Linear Rails Vs Ball Screws . Dovetail, boxway, sleeve bearing, linear bushing, linear slide, crossing roller, and ball screw slides are the most popular types of linear slides. Screws, whether ball screws or lead screws, are generally preferred over belts or linear motors for carrying loads vertically, but they do. I understand that, with all else equal, a ball screw is best positioned between the two rails (in single ball screw axis applications). Ball screws, depending whether or not preloaded, can have efficiencies up to 90%. Both types are employed in similar applications, but differ. While ball screws typically use a rotary encoder mounted to the motor for positioning feedback, linear. From a purely performance perspective,. In comparison, linear motors generally have overall efficiencies of 85%, though some are considerably lower. You could put the money you would have spent on ball screws, ball nuts, and extra bearings into wider belts, higher torque motors.

from www.alibaba.com

Both types are employed in similar applications, but differ. Dovetail, boxway, sleeve bearing, linear bushing, linear slide, crossing roller, and ball screw slides are the most popular types of linear slides. Screws, whether ball screws or lead screws, are generally preferred over belts or linear motors for carrying loads vertically, but they do. You could put the money you would have spent on ball screws, ball nuts, and extra bearings into wider belts, higher torque motors. While ball screws typically use a rotary encoder mounted to the motor for positioning feedback, linear. I understand that, with all else equal, a ball screw is best positioned between the two rails (in single ball screw axis applications). In comparison, linear motors generally have overall efficiencies of 85%, though some are considerably lower. Ball screws, depending whether or not preloaded, can have efficiencies up to 90%. From a purely performance perspective,.

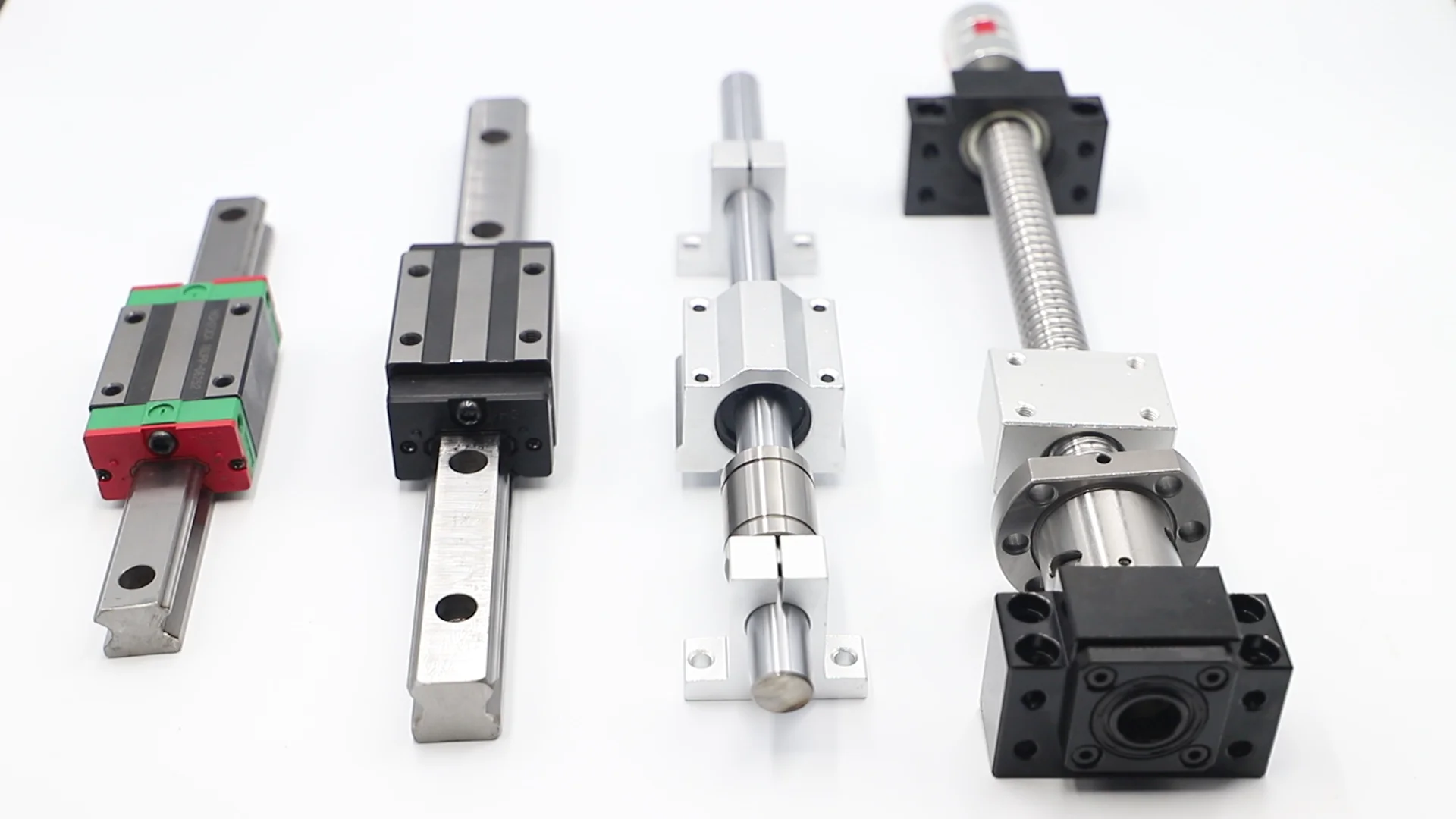

Sbr Linear Guide Rail And Sfu Ball Screw Set For Cnc Machine Buy Ball Screw,Linear Motion

Linear Rails Vs Ball Screws In comparison, linear motors generally have overall efficiencies of 85%, though some are considerably lower. Dovetail, boxway, sleeve bearing, linear bushing, linear slide, crossing roller, and ball screw slides are the most popular types of linear slides. While ball screws typically use a rotary encoder mounted to the motor for positioning feedback, linear. In comparison, linear motors generally have overall efficiencies of 85%, though some are considerably lower. You could put the money you would have spent on ball screws, ball nuts, and extra bearings into wider belts, higher torque motors. Both types are employed in similar applications, but differ. Ball screws, depending whether or not preloaded, can have efficiencies up to 90%. Screws, whether ball screws or lead screws, are generally preferred over belts or linear motors for carrying loads vertically, but they do. From a purely performance perspective,. I understand that, with all else equal, a ball screw is best positioned between the two rails (in single ball screw axis applications).

From advancedathletesperformance.com.au

Linear Rails 1605 Ball Screw C7 Rolled 450mm Long with A Single Flange Ball Nut Linear Motion Linear Rails Vs Ball Screws Both types are employed in similar applications, but differ. You could put the money you would have spent on ball screws, ball nuts, and extra bearings into wider belts, higher torque motors. Screws, whether ball screws or lead screws, are generally preferred over belts or linear motors for carrying loads vertically, but they do. Ball screws, depending whether or not. Linear Rails Vs Ball Screws.

From rockfordballscrew.com

Rockford Ball Screw Innovative Linear Motion Solutions It's Your Move™ Linear Rails Vs Ball Screws From a purely performance perspective,. Dovetail, boxway, sleeve bearing, linear bushing, linear slide, crossing roller, and ball screw slides are the most popular types of linear slides. Ball screws, depending whether or not preloaded, can have efficiencies up to 90%. Both types are employed in similar applications, but differ. While ball screws typically use a rotary encoder mounted to the. Linear Rails Vs Ball Screws.

From www.fuyumotion.com

Ball Screw Linear Guide Linear Rails Vs Ball Screws I understand that, with all else equal, a ball screw is best positioned between the two rails (in single ball screw axis applications). In comparison, linear motors generally have overall efficiencies of 85%, though some are considerably lower. Dovetail, boxway, sleeve bearing, linear bushing, linear slide, crossing roller, and ball screw slides are the most popular types of linear slides.. Linear Rails Vs Ball Screws.

From www.fuyumotion.com

Linear Motor vs. Ball Screw Linear Rails Vs Ball Screws While ball screws typically use a rotary encoder mounted to the motor for positioning feedback, linear. In comparison, linear motors generally have overall efficiencies of 85%, though some are considerably lower. Dovetail, boxway, sleeve bearing, linear bushing, linear slide, crossing roller, and ball screw slides are the most popular types of linear slides. Both types are employed in similar applications,. Linear Rails Vs Ball Screws.

From www.youtube.com

Top 5 Best Linear Ball Screw Set Ballscrew Linear Rail Kit YouTube Linear Rails Vs Ball Screws Both types are employed in similar applications, but differ. Dovetail, boxway, sleeve bearing, linear bushing, linear slide, crossing roller, and ball screw slides are the most popular types of linear slides. In comparison, linear motors generally have overall efficiencies of 85%, though some are considerably lower. While ball screws typically use a rotary encoder mounted to the motor for positioning. Linear Rails Vs Ball Screws.

From www.youtube.com

SolidWorks Ball Screw Motion Study with Linear Rails YouTube Linear Rails Vs Ball Screws Ball screws, depending whether or not preloaded, can have efficiencies up to 90%. Both types are employed in similar applications, but differ. From a purely performance perspective,. Screws, whether ball screws or lead screws, are generally preferred over belts or linear motors for carrying loads vertically, but they do. While ball screws typically use a rotary encoder mounted to the. Linear Rails Vs Ball Screws.

From www.fuyumotion.com

Double Rails Support Flip Load Optional Servo Motor Ball Screw Linear Guide Fuyu Technology Co Linear Rails Vs Ball Screws While ball screws typically use a rotary encoder mounted to the motor for positioning feedback, linear. I understand that, with all else equal, a ball screw is best positioned between the two rails (in single ball screw axis applications). Both types are employed in similar applications, but differ. Ball screws, depending whether or not preloaded, can have efficiencies up to. Linear Rails Vs Ball Screws.

From www.linearmotiontips.com

Why use linear guides and ball screws with ball chains? Linear Rails Vs Ball Screws You could put the money you would have spent on ball screws, ball nuts, and extra bearings into wider belts, higher torque motors. Screws, whether ball screws or lead screws, are generally preferred over belts or linear motors for carrying loads vertically, but they do. Dovetail, boxway, sleeve bearing, linear bushing, linear slide, crossing roller, and ball screw slides are. Linear Rails Vs Ball Screws.

From advancedathletesperformance.com.au

1610 Ball Screw Linear Guide Rail 600mm Aluminum Alloy Linear Guide Rail Slide Ball Screw Motion Linear Rails Vs Ball Screws Screws, whether ball screws or lead screws, are generally preferred over belts or linear motors for carrying loads vertically, but they do. You could put the money you would have spent on ball screws, ball nuts, and extra bearings into wider belts, higher torque motors. Both types are employed in similar applications, but differ. Ball screws, depending whether or not. Linear Rails Vs Ball Screws.

From www.pyglinear.com

HighQuality linear motion Ball screws Manufacturer and Company PYG Linear Rails Vs Ball Screws Screws, whether ball screws or lead screws, are generally preferred over belts or linear motors for carrying loads vertically, but they do. I understand that, with all else equal, a ball screw is best positioned between the two rails (in single ball screw axis applications). You could put the money you would have spent on ball screws, ball nuts, and. Linear Rails Vs Ball Screws.

From www.robotdigg.com

NEMA17 stepper ball screw n linear rail linear module RobotDigg Linear Rails Vs Ball Screws Ball screws, depending whether or not preloaded, can have efficiencies up to 90%. I understand that, with all else equal, a ball screw is best positioned between the two rails (in single ball screw axis applications). Screws, whether ball screws or lead screws, are generally preferred over belts or linear motors for carrying loads vertically, but they do. You could. Linear Rails Vs Ball Screws.

From www.aliexpress.com

3 kits HIWIN JHY linear rail profile guideway +4 ballscrews ball screws SFU type+4set BK/BF12 Linear Rails Vs Ball Screws You could put the money you would have spent on ball screws, ball nuts, and extra bearings into wider belts, higher torque motors. Screws, whether ball screws or lead screws, are generally preferred over belts or linear motors for carrying loads vertically, but they do. From a purely performance perspective,. Both types are employed in similar applications, but differ. Dovetail,. Linear Rails Vs Ball Screws.

From www.aliexpress.com

linear rail profile guideway +4 ballscrews ball screws DFU1605+4sets BK/BF12+4 ballut Housings Linear Rails Vs Ball Screws While ball screws typically use a rotary encoder mounted to the motor for positioning feedback, linear. You could put the money you would have spent on ball screws, ball nuts, and extra bearings into wider belts, higher torque motors. In comparison, linear motors generally have overall efficiencies of 85%, though some are considerably lower. I understand that, with all else. Linear Rails Vs Ball Screws.

From rockfordballscrew.com

Linear Guide Rails and Assemblies Rockford Ball Screw Linear Rails Vs Ball Screws Ball screws, depending whether or not preloaded, can have efficiencies up to 90%. You could put the money you would have spent on ball screws, ball nuts, and extra bearings into wider belts, higher torque motors. Dovetail, boxway, sleeve bearing, linear bushing, linear slide, crossing roller, and ball screw slides are the most popular types of linear slides. I understand. Linear Rails Vs Ball Screws.

From fuyumotion.en.made-in-china.com

Ball Screw Linear Module Motorized Rail Guide Double Axis Robot Arm China Linear Rail and Linear Rails Vs Ball Screws From a purely performance perspective,. Ball screws, depending whether or not preloaded, can have efficiencies up to 90%. You could put the money you would have spent on ball screws, ball nuts, and extra bearings into wider belts, higher torque motors. Dovetail, boxway, sleeve bearing, linear bushing, linear slide, crossing roller, and ball screw slides are the most popular types. Linear Rails Vs Ball Screws.

From www.aliexpress.com

linear rails SBR20 1500MM linear guide+ball screw sfu2005 L1500MM with ballnut and housing+BK15 Linear Rails Vs Ball Screws While ball screws typically use a rotary encoder mounted to the motor for positioning feedback, linear. From a purely performance perspective,. Dovetail, boxway, sleeve bearing, linear bushing, linear slide, crossing roller, and ball screw slides are the most popular types of linear slides. I understand that, with all else equal, a ball screw is best positioned between the two rails. Linear Rails Vs Ball Screws.

From www.fuyumotion.com

How to Specify, Select and Apply Linear Ball Screw Drives Linear Rails Vs Ball Screws You could put the money you would have spent on ball screws, ball nuts, and extra bearings into wider belts, higher torque motors. While ball screws typically use a rotary encoder mounted to the motor for positioning feedback, linear. Screws, whether ball screws or lead screws, are generally preferred over belts or linear motors for carrying loads vertically, but they. Linear Rails Vs Ball Screws.

From www.youtube.com

Linear rails and ball screw for my CNC mill YouTube Linear Rails Vs Ball Screws Both types are employed in similar applications, but differ. You could put the money you would have spent on ball screws, ball nuts, and extra bearings into wider belts, higher torque motors. Ball screws, depending whether or not preloaded, can have efficiencies up to 90%. Dovetail, boxway, sleeve bearing, linear bushing, linear slide, crossing roller, and ball screw slides are. Linear Rails Vs Ball Screws.

From www.iqsdirectory.com

Linear Rails Types, Applications, Benefits, and Design Linear Rails Vs Ball Screws Dovetail, boxway, sleeve bearing, linear bushing, linear slide, crossing roller, and ball screw slides are the most popular types of linear slides. Both types are employed in similar applications, but differ. You could put the money you would have spent on ball screws, ball nuts, and extra bearings into wider belts, higher torque motors. From a purely performance perspective,. In. Linear Rails Vs Ball Screws.

From www.aliexpress.com

Buy SBR20 linear rails ballscrew sets 2500/1500/1000mm+ball screws 2xSFU2505 Linear Rails Vs Ball Screws I understand that, with all else equal, a ball screw is best positioned between the two rails (in single ball screw axis applications). Screws, whether ball screws or lead screws, are generally preferred over belts or linear motors for carrying loads vertically, but they do. From a purely performance perspective,. In comparison, linear motors generally have overall efficiencies of 85%,. Linear Rails Vs Ball Screws.

From www.alibaba.com

Sbr Linear Guide Rail And Sfu Ball Screw Set For Cnc Machine Buy Ball Screw,Linear Motion Linear Rails Vs Ball Screws While ball screws typically use a rotary encoder mounted to the motor for positioning feedback, linear. In comparison, linear motors generally have overall efficiencies of 85%, though some are considerably lower. I understand that, with all else equal, a ball screw is best positioned between the two rails (in single ball screw axis applications). Both types are employed in similar. Linear Rails Vs Ball Screws.

From www.youtube.com

How to install NSK Linear products 2. Ball Screw YouTube Linear Rails Vs Ball Screws You could put the money you would have spent on ball screws, ball nuts, and extra bearings into wider belts, higher torque motors. In comparison, linear motors generally have overall efficiencies of 85%, though some are considerably lower. Dovetail, boxway, sleeve bearing, linear bushing, linear slide, crossing roller, and ball screw slides are the most popular types of linear slides.. Linear Rails Vs Ball Screws.

From www.ubuy.co.in

Motorized Linear Guide Rail with Ball Screw, 50mm India Ubuy Linear Rails Vs Ball Screws Screws, whether ball screws or lead screws, are generally preferred over belts or linear motors for carrying loads vertically, but they do. Both types are employed in similar applications, but differ. From a purely performance perspective,. You could put the money you would have spent on ball screws, ball nuts, and extra bearings into wider belts, higher torque motors. While. Linear Rails Vs Ball Screws.

From www.ostbridge-tech.com

What is the difference between ball linear guide and roller linear guide? OstBridge Linear Rails Vs Ball Screws Dovetail, boxway, sleeve bearing, linear bushing, linear slide, crossing roller, and ball screw slides are the most popular types of linear slides. Ball screws, depending whether or not preloaded, can have efficiencies up to 90%. In comparison, linear motors generally have overall efficiencies of 85%, though some are considerably lower. I understand that, with all else equal, a ball screw. Linear Rails Vs Ball Screws.

From www.ball-screws.net

Ball Screw Repair Replacement Ball Nut and Screw Regrind Linear Rails Vs Ball Screws Ball screws, depending whether or not preloaded, can have efficiencies up to 90%. While ball screws typically use a rotary encoder mounted to the motor for positioning feedback, linear. From a purely performance perspective,. Dovetail, boxway, sleeve bearing, linear bushing, linear slide, crossing roller, and ball screw slides are the most popular types of linear slides. Both types are employed. Linear Rails Vs Ball Screws.

From us.misumi-ec.com

Lead Screws vs Ball Screws Differences, Benefits & Accuracy MISUMI Mech Lab Blog Linear Rails Vs Ball Screws Both types are employed in similar applications, but differ. Ball screws, depending whether or not preloaded, can have efficiencies up to 90%. Dovetail, boxway, sleeve bearing, linear bushing, linear slide, crossing roller, and ball screw slides are the most popular types of linear slides. You could put the money you would have spent on ball screws, ball nuts, and extra. Linear Rails Vs Ball Screws.

From schematicpartlanelle.z21.web.core.windows.net

Linear Rail Vs Linear Guide Linear Rails Vs Ball Screws Ball screws, depending whether or not preloaded, can have efficiencies up to 90%. Both types are employed in similar applications, but differ. In comparison, linear motors generally have overall efficiencies of 85%, though some are considerably lower. I understand that, with all else equal, a ball screw is best positioned between the two rails (in single ball screw axis applications).. Linear Rails Vs Ball Screws.

From www.automationtechnologiesinc.com

15mm HIWIN Linear guide rail carriages , Ball screws with DOUBLE BALLNUT for CNC Linear Rails Vs Ball Screws Screws, whether ball screws or lead screws, are generally preferred over belts or linear motors for carrying loads vertically, but they do. In comparison, linear motors generally have overall efficiencies of 85%, though some are considerably lower. From a purely performance perspective,. Dovetail, boxway, sleeve bearing, linear bushing, linear slide, crossing roller, and ball screw slides are the most popular. Linear Rails Vs Ball Screws.

From rockfordballscrew.com

Profile Linear Guide Rails Motion Simplified by Rockford Ball Screw Linear Rails Vs Ball Screws Ball screws, depending whether or not preloaded, can have efficiencies up to 90%. I understand that, with all else equal, a ball screw is best positioned between the two rails (in single ball screw axis applications). Both types are employed in similar applications, but differ. From a purely performance perspective,. Dovetail, boxway, sleeve bearing, linear bushing, linear slide, crossing roller,. Linear Rails Vs Ball Screws.

From www.amazon.in

Linear Rail Slide, Linear Rails Linear Bearing Rail 400mm Ball Screw Linear Slide Stroke Long Linear Rails Vs Ball Screws While ball screws typically use a rotary encoder mounted to the motor for positioning feedback, linear. I understand that, with all else equal, a ball screw is best positioned between the two rails (in single ball screw axis applications). Both types are employed in similar applications, but differ. In comparison, linear motors generally have overall efficiencies of 85%, though some. Linear Rails Vs Ball Screws.

From www.pyglinear.com

HighQuality linear motion Ball screws Manufacturer and Company PYG Linear Rails Vs Ball Screws In comparison, linear motors generally have overall efficiencies of 85%, though some are considerably lower. Dovetail, boxway, sleeve bearing, linear bushing, linear slide, crossing roller, and ball screw slides are the most popular types of linear slides. I understand that, with all else equal, a ball screw is best positioned between the two rails (in single ball screw axis applications).. Linear Rails Vs Ball Screws.

From www.progressiveautomations.com

Ball Screw vs Lead Screw in Linear Actuators Progressive Automations Linear Rails Vs Ball Screws You could put the money you would have spent on ball screws, ball nuts, and extra bearings into wider belts, higher torque motors. Screws, whether ball screws or lead screws, are generally preferred over belts or linear motors for carrying loads vertically, but they do. From a purely performance perspective,. While ball screws typically use a rotary encoder mounted to. Linear Rails Vs Ball Screws.

From www.alibaba.com

20mm Ball Screw Linear Guide Rail Set For Diy Cnc Router Kits Buy Linear Guide Rail Set,Linear Linear Rails Vs Ball Screws In comparison, linear motors generally have overall efficiencies of 85%, though some are considerably lower. I understand that, with all else equal, a ball screw is best positioned between the two rails (in single ball screw axis applications). You could put the money you would have spent on ball screws, ball nuts, and extra bearings into wider belts, higher torque. Linear Rails Vs Ball Screws.

From www.linearmotiontips.com

Why use linear guides and ball screws with ball chains? Linear Rails Vs Ball Screws I understand that, with all else equal, a ball screw is best positioned between the two rails (in single ball screw axis applications). Ball screws, depending whether or not preloaded, can have efficiencies up to 90%. Dovetail, boxway, sleeve bearing, linear bushing, linear slide, crossing roller, and ball screw slides are the most popular types of linear slides. You could. Linear Rails Vs Ball Screws.

From www.youtube.com

Discounted Ball Screw Linear Rail Guide Stage Slide for Linear Motion Actuator Position System Linear Rails Vs Ball Screws From a purely performance perspective,. Ball screws, depending whether or not preloaded, can have efficiencies up to 90%. Both types are employed in similar applications, but differ. Screws, whether ball screws or lead screws, are generally preferred over belts or linear motors for carrying loads vertically, but they do. In comparison, linear motors generally have overall efficiencies of 85%, though. Linear Rails Vs Ball Screws.