Vacuum Casting Definition . It is very similar to traditional die. Vacuum casting is a manufacturing process commonly used in industrial applications where a liquid material is poured into a silicone. Vacuum casting is a soft tooling technique that employs soft silicone molds for casting polyurethane plastics and elastomers. The whole casting takes place in a vacuum chamber, which eliminates the risk of air bubbles within the cast. That’s how it gets the names, silicone casting and urethane casting. Vacuum die casting uses a vacuum system to inject molten metal into the space between two metal dies. Vacuum casting is a process in which a liquid material is drawn into a silicone mold whilst using a vacuum, to create complex components. Learn more about it here. Vacuum die casting is a method for manufacturing high volumes of identical precision parts, usually with complex geometries. The liquid materials used for vacuum casting are elastomers such as plastic and rubber.

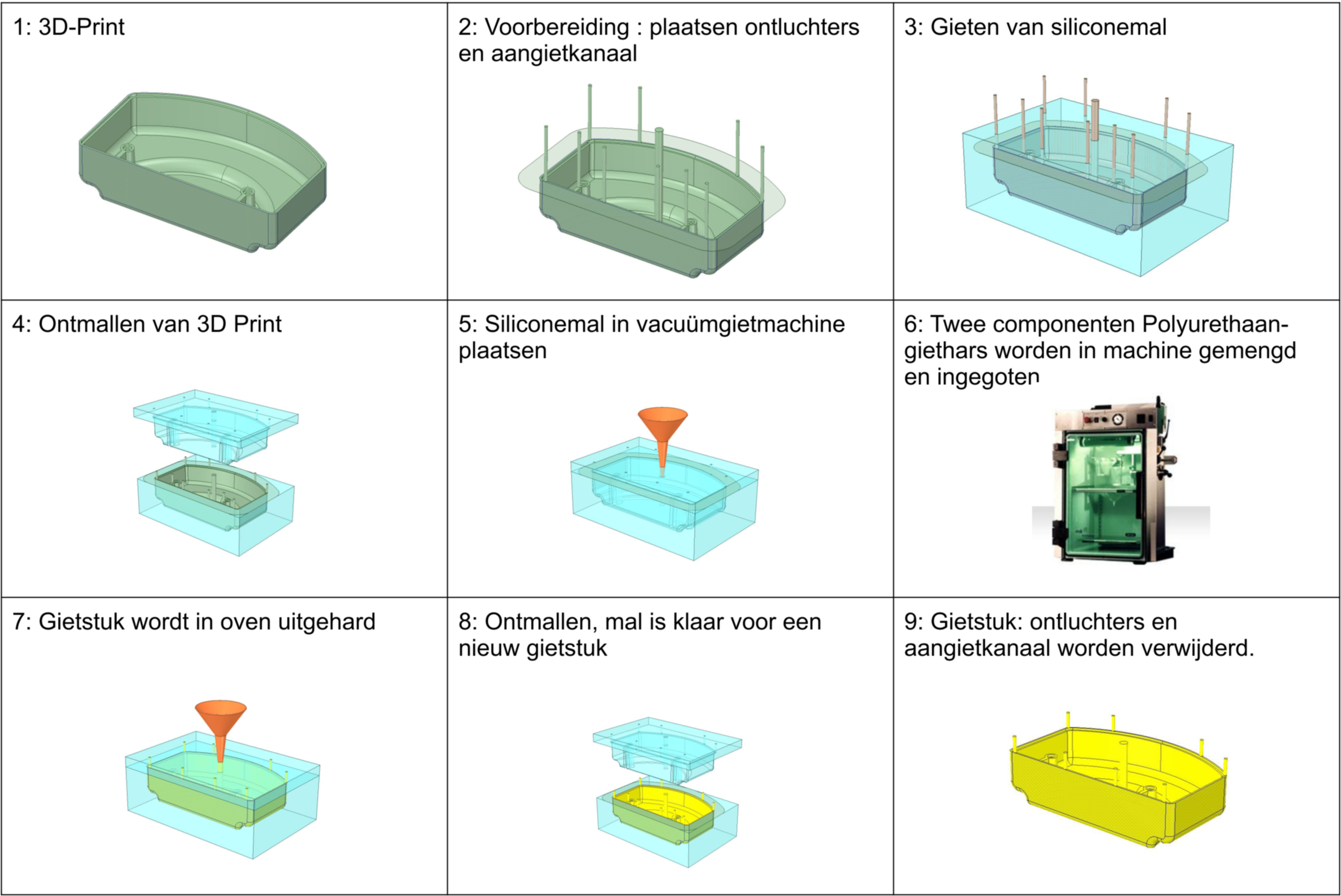

from www.hands-on.be

That’s how it gets the names, silicone casting and urethane casting. It is very similar to traditional die. Vacuum casting is a soft tooling technique that employs soft silicone molds for casting polyurethane plastics and elastomers. The liquid materials used for vacuum casting are elastomers such as plastic and rubber. Vacuum casting is a manufacturing process commonly used in industrial applications where a liquid material is poured into a silicone. Vacuum die casting is a method for manufacturing high volumes of identical precision parts, usually with complex geometries. Vacuum casting is a process in which a liquid material is drawn into a silicone mold whilst using a vacuum, to create complex components. Vacuum die casting uses a vacuum system to inject molten metal into the space between two metal dies. Learn more about it here. The whole casting takes place in a vacuum chamber, which eliminates the risk of air bubbles within the cast.

Vacuum Casting

Vacuum Casting Definition The liquid materials used for vacuum casting are elastomers such as plastic and rubber. Vacuum casting is a process in which a liquid material is drawn into a silicone mold whilst using a vacuum, to create complex components. Vacuum die casting is a method for manufacturing high volumes of identical precision parts, usually with complex geometries. Vacuum casting is a manufacturing process commonly used in industrial applications where a liquid material is poured into a silicone. Vacuum die casting uses a vacuum system to inject molten metal into the space between two metal dies. Vacuum casting is a soft tooling technique that employs soft silicone molds for casting polyurethane plastics and elastomers. That’s how it gets the names, silicone casting and urethane casting. The whole casting takes place in a vacuum chamber, which eliminates the risk of air bubbles within the cast. The liquid materials used for vacuum casting are elastomers such as plastic and rubber. It is very similar to traditional die. Learn more about it here.

From www.jpmcnc.com

Vacuum Casting,Silicon mold Urethane Casting,Short Run Production Vacuum Casting Definition Vacuum casting is a process in which a liquid material is drawn into a silicone mold whilst using a vacuum, to create complex components. That’s how it gets the names, silicone casting and urethane casting. Vacuum die casting uses a vacuum system to inject molten metal into the space between two metal dies. Learn more about it here. Vacuum casting. Vacuum Casting Definition.

From www.xometry.com

Vacuum Die Casting Definition, Importance, How It Works, Applications Vacuum Casting Definition Vacuum die casting uses a vacuum system to inject molten metal into the space between two metal dies. The whole casting takes place in a vacuum chamber, which eliminates the risk of air bubbles within the cast. Vacuum die casting is a method for manufacturing high volumes of identical precision parts, usually with complex geometries. Vacuum casting is a process. Vacuum Casting Definition.

From www.lcrapid.com

The Working Principle of Vacuum Casting and Its Advantages of the Three Vacuum Casting Definition The whole casting takes place in a vacuum chamber, which eliminates the risk of air bubbles within the cast. Vacuum casting is a soft tooling technique that employs soft silicone molds for casting polyurethane plastics and elastomers. The liquid materials used for vacuum casting are elastomers such as plastic and rubber. Vacuum die casting uses a vacuum system to inject. Vacuum Casting Definition.

From www.theengineerspost.com

15 Different Types of Casting Process Explained [with PDF] Vacuum Casting Definition Vacuum die casting uses a vacuum system to inject molten metal into the space between two metal dies. The liquid materials used for vacuum casting are elastomers such as plastic and rubber. The whole casting takes place in a vacuum chamber, which eliminates the risk of air bubbles within the cast. Vacuum casting is a manufacturing process commonly used in. Vacuum Casting Definition.

From www.linkedin.com

Overview of Vacuum Casting Vacuum Casting Definition Vacuum die casting is a method for manufacturing high volumes of identical precision parts, usually with complex geometries. Learn more about it here. Vacuum casting is a manufacturing process commonly used in industrial applications where a liquid material is poured into a silicone. The liquid materials used for vacuum casting are elastomers such as plastic and rubber. Vacuum casting is. Vacuum Casting Definition.

From makenica.com

A Comprehensive Guide on Vacuum Casting Makenica Vacuum Casting Definition It is very similar to traditional die. That’s how it gets the names, silicone casting and urethane casting. The whole casting takes place in a vacuum chamber, which eliminates the risk of air bubbles within the cast. The liquid materials used for vacuum casting are elastomers such as plastic and rubber. Vacuum die casting is a method for manufacturing high. Vacuum Casting Definition.

From www.researchgate.net

Vacuum casting equipment Download Scientific Diagram Vacuum Casting Definition Vacuum die casting is a method for manufacturing high volumes of identical precision parts, usually with complex geometries. Vacuum casting is a manufacturing process commonly used in industrial applications where a liquid material is poured into a silicone. Vacuum casting is a process in which a liquid material is drawn into a silicone mold whilst using a vacuum, to create. Vacuum Casting Definition.

From www.hlhprototypes.com

Vacuum Casting China Cast Urethane Parts HLH Prototypes Co Ltd Vacuum Casting Definition Learn more about it here. Vacuum die casting uses a vacuum system to inject molten metal into the space between two metal dies. Vacuum casting is a process in which a liquid material is drawn into a silicone mold whilst using a vacuum, to create complex components. Vacuum casting is a manufacturing process commonly used in industrial applications where a. Vacuum Casting Definition.

From an-prototype.com

The Ultimate Guide to Vacuum Casting Materials ANPrototype Vacuum Casting Definition Vacuum die casting is a method for manufacturing high volumes of identical precision parts, usually with complex geometries. Vacuum casting is a manufacturing process commonly used in industrial applications where a liquid material is poured into a silicone. Vacuum casting is a process in which a liquid material is drawn into a silicone mold whilst using a vacuum, to create. Vacuum Casting Definition.

From jcadusa.com

Vacuum Casting Process Explained How Does it Work? Vacuum Casting Definition It is very similar to traditional die. Vacuum die casting is a method for manufacturing high volumes of identical precision parts, usually with complex geometries. Vacuum casting is a process in which a liquid material is drawn into a silicone mold whilst using a vacuum, to create complex components. Learn more about it here. The liquid materials used for vacuum. Vacuum Casting Definition.

From www.hands-on.be

Vacuum Casting Vacuum Casting Definition Learn more about it here. It is very similar to traditional die. That’s how it gets the names, silicone casting and urethane casting. Vacuum die casting uses a vacuum system to inject molten metal into the space between two metal dies. Vacuum casting is a manufacturing process commonly used in industrial applications where a liquid material is poured into a. Vacuum Casting Definition.

From www.pcbway.com

Features of Three Types Vacuum Casting 3D Printing PCBway Vacuum Casting Definition Vacuum die casting is a method for manufacturing high volumes of identical precision parts, usually with complex geometries. Vacuum die casting uses a vacuum system to inject molten metal into the space between two metal dies. Vacuum casting is a soft tooling technique that employs soft silicone molds for casting polyurethane plastics and elastomers. The liquid materials used for vacuum. Vacuum Casting Definition.

From www.marmaxdesign.com

Guide to vacuum casting MarMax Vacuum Casting Definition Vacuum die casting uses a vacuum system to inject molten metal into the space between two metal dies. That’s how it gets the names, silicone casting and urethane casting. Vacuum casting is a manufacturing process commonly used in industrial applications where a liquid material is poured into a silicone. Vacuum die casting is a method for manufacturing high volumes of. Vacuum Casting Definition.

From www.scott-am.com

Vacuum Casting Scott AM Vacuum Casting Definition Learn more about it here. The liquid materials used for vacuum casting are elastomers such as plastic and rubber. Vacuum die casting uses a vacuum system to inject molten metal into the space between two metal dies. Vacuum casting is a process in which a liquid material is drawn into a silicone mold whilst using a vacuum, to create complex. Vacuum Casting Definition.

From www.youtube.com

How it's done Vacuum Casting (Introduction) YouTube Vacuum Casting Definition Vacuum casting is a soft tooling technique that employs soft silicone molds for casting polyurethane plastics and elastomers. Vacuum casting is a process in which a liquid material is drawn into a silicone mold whilst using a vacuum, to create complex components. Learn more about it here. That’s how it gets the names, silicone casting and urethane casting. Vacuum casting. Vacuum Casting Definition.

From at-machining.com

Vacuum Casting ATMachining Vacuum Casting Definition The whole casting takes place in a vacuum chamber, which eliminates the risk of air bubbles within the cast. Vacuum die casting uses a vacuum system to inject molten metal into the space between two metal dies. The liquid materials used for vacuum casting are elastomers such as plastic and rubber. Vacuum casting is a manufacturing process commonly used in. Vacuum Casting Definition.

From www.wenext.com

What is Vacuum Casting Simply Explained Wenext Vacuum Casting Definition That’s how it gets the names, silicone casting and urethane casting. It is very similar to traditional die. Vacuum casting is a process in which a liquid material is drawn into a silicone mold whilst using a vacuum, to create complex components. Vacuum die casting is a method for manufacturing high volumes of identical precision parts, usually with complex geometries.. Vacuum Casting Definition.

From www.jyh-prototype.com

What Is Vacuum Casting?Shenzhen Jinyihe Technologies Co., Ltd Vacuum Casting Definition Learn more about it here. Vacuum casting is a soft tooling technique that employs soft silicone molds for casting polyurethane plastics and elastomers. Vacuum casting is a manufacturing process commonly used in industrial applications where a liquid material is poured into a silicone. It is very similar to traditional die. The liquid materials used for vacuum casting are elastomers such. Vacuum Casting Definition.

From www.hlhprototypes.com

What is Vacuum Casting and When to Choose It HLH Prototypes Co Ltd Vacuum Casting Definition Learn more about it here. Vacuum casting is a manufacturing process commonly used in industrial applications where a liquid material is poured into a silicone. The whole casting takes place in a vacuum chamber, which eliminates the risk of air bubbles within the cast. Vacuum die casting uses a vacuum system to inject molten metal into the space between two. Vacuum Casting Definition.

From hlhrapid.com

Vacuum Casting Process Overview, Benefits & Limitations Vacuum Casting Definition The whole casting takes place in a vacuum chamber, which eliminates the risk of air bubbles within the cast. Vacuum casting is a soft tooling technique that employs soft silicone molds for casting polyurethane plastics and elastomers. Learn more about it here. Vacuum casting is a process in which a liquid material is drawn into a silicone mold whilst using. Vacuum Casting Definition.

From sites.google.com

Vacuum Casting eer Vacuum Casting Definition It is very similar to traditional die. Vacuum casting is a process in which a liquid material is drawn into a silicone mold whilst using a vacuum, to create complex components. Vacuum die casting is a method for manufacturing high volumes of identical precision parts, usually with complex geometries. Vacuum casting is a manufacturing process commonly used in industrial applications. Vacuum Casting Definition.

From www.dongruncasting.com

Advantages of vacuum casting Dongrun Casting Vacuum Casting Definition Learn more about it here. Vacuum casting is a manufacturing process commonly used in industrial applications where a liquid material is poured into a silicone. That’s how it gets the names, silicone casting and urethane casting. The whole casting takes place in a vacuum chamber, which eliminates the risk of air bubbles within the cast. Vacuum casting is a soft. Vacuum Casting Definition.

From www.hlhprototypes.com

Understanding the Characteristics of Vacuum Casting HLH Vacuum Casting Definition Learn more about it here. Vacuum die casting is a method for manufacturing high volumes of identical precision parts, usually with complex geometries. That’s how it gets the names, silicone casting and urethane casting. Vacuum casting is a soft tooling technique that employs soft silicone molds for casting polyurethane plastics and elastomers. Vacuum casting is a manufacturing process commonly used. Vacuum Casting Definition.

From www.summative.in

Vacuum Casting Services Summative Engineering Vacuum Casting Definition Vacuum die casting uses a vacuum system to inject molten metal into the space between two metal dies. Vacuum die casting is a method for manufacturing high volumes of identical precision parts, usually with complex geometries. The whole casting takes place in a vacuum chamber, which eliminates the risk of air bubbles within the cast. Learn more about it here.. Vacuum Casting Definition.

From www.essence-proto.com

Vacuum CastingEssence Prototype Technology (HK).Co.,Ltd Vacuum Casting Definition Vacuum casting is a process in which a liquid material is drawn into a silicone mold whilst using a vacuum, to create complex components. Vacuum casting is a soft tooling technique that employs soft silicone molds for casting polyurethane plastics and elastomers. That’s how it gets the names, silicone casting and urethane casting. Vacuum die casting uses a vacuum system. Vacuum Casting Definition.

From www.protobroker.co.uk

Vacuum Casting — Protobroker Vacuum Casting Definition It is very similar to traditional die. Learn more about it here. Vacuum casting is a process in which a liquid material is drawn into a silicone mold whilst using a vacuum, to create complex components. That’s how it gets the names, silicone casting and urethane casting. The whole casting takes place in a vacuum chamber, which eliminates the risk. Vacuum Casting Definition.

From www.pcbway.com

Features of Three Types Vacuum Casting 3D Printing PCBway Vacuum Casting Definition Learn more about it here. The liquid materials used for vacuum casting are elastomers such as plastic and rubber. Vacuum casting is a soft tooling technique that employs soft silicone molds for casting polyurethane plastics and elastomers. Vacuum die casting is a method for manufacturing high volumes of identical precision parts, usually with complex geometries. That’s how it gets the. Vacuum Casting Definition.

From www.marmaxdesign.com

Guide to vacuum casting MarMax Vacuum Casting Definition Vacuum casting is a manufacturing process commonly used in industrial applications where a liquid material is poured into a silicone. Learn more about it here. Vacuum die casting uses a vacuum system to inject molten metal into the space between two metal dies. The whole casting takes place in a vacuum chamber, which eliminates the risk of air bubbles within. Vacuum Casting Definition.

From www.hordrt.com

From Prototype to Reality Vacuum Casting Vacuum Casting Definition Vacuum casting is a manufacturing process commonly used in industrial applications where a liquid material is poured into a silicone. The whole casting takes place in a vacuum chamber, which eliminates the risk of air bubbles within the cast. Vacuum die casting is a method for manufacturing high volumes of identical precision parts, usually with complex geometries. Vacuum die casting. Vacuum Casting Definition.

From blog.thepipingmart.com

What is Vacuum Casting? Vacuum Casting Definition It is very similar to traditional die. Learn more about it here. The liquid materials used for vacuum casting are elastomers such as plastic and rubber. Vacuum casting is a manufacturing process commonly used in industrial applications where a liquid material is poured into a silicone. Vacuum die casting uses a vacuum system to inject molten metal into the space. Vacuum Casting Definition.

From www.rocheindustry.com

Handbook The Ultimate Guide To Vacuum Casting Vacuum Casting Definition Vacuum casting is a manufacturing process commonly used in industrial applications where a liquid material is poured into a silicone. Vacuum casting is a process in which a liquid material is drawn into a silicone mold whilst using a vacuum, to create complex components. The liquid materials used for vacuum casting are elastomers such as plastic and rubber. Vacuum die. Vacuum Casting Definition.

From www.rtprototype.com

Why Choose Vacuum Casting for Medical Products? Ruitai Mould Vacuum Casting Definition Vacuum die casting uses a vacuum system to inject molten metal into the space between two metal dies. Vacuum die casting is a method for manufacturing high volumes of identical precision parts, usually with complex geometries. Vacuum casting is a soft tooling technique that employs soft silicone molds for casting polyurethane plastics and elastomers. The liquid materials used for vacuum. Vacuum Casting Definition.

From www.scott-am.com

Vacuum Casting Scott AM Vacuum Casting Definition Vacuum casting is a soft tooling technique that employs soft silicone molds for casting polyurethane plastics and elastomers. Vacuum die casting uses a vacuum system to inject molten metal into the space between two metal dies. That’s how it gets the names, silicone casting and urethane casting. It is very similar to traditional die. Vacuum casting is a process in. Vacuum Casting Definition.

From www.gzmetalstar.com

Plastic Vacuum Casting Prototype Stamping CNC Machining Custom Vacuum Casting Definition Vacuum die casting is a method for manufacturing high volumes of identical precision parts, usually with complex geometries. Vacuum casting is a process in which a liquid material is drawn into a silicone mold whilst using a vacuum, to create complex components. Vacuum casting is a soft tooling technique that employs soft silicone molds for casting polyurethane plastics and elastomers.. Vacuum Casting Definition.

From abbess.com

Vacuum Mixing & Casting System with PC Based Controller Abbess Vacuum Casting Definition The liquid materials used for vacuum casting are elastomers such as plastic and rubber. Vacuum casting is a process in which a liquid material is drawn into a silicone mold whilst using a vacuum, to create complex components. It is very similar to traditional die. The whole casting takes place in a vacuum chamber, which eliminates the risk of air. Vacuum Casting Definition.