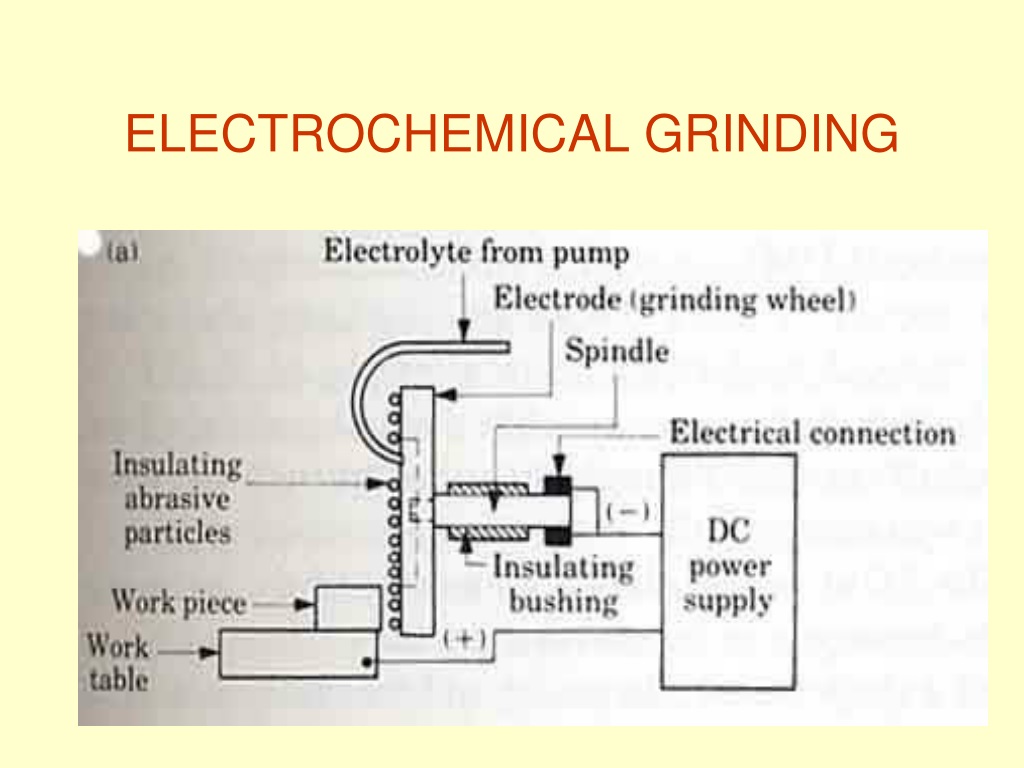

Application Of Electrochemical Grinding . Electrochemical grinding is a process that removes electrically conductive material by grinding with a negatively charged abrasive. Electrochemical grinding (ecg) is a hybrid process combining grinding and ecm, which uses a grinding wheel as electrode to remove. The single largest use for ecg is in the manufacturing and remanufacturing of turbine blades and vanes for aircraft turbine engines. Advances in controls, sensors and automation are making electrochemical grinding more accurate and productive than ever,. It discusses grinding methods that can be performed with. This article describes the various characteristics of electrochemical grinding (ecg). Grinding of tungsten carbide tool inserts. The applications of electrochemical grinding include grinding turbine blades, honeycomb structures in aerospace, finishing hard surfaces, creating sharp. Electrochemical grinding is a process that removes electrically conductive material by grinding with a negatively charged abrasive grinding wheel, an electrolyte fluid, and a.

from www.slideserve.com

Advances in controls, sensors and automation are making electrochemical grinding more accurate and productive than ever,. This article describes the various characteristics of electrochemical grinding (ecg). The single largest use for ecg is in the manufacturing and remanufacturing of turbine blades and vanes for aircraft turbine engines. Grinding of tungsten carbide tool inserts. Electrochemical grinding is a process that removes electrically conductive material by grinding with a negatively charged abrasive grinding wheel, an electrolyte fluid, and a. The applications of electrochemical grinding include grinding turbine blades, honeycomb structures in aerospace, finishing hard surfaces, creating sharp. Electrochemical grinding (ecg) is a hybrid process combining grinding and ecm, which uses a grinding wheel as electrode to remove. It discusses grinding methods that can be performed with. Electrochemical grinding is a process that removes electrically conductive material by grinding with a negatively charged abrasive.

PPT Nontraditional Machining Processes PowerPoint Presentation, free

Application Of Electrochemical Grinding It discusses grinding methods that can be performed with. Electrochemical grinding is a process that removes electrically conductive material by grinding with a negatively charged abrasive. The single largest use for ecg is in the manufacturing and remanufacturing of turbine blades and vanes for aircraft turbine engines. This article describes the various characteristics of electrochemical grinding (ecg). Grinding of tungsten carbide tool inserts. It discusses grinding methods that can be performed with. Electrochemical grinding (ecg) is a hybrid process combining grinding and ecm, which uses a grinding wheel as electrode to remove. The applications of electrochemical grinding include grinding turbine blades, honeycomb structures in aerospace, finishing hard surfaces, creating sharp. Electrochemical grinding is a process that removes electrically conductive material by grinding with a negatively charged abrasive grinding wheel, an electrolyte fluid, and a. Advances in controls, sensors and automation are making electrochemical grinding more accurate and productive than ever,.

From www.researchgate.net

Schematic view grinding and electrochemical removal [49]. Download Application Of Electrochemical Grinding The single largest use for ecg is in the manufacturing and remanufacturing of turbine blades and vanes for aircraft turbine engines. Electrochemical grinding is a process that removes electrically conductive material by grinding with a negatively charged abrasive. Advances in controls, sensors and automation are making electrochemical grinding more accurate and productive than ever,. Grinding of tungsten carbide tool inserts.. Application Of Electrochemical Grinding.

From www.mechanicalbooster.com

What is Electrochemical Grinding and How it Works? Mechanical Booster Application Of Electrochemical Grinding This article describes the various characteristics of electrochemical grinding (ecg). Advances in controls, sensors and automation are making electrochemical grinding more accurate and productive than ever,. The applications of electrochemical grinding include grinding turbine blades, honeycomb structures in aerospace, finishing hard surfaces, creating sharp. Electrochemical grinding is a process that removes electrically conductive material by grinding with a negatively charged. Application Of Electrochemical Grinding.

From themechanicalengineering.com

Electrochemical Grinding Definition, Parts or Construction, Working Application Of Electrochemical Grinding It discusses grinding methods that can be performed with. Grinding of tungsten carbide tool inserts. Electrochemical grinding is a process that removes electrically conductive material by grinding with a negatively charged abrasive grinding wheel, an electrolyte fluid, and a. The single largest use for ecg is in the manufacturing and remanufacturing of turbine blades and vanes for aircraft turbine engines.. Application Of Electrochemical Grinding.

From www.difference.minaprem.com

Difference Between EDG and ECG Electro Discharge Grinding and Electro Application Of Electrochemical Grinding The single largest use for ecg is in the manufacturing and remanufacturing of turbine blades and vanes for aircraft turbine engines. It discusses grinding methods that can be performed with. The applications of electrochemical grinding include grinding turbine blades, honeycomb structures in aerospace, finishing hard surfaces, creating sharp. Electrochemical grinding is a process that removes electrically conductive material by grinding. Application Of Electrochemical Grinding.

From www.engineeringchoice.com

What is Electrochemical Grinding and How it's done? Application Of Electrochemical Grinding Electrochemical grinding is a process that removes electrically conductive material by grinding with a negatively charged abrasive grinding wheel, an electrolyte fluid, and a. Electrochemical grinding is a process that removes electrically conductive material by grinding with a negatively charged abrasive. Grinding of tungsten carbide tool inserts. This article describes the various characteristics of electrochemical grinding (ecg). Electrochemical grinding (ecg). Application Of Electrochemical Grinding.

From slideplayer.com

Chemical Machining Fig (a) Schematic illustration of the chemical Application Of Electrochemical Grinding The single largest use for ecg is in the manufacturing and remanufacturing of turbine blades and vanes for aircraft turbine engines. Electrochemical grinding is a process that removes electrically conductive material by grinding with a negatively charged abrasive grinding wheel, an electrolyte fluid, and a. This article describes the various characteristics of electrochemical grinding (ecg). Electrochemical grinding (ecg) is a. Application Of Electrochemical Grinding.

From www.researchgate.net

Photograph of electrochemical cutoff grinding (ECCG) machine Application Of Electrochemical Grinding Advances in controls, sensors and automation are making electrochemical grinding more accurate and productive than ever,. Electrochemical grinding is a process that removes electrically conductive material by grinding with a negatively charged abrasive grinding wheel, an electrolyte fluid, and a. Electrochemical grinding is a process that removes electrically conductive material by grinding with a negatively charged abrasive. This article describes. Application Of Electrochemical Grinding.

From www.slideserve.com

PPT Nontraditional Machining Processes PowerPoint Presentation, free Application Of Electrochemical Grinding The applications of electrochemical grinding include grinding turbine blades, honeycomb structures in aerospace, finishing hard surfaces, creating sharp. It discusses grinding methods that can be performed with. Grinding of tungsten carbide tool inserts. Electrochemical grinding (ecg) is a hybrid process combining grinding and ecm, which uses a grinding wheel as electrode to remove. This article describes the various characteristics of. Application Of Electrochemical Grinding.

From www.youtube.com

electrochemical grinding YouTube Application Of Electrochemical Grinding It discusses grinding methods that can be performed with. This article describes the various characteristics of electrochemical grinding (ecg). Advances in controls, sensors and automation are making electrochemical grinding more accurate and productive than ever,. Grinding of tungsten carbide tool inserts. The single largest use for ecg is in the manufacturing and remanufacturing of turbine blades and vanes for aircraft. Application Of Electrochemical Grinding.

From www.theengineerspost.com

Electrochemical Machining (ECM) Process, Working & Diagram Application Of Electrochemical Grinding Electrochemical grinding is a process that removes electrically conductive material by grinding with a negatively charged abrasive grinding wheel, an electrolyte fluid, and a. It discusses grinding methods that can be performed with. This article describes the various characteristics of electrochemical grinding (ecg). The applications of electrochemical grinding include grinding turbine blades, honeycomb structures in aerospace, finishing hard surfaces, creating. Application Of Electrochemical Grinding.

From www.mdpi.com

Applied Sciences Free FullText Simulation Analysis and Application Of Electrochemical Grinding The applications of electrochemical grinding include grinding turbine blades, honeycomb structures in aerospace, finishing hard surfaces, creating sharp. Advances in controls, sensors and automation are making electrochemical grinding more accurate and productive than ever,. It discusses grinding methods that can be performed with. This article describes the various characteristics of electrochemical grinding (ecg). Electrochemical grinding is a process that removes. Application Of Electrochemical Grinding.

From www.researchgate.net

Schematic diagram of electrochemical cutoff grinding process Application Of Electrochemical Grinding This article describes the various characteristics of electrochemical grinding (ecg). The single largest use for ecg is in the manufacturing and remanufacturing of turbine blades and vanes for aircraft turbine engines. Advances in controls, sensors and automation are making electrochemical grinding more accurate and productive than ever,. Electrochemical grinding (ecg) is a hybrid process combining grinding and ecm, which uses. Application Of Electrochemical Grinding.

From www.manufacturingguide.com

Electrochemical grinding Find suppliers, processes & material Application Of Electrochemical Grinding The applications of electrochemical grinding include grinding turbine blades, honeycomb structures in aerospace, finishing hard surfaces, creating sharp. This article describes the various characteristics of electrochemical grinding (ecg). Advances in controls, sensors and automation are making electrochemical grinding more accurate and productive than ever,. It discusses grinding methods that can be performed with. The single largest use for ecg is. Application Of Electrochemical Grinding.

From www.youtube.com

Electro Chemical Grinding (हिन्दी) YouTube Application Of Electrochemical Grinding Advances in controls, sensors and automation are making electrochemical grinding more accurate and productive than ever,. The applications of electrochemical grinding include grinding turbine blades, honeycomb structures in aerospace, finishing hard surfaces, creating sharp. The single largest use for ecg is in the manufacturing and remanufacturing of turbine blades and vanes for aircraft turbine engines. Grinding of tungsten carbide tool. Application Of Electrochemical Grinding.

From slideplayer.com

Chemical Machining Fig (a) Schematic illustration of the chemical Application Of Electrochemical Grinding Electrochemical grinding is a process that removes electrically conductive material by grinding with a negatively charged abrasive. It discusses grinding methods that can be performed with. This article describes the various characteristics of electrochemical grinding (ecg). The single largest use for ecg is in the manufacturing and remanufacturing of turbine blades and vanes for aircraft turbine engines. Grinding of tungsten. Application Of Electrochemical Grinding.

From www.slideshare.net

Electro Chemical Grinding & Electro Chemical Honing processes Application Of Electrochemical Grinding Electrochemical grinding is a process that removes electrically conductive material by grinding with a negatively charged abrasive. The single largest use for ecg is in the manufacturing and remanufacturing of turbine blades and vanes for aircraft turbine engines. The applications of electrochemical grinding include grinding turbine blades, honeycomb structures in aerospace, finishing hard surfaces, creating sharp. Advances in controls, sensors. Application Of Electrochemical Grinding.

From www.researchgate.net

Electrochemical grinding system Download Scientific Diagram Application Of Electrochemical Grinding Grinding of tungsten carbide tool inserts. The applications of electrochemical grinding include grinding turbine blades, honeycomb structures in aerospace, finishing hard surfaces, creating sharp. Advances in controls, sensors and automation are making electrochemical grinding more accurate and productive than ever,. The single largest use for ecg is in the manufacturing and remanufacturing of turbine blades and vanes for aircraft turbine. Application Of Electrochemical Grinding.

From www.slideshare.net

Electrochemical grinding (ecg) PPT Application Of Electrochemical Grinding Grinding of tungsten carbide tool inserts. Electrochemical grinding (ecg) is a hybrid process combining grinding and ecm, which uses a grinding wheel as electrode to remove. This article describes the various characteristics of electrochemical grinding (ecg). Electrochemical grinding is a process that removes electrically conductive material by grinding with a negatively charged abrasive. The single largest use for ecg is. Application Of Electrochemical Grinding.

From electricalworkbook.com

What is Electrochemical Grinding (ECG)? Process, Diagram, Advantages Application Of Electrochemical Grinding Electrochemical grinding is a process that removes electrically conductive material by grinding with a negatively charged abrasive grinding wheel, an electrolyte fluid, and a. Electrochemical grinding is a process that removes electrically conductive material by grinding with a negatively charged abrasive. It discusses grinding methods that can be performed with. Advances in controls, sensors and automation are making electrochemical grinding. Application Of Electrochemical Grinding.

From www.researchgate.net

Initial flow field model of innerjet electrochemical grinding with a Application Of Electrochemical Grinding This article describes the various characteristics of electrochemical grinding (ecg). Advances in controls, sensors and automation are making electrochemical grinding more accurate and productive than ever,. Electrochemical grinding is a process that removes electrically conductive material by grinding with a negatively charged abrasive grinding wheel, an electrolyte fluid, and a. The applications of electrochemical grinding include grinding turbine blades, honeycomb. Application Of Electrochemical Grinding.

From www.slideserve.com

PPT Advanced Machining Processes PowerPoint Presentation, free Application Of Electrochemical Grinding Electrochemical grinding is a process that removes electrically conductive material by grinding with a negatively charged abrasive grinding wheel, an electrolyte fluid, and a. Electrochemical grinding (ecg) is a hybrid process combining grinding and ecm, which uses a grinding wheel as electrode to remove. It discusses grinding methods that can be performed with. The applications of electrochemical grinding include grinding. Application Of Electrochemical Grinding.

From www.youtube.com

Benefits of Electrochemical Grinding ECG Tridex Technology, a Glebar Application Of Electrochemical Grinding This article describes the various characteristics of electrochemical grinding (ecg). Grinding of tungsten carbide tool inserts. Advances in controls, sensors and automation are making electrochemical grinding more accurate and productive than ever,. It discusses grinding methods that can be performed with. Electrochemical grinding (ecg) is a hybrid process combining grinding and ecm, which uses a grinding wheel as electrode to. Application Of Electrochemical Grinding.

From www.youtube.com

Electrochemical Grinding Process How electrochemical grinding works Application Of Electrochemical Grinding The applications of electrochemical grinding include grinding turbine blades, honeycomb structures in aerospace, finishing hard surfaces, creating sharp. Grinding of tungsten carbide tool inserts. Electrochemical grinding is a process that removes electrically conductive material by grinding with a negatively charged abrasive grinding wheel, an electrolyte fluid, and a. This article describes the various characteristics of electrochemical grinding (ecg). Advances in. Application Of Electrochemical Grinding.

From www.youtube.com

ANUNIVERSE 22 WORKING OF ELECTROCHEMICAL GRINDING (ECG) NTM 13 Application Of Electrochemical Grinding Advances in controls, sensors and automation are making electrochemical grinding more accurate and productive than ever,. Electrochemical grinding is a process that removes electrically conductive material by grinding with a negatively charged abrasive. The single largest use for ecg is in the manufacturing and remanufacturing of turbine blades and vanes for aircraft turbine engines. Electrochemical grinding (ecg) is a hybrid. Application Of Electrochemical Grinding.

From www.youtube.com

Electrochemical Grinding YouTube Application Of Electrochemical Grinding Electrochemical grinding (ecg) is a hybrid process combining grinding and ecm, which uses a grinding wheel as electrode to remove. Advances in controls, sensors and automation are making electrochemical grinding more accurate and productive than ever,. Electrochemical grinding is a process that removes electrically conductive material by grinding with a negatively charged abrasive. The single largest use for ecg is. Application Of Electrochemical Grinding.

From www.youtube.com

WORKING OF ELECTROCHEMICAL GRINDING [ECG] YouTube Application Of Electrochemical Grinding Electrochemical grinding is a process that removes electrically conductive material by grinding with a negatively charged abrasive. This article describes the various characteristics of electrochemical grinding (ecg). The single largest use for ecg is in the manufacturing and remanufacturing of turbine blades and vanes for aircraft turbine engines. Advances in controls, sensors and automation are making electrochemical grinding more accurate. Application Of Electrochemical Grinding.

From www.researchgate.net

Schematic of the electrolytic inprocess dressing (ELID) grinding Application Of Electrochemical Grinding The applications of electrochemical grinding include grinding turbine blades, honeycomb structures in aerospace, finishing hard surfaces, creating sharp. The single largest use for ecg is in the manufacturing and remanufacturing of turbine blades and vanes for aircraft turbine engines. This article describes the various characteristics of electrochemical grinding (ecg). It discusses grinding methods that can be performed with. Electrochemical grinding. Application Of Electrochemical Grinding.

From www.youtube.com

ELECTROCHEMICAL GRINDING WORKING YouTube Application Of Electrochemical Grinding The applications of electrochemical grinding include grinding turbine blades, honeycomb structures in aerospace, finishing hard surfaces, creating sharp. It discusses grinding methods that can be performed with. Electrochemical grinding is a process that removes electrically conductive material by grinding with a negatively charged abrasive. Electrochemical grinding is a process that removes electrically conductive material by grinding with a negatively charged. Application Of Electrochemical Grinding.

From www.researchgate.net

Electrochemical grinding system Download Scientific Diagram Application Of Electrochemical Grinding The single largest use for ecg is in the manufacturing and remanufacturing of turbine blades and vanes for aircraft turbine engines. Advances in controls, sensors and automation are making electrochemical grinding more accurate and productive than ever,. Grinding of tungsten carbide tool inserts. It discusses grinding methods that can be performed with. The applications of electrochemical grinding include grinding turbine. Application Of Electrochemical Grinding.

From vimeo.com

Tridex Technology Electrochemical Grinding (ECG) on Vimeo Application Of Electrochemical Grinding Electrochemical grinding is a process that removes electrically conductive material by grinding with a negatively charged abrasive grinding wheel, an electrolyte fluid, and a. Electrochemical grinding is a process that removes electrically conductive material by grinding with a negatively charged abrasive. Advances in controls, sensors and automation are making electrochemical grinding more accurate and productive than ever,. The single largest. Application Of Electrochemical Grinding.

From www.studypool.com

SOLUTION Electrochemical grinding Studypool Application Of Electrochemical Grinding The applications of electrochemical grinding include grinding turbine blades, honeycomb structures in aerospace, finishing hard surfaces, creating sharp. Advances in controls, sensors and automation are making electrochemical grinding more accurate and productive than ever,. This article describes the various characteristics of electrochemical grinding (ecg). The single largest use for ecg is in the manufacturing and remanufacturing of turbine blades and. Application Of Electrochemical Grinding.

From www.researchgate.net

Sectional diagram of the electrochemical grinding processing area Application Of Electrochemical Grinding Advances in controls, sensors and automation are making electrochemical grinding more accurate and productive than ever,. The single largest use for ecg is in the manufacturing and remanufacturing of turbine blades and vanes for aircraft turbine engines. It discusses grinding methods that can be performed with. This article describes the various characteristics of electrochemical grinding (ecg). Electrochemical grinding (ecg) is. Application Of Electrochemical Grinding.

From www.microgroup.com

Electro Chemical Grinding • TE Connectivity, CUC Application Of Electrochemical Grinding The applications of electrochemical grinding include grinding turbine blades, honeycomb structures in aerospace, finishing hard surfaces, creating sharp. Advances in controls, sensors and automation are making electrochemical grinding more accurate and productive than ever,. The single largest use for ecg is in the manufacturing and remanufacturing of turbine blades and vanes for aircraft turbine engines. Electrochemical grinding is a process. Application Of Electrochemical Grinding.

From www.worthyhardware.com

Complete Guide on Electrochemical Machining Worthy Hardware Application Of Electrochemical Grinding The single largest use for ecg is in the manufacturing and remanufacturing of turbine blades and vanes for aircraft turbine engines. Electrochemical grinding is a process that removes electrically conductive material by grinding with a negatively charged abrasive grinding wheel, an electrolyte fluid, and a. Advances in controls, sensors and automation are making electrochemical grinding more accurate and productive than. Application Of Electrochemical Grinding.

From www.thermalspray.com

What You Need To Know About Electrochemical Grinding A&A Thermal Application Of Electrochemical Grinding Electrochemical grinding is a process that removes electrically conductive material by grinding with a negatively charged abrasive. The single largest use for ecg is in the manufacturing and remanufacturing of turbine blades and vanes for aircraft turbine engines. It discusses grinding methods that can be performed with. Electrochemical grinding (ecg) is a hybrid process combining grinding and ecm, which uses. Application Of Electrochemical Grinding.