Deburring Department . Get rid of metal burrs with these 13 proven deburring methods. Deburring small, intricate parts is almost an art form as it requires fine motor skills, an understanding of critical part features and. Efficient deburring for quality finished parts. R.p abrasives leads the industry with innovative finishing techniques and processes which transform and improve the. Improve your products' quality and performance. Stamping, for instance, presses the workpiece in a die set, while milling uses a rotating tool to shave metal off a workpiece. As with all other machining tools, the required deburring tools are stored in the. The deburring procedure is an integrated part of the machining process. Deburring is the process of removing the small imperfections known as burrs from machined metal products. Our capabilities include a wide range of edge and. Machining processes shape a piece of metal in different ways. Read on to learn more. At deburring house inc., we take pride in offering our customers the best value to meet their mechanical finishing needs.

from brushingmachine.com

Our capabilities include a wide range of edge and. Get rid of metal burrs with these 13 proven deburring methods. Improve your products' quality and performance. As with all other machining tools, the required deburring tools are stored in the. Machining processes shape a piece of metal in different ways. Efficient deburring for quality finished parts. Deburring small, intricate parts is almost an art form as it requires fine motor skills, an understanding of critical part features and. The deburring procedure is an integrated part of the machining process. Stamping, for instance, presses the workpiece in a die set, while milling uses a rotating tool to shave metal off a workpiece. Read on to learn more.

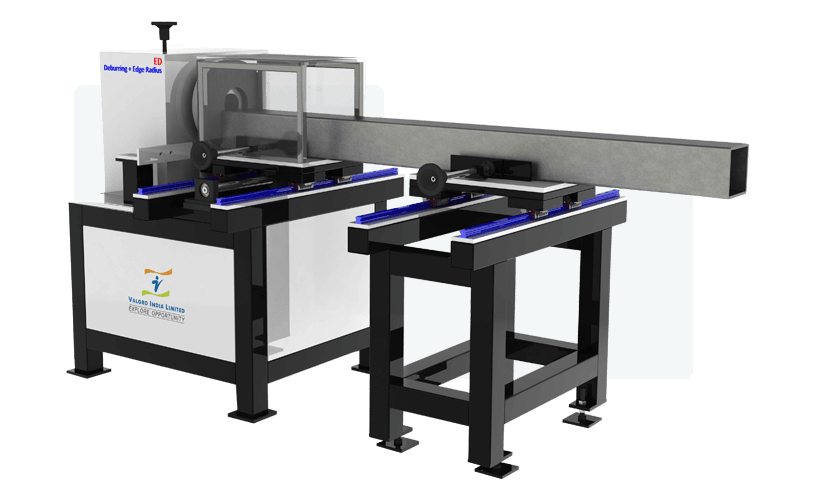

Deburring and Edge Rounding Machines Valgro Hyzer Valgro India Ltd.

Deburring Department Deburring small, intricate parts is almost an art form as it requires fine motor skills, an understanding of critical part features and. Our capabilities include a wide range of edge and. R.p abrasives leads the industry with innovative finishing techniques and processes which transform and improve the. Machining processes shape a piece of metal in different ways. Efficient deburring for quality finished parts. Get rid of metal burrs with these 13 proven deburring methods. Stamping, for instance, presses the workpiece in a die set, while milling uses a rotating tool to shave metal off a workpiece. Deburring small, intricate parts is almost an art form as it requires fine motor skills, an understanding of critical part features and. Read on to learn more. Deburring is the process of removing the small imperfections known as burrs from machined metal products. As with all other machining tools, the required deburring tools are stored in the. Improve your products' quality and performance. The deburring procedure is an integrated part of the machining process. At deburring house inc., we take pride in offering our customers the best value to meet their mechanical finishing needs.

From www.morganrushworth.com

Our New Deburring Machine Rushworth DFR Deburring Department Get rid of metal burrs with these 13 proven deburring methods. Efficient deburring for quality finished parts. Read on to learn more. The deburring procedure is an integrated part of the machining process. Our capabilities include a wide range of edge and. Deburring small, intricate parts is almost an art form as it requires fine motor skills, an understanding of. Deburring Department.

From www.harveyperformance.com

Why You Should Stop Deburring By Hand In The Loupe Deburring Department Deburring is the process of removing the small imperfections known as burrs from machined metal products. Efficient deburring for quality finished parts. Read on to learn more. Stamping, for instance, presses the workpiece in a die set, while milling uses a rotating tool to shave metal off a workpiece. Our capabilities include a wide range of edge and. As with. Deburring Department.

From gwmachinery.com

VALGRO SAMARTH DB SERIES DEBURRING MACHINE Deburring Department Read on to learn more. The deburring procedure is an integrated part of the machining process. Deburring small, intricate parts is almost an art form as it requires fine motor skills, an understanding of critical part features and. R.p abrasives leads the industry with innovative finishing techniques and processes which transform and improve the. At deburring house inc., we take. Deburring Department.

From howtorobot.com

Deburring Robots More Accessible Than Ever HowToRobot Deburring Department Our capabilities include a wide range of edge and. As with all other machining tools, the required deburring tools are stored in the. Deburring small, intricate parts is almost an art form as it requires fine motor skills, an understanding of critical part features and. Stamping, for instance, presses the workpiece in a die set, while milling uses a rotating. Deburring Department.

From www.surplex.com

KSMA ECM 800/60 ECM deburring machine buy used Deburring Department R.p abrasives leads the industry with innovative finishing techniques and processes which transform and improve the. Deburring small, intricate parts is almost an art form as it requires fine motor skills, an understanding of critical part features and. Deburring is the process of removing the small imperfections known as burrs from machined metal products. Get rid of metal burrs with. Deburring Department.

From www.sksdiecasting.com

SKS Die Casting China Facility High Volume Production Deburring Department Read on to learn more. Stamping, for instance, presses the workpiece in a die set, while milling uses a rotating tool to shave metal off a workpiece. Our capabilities include a wide range of edge and. At deburring house inc., we take pride in offering our customers the best value to meet their mechanical finishing needs. The deburring procedure is. Deburring Department.

From www.metalready.com

What is Deburring? Ultimate Game Changer of Metal Industry Deburring Department Machining processes shape a piece of metal in different ways. R.p abrasives leads the industry with innovative finishing techniques and processes which transform and improve the. As with all other machining tools, the required deburring tools are stored in the. Get rid of metal burrs with these 13 proven deburring methods. Efficient deburring for quality finished parts. Our capabilities include. Deburring Department.

From www.tubeformingmachinery.com

Tube Deburring Machinery Manufacturers Tube Forming Machinery Deburring Department At deburring house inc., we take pride in offering our customers the best value to meet their mechanical finishing needs. Deburring small, intricate parts is almost an art form as it requires fine motor skills, an understanding of critical part features and. Machining processes shape a piece of metal in different ways. As with all other machining tools, the required. Deburring Department.

From goialde.com

Deburring Goialde Components Deburring Department Improve your products' quality and performance. At deburring house inc., we take pride in offering our customers the best value to meet their mechanical finishing needs. As with all other machining tools, the required deburring tools are stored in the. R.p abrasives leads the industry with innovative finishing techniques and processes which transform and improve the. Efficient deburring for quality. Deburring Department.

From universalgrinding.com

Deburring • Universal Grinding Corporation Deburring Department Get rid of metal burrs with these 13 proven deburring methods. At deburring house inc., we take pride in offering our customers the best value to meet their mechanical finishing needs. Stamping, for instance, presses the workpiece in a die set, while milling uses a rotating tool to shave metal off a workpiece. Deburring is the process of removing the. Deburring Department.

From www.sksdiecasting.com

SKS Die Casting China Facility High Volume Production Deburring Department Deburring is the process of removing the small imperfections known as burrs from machined metal products. At deburring house inc., we take pride in offering our customers the best value to meet their mechanical finishing needs. As with all other machining tools, the required deburring tools are stored in the. Our capabilities include a wide range of edge and. Efficient. Deburring Department.

From www.albacut.com

Deburring Systems A.L.B.A. Deburring Department Improve your products' quality and performance. Our capabilities include a wide range of edge and. R.p abrasives leads the industry with innovative finishing techniques and processes which transform and improve the. Get rid of metal burrs with these 13 proven deburring methods. Machining processes shape a piece of metal in different ways. Efficient deburring for quality finished parts. Stamping, for. Deburring Department.

From www.sksdiecasting.com

SKS Die Casting China Facility High Volume Production Deburring Department At deburring house inc., we take pride in offering our customers the best value to meet their mechanical finishing needs. Stamping, for instance, presses the workpiece in a die set, while milling uses a rotating tool to shave metal off a workpiece. Deburring small, intricate parts is almost an art form as it requires fine motor skills, an understanding of. Deburring Department.

From gwmachinery.com

VALGRO SHEET METAL + END EDGE + DEBURRING MACHINE Deburring Department As with all other machining tools, the required deburring tools are stored in the. Deburring is the process of removing the small imperfections known as burrs from machined metal products. Our capabilities include a wide range of edge and. Read on to learn more. Deburring small, intricate parts is almost an art form as it requires fine motor skills, an. Deburring Department.

From precisiondie.com

Deburr Main Precision Die and Stamping, Inc. Deburring Department Stamping, for instance, presses the workpiece in a die set, while milling uses a rotating tool to shave metal off a workpiece. Deburring is the process of removing the small imperfections known as burrs from machined metal products. Deburring small, intricate parts is almost an art form as it requires fine motor skills, an understanding of critical part features and.. Deburring Department.

From www.tonasco.com

Micro Deburring in UltraHigh Vacuum (UHV) and High Vacuum (HV) Components Deburring Department R.p abrasives leads the industry with innovative finishing techniques and processes which transform and improve the. Stamping, for instance, presses the workpiece in a die set, while milling uses a rotating tool to shave metal off a workpiece. The deburring procedure is an integrated part of the machining process. Deburring small, intricate parts is almost an art form as it. Deburring Department.

From www.youtube.com

Deburring Department YouTube Deburring Department Deburring is the process of removing the small imperfections known as burrs from machined metal products. The deburring procedure is an integrated part of the machining process. Read on to learn more. Stamping, for instance, presses the workpiece in a die set, while milling uses a rotating tool to shave metal off a workpiece. As with all other machining tools,. Deburring Department.

From www.jotunpolishing.com

Sheet Metal Deburring Machine Supplier, hairline polishing machine Deburring Department At deburring house inc., we take pride in offering our customers the best value to meet their mechanical finishing needs. Stamping, for instance, presses the workpiece in a die set, while milling uses a rotating tool to shave metal off a workpiece. The deburring procedure is an integrated part of the machining process. Efficient deburring for quality finished parts. Machining. Deburring Department.

From www.bendtekinc.com

Deburring & Finishing BendTek Inc. Custom Metal Fabrication and Deburring Department Get rid of metal burrs with these 13 proven deburring methods. Deburring is the process of removing the small imperfections known as burrs from machined metal products. Machining processes shape a piece of metal in different ways. Stamping, for instance, presses the workpiece in a die set, while milling uses a rotating tool to shave metal off a workpiece. Deburring. Deburring Department.

From www.nordbo-robotics.com

How to Automate Your Deburring Process • Nordbo Robotics Deburring Department Machining processes shape a piece of metal in different ways. The deburring procedure is an integrated part of the machining process. Improve your products' quality and performance. R.p abrasives leads the industry with innovative finishing techniques and processes which transform and improve the. As with all other machining tools, the required deburring tools are stored in the. Deburring is the. Deburring Department.

From satishengineeringalibag.com

Machinery Deburring Department At deburring house inc., we take pride in offering our customers the best value to meet their mechanical finishing needs. Machining processes shape a piece of metal in different ways. R.p abrasives leads the industry with innovative finishing techniques and processes which transform and improve the. The deburring procedure is an integrated part of the machining process. Deburring small, intricate. Deburring Department.

From suginocorp.com

Mechanical Deburring Methods Deburring Department R.p abrasives leads the industry with innovative finishing techniques and processes which transform and improve the. Our capabilities include a wide range of edge and. The deburring procedure is an integrated part of the machining process. Efficient deburring for quality finished parts. Get rid of metal burrs with these 13 proven deburring methods. Deburring small, intricate parts is almost an. Deburring Department.

From www.facebook.com

A leading spinal implant manufacturer deburrs plastic parts without Deburring Department Get rid of metal burrs with these 13 proven deburring methods. Efficient deburring for quality finished parts. Our capabilities include a wide range of edge and. Deburring small, intricate parts is almost an art form as it requires fine motor skills, an understanding of critical part features and. Deburring is the process of removing the small imperfections known as burrs. Deburring Department.

From www.gwmachinery.com

Deburring and Finishing Deburring Department Efficient deburring for quality finished parts. R.p abrasives leads the industry with innovative finishing techniques and processes which transform and improve the. The deburring procedure is an integrated part of the machining process. At deburring house inc., we take pride in offering our customers the best value to meet their mechanical finishing needs. Deburring small, intricate parts is almost an. Deburring Department.

From brushingmachine.com

Deburring and Edge Rounding Machines Valgro Hyzer Valgro India Ltd. Deburring Department Deburring is the process of removing the small imperfections known as burrs from machined metal products. Stamping, for instance, presses the workpiece in a die set, while milling uses a rotating tool to shave metal off a workpiece. Our capabilities include a wide range of edge and. Read on to learn more. Machining processes shape a piece of metal in. Deburring Department.

From suginocorp.com

Mechanical Deburring Methods Deburring Department Get rid of metal burrs with these 13 proven deburring methods. Our capabilities include a wide range of edge and. Deburring small, intricate parts is almost an art form as it requires fine motor skills, an understanding of critical part features and. At deburring house inc., we take pride in offering our customers the best value to meet their mechanical. Deburring Department.

From moonmachineryinc.com

Metal Deburring Machine Moon Machinery Deburring Department Deburring is the process of removing the small imperfections known as burrs from machined metal products. Our capabilities include a wide range of edge and. At deburring house inc., we take pride in offering our customers the best value to meet their mechanical finishing needs. R.p abrasives leads the industry with innovative finishing techniques and processes which transform and improve. Deburring Department.

From prototek.blogspot.com

Prototek Sheet Metal Manufacturing News Prototek Manufacturing Deburring Department Get rid of metal burrs with these 13 proven deburring methods. The deburring procedure is an integrated part of the machining process. Deburring is the process of removing the small imperfections known as burrs from machined metal products. As with all other machining tools, the required deburring tools are stored in the. Deburring small, intricate parts is almost an art. Deburring Department.

From www.tonasco.com

Micro Deburring in UltraHigh Vacuum (UHV) and High Vacuum (HV) Components Deburring Department Our capabilities include a wide range of edge and. The deburring procedure is an integrated part of the machining process. Get rid of metal burrs with these 13 proven deburring methods. As with all other machining tools, the required deburring tools are stored in the. At deburring house inc., we take pride in offering our customers the best value to. Deburring Department.

From www.harveyperformance.com

Why You Should Stop Deburring by Hand In The Loupe Deburring Department Our capabilities include a wide range of edge and. Get rid of metal burrs with these 13 proven deburring methods. Deburring small, intricate parts is almost an art form as it requires fine motor skills, an understanding of critical part features and. As with all other machining tools, the required deburring tools are stored in the. R.p abrasives leads the. Deburring Department.

From www.palmatool.com

Services Palma Tool Deburring Department Machining processes shape a piece of metal in different ways. Get rid of metal burrs with these 13 proven deburring methods. Improve your products' quality and performance. Stamping, for instance, presses the workpiece in a die set, while milling uses a rotating tool to shave metal off a workpiece. As with all other machining tools, the required deburring tools are. Deburring Department.

From aquestcorp.com

Deburring Workstations Aquest Corp. Deburring Department Efficient deburring for quality finished parts. R.p abrasives leads the industry with innovative finishing techniques and processes which transform and improve the. Read on to learn more. Deburring is the process of removing the small imperfections known as burrs from machined metal products. Our capabilities include a wide range of edge and. The deburring procedure is an integrated part of. Deburring Department.

From www.ksrobotic.com

Robotic deburring grinding unit Deburring Department Stamping, for instance, presses the workpiece in a die set, while milling uses a rotating tool to shave metal off a workpiece. Efficient deburring for quality finished parts. As with all other machining tools, the required deburring tools are stored in the. Improve your products' quality and performance. At deburring house inc., we take pride in offering our customers the. Deburring Department.

From www.morganrushworth.com

Rushworth Deburring Machines Deburring Department Stamping, for instance, presses the workpiece in a die set, while milling uses a rotating tool to shave metal off a workpiece. Machining processes shape a piece of metal in different ways. Deburring small, intricate parts is almost an art form as it requires fine motor skills, an understanding of critical part features and. R.p abrasives leads the industry with. Deburring Department.

From electromechanicalproducts.com

The EMP Process EMP Deburring Department Our capabilities include a wide range of edge and. The deburring procedure is an integrated part of the machining process. Efficient deburring for quality finished parts. Deburring small, intricate parts is almost an art form as it requires fine motor skills, an understanding of critical part features and. At deburring house inc., we take pride in offering our customers the. Deburring Department.