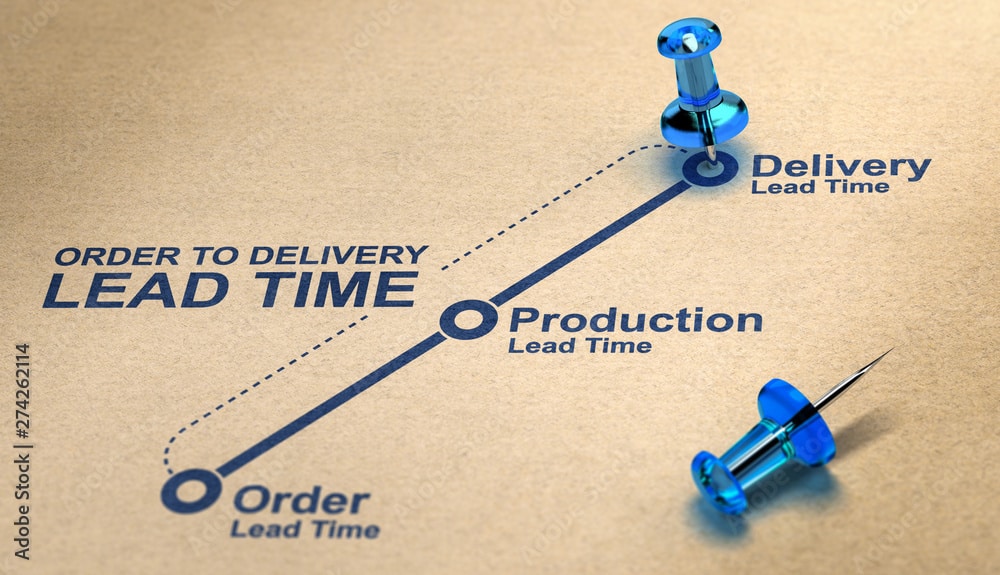

Maximum Lead Time . Preproduction + production + completion = lead time. Lead time is the time from beginning a process to completing it, and it is a term commonly used in supply chains, shipping, procurement, and purchasing. Lead time is calculated with a simple formula: Lead time can also refer to task. It’s also called working in parallel. But what are the lead time. An example of lead time in a supply chain is when a manufacturer might need between two weeks and eight months, depending on certain variables, to deliver new cars after the buyer places an order. Reordering delay is the time. Lead time in project management occurs when one activity begins as another is being executed. Lead times are essential in achieving optimal results from your business operations. Lead time is the minimum time needed between placing an order and receiving it. Therefore, lead time in the eoq model is the maximum amount of lead time acceptable to keep inventory. Your lead time is how much time you need to receive the order, create the product (whether you’re manufacturing it yourself or relying on suppliers), and. Lead time (lt) = supply delay (sd) + reordering delay (rd) supply delay is the time a supplier takes to fulfill a customer order after it’s placed. The three steps added together help determine how long a task or project will take, from.

from www.mas-software.com

Lead time (lt) = supply delay (sd) + reordering delay (rd) supply delay is the time a supplier takes to fulfill a customer order after it’s placed. Lead time is the time from beginning a process to completing it, and it is a term commonly used in supply chains, shipping, procurement, and purchasing. But what are the lead time. An example of lead time in a supply chain is when a manufacturer might need between two weeks and eight months, depending on certain variables, to deliver new cars after the buyer places an order. Therefore, lead time in the eoq model is the maximum amount of lead time acceptable to keep inventory. Reordering delay is the time. The three steps added together help determine how long a task or project will take, from. Lead time can also refer to task. Lead time is calculated with a simple formula: It’s also called working in parallel.

Apa Itu Lead Time? 5 Komponen dan 7 Jenis Lead Time

Maximum Lead Time It’s also called working in parallel. Reordering delay is the time. Lead time is calculated with a simple formula: Lead time (lt) = supply delay (sd) + reordering delay (rd) supply delay is the time a supplier takes to fulfill a customer order after it’s placed. Therefore, lead time in the eoq model is the maximum amount of lead time acceptable to keep inventory. An example of lead time in a supply chain is when a manufacturer might need between two weeks and eight months, depending on certain variables, to deliver new cars after the buyer places an order. Your lead time is how much time you need to receive the order, create the product (whether you’re manufacturing it yourself or relying on suppliers), and. The three steps added together help determine how long a task or project will take, from. Lead time is the minimum time needed between placing an order and receiving it. Lead time can also refer to task. Lead times are essential in achieving optimal results from your business operations. Lead time in project management occurs when one activity begins as another is being executed. But what are the lead time. Lead time is the time from beginning a process to completing it, and it is a term commonly used in supply chains, shipping, procurement, and purchasing. Preproduction + production + completion = lead time. It’s also called working in parallel.

From businessfluency.com.br

A Quick Guide to Understanding Lead Time Business Fluency Maximum Lead Time Your lead time is how much time you need to receive the order, create the product (whether you’re manufacturing it yourself or relying on suppliers), and. Lead time is the minimum time needed between placing an order and receiving it. Lead time (lt) = supply delay (sd) + reordering delay (rd) supply delay is the time a supplier takes to. Maximum Lead Time.

From sixsigmadsi.com

Cycle Time vs. Takt Time vs. Lead Time Key Differences Maximum Lead Time Lead time in project management occurs when one activity begins as another is being executed. Lead time is the time from beginning a process to completing it, and it is a term commonly used in supply chains, shipping, procurement, and purchasing. An example of lead time in a supply chain is when a manufacturer might need between two weeks and. Maximum Lead Time.

From endel.afphila.com

Lead Time Overview, Components, and How to Reduce LT Maximum Lead Time The three steps added together help determine how long a task or project will take, from. It’s also called working in parallel. Preproduction + production + completion = lead time. Lead time is the minimum time needed between placing an order and receiving it. Lead time is the time from beginning a process to completing it, and it is a. Maximum Lead Time.

From www.mas-software.com

Apa Itu Lead Time? 5 Komponen dan 7 Jenis Lead Time Maximum Lead Time Lead time is calculated with a simple formula: Therefore, lead time in the eoq model is the maximum amount of lead time acceptable to keep inventory. But what are the lead time. Lead times are essential in achieving optimal results from your business operations. Lead time is the time from beginning a process to completing it, and it is a. Maximum Lead Time.

From www.brightworkresearch.com

How to Best Perform Supply Chain Lead Time Calculation Brightwork Maximum Lead Time The three steps added together help determine how long a task or project will take, from. Lead time is calculated with a simple formula: Your lead time is how much time you need to receive the order, create the product (whether you’re manufacturing it yourself or relying on suppliers), and. Lead time in project management occurs when one activity begins. Maximum Lead Time.

From redstagfulfillment.com

Lead Time Your Complete Guide Red Stag Fulfillment Maximum Lead Time But what are the lead time. Reordering delay is the time. Preproduction + production + completion = lead time. Lead time is the minimum time needed between placing an order and receiving it. Lead times are essential in achieving optimal results from your business operations. Your lead time is how much time you need to receive the order, create the. Maximum Lead Time.

From sheleighezra.blogspot.com

21+ lead time calculator SheleighEzra Maximum Lead Time Your lead time is how much time you need to receive the order, create the product (whether you’re manufacturing it yourself or relying on suppliers), and. It’s also called working in parallel. Lead times are essential in achieving optimal results from your business operations. Lead time is calculated with a simple formula: Lead time (lt) = supply delay (sd) +. Maximum Lead Time.

From news.ewmfg.com

Your Complete Guide to Lead Times Maximum Lead Time An example of lead time in a supply chain is when a manufacturer might need between two weeks and eight months, depending on certain variables, to deliver new cars after the buyer places an order. Your lead time is how much time you need to receive the order, create the product (whether you’re manufacturing it yourself or relying on suppliers),. Maximum Lead Time.

From blog.plataformatec.com.br

Lead Time Experiment Calculating Lead Time of the whole process Maximum Lead Time Your lead time is how much time you need to receive the order, create the product (whether you’re manufacturing it yourself or relying on suppliers), and. It’s also called working in parallel. Lead time is the time from beginning a process to completing it, and it is a term commonly used in supply chains, shipping, procurement, and purchasing. Reordering delay. Maximum Lead Time.

From efinancemanagement.com

Lead Time Meaning, Importance, How to Improve and More Maximum Lead Time The three steps added together help determine how long a task or project will take, from. Lead time can also refer to task. Lead times are essential in achieving optimal results from your business operations. Preproduction + production + completion = lead time. Reordering delay is the time. Therefore, lead time in the eoq model is the maximum amount of. Maximum Lead Time.

From www.exceldemy.com

How to Calculate Safety Stock and Reorder Point in Excel (6 Methods) Maximum Lead Time Your lead time is how much time you need to receive the order, create the product (whether you’re manufacturing it yourself or relying on suppliers), and. Lead time is the minimum time needed between placing an order and receiving it. Lead time (lt) = supply delay (sd) + reordering delay (rd) supply delay is the time a supplier takes to. Maximum Lead Time.

From www.gorillaroi.com

Free lead time calculator, formula, and management Gorilla ROI Maximum Lead Time It’s also called working in parallel. Lead time (lt) = supply delay (sd) + reordering delay (rd) supply delay is the time a supplier takes to fulfill a customer order after it’s placed. Lead time is the minimum time needed between placing an order and receiving it. Therefore, lead time in the eoq model is the maximum amount of lead. Maximum Lead Time.

From www.exceldemy.com

How to Calculate Safety Stock and Reorder Point in Excel (6 Methods) Maximum Lead Time Preproduction + production + completion = lead time. Lead time (lt) = supply delay (sd) + reordering delay (rd) supply delay is the time a supplier takes to fulfill a customer order after it’s placed. Lead time in project management occurs when one activity begins as another is being executed. Lead time is calculated with a simple formula: It’s also. Maximum Lead Time.

From 1investing.in

Lead Time India Dictionary Maximum Lead Time Reordering delay is the time. But what are the lead time. Lead time can also refer to task. Lead time is calculated with a simple formula: Lead time (lt) = supply delay (sd) + reordering delay (rd) supply delay is the time a supplier takes to fulfill a customer order after it’s placed. The three steps added together help determine. Maximum Lead Time.

From leanteams.com

Streamlining Your Business Operations Understanding Cycle Time and Maximum Lead Time Your lead time is how much time you need to receive the order, create the product (whether you’re manufacturing it yourself or relying on suppliers), and. But what are the lead time. Lead time is the minimum time needed between placing an order and receiving it. Lead time (lt) = supply delay (sd) + reordering delay (rd) supply delay is. Maximum Lead Time.

From eprconsultoria.com.br

Lead time entenda a importância e como calcular Maximum Lead Time Lead time is the minimum time needed between placing an order and receiving it. Preproduction + production + completion = lead time. Lead time can also refer to task. An example of lead time in a supply chain is when a manufacturer might need between two weeks and eight months, depending on certain variables, to deliver new cars after the. Maximum Lead Time.

From www.youtube.com

Calculating lead time and resource time YouTube Maximum Lead Time Lead time is the time from beginning a process to completing it, and it is a term commonly used in supply chains, shipping, procurement, and purchasing. Therefore, lead time in the eoq model is the maximum amount of lead time acceptable to keep inventory. Lead time in project management occurs when one activity begins as another is being executed. But. Maximum Lead Time.

From matob.web.id

Understanding TAKT Time and Cycle Time vs. Lead Time Maximum Lead Time Lead time (lt) = supply delay (sd) + reordering delay (rd) supply delay is the time a supplier takes to fulfill a customer order after it’s placed. Your lead time is how much time you need to receive the order, create the product (whether you’re manufacturing it yourself or relying on suppliers), and. Reordering delay is the time. Lead time. Maximum Lead Time.

From aiko.digital

Lead time Saiba o que é e como calcular Aiko Gestão de frotas Maximum Lead Time An example of lead time in a supply chain is when a manufacturer might need between two weeks and eight months, depending on certain variables, to deliver new cars after the buyer places an order. Lead time is the minimum time needed between placing an order and receiving it. Therefore, lead time in the eoq model is the maximum amount. Maximum Lead Time.

From blog.tara.ai

Lead Time vs Cycle Time in Kanban A 2023 Guide Maximum Lead Time It’s also called working in parallel. Preproduction + production + completion = lead time. The three steps added together help determine how long a task or project will take, from. Lead time is the minimum time needed between placing an order and receiving it. Lead time (lt) = supply delay (sd) + reordering delay (rd) supply delay is the time. Maximum Lead Time.

From cashflowinventory.com

Lead Times Meaning, How It Impacts Your Business, With Example Maximum Lead Time An example of lead time in a supply chain is when a manufacturer might need between two weeks and eight months, depending on certain variables, to deliver new cars after the buyer places an order. Lead time is calculated with a simple formula: The three steps added together help determine how long a task or project will take, from. Lead. Maximum Lead Time.

From buildd.co

Lead Time What it is, How to Calculate it and How to Reduce Lead Time Maximum Lead Time Preproduction + production + completion = lead time. Lead times are essential in achieving optimal results from your business operations. The three steps added together help determine how long a task or project will take, from. Your lead time is how much time you need to receive the order, create the product (whether you’re manufacturing it yourself or relying on. Maximum Lead Time.

From www.brightworkresearch.com

How to Plan Long Lead Time vs Short Lead Time Items Brightwork Maximum Lead Time Lead time is calculated with a simple formula: Lead times are essential in achieving optimal results from your business operations. Lead time is the time from beginning a process to completing it, and it is a term commonly used in supply chains, shipping, procurement, and purchasing. Your lead time is how much time you need to receive the order, create. Maximum Lead Time.

From www.investopedia.com

Lead Time Definition, How It Works, and Example Maximum Lead Time Lead time in project management occurs when one activity begins as another is being executed. It’s also called working in parallel. The three steps added together help determine how long a task or project will take, from. Your lead time is how much time you need to receive the order, create the product (whether you’re manufacturing it yourself or relying. Maximum Lead Time.

From www.gorillaroi.com

Free lead time calculator, formula, and management Gorilla ROI Maximum Lead Time Reordering delay is the time. Lead time is calculated with a simple formula: But what are the lead time. The three steps added together help determine how long a task or project will take, from. Lead time can also refer to task. Preproduction + production + completion = lead time. Your lead time is how much time you need to. Maximum Lead Time.

From www.slideserve.com

PPT Materials PowerPoint Presentation, free download ID3432048 Maximum Lead Time Lead time can also refer to task. Lead time is calculated with a simple formula: Reordering delay is the time. It’s also called working in parallel. Therefore, lead time in the eoq model is the maximum amount of lead time acceptable to keep inventory. An example of lead time in a supply chain is when a manufacturer might need between. Maximum Lead Time.

From www.gorillaroi.com

Free lead time calculator, formula, and management Gorilla ROI Maximum Lead Time Lead time is the time from beginning a process to completing it, and it is a term commonly used in supply chains, shipping, procurement, and purchasing. The three steps added together help determine how long a task or project will take, from. It’s also called working in parallel. Lead time is calculated with a simple formula: An example of lead. Maximum Lead Time.

From www.scmdojo.com

Lead Time Definition How to Calculate & Reduce it? SCMDOJO Maximum Lead Time Lead time in project management occurs when one activity begins as another is being executed. It’s also called working in parallel. Reordering delay is the time. The three steps added together help determine how long a task or project will take, from. Lead time is calculated with a simple formula: Lead time is the time from beginning a process to. Maximum Lead Time.

From www.gkseries.com

The maximum and minimum lead time is 4 weeks and 3 weeks respectively Maximum Lead Time Lead time is the time from beginning a process to completing it, and it is a term commonly used in supply chains, shipping, procurement, and purchasing. Reordering delay is the time. It’s also called working in parallel. Preproduction + production + completion = lead time. Therefore, lead time in the eoq model is the maximum amount of lead time acceptable. Maximum Lead Time.

From www.bluecart.com

Lead Time Definition & Formula What Is Lead Time? Maximum Lead Time Therefore, lead time in the eoq model is the maximum amount of lead time acceptable to keep inventory. It’s also called working in parallel. Lead time in project management occurs when one activity begins as another is being executed. The three steps added together help determine how long a task or project will take, from. Lead time can also refer. Maximum Lead Time.

From www.vistable.com

How important is lead time in factory planning? visTABLE® Maximum Lead Time Lead time is the minimum time needed between placing an order and receiving it. Lead time in project management occurs when one activity begins as another is being executed. But what are the lead time. Lead times are essential in achieving optimal results from your business operations. Reordering delay is the time. Lead time can also refer to task. An. Maximum Lead Time.

From www.logiwa.com

Lead Time Logiwa WMS Maximum Lead Time Your lead time is how much time you need to receive the order, create the product (whether you’re manufacturing it yourself or relying on suppliers), and. Lead time can also refer to task. But what are the lead time. Lead time is the time from beginning a process to completing it, and it is a term commonly used in supply. Maximum Lead Time.

From www.gkseries.com

(Maximum usage Average Usage) × Lead Time Maximum Lead Time Preproduction + production + completion = lead time. Lead time can also refer to task. Lead time in project management occurs when one activity begins as another is being executed. Your lead time is how much time you need to receive the order, create the product (whether you’re manufacturing it yourself or relying on suppliers), and. Therefore, lead time in. Maximum Lead Time.

From getnave.com

Lead Time vs Cycle Time in Kanban Everything You Need to Know Nave Maximum Lead Time Lead time is calculated with a simple formula: Reordering delay is the time. Your lead time is how much time you need to receive the order, create the product (whether you’re manufacturing it yourself or relying on suppliers), and. Lead time is the minimum time needed between placing an order and receiving it. Lead time in project management occurs when. Maximum Lead Time.

From www.theodmgroup.com

Manufacturing Lead Time A Quick Guide to Improve Business Efficiency Maximum Lead Time Lead time (lt) = supply delay (sd) + reordering delay (rd) supply delay is the time a supplier takes to fulfill a customer order after it’s placed. An example of lead time in a supply chain is when a manufacturer might need between two weeks and eight months, depending on certain variables, to deliver new cars after the buyer places. Maximum Lead Time.