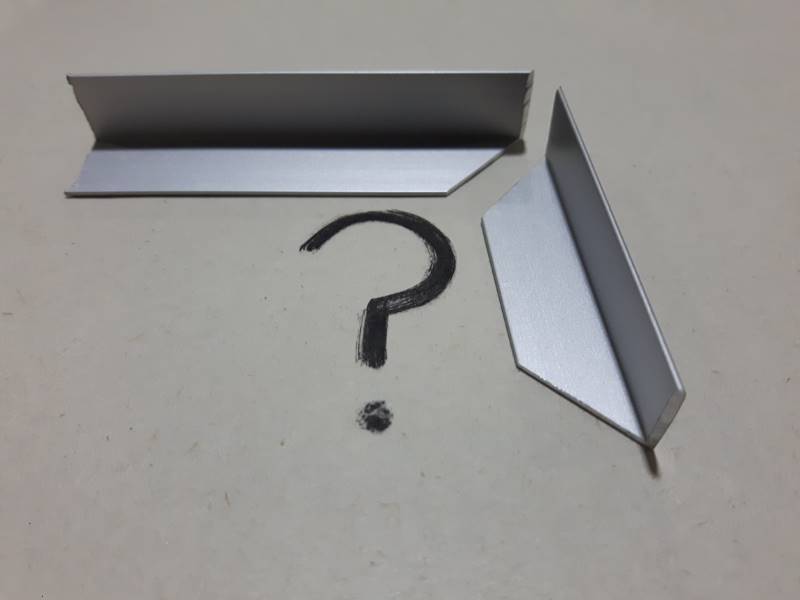

Riveting Aluminum Angle . You’ll learn about the various types of riveting,. Riveting is one of the simplest methods for joining aluminum sheets together. All these are alternative options that help you join aluminum but won’t require any welding to complete the process. Rivets come in a variety of materials, including aluminum,. This article explores the riveting process, a critical technique in metal fabrication. Riveting refers to the forging process of fastening or securing two metals with power by gripping and engaging,. Start by making sure both pieces of aluminum are clean and free from debris, then mark the holes you need to drill using a center punch tool. Rivets with no head marking are made of 1100 aluminum and called a rivets. Riveting is another common method of joining aluminum angle extrusions. To complete this method, you will need to use a drill press with a countersink bit and some rivets. They are mainly used for non structural applications.

from makeitfrommetal.com

You’ll learn about the various types of riveting,. To complete this method, you will need to use a drill press with a countersink bit and some rivets. Riveting refers to the forging process of fastening or securing two metals with power by gripping and engaging,. They are mainly used for non structural applications. Riveting is another common method of joining aluminum angle extrusions. This article explores the riveting process, a critical technique in metal fabrication. Rivets with no head marking are made of 1100 aluminum and called a rivets. Riveting is one of the simplest methods for joining aluminum sheets together. Rivets come in a variety of materials, including aluminum,. All these are alternative options that help you join aluminum but won’t require any welding to complete the process.

How to Cut Aluminum Angle for DIY Projects Make It From Metal

Riveting Aluminum Angle Rivets with no head marking are made of 1100 aluminum and called a rivets. Rivets with no head marking are made of 1100 aluminum and called a rivets. They are mainly used for non structural applications. Start by making sure both pieces of aluminum are clean and free from debris, then mark the holes you need to drill using a center punch tool. Riveting is another common method of joining aluminum angle extrusions. Riveting refers to the forging process of fastening or securing two metals with power by gripping and engaging,. Rivets come in a variety of materials, including aluminum,. All these are alternative options that help you join aluminum but won’t require any welding to complete the process. Riveting is one of the simplest methods for joining aluminum sheets together. To complete this method, you will need to use a drill press with a countersink bit and some rivets. This article explores the riveting process, a critical technique in metal fabrication. You’ll learn about the various types of riveting,.

From www.museoinclusivo.com

6061 Aluminum Angle Profile A Comprehensive Guide to Its Properties Riveting Aluminum Angle Riveting refers to the forging process of fastening or securing two metals with power by gripping and engaging,. You’ll learn about the various types of riveting,. To complete this method, you will need to use a drill press with a countersink bit and some rivets. Rivets come in a variety of materials, including aluminum,. This article explores the riveting process,. Riveting Aluminum Angle.

From onlinemetalsupply.com

Guide to Aluminum Angle Online Metal Supply Riveting Aluminum Angle To complete this method, you will need to use a drill press with a countersink bit and some rivets. Riveting is another common method of joining aluminum angle extrusions. Rivets come in a variety of materials, including aluminum,. Rivets with no head marking are made of 1100 aluminum and called a rivets. Start by making sure both pieces of aluminum. Riveting Aluminum Angle.

From goodingalum.com

Gooding Aluminium Angle (Equal) Suppliers of Extrusions and Profiles Riveting Aluminum Angle They are mainly used for non structural applications. All these are alternative options that help you join aluminum but won’t require any welding to complete the process. Riveting is another common method of joining aluminum angle extrusions. Riveting refers to the forging process of fastening or securing two metals with power by gripping and engaging,. You’ll learn about the various. Riveting Aluminum Angle.

From onlinemetalsupply.com

Guide to Aluminum Angle Online Metal Supply Riveting Aluminum Angle Start by making sure both pieces of aluminum are clean and free from debris, then mark the holes you need to drill using a center punch tool. They are mainly used for non structural applications. Riveting refers to the forging process of fastening or securing two metals with power by gripping and engaging,. Rivets with no head marking are made. Riveting Aluminum Angle.

From blog.thepipingmart.com

A Comprehensive Guide to Aluminium Angles Riveting Aluminum Angle All these are alternative options that help you join aluminum but won’t require any welding to complete the process. Riveting refers to the forging process of fastening or securing two metals with power by gripping and engaging,. Riveting is another common method of joining aluminum angle extrusions. Rivets come in a variety of materials, including aluminum,. They are mainly used. Riveting Aluminum Angle.

From www.diyaluminium.com.au

Black + WHITE ALUMINIUM Angles DIY Aluminium Riveting Aluminum Angle Start by making sure both pieces of aluminum are clean and free from debris, then mark the holes you need to drill using a center punch tool. They are mainly used for non structural applications. This article explores the riveting process, a critical technique in metal fabrication. Rivets with no head marking are made of 1100 aluminum and called a. Riveting Aluminum Angle.

From ezimetal.com.au

Aluminium Angle Newcastle Versatile Metal Angles Ezi Metal Riveting Aluminum Angle To complete this method, you will need to use a drill press with a countersink bit and some rivets. All these are alternative options that help you join aluminum but won’t require any welding to complete the process. Riveting refers to the forging process of fastening or securing two metals with power by gripping and engaging,. Start by making sure. Riveting Aluminum Angle.

From www.outwater.com

Extruded Aluminum Angle 1in x 1in x 1/16in Thick Riveting Aluminum Angle They are mainly used for non structural applications. You’ll learn about the various types of riveting,. Riveting is one of the simplest methods for joining aluminum sheets together. This article explores the riveting process, a critical technique in metal fabrication. Rivets come in a variety of materials, including aluminum,. Rivets with no head marking are made of 1100 aluminum and. Riveting Aluminum Angle.

From www.museoinclusivo.com

Exploring Aluminum Angles Uses, Benefits, and Installation Tips Riveting Aluminum Angle All these are alternative options that help you join aluminum but won’t require any welding to complete the process. Riveting is another common method of joining aluminum angle extrusions. Rivets come in a variety of materials, including aluminum,. They are mainly used for non structural applications. Start by making sure both pieces of aluminum are clean and free from debris,. Riveting Aluminum Angle.

From www.youtube.com

How To Install Aluminum Right Angle Trim Strip Shenghai Aluminum Riveting Aluminum Angle Riveting refers to the forging process of fastening or securing two metals with power by gripping and engaging,. They are mainly used for non structural applications. Riveting is one of the simplest methods for joining aluminum sheets together. You’ll learn about the various types of riveting,. This article explores the riveting process, a critical technique in metal fabrication. Rivets come. Riveting Aluminum Angle.

From materialschoollavonne.z21.web.core.windows.net

Aluminum Angle Sizes Chart In Mm Riveting Aluminum Angle This article explores the riveting process, a critical technique in metal fabrication. All these are alternative options that help you join aluminum but won’t require any welding to complete the process. Riveting is one of the simplest methods for joining aluminum sheets together. Riveting is another common method of joining aluminum angle extrusions. Rivets with no head marking are made. Riveting Aluminum Angle.

From www.allwynnsteelonline.com

Aluminum Angle 6061T6 .75″ x .75″ x .125″ Allwynn Steel Online Store Riveting Aluminum Angle Start by making sure both pieces of aluminum are clean and free from debris, then mark the holes you need to drill using a center punch tool. To complete this method, you will need to use a drill press with a countersink bit and some rivets. You’ll learn about the various types of riveting,. This article explores the riveting process,. Riveting Aluminum Angle.

From www.youtube.com

How to rivet Aluminum Tutorial & Demo + Tools needed, DIY. YouTube Riveting Aluminum Angle They are mainly used for non structural applications. Riveting is another common method of joining aluminum angle extrusions. Riveting is one of the simplest methods for joining aluminum sheets together. All these are alternative options that help you join aluminum but won’t require any welding to complete the process. This article explores the riveting process, a critical technique in metal. Riveting Aluminum Angle.

From makeitfrommetal.com

How to Cut Aluminum Angle for DIY Projects Make It From Metal Riveting Aluminum Angle Riveting refers to the forging process of fastening or securing two metals with power by gripping and engaging,. You’ll learn about the various types of riveting,. This article explores the riveting process, a critical technique in metal fabrication. Riveting is one of the simplest methods for joining aluminum sheets together. Rivets come in a variety of materials, including aluminum,. To. Riveting Aluminum Angle.

From www.protocase.com

Standard Tolerances For Structural Aluminum Angle Riveting Aluminum Angle Rivets come in a variety of materials, including aluminum,. Riveting refers to the forging process of fastening or securing two metals with power by gripping and engaging,. Riveting is one of the simplest methods for joining aluminum sheets together. Start by making sure both pieces of aluminum are clean and free from debris, then mark the holes you need to. Riveting Aluminum Angle.

From www.metalsdepot.com

MetalsDepot® Buy 6061 Aluminum Angle Online! Riveting Aluminum Angle Riveting refers to the forging process of fastening or securing two metals with power by gripping and engaging,. You’ll learn about the various types of riveting,. Riveting is one of the simplest methods for joining aluminum sheets together. This article explores the riveting process, a critical technique in metal fabrication. Rivets come in a variety of materials, including aluminum,. They. Riveting Aluminum Angle.

From www.rapidmetals.co.uk

How to Bend Aluminium Angle Rapid Metals UK Riveting Aluminum Angle To complete this method, you will need to use a drill press with a countersink bit and some rivets. This article explores the riveting process, a critical technique in metal fabrication. Riveting is another common method of joining aluminum angle extrusions. All these are alternative options that help you join aluminum but won’t require any welding to complete the process.. Riveting Aluminum Angle.

From eagle-aluminum.com

Aluminum Angle Extrusions Eagle Aluminum Angles & Profiles Riveting Aluminum Angle You’ll learn about the various types of riveting,. They are mainly used for non structural applications. Riveting is another common method of joining aluminum angle extrusions. Start by making sure both pieces of aluminum are clean and free from debris, then mark the holes you need to drill using a center punch tool. Riveting refers to the forging process of. Riveting Aluminum Angle.

From www.metalswarehouse.co.uk

Aluminium Angle Aluminium Angle Sizes Metals Warehouse Riveting Aluminum Angle All these are alternative options that help you join aluminum but won’t require any welding to complete the process. Rivets with no head marking are made of 1100 aluminum and called a rivets. You’ll learn about the various types of riveting,. To complete this method, you will need to use a drill press with a countersink bit and some rivets.. Riveting Aluminum Angle.

From onlinetilersstore.com.au

Geometric Aluminium Angle 3m (2 Thicknesses & 20 Sizes) Online Tilers Riveting Aluminum Angle Rivets with no head marking are made of 1100 aluminum and called a rivets. Riveting is one of the simplest methods for joining aluminum sheets together. You’ll learn about the various types of riveting,. Riveting is another common method of joining aluminum angle extrusions. Start by making sure both pieces of aluminum are clean and free from debris, then mark. Riveting Aluminum Angle.

From www.metalsupermarkets.com

Aluminum Angle 6061 Metal Supermarkets Riveting Aluminum Angle Start by making sure both pieces of aluminum are clean and free from debris, then mark the holes you need to drill using a center punch tool. To complete this method, you will need to use a drill press with a countersink bit and some rivets. They are mainly used for non structural applications. This article explores the riveting process,. Riveting Aluminum Angle.

From www.museoinclusivo.com

Aluminium Angles A Comprehensive Guide Aluminum Profile Blog Riveting Aluminum Angle Rivets come in a variety of materials, including aluminum,. Start by making sure both pieces of aluminum are clean and free from debris, then mark the holes you need to drill using a center punch tool. Riveting refers to the forging process of fastening or securing two metals with power by gripping and engaging,. This article explores the riveting process,. Riveting Aluminum Angle.

From eaaforums.org

Design handbook for bolted/riveted aluminum tube & gusset structures? Riveting Aluminum Angle All these are alternative options that help you join aluminum but won’t require any welding to complete the process. This article explores the riveting process, a critical technique in metal fabrication. To complete this method, you will need to use a drill press with a countersink bit and some rivets. Rivets with no head marking are made of 1100 aluminum. Riveting Aluminum Angle.

From store.steelandpipes.com

Aluminum Angle Steel and Pipes Inc. Riveting Aluminum Angle Riveting is one of the simplest methods for joining aluminum sheets together. Riveting is another common method of joining aluminum angle extrusions. Rivets come in a variety of materials, including aluminum,. This article explores the riveting process, a critical technique in metal fabrication. Rivets with no head marking are made of 1100 aluminum and called a rivets. They are mainly. Riveting Aluminum Angle.

From www.museoinclusivo.com

Aluminum Angle Iron Uses, Benefits, and Installation Aluminum Riveting Aluminum Angle Rivets come in a variety of materials, including aluminum,. This article explores the riveting process, a critical technique in metal fabrication. You’ll learn about the various types of riveting,. To complete this method, you will need to use a drill press with a countersink bit and some rivets. Rivets with no head marking are made of 1100 aluminum and called. Riveting Aluminum Angle.

From store.steelandpipes.com

Aluminum Angle Steel and Pipes Inc. Riveting Aluminum Angle Riveting is another common method of joining aluminum angle extrusions. Start by making sure both pieces of aluminum are clean and free from debris, then mark the holes you need to drill using a center punch tool. Riveting is one of the simplest methods for joining aluminum sheets together. Rivets with no head marking are made of 1100 aluminum and. Riveting Aluminum Angle.

From www.museoinclusivo.com

6061 Aluminum Angle Profile A Comprehensive Guide to Its Properties Riveting Aluminum Angle Rivets with no head marking are made of 1100 aluminum and called a rivets. All these are alternative options that help you join aluminum but won’t require any welding to complete the process. Riveting is one of the simplest methods for joining aluminum sheets together. Riveting refers to the forging process of fastening or securing two metals with power by. Riveting Aluminum Angle.

From www.metalmate.com.au

Aluminium Angle Unequal Mill Finish Metal Mate Riveting Aluminum Angle Start by making sure both pieces of aluminum are clean and free from debris, then mark the holes you need to drill using a center punch tool. This article explores the riveting process, a critical technique in metal fabrication. You’ll learn about the various types of riveting,. Riveting is one of the simplest methods for joining aluminum sheets together. Riveting. Riveting Aluminum Angle.

From materialschoollavonne.z21.web.core.windows.net

Structural Aluminum Angle Sizes Riveting Aluminum Angle Riveting refers to the forging process of fastening or securing two metals with power by gripping and engaging,. Riveting is another common method of joining aluminum angle extrusions. To complete this method, you will need to use a drill press with a countersink bit and some rivets. This article explores the riveting process, a critical technique in metal fabrication. Start. Riveting Aluminum Angle.

From dmsteel.com

3" x 3" Aluminum Angle Thickness 1/2 Real Steel Riveting Aluminum Angle All these are alternative options that help you join aluminum but won’t require any welding to complete the process. Riveting refers to the forging process of fastening or securing two metals with power by gripping and engaging,. To complete this method, you will need to use a drill press with a countersink bit and some rivets. Riveting is another common. Riveting Aluminum Angle.

From onlinemetalsupply.com

Guide to Aluminum Angle Online Metal Supply Riveting Aluminum Angle Riveting is one of the simplest methods for joining aluminum sheets together. Rivets come in a variety of materials, including aluminum,. Riveting refers to the forging process of fastening or securing two metals with power by gripping and engaging,. Start by making sure both pieces of aluminum are clean and free from debris, then mark the holes you need to. Riveting Aluminum Angle.

From www.shapealuminium.net.au

ALUMINIUM HEAVY ANGLE 25 x 20 x 3mm MILL FINISH Riveting Aluminum Angle To complete this method, you will need to use a drill press with a countersink bit and some rivets. All these are alternative options that help you join aluminum but won’t require any welding to complete the process. This article explores the riveting process, a critical technique in metal fabrication. Start by making sure both pieces of aluminum are clean. Riveting Aluminum Angle.

From www.museoinclusivo.com

6061 Aluminum Angle Profile A Comprehensive Guide to Its Properties Riveting Aluminum Angle Riveting is one of the simplest methods for joining aluminum sheets together. All these are alternative options that help you join aluminum but won’t require any welding to complete the process. Riveting is another common method of joining aluminum angle extrusions. Rivets come in a variety of materials, including aluminum,. Riveting refers to the forging process of fastening or securing. Riveting Aluminum Angle.

From www.airoldimetalli.com

Angles Aluminium Profiles Angles Riveting Aluminum Angle Rivets with no head marking are made of 1100 aluminum and called a rivets. Rivets come in a variety of materials, including aluminum,. Riveting is another common method of joining aluminum angle extrusions. They are mainly used for non structural applications. Riveting is one of the simplest methods for joining aluminum sheets together. To complete this method, you will need. Riveting Aluminum Angle.

From www.thefabricator.com

Advances in riveting and mechanical fastening Riveting Aluminum Angle All these are alternative options that help you join aluminum but won’t require any welding to complete the process. To complete this method, you will need to use a drill press with a countersink bit and some rivets. Riveting is another common method of joining aluminum angle extrusions. You’ll learn about the various types of riveting,. Rivets come in a. Riveting Aluminum Angle.