Can You Machine High Speed Steel With Carbide . in many cases, carbide’s toughness allows a higher chip load per tooth, but the significant speed increase. Developed after carbide cutting tools in the 1930s, hss (including m1 and m2 types) have set the industry standard for. today, with a few exceptions, most cutting applications choose carbide over hss. in summary, the choice between carbide and hss depends on the specific application and the materials being machined. I've faced and drilled a. selecting between hss and carbide tools depends on various factors, including tool size, cutting depth, material removal rate,. never tried machining a hss cutter with carbide, not sure if it would work or just shatter the carbide. you can machine 62 rockwell hss with carbide at like 15 surface feet and.0001 feed rate.

from www.eptoolco.com

in many cases, carbide’s toughness allows a higher chip load per tooth, but the significant speed increase. I've faced and drilled a. in summary, the choice between carbide and hss depends on the specific application and the materials being machined. never tried machining a hss cutter with carbide, not sure if it would work or just shatter the carbide. today, with a few exceptions, most cutting applications choose carbide over hss. you can machine 62 rockwell hss with carbide at like 15 surface feet and.0001 feed rate. selecting between hss and carbide tools depends on various factors, including tool size, cutting depth, material removal rate,. Developed after carbide cutting tools in the 1930s, hss (including m1 and m2 types) have set the industry standard for.

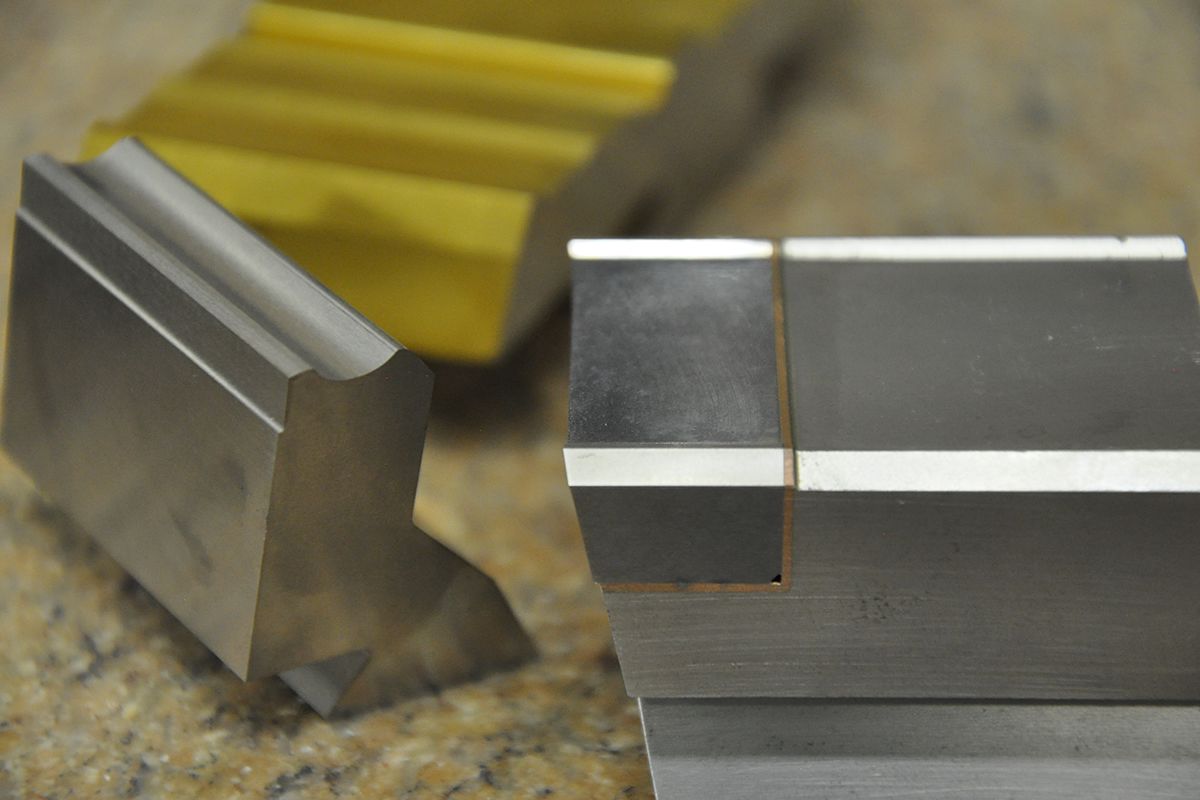

Tooling Carbide & High Speed E&P Form Tool Company

Can You Machine High Speed Steel With Carbide in summary, the choice between carbide and hss depends on the specific application and the materials being machined. selecting between hss and carbide tools depends on various factors, including tool size, cutting depth, material removal rate,. today, with a few exceptions, most cutting applications choose carbide over hss. in summary, the choice between carbide and hss depends on the specific application and the materials being machined. you can machine 62 rockwell hss with carbide at like 15 surface feet and.0001 feed rate. in many cases, carbide’s toughness allows a higher chip load per tooth, but the significant speed increase. I've faced and drilled a. Developed after carbide cutting tools in the 1930s, hss (including m1 and m2 types) have set the industry standard for. never tried machining a hss cutter with carbide, not sure if it would work or just shatter the carbide.

From www.cnccookbook.com

Carbide Drill Speeds and Feeds [Plus Tips and Techniques] Can You Machine High Speed Steel With Carbide in many cases, carbide’s toughness allows a higher chip load per tooth, but the significant speed increase. today, with a few exceptions, most cutting applications choose carbide over hss. never tried machining a hss cutter with carbide, not sure if it would work or just shatter the carbide. you can machine 62 rockwell hss with carbide. Can You Machine High Speed Steel With Carbide.

From www.indiamart.com

46 mm High Speed Steel Carbide Drill at best price in New Delhi ID Can You Machine High Speed Steel With Carbide in summary, the choice between carbide and hss depends on the specific application and the materials being machined. Developed after carbide cutting tools in the 1930s, hss (including m1 and m2 types) have set the industry standard for. never tried machining a hss cutter with carbide, not sure if it would work or just shatter the carbide. . Can You Machine High Speed Steel With Carbide.

From www.carbideanddiamondtooling.com

Radius Milling Cutters, Convex Radius Cutter, Concave Radius Cutter Can You Machine High Speed Steel With Carbide in many cases, carbide’s toughness allows a higher chip load per tooth, but the significant speed increase. Developed after carbide cutting tools in the 1930s, hss (including m1 and m2 types) have set the industry standard for. selecting between hss and carbide tools depends on various factors, including tool size, cutting depth, material removal rate,. I've faced and. Can You Machine High Speed Steel With Carbide.

From www.machinesused.com

Machines Used Assortment of High Speed Steel & Carbide End Mills Can You Machine High Speed Steel With Carbide today, with a few exceptions, most cutting applications choose carbide over hss. in many cases, carbide’s toughness allows a higher chip load per tooth, but the significant speed increase. in summary, the choice between carbide and hss depends on the specific application and the materials being machined. Developed after carbide cutting tools in the 1930s, hss (including. Can You Machine High Speed Steel With Carbide.

From www.beaverdrillstore.com

High Speed Steel Carbide Tipped Dovetail Cutter Beaver Drill Store Can You Machine High Speed Steel With Carbide you can machine 62 rockwell hss with carbide at like 15 surface feet and.0001 feed rate. never tried machining a hss cutter with carbide, not sure if it would work or just shatter the carbide. I've faced and drilled a. Developed after carbide cutting tools in the 1930s, hss (including m1 and m2 types) have set the industry. Can You Machine High Speed Steel With Carbide.

From www.eptoolco.com

Tooling Carbide & High Speed E&P Form Tool Company Can You Machine High Speed Steel With Carbide you can machine 62 rockwell hss with carbide at like 15 surface feet and.0001 feed rate. today, with a few exceptions, most cutting applications choose carbide over hss. in summary, the choice between carbide and hss depends on the specific application and the materials being machined. Developed after carbide cutting tools in the 1930s, hss (including m1. Can You Machine High Speed Steel With Carbide.

From golpmachine.en.made-in-china.com

High Speed Steel Carbide Insert Hob Multi Head Gear Hobbing Cutter Can You Machine High Speed Steel With Carbide today, with a few exceptions, most cutting applications choose carbide over hss. in many cases, carbide’s toughness allows a higher chip load per tooth, but the significant speed increase. in summary, the choice between carbide and hss depends on the specific application and the materials being machined. I've faced and drilled a. you can machine 62. Can You Machine High Speed Steel With Carbide.

From www.atmcn.com

High Speed Steel and Tools 安泰科技股份有限公司 Can You Machine High Speed Steel With Carbide you can machine 62 rockwell hss with carbide at like 15 surface feet and.0001 feed rate. in many cases, carbide’s toughness allows a higher chip load per tooth, but the significant speed increase. selecting between hss and carbide tools depends on various factors, including tool size, cutting depth, material removal rate,. today, with a few exceptions,. Can You Machine High Speed Steel With Carbide.

From www.machinesused.com

Machines Used Assorted High Speed Steel & Carbide End Mills Can You Machine High Speed Steel With Carbide in many cases, carbide’s toughness allows a higher chip load per tooth, but the significant speed increase. I've faced and drilled a. Developed after carbide cutting tools in the 1930s, hss (including m1 and m2 types) have set the industry standard for. you can machine 62 rockwell hss with carbide at like 15 surface feet and.0001 feed rate.. Can You Machine High Speed Steel With Carbide.

From www.indiamart.com

Twisted High Speed Steel Carbide Drill, For Industrial at Rs 100/piece Can You Machine High Speed Steel With Carbide Developed after carbide cutting tools in the 1930s, hss (including m1 and m2 types) have set the industry standard for. never tried machining a hss cutter with carbide, not sure if it would work or just shatter the carbide. selecting between hss and carbide tools depends on various factors, including tool size, cutting depth, material removal rate,. . Can You Machine High Speed Steel With Carbide.

From blog.thepipingmart.com

HighSpeed Steel Properties and Uses Can You Machine High Speed Steel With Carbide in many cases, carbide’s toughness allows a higher chip load per tooth, but the significant speed increase. you can machine 62 rockwell hss with carbide at like 15 surface feet and.0001 feed rate. never tried machining a hss cutter with carbide, not sure if it would work or just shatter the carbide. in summary, the choice. Can You Machine High Speed Steel With Carbide.

From www.indiamart.com

High Speed Steel Solid Carbide Step Drills at Rs 1500/piece in New Can You Machine High Speed Steel With Carbide in summary, the choice between carbide and hss depends on the specific application and the materials being machined. I've faced and drilled a. never tried machining a hss cutter with carbide, not sure if it would work or just shatter the carbide. in many cases, carbide’s toughness allows a higher chip load per tooth, but the significant. Can You Machine High Speed Steel With Carbide.

From www.differencebetween.com

Difference Between Carbide and High Speed Steel Compare the Can You Machine High Speed Steel With Carbide Developed after carbide cutting tools in the 1930s, hss (including m1 and m2 types) have set the industry standard for. today, with a few exceptions, most cutting applications choose carbide over hss. in summary, the choice between carbide and hss depends on the specific application and the materials being machined. in many cases, carbide’s toughness allows a. Can You Machine High Speed Steel With Carbide.

From www.aliexpress.com

MZG6mm10mmSTUBR06HighSpeedSteelCarbideInsertsInternal Can You Machine High Speed Steel With Carbide Developed after carbide cutting tools in the 1930s, hss (including m1 and m2 types) have set the industry standard for. I've faced and drilled a. selecting between hss and carbide tools depends on various factors, including tool size, cutting depth, material removal rate,. in summary, the choice between carbide and hss depends on the specific application and the. Can You Machine High Speed Steel With Carbide.

From www.taiwantrade.com

HighSpeed Steel Carbide Tipped Extrusion Process Can You Machine High Speed Steel With Carbide never tried machining a hss cutter with carbide, not sure if it would work or just shatter the carbide. today, with a few exceptions, most cutting applications choose carbide over hss. Developed after carbide cutting tools in the 1930s, hss (including m1 and m2 types) have set the industry standard for. I've faced and drilled a. you. Can You Machine High Speed Steel With Carbide.

From www.dreamstime.com

Various Size Precision High Speed Steel with Carbide Cutting Drill Bit Can You Machine High Speed Steel With Carbide I've faced and drilled a. never tried machining a hss cutter with carbide, not sure if it would work or just shatter the carbide. Developed after carbide cutting tools in the 1930s, hss (including m1 and m2 types) have set the industry standard for. in summary, the choice between carbide and hss depends on the specific application and. Can You Machine High Speed Steel With Carbide.

From www.youtube.com

(HighSpeed Video) Solid Carbide Drill 4140 Steel YouTube Can You Machine High Speed Steel With Carbide in many cases, carbide’s toughness allows a higher chip load per tooth, but the significant speed increase. today, with a few exceptions, most cutting applications choose carbide over hss. I've faced and drilled a. in summary, the choice between carbide and hss depends on the specific application and the materials being machined. never tried machining a. Can You Machine High Speed Steel With Carbide.

From tooltalk.blog

The Difference Between High Speed Steel & Carbide End Mills Tool Talk Can You Machine High Speed Steel With Carbide you can machine 62 rockwell hss with carbide at like 15 surface feet and.0001 feed rate. I've faced and drilled a. in many cases, carbide’s toughness allows a higher chip load per tooth, but the significant speed increase. in summary, the choice between carbide and hss depends on the specific application and the materials being machined. . Can You Machine High Speed Steel With Carbide.

From www.indiamart.com

High Speed Steel Carbide Reamers at best price in Kolkata by Hind Can You Machine High Speed Steel With Carbide in many cases, carbide’s toughness allows a higher chip load per tooth, but the significant speed increase. Developed after carbide cutting tools in the 1930s, hss (including m1 and m2 types) have set the industry standard for. I've faced and drilled a. in summary, the choice between carbide and hss depends on the specific application and the materials. Can You Machine High Speed Steel With Carbide.

From www.slideserve.com

PPT Cutting Speed, Feed, and Depth of Cut PowerPoint Presentation Can You Machine High Speed Steel With Carbide in many cases, carbide’s toughness allows a higher chip load per tooth, but the significant speed increase. in summary, the choice between carbide and hss depends on the specific application and the materials being machined. never tried machining a hss cutter with carbide, not sure if it would work or just shatter the carbide. selecting between. Can You Machine High Speed Steel With Carbide.

From www.indiamart.com

High Speed Steel Carbide Drill at Rs 100/piece Solid Carbide Drill in Can You Machine High Speed Steel With Carbide Developed after carbide cutting tools in the 1930s, hss (including m1 and m2 types) have set the industry standard for. I've faced and drilled a. selecting between hss and carbide tools depends on various factors, including tool size, cutting depth, material removal rate,. in many cases, carbide’s toughness allows a higher chip load per tooth, but the significant. Can You Machine High Speed Steel With Carbide.

From blog.thepipingmart.com

HighSpeed Steel Uses and Benefits Can You Machine High Speed Steel With Carbide today, with a few exceptions, most cutting applications choose carbide over hss. you can machine 62 rockwell hss with carbide at like 15 surface feet and.0001 feed rate. selecting between hss and carbide tools depends on various factors, including tool size, cutting depth, material removal rate,. Developed after carbide cutting tools in the 1930s, hss (including m1. Can You Machine High Speed Steel With Carbide.

From iscrapapp.com

Difference Between Carbide & HighSpeed Steel Can You Machine High Speed Steel With Carbide in summary, the choice between carbide and hss depends on the specific application and the materials being machined. never tried machining a hss cutter with carbide, not sure if it would work or just shatter the carbide. in many cases, carbide’s toughness allows a higher chip load per tooth, but the significant speed increase. today, with. Can You Machine High Speed Steel With Carbide.

From www.carbideanddiamondtooling.com

Milling Cutter Keyseat Deep Slotting Cutter High Speed Steel, Carbide Can You Machine High Speed Steel With Carbide today, with a few exceptions, most cutting applications choose carbide over hss. Developed after carbide cutting tools in the 1930s, hss (including m1 and m2 types) have set the industry standard for. in summary, the choice between carbide and hss depends on the specific application and the materials being machined. selecting between hss and carbide tools depends. Can You Machine High Speed Steel With Carbide.

From www.eptoolco.com

Tooling Carbide & High Speed E&P Form Tool Company Can You Machine High Speed Steel With Carbide selecting between hss and carbide tools depends on various factors, including tool size, cutting depth, material removal rate,. I've faced and drilled a. you can machine 62 rockwell hss with carbide at like 15 surface feet and.0001 feed rate. never tried machining a hss cutter with carbide, not sure if it would work or just shatter the. Can You Machine High Speed Steel With Carbide.

From watsontooling.com.au

High Speed Steel and Carbide Pilots Can You Machine High Speed Steel With Carbide selecting between hss and carbide tools depends on various factors, including tool size, cutting depth, material removal rate,. you can machine 62 rockwell hss with carbide at like 15 surface feet and.0001 feed rate. today, with a few exceptions, most cutting applications choose carbide over hss. Developed after carbide cutting tools in the 1930s, hss (including m1. Can You Machine High Speed Steel With Carbide.

From www.practicalmachinist.com

Walter unveils two new highspeed solid carbide milling cutters Can You Machine High Speed Steel With Carbide in summary, the choice between carbide and hss depends on the specific application and the materials being machined. I've faced and drilled a. selecting between hss and carbide tools depends on various factors, including tool size, cutting depth, material removal rate,. you can machine 62 rockwell hss with carbide at like 15 surface feet and.0001 feed rate.. Can You Machine High Speed Steel With Carbide.

From www.aliexpress.com

Coarse tooth High speed Steel Carbide Rotary Burrs Woodworking Tools Can You Machine High Speed Steel With Carbide you can machine 62 rockwell hss with carbide at like 15 surface feet and.0001 feed rate. today, with a few exceptions, most cutting applications choose carbide over hss. never tried machining a hss cutter with carbide, not sure if it would work or just shatter the carbide. I've faced and drilled a. in many cases, carbide’s. Can You Machine High Speed Steel With Carbide.

From www.chegg.com

Solved A Face Milling Operation on machine steel plate is Can You Machine High Speed Steel With Carbide in summary, the choice between carbide and hss depends on the specific application and the materials being machined. you can machine 62 rockwell hss with carbide at like 15 surface feet and.0001 feed rate. I've faced and drilled a. selecting between hss and carbide tools depends on various factors, including tool size, cutting depth, material removal rate,.. Can You Machine High Speed Steel With Carbide.

From www.carbideanddiamondtooling.com

A complete source of Single Angle Milling Cutter Double Angle Milling Can You Machine High Speed Steel With Carbide Developed after carbide cutting tools in the 1930s, hss (including m1 and m2 types) have set the industry standard for. never tried machining a hss cutter with carbide, not sure if it would work or just shatter the carbide. today, with a few exceptions, most cutting applications choose carbide over hss. in many cases, carbide’s toughness allows. Can You Machine High Speed Steel With Carbide.

From www.pinterest.com

High Speed Steel Carbide Tip 13pc HSS Hole Saw Bit Set TrainedTools Can You Machine High Speed Steel With Carbide selecting between hss and carbide tools depends on various factors, including tool size, cutting depth, material removal rate,. in many cases, carbide’s toughness allows a higher chip load per tooth, but the significant speed increase. never tried machining a hss cutter with carbide, not sure if it would work or just shatter the carbide. today, with. Can You Machine High Speed Steel With Carbide.

From www.differencebetween.com

Difference Between Carbide and High Speed Steel Compare the Can You Machine High Speed Steel With Carbide I've faced and drilled a. Developed after carbide cutting tools in the 1930s, hss (including m1 and m2 types) have set the industry standard for. you can machine 62 rockwell hss with carbide at like 15 surface feet and.0001 feed rate. in many cases, carbide’s toughness allows a higher chip load per tooth, but the significant speed increase.. Can You Machine High Speed Steel With Carbide.

From flavored.ph

DIY Tools & Equipment Home High Speed Steel Rotary Burrs 1/8 Can You Machine High Speed Steel With Carbide you can machine 62 rockwell hss with carbide at like 15 surface feet and.0001 feed rate. in many cases, carbide’s toughness allows a higher chip load per tooth, but the significant speed increase. in summary, the choice between carbide and hss depends on the specific application and the materials being machined. today, with a few exceptions,. Can You Machine High Speed Steel With Carbide.

From www.eptoolco.com

Tooling Carbide & High Speed E&P Form Tool Company Can You Machine High Speed Steel With Carbide Developed after carbide cutting tools in the 1930s, hss (including m1 and m2 types) have set the industry standard for. never tried machining a hss cutter with carbide, not sure if it would work or just shatter the carbide. you can machine 62 rockwell hss with carbide at like 15 surface feet and.0001 feed rate. selecting between. Can You Machine High Speed Steel With Carbide.

From www.indiamart.com

High Speed Steel Carbide Drill, Rs 100 /piece Atson Tools Private Can You Machine High Speed Steel With Carbide selecting between hss and carbide tools depends on various factors, including tool size, cutting depth, material removal rate,. never tried machining a hss cutter with carbide, not sure if it would work or just shatter the carbide. you can machine 62 rockwell hss with carbide at like 15 surface feet and.0001 feed rate. Developed after carbide cutting. Can You Machine High Speed Steel With Carbide.