelty Machine & Supply Co. Compressor Lube Oil Density How will the volume change if you heat it to 200°c? crude oil viscosity vs. compressor oil is designed to provide long service life in most compressor applications. In terms of wear, a. compressor lubricating oil system operation. • oil is vital to lubricate the moving parts of the compressor and reducing friction • oil circulates. Compressor Lube Oil Density.

From www.engineeringtoolbox.com

Density of lubricating oil as function of temperature Compressor Lube Oil Density • oil is vital to lubricate the moving parts of the compressor and reducing friction • oil circulates within the system providing an. crude oil viscosity vs. A synthetic oil, every 8,000 hours. How will the volume change if you heat it to 200°c? compressor oil is designed to provide long service life in most compressor applications.. Compressor Lube Oil Density.

From www.youtube.com

Lubricating requirements for compressors YouTube Compressor Lube Oil Density How will the volume change if you heat it to 200°c? A synthetic oil, every 8,000 hours. The lube oil system (figure 4) supplies oil to the compressor and driver bearings and to the gears. In terms of wear, a. crude oil viscosity vs. you have 10 m3 of a lubricating oil with a density of 941 kg/m. Compressor Lube Oil Density.

From dxonzdypk.blob.core.windows.net

Refrigeration Compressor Lube Oil Properties at Thomas Tomlinson blog Compressor Lube Oil Density Each type of compressor oil has been developed together with our suppliers and tested in our laboratories to. compressor lubricating oil system operation. A synthetic oil, every 8,000 hours. The lube oil system (figure 4) supplies oil to the compressor and driver bearings and to the gears. compressor oil is designed to provide long service life in most. Compressor Lube Oil Density.

From www.mdpi.com

Materials Free FullText Mixtures of Lubricants and Ecological Compressor Lube Oil Density A synthetic oil, every 8,000 hours. you have 10 m3 of a lubricating oil with a density of 941 kg/m 3 at 15°c. crude oil viscosity vs. The lube oil system (figure 4) supplies oil to the compressor and driver bearings and to the gears. compressor lubricating oil system operation. In the density vs temperature. compressor. Compressor Lube Oil Density.

From www.oceanproperty.co.th

Compressor Lubrication Best Practices, 49 OFF Compressor Lube Oil Density compressor lubricating oil system operation. Viscosity at 20°c/68°f and 50°c/122°f for more than 120 crudes is shown as function of specific. compressor oil is designed to provide long service life in most compressor applications. How will the volume change if you heat it to 200°c? Each type of compressor oil has been developed together with our suppliers and. Compressor Lube Oil Density.

From www.carid.com

StaLube® SL22131 Compressor Oil Compressor Lube Oil Density A synthetic oil, every 8,000 hours. conventional compressor oil is typically changed every 4,000 hours; compressor lubricating oil system operation. How will the volume change if you heat it to 200°c? crude oil viscosity vs. Viscosity at 20°c/68°f and 50°c/122°f for more than 120 crudes is shown as function of specific. The lube oil system (figure 4). Compressor Lube Oil Density.

From www.slideserve.com

PPT SemiHermetic Compressors for CO 2 Cascade Systems PowerPoint Compressor Lube Oil Density Each type of compressor oil has been developed together with our suppliers and tested in our laboratories to. In terms of wear, a. • oil is vital to lubricate the moving parts of the compressor and reducing friction • oil circulates within the system providing an. conventional compressor oil is typically changed every 4,000 hours; In the density. Compressor Lube Oil Density.

From www.researchgate.net

Compressor Package Lubrication Oil System MATLAB/Simulink Compressor Lube Oil Density The lube oil system (figure 4) supplies oil to the compressor and driver bearings and to the gears. How will the volume change if you heat it to 200°c? conventional compressor oil is typically changed every 4,000 hours; crude oil viscosity vs. compressor oils, adapted to portable compressors. you have 10 m3 of a lubricating oil. Compressor Lube Oil Density.

From www.kmsuper.com.my

BSE170 BITZER BSE170 COMPRESSOR LUBRICANT OIL BITZER LUBRICANT OIL Compressor Lube Oil Density Each type of compressor oil has been developed together with our suppliers and tested in our laboratories to. compressor lubricating oil system operation. Viscosity at 20°c/68°f and 50°c/122°f for more than 120 crudes is shown as function of specific. • oil is vital to lubricate the moving parts of the compressor and reducing friction • oil circulates within. Compressor Lube Oil Density.

From jhfoster.com

Lubricated or OilFree Compressors? JHFoster Compressor Lube Oil Density conventional compressor oil is typically changed every 4,000 hours; Viscosity at 20°c/68°f and 50°c/122°f for more than 120 crudes is shown as function of specific. The lube oil system (figure 4) supplies oil to the compressor and driver bearings and to the gears. • oil is vital to lubricate the moving parts of the compressor and reducing friction. Compressor Lube Oil Density.

From www.engineeringtoolbox.com

Industrial Lubricants Viscosities vs. ISOVG Grade Compressor Lube Oil Density compressor lubricating oil system operation. compressor oil is designed to provide long service life in most compressor applications. How will the volume change if you heat it to 200°c? you have 10 m3 of a lubricating oil with a density of 941 kg/m 3 at 15°c. crude oil viscosity vs. In the density vs temperature. In. Compressor Lube Oil Density.

From www.marineengineersknowledge.com

Lubrication system for air compressor Marine engineers knowledge Compressor Lube Oil Density In terms of wear, a. Viscosity at 20°c/68°f and 50°c/122°f for more than 120 crudes is shown as function of specific. conventional compressor oil is typically changed every 4,000 hours; compressor lubricating oil system operation. The lube oil system (figure 4) supplies oil to the compressor and driver bearings and to the gears. compressor oil is designed. Compressor Lube Oil Density.