Countersunk Hole Angle . Selecting the right countersink angle: For example, an iso m10 flat head screw with a normal fit countersunk hole will require a pilot hole diameter of 11 mm, a countersunk diameter of 22.73 mm, and a countersunk angle of 90°. The ‘conical’ element differentiates a countersink from a counterbore, which has a flat bottom. A countersink consists of a conical hole that is coaxial to a cylindrical hole, where the angle of the cone is determined by the fastener to be used. A countersink hole is a conical depression with a specific angle, typically 82 or 90 degrees, depending on the screw type. This chart shows the dimensions of counterbore and countersink holes for different screw sizes, in metric units (millimeters). Below are visuals of countersinking and counterboring in cutting and forming applications. The most common angles for countersink holes are 82 degrees and 90 degrees, though other angles like 100. Why do you need a. Understand the types and use of countersink drill bit,. A countersink is a conical hole (cut) or conical depression (form) created in a material around a hole. The purpose of a countersink is to allow a. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or below.

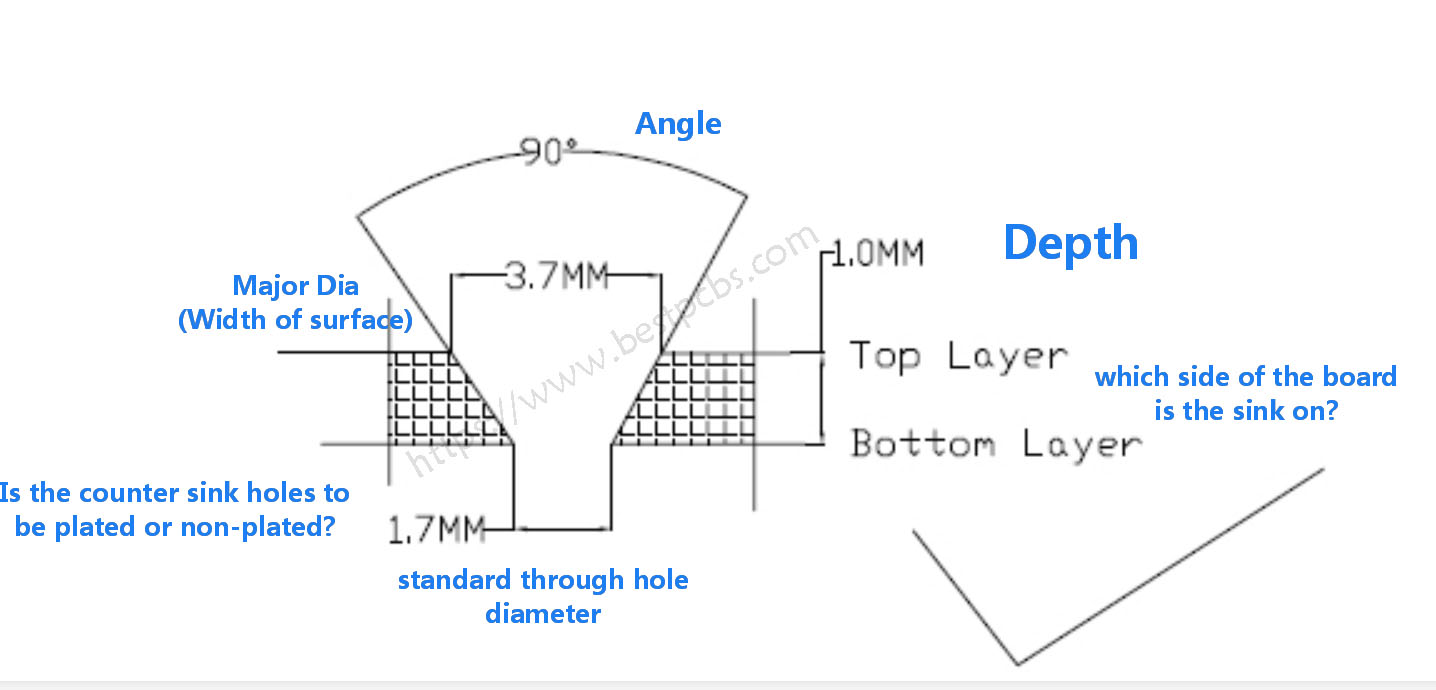

from www.bestpcbs.com

For example, an iso m10 flat head screw with a normal fit countersunk hole will require a pilot hole diameter of 11 mm, a countersunk diameter of 22.73 mm, and a countersunk angle of 90°. Selecting the right countersink angle: Understand the types and use of countersink drill bit,. A countersink is a conical hole (cut) or conical depression (form) created in a material around a hole. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or below. The purpose of a countersink is to allow a. A countersink consists of a conical hole that is coaxial to a cylindrical hole, where the angle of the cone is determined by the fastener to be used. Below are visuals of countersinking and counterboring in cutting and forming applications. The ‘conical’ element differentiates a countersink from a counterbore, which has a flat bottom. The most common angles for countersink holes are 82 degrees and 90 degrees, though other angles like 100.

What’s the Countersink and counter bore on a PCB drawing? PCB & MCPCB

Countersunk Hole Angle The purpose of a countersink is to allow a. This chart shows the dimensions of counterbore and countersink holes for different screw sizes, in metric units (millimeters). A countersink is a conical hole (cut) or conical depression (form) created in a material around a hole. A countersink consists of a conical hole that is coaxial to a cylindrical hole, where the angle of the cone is determined by the fastener to be used. The ‘conical’ element differentiates a countersink from a counterbore, which has a flat bottom. Below are visuals of countersinking and counterboring in cutting and forming applications. Understand the types and use of countersink drill bit,. A countersink hole is a conical depression with a specific angle, typically 82 or 90 degrees, depending on the screw type. The most common angles for countersink holes are 82 degrees and 90 degrees, though other angles like 100. Why do you need a. For example, an iso m10 flat head screw with a normal fit countersunk hole will require a pilot hole diameter of 11 mm, a countersunk diameter of 22.73 mm, and a countersunk angle of 90°. The purpose of a countersink is to allow a. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or below. Selecting the right countersink angle:

From ar.inspiredpencil.com

Standard Countersink Hole Countersunk Hole Angle A countersink hole is a conical depression with a specific angle, typically 82 or 90 degrees, depending on the screw type. The most common angles for countersink holes are 82 degrees and 90 degrees, though other angles like 100. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar). Countersunk Hole Angle.

From www.gdandtbasics.com

Countersink GD&T Basics Countersunk Hole Angle The purpose of a countersink is to allow a. Why do you need a. For example, an iso m10 flat head screw with a normal fit countersunk hole will require a pilot hole diameter of 11 mm, a countersunk diameter of 22.73 mm, and a countersunk angle of 90°. Selecting the right countersink angle: Understand the types and use of. Countersunk Hole Angle.

From mechheart.com

What is a Countersunk Screw? MECHHEART Countersunk Hole Angle Why do you need a. The purpose of a countersink is to allow a. This chart shows the dimensions of counterbore and countersink holes for different screw sizes, in metric units (millimeters). A countersink hole is a conical depression with a specific angle, typically 82 or 90 degrees, depending on the screw type. A countersink is a conical hole (cut). Countersunk Hole Angle.

From www.finepowertools.com

Countersink Angles Common Angles and Their Applications Countersunk Hole Angle Why do you need a. A countersink hole is a conical depression with a specific angle, typically 82 or 90 degrees, depending on the screw type. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or below. A countersink consists of a conical hole. Countersunk Hole Angle.

From www.scribd.com

CounterSink Holes Chart PDF Engineering Tolerance Screw Countersunk Hole Angle The ‘conical’ element differentiates a countersink from a counterbore, which has a flat bottom. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or below. For example, an iso m10 flat head screw with a normal fit countersunk hole will require a pilot hole. Countersunk Hole Angle.

From www.protoexpress.com

Countersink Holes in PCBs Sierra Circuits Countersunk Hole Angle Understand the types and use of countersink drill bit,. The ‘conical’ element differentiates a countersink from a counterbore, which has a flat bottom. This chart shows the dimensions of counterbore and countersink holes for different screw sizes, in metric units (millimeters). A countersink hole is a conical depression with a specific angle, typically 82 or 90 degrees, depending on the. Countersunk Hole Angle.

From www.theengineeringknowledge.com

What is Countersink vs. Counterbore Holes in Machining The Countersunk Hole Angle A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or below. This chart shows the dimensions of counterbore and countersink holes for different screw sizes, in metric units (millimeters). For example, an iso m10 flat head screw with a normal fit countersunk hole will. Countersunk Hole Angle.

From www.finepowertools.com

Countersink Angles Common Angles and Their Applications Countersunk Hole Angle The ‘conical’ element differentiates a countersink from a counterbore, which has a flat bottom. Why do you need a. The most common angles for countersink holes are 82 degrees and 90 degrees, though other angles like 100. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit. Countersunk Hole Angle.

From ar.inspiredpencil.com

Standard Countersink Hole Countersunk Hole Angle The purpose of a countersink is to allow a. Why do you need a. A countersink hole is a conical depression with a specific angle, typically 82 or 90 degrees, depending on the screw type. A countersink is a conical hole (cut) or conical depression (form) created in a material around a hole. The ‘conical’ element differentiates a countersink from. Countersunk Hole Angle.

From fyoyedwig.blob.core.windows.net

How To Measure Angle Of Countersink at Patricia Seifert blog Countersunk Hole Angle Below are visuals of countersinking and counterboring in cutting and forming applications. Selecting the right countersink angle: The ‘conical’ element differentiates a countersink from a counterbore, which has a flat bottom. Understand the types and use of countersink drill bit,. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or. Countersunk Hole Angle.

From www.wisc-online.com

Countersink Example3 OER Countersunk Hole Angle The purpose of a countersink is to allow a. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or below. This chart shows the dimensions of counterbore and countersink holes for different screw sizes, in metric units (millimeters). Why do you need a. The. Countersunk Hole Angle.

From www.7pcb.com

The Difference Between Counterbore and Countersink Holes Countersunk Hole Angle The most common angles for countersink holes are 82 degrees and 90 degrees, though other angles like 100. For example, an iso m10 flat head screw with a normal fit countersunk hole will require a pilot hole diameter of 11 mm, a countersunk diameter of 22.73 mm, and a countersunk angle of 90°. Understand the types and use of countersink. Countersunk Hole Angle.

From engineersbible.com

Countersunk Hole Size for Socket Flat Head (ANSI Metric) Countersunk Hole Angle Selecting the right countersink angle: The purpose of a countersink is to allow a. The ‘conical’ element differentiates a countersink from a counterbore, which has a flat bottom. A countersink is a conical hole (cut) or conical depression (form) created in a material around a hole. Below are visuals of countersinking and counterboring in cutting and forming applications. A countersink. Countersunk Hole Angle.

From www.slideserve.com

PPT Holes PowerPoint Presentation ID2107959 Countersunk Hole Angle A countersink hole is a conical depression with a specific angle, typically 82 or 90 degrees, depending on the screw type. Selecting the right countersink angle: The ‘conical’ element differentiates a countersink from a counterbore, which has a flat bottom. A countersink is a conical hole (cut) or conical depression (form) created in a material around a hole. This chart. Countersunk Hole Angle.

From www.gdandtbasics.com

Countersink GD&T Basics Countersunk Hole Angle This chart shows the dimensions of counterbore and countersink holes for different screw sizes, in metric units (millimeters). A countersink consists of a conical hole that is coaxial to a cylindrical hole, where the angle of the cone is determined by the fastener to be used. Why do you need a. Below are visuals of countersinking and counterboring in cutting. Countersunk Hole Angle.

From www.theengineeringknowledge.com

What are Countersink Holes in Engineering? The Engineering Knowledge Countersunk Hole Angle This chart shows the dimensions of counterbore and countersink holes for different screw sizes, in metric units (millimeters). The most common angles for countersink holes are 82 degrees and 90 degrees, though other angles like 100. The purpose of a countersink is to allow a. A countersink is a conical hole (cut) or conical depression (form) created in a material. Countersunk Hole Angle.

From www.youtube.com

🔩 How To Make Countersink And Counterbore Holes FreeCAD Hole Tutorial Countersunk Hole Angle This chart shows the dimensions of counterbore and countersink holes for different screw sizes, in metric units (millimeters). A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or below. The most common angles for countersink holes are 82 degrees and 90 degrees, though other. Countersunk Hole Angle.

From www.gdandtbasics.com

Applying Position Tolerances to Countersunk Fixed Fastener Assembly Countersunk Hole Angle Below are visuals of countersinking and counterboring in cutting and forming applications. Selecting the right countersink angle: Why do you need a. For example, an iso m10 flat head screw with a normal fit countersunk hole will require a pilot hole diameter of 11 mm, a countersunk diameter of 22.73 mm, and a countersunk angle of 90°. A countersink hole. Countersunk Hole Angle.

From fyoyedwig.blob.core.windows.net

How To Measure Angle Of Countersink at Patricia Seifert blog Countersunk Hole Angle Understand the types and use of countersink drill bit,. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or below. A countersink hole is a conical depression with a specific angle, typically 82 or 90 degrees, depending on the screw type. The ‘conical’ element. Countersunk Hole Angle.

From mathscinotes.com

Measuring Countersink Diameter Using Gage Balls Math Encounters Blog Countersunk Hole Angle For example, an iso m10 flat head screw with a normal fit countersunk hole will require a pilot hole diameter of 11 mm, a countersunk diameter of 22.73 mm, and a countersunk angle of 90°. Why do you need a. Below are visuals of countersinking and counterboring in cutting and forming applications. The ‘conical’ element differentiates a countersink from a. Countersunk Hole Angle.

From joieaovwn.blob.core.windows.net

Common Countersink Angle at William McDaniels blog Countersunk Hole Angle A countersink hole is a conical depression with a specific angle, typically 82 or 90 degrees, depending on the screw type. This chart shows the dimensions of counterbore and countersink holes for different screw sizes, in metric units (millimeters). A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar). Countersunk Hole Angle.

From www.mathscinotes.com

Measuring Countersink Angle Using Gage Balls Math Encounters Blog Countersunk Hole Angle Understand the types and use of countersink drill bit,. Why do you need a. Selecting the right countersink angle: Below are visuals of countersinking and counterboring in cutting and forming applications. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or below. A countersink. Countersunk Hole Angle.

From worksheetzonehahn.z19.web.core.windows.net

Countersink Hole Size Chart Countersunk Hole Angle This chart shows the dimensions of counterbore and countersink holes for different screw sizes, in metric units (millimeters). The most common angles for countersink holes are 82 degrees and 90 degrees, though other angles like 100. For example, an iso m10 flat head screw with a normal fit countersunk hole will require a pilot hole diameter of 11 mm, a. Countersunk Hole Angle.

From www.bestpcbs.com

What’s the Countersink and counter bore on a PCB drawing? PCB & MCPCB Countersunk Hole Angle A countersink hole is a conical depression with a specific angle, typically 82 or 90 degrees, depending on the screw type. For example, an iso m10 flat head screw with a normal fit countersunk hole will require a pilot hole diameter of 11 mm, a countersunk diameter of 22.73 mm, and a countersunk angle of 90°. The purpose of a. Countersunk Hole Angle.

From engineersbible.com

Types of Holes The Complete Guide The Engineer's Bible Countersunk Hole Angle A countersink hole is a conical depression with a specific angle, typically 82 or 90 degrees, depending on the screw type. The most common angles for countersink holes are 82 degrees and 90 degrees, though other angles like 100. Understand the types and use of countersink drill bit,. Selecting the right countersink angle: A countersink is an angled taper applied. Countersunk Hole Angle.

From forums.autodesk.com

Measure a countersink angle? Autodesk Community Countersunk Hole Angle Below are visuals of countersinking and counterboring in cutting and forming applications. Why do you need a. This chart shows the dimensions of counterbore and countersink holes for different screw sizes, in metric units (millimeters). The purpose of a countersink is to allow a. A countersink consists of a conical hole that is coaxial to a cylindrical hole, where the. Countersunk Hole Angle.

From sendcutsend.com

The Benefits of Countersinking SendCutSend Countersunk Hole Angle Below are visuals of countersinking and counterboring in cutting and forming applications. A countersink is a conical hole (cut) or conical depression (form) created in a material around a hole. The most common angles for countersink holes are 82 degrees and 90 degrees, though other angles like 100. For example, an iso m10 flat head screw with a normal fit. Countersunk Hole Angle.

From www.walmart.com

Angle Corner Connector, Anodic Oxidation Treatment Countersunk Holes Countersunk Hole Angle The purpose of a countersink is to allow a. This chart shows the dimensions of counterbore and countersink holes for different screw sizes, in metric units (millimeters). A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or below. Selecting the right countersink angle: A. Countersunk Hole Angle.

From www.theengineeringknowledge.com

What are Countersink Holes in Engineering? The Engineering Knowledge Countersunk Hole Angle Why do you need a. For example, an iso m10 flat head screw with a normal fit countersunk hole will require a pilot hole diameter of 11 mm, a countersunk diameter of 22.73 mm, and a countersunk angle of 90°. A countersink hole is a conical depression with a specific angle, typically 82 or 90 degrees, depending on the screw. Countersunk Hole Angle.

From sendcutsend.com

The Benefits of Countersinking SendCutSend Countersunk Hole Angle A countersink consists of a conical hole that is coaxial to a cylindrical hole, where the angle of the cone is determined by the fastener to be used. For example, an iso m10 flat head screw with a normal fit countersunk hole will require a pilot hole diameter of 11 mm, a countersunk diameter of 22.73 mm, and a countersunk. Countersunk Hole Angle.

From www.youtube.com

SolidWorks Drafting Tutorial Countersinks Hole Angle Bracket Countersunk Hole Angle A countersink is a conical hole (cut) or conical depression (form) created in a material around a hole. The most common angles for countersink holes are 82 degrees and 90 degrees, though other angles like 100. A countersink hole is a conical depression with a specific angle, typically 82 or 90 degrees, depending on the screw type. Selecting the right. Countersunk Hole Angle.

From klaobvqok.blob.core.windows.net

What Is Counterbore And Countersink at Song Bell blog Countersunk Hole Angle Understand the types and use of countersink drill bit,. The purpose of a countersink is to allow a. This chart shows the dimensions of counterbore and countersink holes for different screw sizes, in metric units (millimeters). A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even. Countersunk Hole Angle.

From www.reddit.com

How to calculate countersink angle from hole diameter and countersink Countersunk Hole Angle Why do you need a. Understand the types and use of countersink drill bit,. The purpose of a countersink is to allow a. A countersink consists of a conical hole that is coaxial to a cylindrical hole, where the angle of the cone is determined by the fastener to be used. The ‘conical’ element differentiates a countersink from a counterbore,. Countersunk Hole Angle.

From sendcutsend.com

The Benefits of Countersinking SendCutSend Countersunk Hole Angle Selecting the right countersink angle: A countersink consists of a conical hole that is coaxial to a cylindrical hole, where the angle of the cone is determined by the fastener to be used. A countersink hole is a conical depression with a specific angle, typically 82 or 90 degrees, depending on the screw type. The purpose of a countersink is. Countersunk Hole Angle.

From ceeojgcl.blob.core.windows.net

How To Size A Countersink at Fred Mota blog Countersunk Hole Angle The ‘conical’ element differentiates a countersink from a counterbore, which has a flat bottom. For example, an iso m10 flat head screw with a normal fit countersunk hole will require a pilot hole diameter of 11 mm, a countersunk diameter of 22.73 mm, and a countersunk angle of 90°. The purpose of a countersink is to allow a. Why do. Countersunk Hole Angle.