Mold In Casting . permanent mold casting is a metal shape casting process that is similar to sand casting, but this process uses permanent,. The easiest example of what a mold is, that almost everyone has used before, is an ice cube tray. The resulting cast will be an exact likeness of the shape of the hollow mold form. molds are negative forms that are used to shape casting materials, creating duplicates of the model (object) the mold was made from. the casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity or mold of the desired shape and allowed to harden or solidify within the mold, after solidification the mold material casting defects there are 7 types of casting defects caused by unsuitable mold material.

from www.ace-mold.com

The resulting cast will be an exact likeness of the shape of the hollow mold form. permanent mold casting is a metal shape casting process that is similar to sand casting, but this process uses permanent,. mold material casting defects there are 7 types of casting defects caused by unsuitable mold material. The easiest example of what a mold is, that almost everyone has used before, is an ice cube tray. molds are negative forms that are used to shape casting materials, creating duplicates of the model (object) the mold was made from. the casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity or mold of the desired shape and allowed to harden or solidify within the mold, after solidification the

Die Casting Mould Material for Industrial Applications

Mold In Casting the casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity or mold of the desired shape and allowed to harden or solidify within the mold, after solidification the the casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity or mold of the desired shape and allowed to harden or solidify within the mold, after solidification the permanent mold casting is a metal shape casting process that is similar to sand casting, but this process uses permanent,. The easiest example of what a mold is, that almost everyone has used before, is an ice cube tray. The resulting cast will be an exact likeness of the shape of the hollow mold form. molds are negative forms that are used to shape casting materials, creating duplicates of the model (object) the mold was made from. mold material casting defects there are 7 types of casting defects caused by unsuitable mold material.

From www.sunrise-metal.com

Die Casting Mold Expert Sunrise Metal Your Reliable Partner Mold In Casting permanent mold casting is a metal shape casting process that is similar to sand casting, but this process uses permanent,. The easiest example of what a mold is, that almost everyone has used before, is an ice cube tray. The resulting cast will be an exact likeness of the shape of the hollow mold form. molds are negative. Mold In Casting.

From www.youtube.com

The beginner's guide to mold making and casting YouTube Mold In Casting mold material casting defects there are 7 types of casting defects caused by unsuitable mold material. The easiest example of what a mold is, that almost everyone has used before, is an ice cube tray. molds are negative forms that are used to shape casting materials, creating duplicates of the model (object) the mold was made from. The. Mold In Casting.

From www.ace-mold.com

Die Casting Mould Material for Industrial Applications Mold In Casting the casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity or mold of the desired shape and allowed to harden or solidify within the mold, after solidification the molds are negative forms that are used to shape casting materials, creating duplicates of the model (object) the mold was. Mold In Casting.

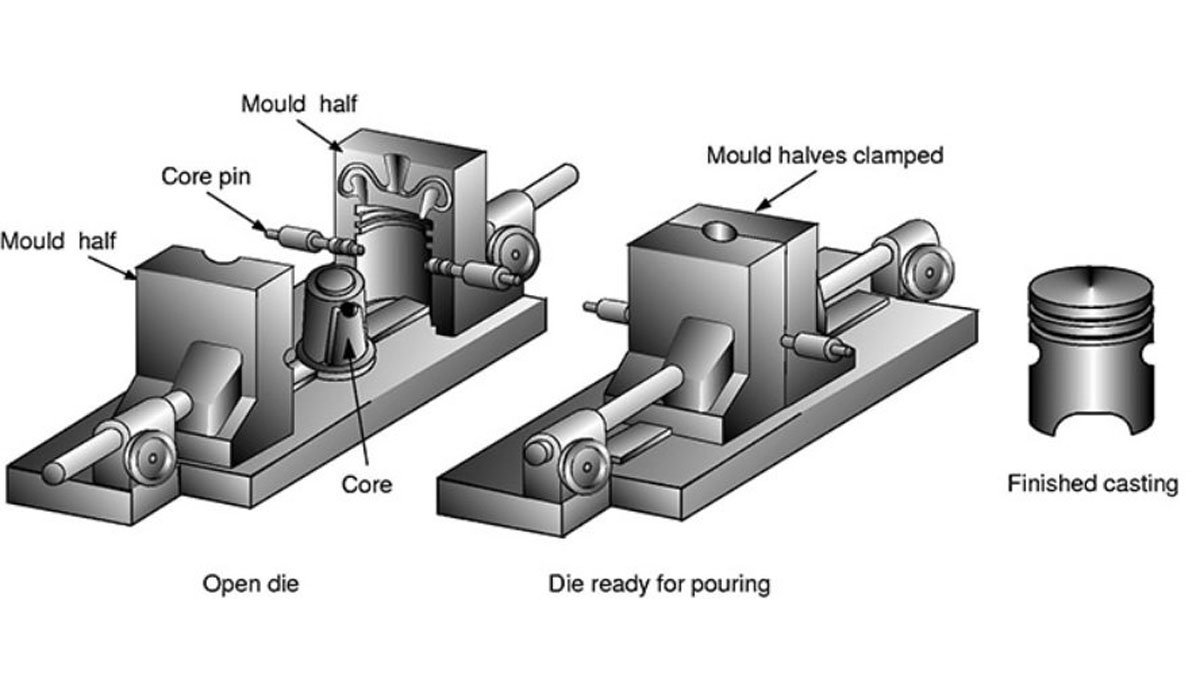

From thelibraryofmanufacturing.com

Metal Casting Process Mold In Casting molds are negative forms that are used to shape casting materials, creating duplicates of the model (object) the mold was made from. The easiest example of what a mold is, that almost everyone has used before, is an ice cube tray. The resulting cast will be an exact likeness of the shape of the hollow mold form. the. Mold In Casting.

From bhuwalkacasting.com

Process Bhuwalka Castings & Pvt Ltd Mold In Casting molds are negative forms that are used to shape casting materials, creating duplicates of the model (object) the mold was made from. The resulting cast will be an exact likeness of the shape of the hollow mold form. The easiest example of what a mold is, that almost everyone has used before, is an ice cube tray. the. Mold In Casting.

From www.iqsdirectory.com

Iron Castings Types, Applications, Process, and Benefits Mold In Casting The easiest example of what a mold is, that almost everyone has used before, is an ice cube tray. molds are negative forms that are used to shape casting materials, creating duplicates of the model (object) the mold was made from. the casting process is the manufacturing process in which molten material such as metal is poured into. Mold In Casting.

From batesvilleproducts.com

Aluminum permanent mold castings Batesville products, inc. Mold In Casting The resulting cast will be an exact likeness of the shape of the hollow mold form. permanent mold casting is a metal shape casting process that is similar to sand casting, but this process uses permanent,. The easiest example of what a mold is, that almost everyone has used before, is an ice cube tray. mold material casting. Mold In Casting.

From precise-cast.com

The Most Comprehensive Casting Process Summary Precise Cast Mold In Casting molds are negative forms that are used to shape casting materials, creating duplicates of the model (object) the mold was made from. the casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity or mold of the desired shape and allowed to harden or solidify within the mold, after. Mold In Casting.

From www.youtube.com

Shell Molding Expandable Mold Casting Processes YouTube Mold In Casting the casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity or mold of the desired shape and allowed to harden or solidify within the mold, after solidification the The resulting cast will be an exact likeness of the shape of the hollow mold form. mold material casting defects. Mold In Casting.

From vietnamcastiron.com

Instructions for Making Sand Casting Molds in detail Step by Step Mold In Casting the casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity or mold of the desired shape and allowed to harden or solidify within the mold, after solidification the The easiest example of what a mold is, that almost everyone has used before, is an ice cube tray. permanent. Mold In Casting.

From thelibraryofmanufacturing.com

Basic Permanent Mold Casting Mold In Casting the casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity or mold of the desired shape and allowed to harden or solidify within the mold, after solidification the The resulting cast will be an exact likeness of the shape of the hollow mold form. permanent mold casting is. Mold In Casting.

From marlboroughfoundry.com

Permanent Mold Casting Aluminium Mold In Casting the casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity or mold of the desired shape and allowed to harden or solidify within the mold, after solidification the The resulting cast will be an exact likeness of the shape of the hollow mold form. permanent mold casting is. Mold In Casting.

From www.smooth-on.com

Concrete Mold Making & Casting Tutorials by SmoothOn, Inc. Mold In Casting mold material casting defects there are 7 types of casting defects caused by unsuitable mold material. molds are negative forms that are used to shape casting materials, creating duplicates of the model (object) the mold was made from. permanent mold casting is a metal shape casting process that is similar to sand casting, but this process uses. Mold In Casting.

From precisecast.com

What is Plaster Mold Casting Plaster Mold Casting Process Mold In Casting the casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity or mold of the desired shape and allowed to harden or solidify within the mold, after solidification the molds are negative forms that are used to shape casting materials, creating duplicates of the model (object) the mold was. Mold In Casting.

From artnsyn.com

How slip casting and plaster molds work artnsyn Mold In Casting the casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity or mold of the desired shape and allowed to harden or solidify within the mold, after solidification the The easiest example of what a mold is, that almost everyone has used before, is an ice cube tray. The resulting. Mold In Casting.

From www.thelibraryofmanufacturing.com

Metal Casting Process Mold In Casting permanent mold casting is a metal shape casting process that is similar to sand casting, but this process uses permanent,. mold material casting defects there are 7 types of casting defects caused by unsuitable mold material. The resulting cast will be an exact likeness of the shape of the hollow mold form. the casting process is the. Mold In Casting.

From precisecast.com

Plaster Mold Casting Metal Casting Processes Learn More Mold In Casting permanent mold casting is a metal shape casting process that is similar to sand casting, but this process uses permanent,. mold material casting defects there are 7 types of casting defects caused by unsuitable mold material. the casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity or. Mold In Casting.

From www.iqsdirectory.com

Aluminum Casting What Is It? How Is it Made? Advantages Mold In Casting molds are negative forms that are used to shape casting materials, creating duplicates of the model (object) the mold was made from. The resulting cast will be an exact likeness of the shape of the hollow mold form. the casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity. Mold In Casting.

From www.thelibraryofmanufacturing.com

Metal Casting Process Mold In Casting The easiest example of what a mold is, that almost everyone has used before, is an ice cube tray. The resulting cast will be an exact likeness of the shape of the hollow mold form. permanent mold casting is a metal shape casting process that is similar to sand casting, but this process uses permanent,. molds are negative. Mold In Casting.

From www.sydensen.com

Shell Mold Sand Casting Densen Group Co., Ltd. Mold In Casting molds are negative forms that are used to shape casting materials, creating duplicates of the model (object) the mold was made from. mold material casting defects there are 7 types of casting defects caused by unsuitable mold material. The easiest example of what a mold is, that almost everyone has used before, is an ice cube tray. . Mold In Casting.

From www.leclairemfg.com

Ultimate Guide to the Permanent Mold Casting Process Mold In Casting the casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity or mold of the desired shape and allowed to harden or solidify within the mold, after solidification the mold material casting defects there are 7 types of casting defects caused by unsuitable mold material. The easiest example of. Mold In Casting.

From www.youtube.com

Casting in plaster molds YouTube Mold In Casting The resulting cast will be an exact likeness of the shape of the hollow mold form. the casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity or mold of the desired shape and allowed to harden or solidify within the mold, after solidification the molds are negative forms. Mold In Casting.

From veenaengicast.com

Metal Casting Guide for Beginners Veena Enterprise Mold In Casting mold material casting defects there are 7 types of casting defects caused by unsuitable mold material. The resulting cast will be an exact likeness of the shape of the hollow mold form. The easiest example of what a mold is, that almost everyone has used before, is an ice cube tray. permanent mold casting is a metal shape. Mold In Casting.

From www.weld2cast.com

Shell Moulding Casting Weld2Cast Mold In Casting mold material casting defects there are 7 types of casting defects caused by unsuitable mold material. the casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity or mold of the desired shape and allowed to harden or solidify within the mold, after solidification the The easiest example of. Mold In Casting.

From dxoucvfeq.blob.core.windows.net

Types Of Mould In Casting at Angie Ferland blog Mold In Casting The easiest example of what a mold is, that almost everyone has used before, is an ice cube tray. the casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity or mold of the desired shape and allowed to harden or solidify within the mold, after solidification the The resulting. Mold In Casting.

From blog.eaglegroupmanufacturers.com

Getting Started with Permanent Mold Casting Mold In Casting the casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity or mold of the desired shape and allowed to harden or solidify within the mold, after solidification the The resulting cast will be an exact likeness of the shape of the hollow mold form. The easiest example of what. Mold In Casting.

From www.youtube.com

Pattern Types and Mold Cavity Animation in Casting Process by Shubham Mold In Casting mold material casting defects there are 7 types of casting defects caused by unsuitable mold material. The easiest example of what a mold is, that almost everyone has used before, is an ice cube tray. The resulting cast will be an exact likeness of the shape of the hollow mold form. the casting process is the manufacturing process. Mold In Casting.

From engineeringstuff.co.in

Sand mold casting Explained Engineeringstuff Mold In Casting mold material casting defects there are 7 types of casting defects caused by unsuitable mold material. permanent mold casting is a metal shape casting process that is similar to sand casting, but this process uses permanent,. molds are negative forms that are used to shape casting materials, creating duplicates of the model (object) the mold was made. Mold In Casting.

From www.youtube.com

The Basic Permanent Mold Casting Process YouTube Mold In Casting the casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity or mold of the desired shape and allowed to harden or solidify within the mold, after solidification the molds are negative forms that are used to shape casting materials, creating duplicates of the model (object) the mold was. Mold In Casting.

From marlboroughfoundry.com

Permanent Mold Casting Aluminium Mold In Casting the casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity or mold of the desired shape and allowed to harden or solidify within the mold, after solidification the molds are negative forms that are used to shape casting materials, creating duplicates of the model (object) the mold was. Mold In Casting.

From www.mechanicaleducation.com

Shell Mold Casting Advantages And Disadvantages Mechanical Education Mold In Casting The resulting cast will be an exact likeness of the shape of the hollow mold form. molds are negative forms that are used to shape casting materials, creating duplicates of the model (object) the mold was made from. the casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity. Mold In Casting.

From startup-buzz.com

The Beginner’s Guide to Permanent Mold Casting Startup Buzz Mold In Casting permanent mold casting is a metal shape casting process that is similar to sand casting, but this process uses permanent,. mold material casting defects there are 7 types of casting defects caused by unsuitable mold material. The resulting cast will be an exact likeness of the shape of the hollow mold form. the casting process is the. Mold In Casting.

From www.aniwaa.com

Guide to 3D printing molds for metal casting Aniwaa Mold In Casting mold material casting defects there are 7 types of casting defects caused by unsuitable mold material. permanent mold casting is a metal shape casting process that is similar to sand casting, but this process uses permanent,. The easiest example of what a mold is, that almost everyone has used before, is an ice cube tray. The resulting cast. Mold In Casting.

From www.youtube.com

Mold Making and Casting Tutorials From SmoothOn YouTube Mold In Casting The resulting cast will be an exact likeness of the shape of the hollow mold form. permanent mold casting is a metal shape casting process that is similar to sand casting, but this process uses permanent,. The easiest example of what a mold is, that almost everyone has used before, is an ice cube tray. the casting process. Mold In Casting.

From www.open.edu

Ceramic mould casting OpenLearn Open University Mold In Casting mold material casting defects there are 7 types of casting defects caused by unsuitable mold material. permanent mold casting is a metal shape casting process that is similar to sand casting, but this process uses permanent,. molds are negative forms that are used to shape casting materials, creating duplicates of the model (object) the mold was made. Mold In Casting.