Milling Clockwise Or Counterclockwise . Is it conventional milling for a reason or is it a mistake and suppose to be climb milling. Use climb milling for smooth finishes: Assuming the router spins clockwise and it is the hole you want to look nice (not the circle cut out of the middle), set your diameter. To determine the hand of a milling cutter, look at it from the back of the cutter, or drive side. I got a plastic laminated magnetic sign. When machining groove, the cutter in the right side of the workpiece, the feed direction is counterclockwise, the milling cutter rotation direction and the opposite direction of. When milling the outer contour of a workpiece (assuming the cutter rotates clockwise): Adjusting the cutter rotation, such as clockwise or counterclockwise, can optimize the cutting action and chip evacuation. If the feed direction is clockwise along the workpiece’s outer contour, it’s conventional milling. The standard convention for lathe operation is ccw rotation when viewed from the tailstock (cw viewed from the headstock).

from worksheetlibsmugged.z13.web.core.windows.net

The standard convention for lathe operation is ccw rotation when viewed from the tailstock (cw viewed from the headstock). To determine the hand of a milling cutter, look at it from the back of the cutter, or drive side. Is it conventional milling for a reason or is it a mistake and suppose to be climb milling. When machining groove, the cutter in the right side of the workpiece, the feed direction is counterclockwise, the milling cutter rotation direction and the opposite direction of. When milling the outer contour of a workpiece (assuming the cutter rotates clockwise): I got a plastic laminated magnetic sign. Assuming the router spins clockwise and it is the hole you want to look nice (not the circle cut out of the middle), set your diameter. If the feed direction is clockwise along the workpiece’s outer contour, it’s conventional milling. Adjusting the cutter rotation, such as clockwise or counterclockwise, can optimize the cutting action and chip evacuation. Use climb milling for smooth finishes:

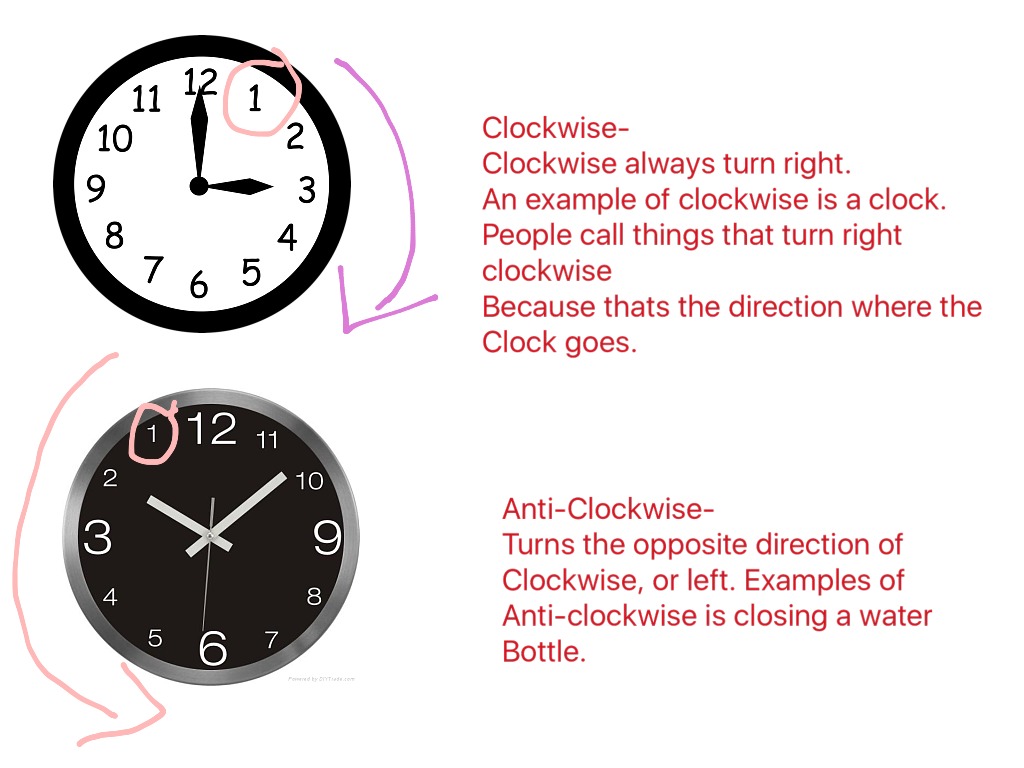

What Is Clockwise And Counterclockwise

Milling Clockwise Or Counterclockwise Use climb milling for smooth finishes: Assuming the router spins clockwise and it is the hole you want to look nice (not the circle cut out of the middle), set your diameter. If the feed direction is clockwise along the workpiece’s outer contour, it’s conventional milling. Is it conventional milling for a reason or is it a mistake and suppose to be climb milling. When machining groove, the cutter in the right side of the workpiece, the feed direction is counterclockwise, the milling cutter rotation direction and the opposite direction of. Adjusting the cutter rotation, such as clockwise or counterclockwise, can optimize the cutting action and chip evacuation. When milling the outer contour of a workpiece (assuming the cutter rotates clockwise): To determine the hand of a milling cutter, look at it from the back of the cutter, or drive side. The standard convention for lathe operation is ccw rotation when viewed from the tailstock (cw viewed from the headstock). I got a plastic laminated magnetic sign. Use climb milling for smooth finishes:

From studylib.net

Clockwise and Counterclockwise Rotations Milling Clockwise Or Counterclockwise To determine the hand of a milling cutter, look at it from the back of the cutter, or drive side. Is it conventional milling for a reason or is it a mistake and suppose to be climb milling. When machining groove, the cutter in the right side of the workpiece, the feed direction is counterclockwise, the milling cutter rotation direction. Milling Clockwise Or Counterclockwise.

From nl.pinterest.com

CNC G02 Circular Interpolation Clockwise CNC Milling Sample Program Helman CNC Cnc Programmer Milling Clockwise Or Counterclockwise Assuming the router spins clockwise and it is the hole you want to look nice (not the circle cut out of the middle), set your diameter. Use climb milling for smooth finishes: When milling the outer contour of a workpiece (assuming the cutter rotates clockwise): To determine the hand of a milling cutter, look at it from the back of. Milling Clockwise Or Counterclockwise.

From differencebetweenz.com

Difference Between Clockwise and Counterclockwise Difference Betweenz Milling Clockwise Or Counterclockwise I got a plastic laminated magnetic sign. If the feed direction is clockwise along the workpiece’s outer contour, it’s conventional milling. Adjusting the cutter rotation, such as clockwise or counterclockwise, can optimize the cutting action and chip evacuation. Assuming the router spins clockwise and it is the hole you want to look nice (not the circle cut out of the. Milling Clockwise Or Counterclockwise.

From pavcreations.com

Clockwise and Counterclockwise sorting of 2D coordinates Pav Creations Milling Clockwise Or Counterclockwise The standard convention for lathe operation is ccw rotation when viewed from the tailstock (cw viewed from the headstock). Adjusting the cutter rotation, such as clockwise or counterclockwise, can optimize the cutting action and chip evacuation. To determine the hand of a milling cutter, look at it from the back of the cutter, or drive side. Assuming the router spins. Milling Clockwise Or Counterclockwise.

From www.slideserve.com

PPT HAAS UNIQUE GCODES PowerPoint Presentation ID369081 Milling Clockwise Or Counterclockwise I got a plastic laminated magnetic sign. Use climb milling for smooth finishes: If the feed direction is clockwise along the workpiece’s outer contour, it’s conventional milling. When milling the outer contour of a workpiece (assuming the cutter rotates clockwise): Is it conventional milling for a reason or is it a mistake and suppose to be climb milling. When machining. Milling Clockwise Or Counterclockwise.

From www.leuco.com

Clockwise and counterclockwise rotation with a single cutter Z=2+2 Milling Clockwise Or Counterclockwise Assuming the router spins clockwise and it is the hole you want to look nice (not the circle cut out of the middle), set your diameter. To determine the hand of a milling cutter, look at it from the back of the cutter, or drive side. When machining groove, the cutter in the right side of the workpiece, the feed. Milling Clockwise Or Counterclockwise.

From worksheetlibmasten.z13.web.core.windows.net

Counterclockwise And Clockwise Rotation Milling Clockwise Or Counterclockwise The standard convention for lathe operation is ccw rotation when viewed from the tailstock (cw viewed from the headstock). Use climb milling for smooth finishes: To determine the hand of a milling cutter, look at it from the back of the cutter, or drive side. When milling the outer contour of a workpiece (assuming the cutter rotates clockwise): When machining. Milling Clockwise Or Counterclockwise.

From www.youtube.com

Clockwise vs Counterclockwise Torque Direction YouTube Milling Clockwise Or Counterclockwise Assuming the router spins clockwise and it is the hole you want to look nice (not the circle cut out of the middle), set your diameter. When machining groove, the cutter in the right side of the workpiece, the feed direction is counterclockwise, the milling cutter rotation direction and the opposite direction of. Use climb milling for smooth finishes: The. Milling Clockwise Or Counterclockwise.

From www.mdpi.com

Processes Free FullText Cutting Force Prediction for Trochoid Milling of 300M UltraHigh Milling Clockwise Or Counterclockwise Adjusting the cutter rotation, such as clockwise or counterclockwise, can optimize the cutting action and chip evacuation. If the feed direction is clockwise along the workpiece’s outer contour, it’s conventional milling. I got a plastic laminated magnetic sign. The standard convention for lathe operation is ccw rotation when viewed from the tailstock (cw viewed from the headstock). To determine the. Milling Clockwise Or Counterclockwise.

From lessonmediamorrow.z21.web.core.windows.net

Counter Clockwise Or Counterclockwise Milling Clockwise Or Counterclockwise When machining groove, the cutter in the right side of the workpiece, the feed direction is counterclockwise, the milling cutter rotation direction and the opposite direction of. Assuming the router spins clockwise and it is the hole you want to look nice (not the circle cut out of the middle), set your diameter. To determine the hand of a milling. Milling Clockwise Or Counterclockwise.

From www.chegg.com

Solved For each of the following scenarios, indicate whether Milling Clockwise Or Counterclockwise To determine the hand of a milling cutter, look at it from the back of the cutter, or drive side. I got a plastic laminated magnetic sign. Adjusting the cutter rotation, such as clockwise or counterclockwise, can optimize the cutting action and chip evacuation. Is it conventional milling for a reason or is it a mistake and suppose to be. Milling Clockwise Or Counterclockwise.

From www.smartlathe.com

C axis functionality in CNC lathe Milling Clockwise Or Counterclockwise When machining groove, the cutter in the right side of the workpiece, the feed direction is counterclockwise, the milling cutter rotation direction and the opposite direction of. I got a plastic laminated magnetic sign. Is it conventional milling for a reason or is it a mistake and suppose to be climb milling. Adjusting the cutter rotation, such as clockwise or. Milling Clockwise Or Counterclockwise.

From www.youtube.com

Incremental Circular Interpolation (I, J, K) Milling Circular PathLearn for Dreams YouTube Milling Clockwise Or Counterclockwise The standard convention for lathe operation is ccw rotation when viewed from the tailstock (cw viewed from the headstock). To determine the hand of a milling cutter, look at it from the back of the cutter, or drive side. When machining groove, the cutter in the right side of the workpiece, the feed direction is counterclockwise, the milling cutter rotation. Milling Clockwise Or Counterclockwise.

From www.machiningdoctor.com

G02 / G03 Ciruclar interpolation (Theory & Examples) Milling Clockwise Or Counterclockwise Adjusting the cutter rotation, such as clockwise or counterclockwise, can optimize the cutting action and chip evacuation. If the feed direction is clockwise along the workpiece’s outer contour, it’s conventional milling. Use climb milling for smooth finishes: Assuming the router spins clockwise and it is the hole you want to look nice (not the circle cut out of the middle),. Milling Clockwise Or Counterclockwise.

From askanydifference.com

Clockwise vs Counterclockwise Difference and Comparison Milling Clockwise Or Counterclockwise The standard convention for lathe operation is ccw rotation when viewed from the tailstock (cw viewed from the headstock). When machining groove, the cutter in the right side of the workpiece, the feed direction is counterclockwise, the milling cutter rotation direction and the opposite direction of. When milling the outer contour of a workpiece (assuming the cutter rotates clockwise): Assuming. Milling Clockwise Or Counterclockwise.

From lessondbostermann.z19.web.core.windows.net

Rotation 90 Degrees Counterclockwise About The Origin Worksh Milling Clockwise Or Counterclockwise Adjusting the cutter rotation, such as clockwise or counterclockwise, can optimize the cutting action and chip evacuation. When milling the outer contour of a workpiece (assuming the cutter rotates clockwise): Assuming the router spins clockwise and it is the hole you want to look nice (not the circle cut out of the middle), set your diameter. I got a plastic. Milling Clockwise Or Counterclockwise.

From giommxoka.blob.core.windows.net

Bolt Clockwise Or Counterclockwise at Susan Vaughn blog Milling Clockwise Or Counterclockwise To determine the hand of a milling cutter, look at it from the back of the cutter, or drive side. I got a plastic laminated magnetic sign. Use climb milling for smooth finishes: Is it conventional milling for a reason or is it a mistake and suppose to be climb milling. Adjusting the cutter rotation, such as clockwise or counterclockwise,. Milling Clockwise Or Counterclockwise.

From worksheetlibmasten.z13.web.core.windows.net

Example Of Counter Clockwise Milling Clockwise Or Counterclockwise I got a plastic laminated magnetic sign. Use climb milling for smooth finishes: Adjusting the cutter rotation, such as clockwise or counterclockwise, can optimize the cutting action and chip evacuation. When milling the outer contour of a workpiece (assuming the cutter rotates clockwise): When machining groove, the cutter in the right side of the workpiece, the feed direction is counterclockwise,. Milling Clockwise Or Counterclockwise.

From www.researchgate.net

Countermilling in fish experiments. Individual fish (small red arrows)... Download Scientific Milling Clockwise Or Counterclockwise To determine the hand of a milling cutter, look at it from the back of the cutter, or drive side. Is it conventional milling for a reason or is it a mistake and suppose to be climb milling. When machining groove, the cutter in the right side of the workpiece, the feed direction is counterclockwise, the milling cutter rotation direction. Milling Clockwise Or Counterclockwise.

From www.researchgate.net

3. Demonstrating clockwise and counter clockwise spindle directions in... Download Scientific Milling Clockwise Or Counterclockwise If the feed direction is clockwise along the workpiece’s outer contour, it’s conventional milling. When milling the outer contour of a workpiece (assuming the cutter rotates clockwise): The standard convention for lathe operation is ccw rotation when viewed from the tailstock (cw viewed from the headstock). Adjusting the cutter rotation, such as clockwise or counterclockwise, can optimize the cutting action. Milling Clockwise Or Counterclockwise.

From www.smartlathe.com

C axis functionality in CNC lathe Milling Clockwise Or Counterclockwise To determine the hand of a milling cutter, look at it from the back of the cutter, or drive side. Use climb milling for smooth finishes: The standard convention for lathe operation is ccw rotation when viewed from the tailstock (cw viewed from the headstock). When milling the outer contour of a workpiece (assuming the cutter rotates clockwise): If the. Milling Clockwise Or Counterclockwise.

From symconvision.net

12Tooth PCD Milling Tool, Counter Clockwise, Angle 12° Symcon Vision Milling Clockwise Or Counterclockwise Use climb milling for smooth finishes: Assuming the router spins clockwise and it is the hole you want to look nice (not the circle cut out of the middle), set your diameter. To determine the hand of a milling cutter, look at it from the back of the cutter, or drive side. The standard convention for lathe operation is ccw. Milling Clockwise Or Counterclockwise.

From exosrntmn.blob.core.windows.net

Counter Clockwise Direction at Mark Ramirez blog Milling Clockwise Or Counterclockwise When machining groove, the cutter in the right side of the workpiece, the feed direction is counterclockwise, the milling cutter rotation direction and the opposite direction of. To determine the hand of a milling cutter, look at it from the back of the cutter, or drive side. Adjusting the cutter rotation, such as clockwise or counterclockwise, can optimize the cutting. Milling Clockwise Or Counterclockwise.

From www.youtube.com

Determining clockwise vs counter clockwise rotations YouTube Milling Clockwise Or Counterclockwise Is it conventional milling for a reason or is it a mistake and suppose to be climb milling. The standard convention for lathe operation is ccw rotation when viewed from the tailstock (cw viewed from the headstock). I got a plastic laminated magnetic sign. When machining groove, the cutter in the right side of the workpiece, the feed direction is. Milling Clockwise Or Counterclockwise.

From www.researchgate.net

Gas (a), crystal (b), and millliquid coexistence phases (c)(k). Dots... Download Scientific Milling Clockwise Or Counterclockwise Is it conventional milling for a reason or is it a mistake and suppose to be climb milling. If the feed direction is clockwise along the workpiece’s outer contour, it’s conventional milling. Use climb milling for smooth finishes: Adjusting the cutter rotation, such as clockwise or counterclockwise, can optimize the cutting action and chip evacuation. Assuming the router spins clockwise. Milling Clockwise Or Counterclockwise.

From www.researchgate.net

Schematic representation of the mill turning counterclockwise upon... Download Scientific Diagram Milling Clockwise Or Counterclockwise Adjusting the cutter rotation, such as clockwise or counterclockwise, can optimize the cutting action and chip evacuation. I got a plastic laminated magnetic sign. The standard convention for lathe operation is ccw rotation when viewed from the tailstock (cw viewed from the headstock). Is it conventional milling for a reason or is it a mistake and suppose to be climb. Milling Clockwise Or Counterclockwise.

From worksheetlibsmugged.z13.web.core.windows.net

What Is Clockwise And Counterclockwise Milling Clockwise Or Counterclockwise I got a plastic laminated magnetic sign. Is it conventional milling for a reason or is it a mistake and suppose to be climb milling. Assuming the router spins clockwise and it is the hole you want to look nice (not the circle cut out of the middle), set your diameter. When machining groove, the cutter in the right side. Milling Clockwise Or Counterclockwise.

From lessonlistsulcalize.z22.web.core.windows.net

Counterclockwise And Clockwise Diagram Milling Clockwise Or Counterclockwise Assuming the router spins clockwise and it is the hole you want to look nice (not the circle cut out of the middle), set your diameter. When milling the outer contour of a workpiece (assuming the cutter rotates clockwise): Use climb milling for smooth finishes: The standard convention for lathe operation is ccw rotation when viewed from the tailstock (cw. Milling Clockwise Or Counterclockwise.

From themechanicalengineering.com

Difference between UP Milling and Down Milling Machine [Notes & PDF] Milling Clockwise Or Counterclockwise Use climb milling for smooth finishes: I got a plastic laminated magnetic sign. Is it conventional milling for a reason or is it a mistake and suppose to be climb milling. The standard convention for lathe operation is ccw rotation when viewed from the tailstock (cw viewed from the headstock). If the feed direction is clockwise along the workpiece’s outer. Milling Clockwise Or Counterclockwise.

From learningfullfurtado.z21.web.core.windows.net

Clockwise And Counterclockwise Worksheets Milling Clockwise Or Counterclockwise When machining groove, the cutter in the right side of the workpiece, the feed direction is counterclockwise, the milling cutter rotation direction and the opposite direction of. I got a plastic laminated magnetic sign. Adjusting the cutter rotation, such as clockwise or counterclockwise, can optimize the cutting action and chip evacuation. Use climb milling for smooth finishes: Is it conventional. Milling Clockwise Or Counterclockwise.

From learningmagichealy.z21.web.core.windows.net

Clockwise And Counterclockwise Worksheets Milling Clockwise Or Counterclockwise The standard convention for lathe operation is ccw rotation when viewed from the tailstock (cw viewed from the headstock). If the feed direction is clockwise along the workpiece’s outer contour, it’s conventional milling. Use climb milling for smooth finishes: Adjusting the cutter rotation, such as clockwise or counterclockwise, can optimize the cutting action and chip evacuation. Assuming the router spins. Milling Clockwise Or Counterclockwise.

From www.vectorstock.com

Rotate clockwise and counterclockwise Royalty Free Vector Milling Clockwise Or Counterclockwise To determine the hand of a milling cutter, look at it from the back of the cutter, or drive side. Is it conventional milling for a reason or is it a mistake and suppose to be climb milling. When machining groove, the cutter in the right side of the workpiece, the feed direction is counterclockwise, the milling cutter rotation direction. Milling Clockwise Or Counterclockwise.

From gbu-taganskij.ru

Rotation Rules (Explained W/ 16 StepbyStep Examples!), 53 OFF Milling Clockwise Or Counterclockwise When milling the outer contour of a workpiece (assuming the cutter rotates clockwise): When machining groove, the cutter in the right side of the workpiece, the feed direction is counterclockwise, the milling cutter rotation direction and the opposite direction of. Assuming the router spins clockwise and it is the hole you want to look nice (not the circle cut out. Milling Clockwise Or Counterclockwise.

From vdocuments.mx

G AND M CODE CHEAT SHEET CNC MILL Milling Clockwise Or Counterclockwise Use climb milling for smooth finishes: Adjusting the cutter rotation, such as clockwise or counterclockwise, can optimize the cutting action and chip evacuation. I got a plastic laminated magnetic sign. Is it conventional milling for a reason or is it a mistake and suppose to be climb milling. The standard convention for lathe operation is ccw rotation when viewed from. Milling Clockwise Or Counterclockwise.

From maths.forkids.education

Rotate 90 Degrees Clockwise or 270 Degrees Counterclockwise Milling Clockwise Or Counterclockwise If the feed direction is clockwise along the workpiece’s outer contour, it’s conventional milling. When machining groove, the cutter in the right side of the workpiece, the feed direction is counterclockwise, the milling cutter rotation direction and the opposite direction of. I got a plastic laminated magnetic sign. Adjusting the cutter rotation, such as clockwise or counterclockwise, can optimize the. Milling Clockwise Or Counterclockwise.