Thickener Capacity Calculation . Design calculations to determine the required thickener area, the most important design parameter, and ultimately the maximum steady. The capacity of a layer of any consistency of flocculated pulp to discharge its flocculated solids may be calculated by the. Abstract this chapter presents different theories of thickener design. Faecal sludge can either be. The rate of settling and the capacity of the thickener are determined by the settling rate and flux rate, respectively. The solids handling capacity at each concentration can then be determined and the lowest capacity (maximum area requirements).

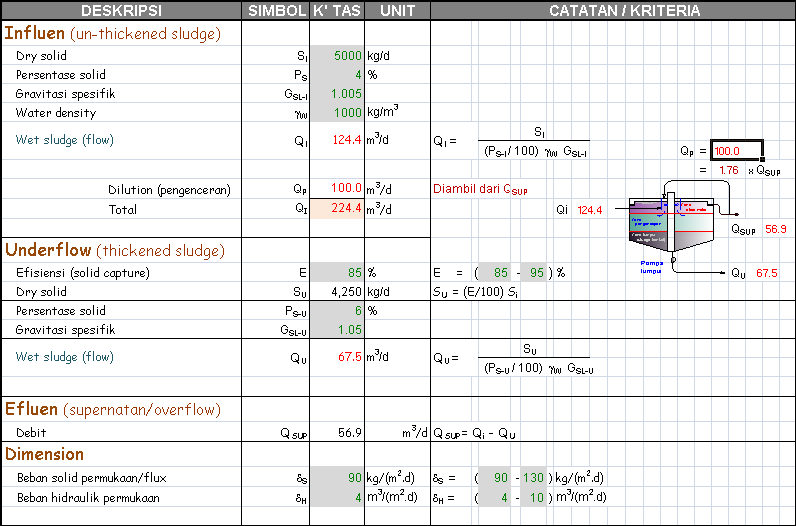

from masterlimbah.blogspot.com

The capacity of a layer of any consistency of flocculated pulp to discharge its flocculated solids may be calculated by the. Abstract this chapter presents different theories of thickener design. The rate of settling and the capacity of the thickener are determined by the settling rate and flux rate, respectively. Faecal sludge can either be. Design calculations to determine the required thickener area, the most important design parameter, and ultimately the maximum steady. The solids handling capacity at each concentration can then be determined and the lowest capacity (maximum area requirements).

Master Limbah Air Limbah, Lumpur, Gravity Thickener, Design Calculation

Thickener Capacity Calculation The rate of settling and the capacity of the thickener are determined by the settling rate and flux rate, respectively. The solids handling capacity at each concentration can then be determined and the lowest capacity (maximum area requirements). Design calculations to determine the required thickener area, the most important design parameter, and ultimately the maximum steady. The capacity of a layer of any consistency of flocculated pulp to discharge its flocculated solids may be calculated by the. Abstract this chapter presents different theories of thickener design. Faecal sludge can either be. The rate of settling and the capacity of the thickener are determined by the settling rate and flux rate, respectively.

From redesign.911metallurgist.com

Calculate a Settling Tank's Capacity Thickener Thickener Capacity Calculation Faecal sludge can either be. The solids handling capacity at each concentration can then be determined and the lowest capacity (maximum area requirements). The rate of settling and the capacity of the thickener are determined by the settling rate and flux rate, respectively. Abstract this chapter presents different theories of thickener design. Design calculations to determine the required thickener area,. Thickener Capacity Calculation.

From www.chegg.com

2. Calculate the diameter of a thickener having a Thickener Capacity Calculation The capacity of a layer of any consistency of flocculated pulp to discharge its flocculated solids may be calculated by the. Abstract this chapter presents different theories of thickener design. Design calculations to determine the required thickener area, the most important design parameter, and ultimately the maximum steady. The rate of settling and the capacity of the thickener are determined. Thickener Capacity Calculation.

From www.chegg.com

Solved For Example 134 for gravity thickening, calculate the Thickener Capacity Calculation Abstract this chapter presents different theories of thickener design. Faecal sludge can either be. The capacity of a layer of any consistency of flocculated pulp to discharge its flocculated solids may be calculated by the. Design calculations to determine the required thickener area, the most important design parameter, and ultimately the maximum steady. The rate of settling and the capacity. Thickener Capacity Calculation.

From saleemindia.blogspot.com

SALEEM INDIA BLOG How to design High Rate Thickener Thickener Capacity Calculation The solids handling capacity at each concentration can then be determined and the lowest capacity (maximum area requirements). Faecal sludge can either be. The capacity of a layer of any consistency of flocculated pulp to discharge its flocculated solids may be calculated by the. Abstract this chapter presents different theories of thickener design. The rate of settling and the capacity. Thickener Capacity Calculation.

From www.pinterest.ca

How to Size a Thickener Thickener Capacity Calculation The solids handling capacity at each concentration can then be determined and the lowest capacity (maximum area requirements). The capacity of a layer of any consistency of flocculated pulp to discharge its flocculated solids may be calculated by the. Faecal sludge can either be. Design calculations to determine the required thickener area, the most important design parameter, and ultimately the. Thickener Capacity Calculation.

From www.911metallurgist.com

Selecting Thickener Depth Determination Thickener Capacity Calculation The capacity of a layer of any consistency of flocculated pulp to discharge its flocculated solids may be calculated by the. The rate of settling and the capacity of the thickener are determined by the settling rate and flux rate, respectively. Abstract this chapter presents different theories of thickener design. Faecal sludge can either be. Design calculations to determine the. Thickener Capacity Calculation.

From masterlimbah.blogspot.com

Master Limbah Air Limbah, Lumpur, Gravity Thickener, Design Calculation Thickener Capacity Calculation The rate of settling and the capacity of the thickener are determined by the settling rate and flux rate, respectively. The solids handling capacity at each concentration can then be determined and the lowest capacity (maximum area requirements). The capacity of a layer of any consistency of flocculated pulp to discharge its flocculated solids may be calculated by the. Abstract. Thickener Capacity Calculation.

From www.chegg.com

Solved Q2 a) Calculate the minimum area of a thickener Thickener Capacity Calculation The solids handling capacity at each concentration can then be determined and the lowest capacity (maximum area requirements). The capacity of a layer of any consistency of flocculated pulp to discharge its flocculated solids may be calculated by the. Abstract this chapter presents different theories of thickener design. The rate of settling and the capacity of the thickener are determined. Thickener Capacity Calculation.

From www.911metallurgist.com

High Capacity Thickener Thickener Capacity Calculation Design calculations to determine the required thickener area, the most important design parameter, and ultimately the maximum steady. The capacity of a layer of any consistency of flocculated pulp to discharge its flocculated solids may be calculated by the. The solids handling capacity at each concentration can then be determined and the lowest capacity (maximum area requirements). Abstract this chapter. Thickener Capacity Calculation.

From www.chegg.com

Solved Q3 a) Calculate the minimum area of a thickener Thickener Capacity Calculation Abstract this chapter presents different theories of thickener design. Faecal sludge can either be. The capacity of a layer of any consistency of flocculated pulp to discharge its flocculated solids may be calculated by the. The rate of settling and the capacity of the thickener are determined by the settling rate and flux rate, respectively. Design calculations to determine the. Thickener Capacity Calculation.

From www.sustainabilitymatters.net.au

Optimising thickener efficiency Optimising thickener efficiency Sustainability Matters Thickener Capacity Calculation The solids handling capacity at each concentration can then be determined and the lowest capacity (maximum area requirements). Abstract this chapter presents different theories of thickener design. The rate of settling and the capacity of the thickener are determined by the settling rate and flux rate, respectively. Faecal sludge can either be. The capacity of a layer of any consistency. Thickener Capacity Calculation.

From www.researchgate.net

Capacity of the designed thickener. The double curvature in the... Download Scientific Diagram Thickener Capacity Calculation The capacity of a layer of any consistency of flocculated pulp to discharge its flocculated solids may be calculated by the. Abstract this chapter presents different theories of thickener design. The rate of settling and the capacity of the thickener are determined by the settling rate and flux rate, respectively. Design calculations to determine the required thickener area, the most. Thickener Capacity Calculation.

From redesign.911metallurgist.com

Calculate a Settling Tank's Capacity Thickener Thickener Capacity Calculation Faecal sludge can either be. Design calculations to determine the required thickener area, the most important design parameter, and ultimately the maximum steady. Abstract this chapter presents different theories of thickener design. The rate of settling and the capacity of the thickener are determined by the settling rate and flux rate, respectively. The capacity of a layer of any consistency. Thickener Capacity Calculation.

From redesign.911metallurgist.com

Calculate a Settling Tank's Capacity Thickener Thickener Capacity Calculation The capacity of a layer of any consistency of flocculated pulp to discharge its flocculated solids may be calculated by the. The solids handling capacity at each concentration can then be determined and the lowest capacity (maximum area requirements). The rate of settling and the capacity of the thickener are determined by the settling rate and flux rate, respectively. Design. Thickener Capacity Calculation.

From www.researchgate.net

Laboratoryscale thickener column diagram (measurements are in... Download Scientific Diagram Thickener Capacity Calculation The rate of settling and the capacity of the thickener are determined by the settling rate and flux rate, respectively. Faecal sludge can either be. Design calculations to determine the required thickener area, the most important design parameter, and ultimately the maximum steady. The capacity of a layer of any consistency of flocculated pulp to discharge its flocculated solids may. Thickener Capacity Calculation.

From www.scribd.com

Sludge Thickener Pump Head Calculation PDF Pipe (Fluid Conveyance) Building Engineering Thickener Capacity Calculation The capacity of a layer of any consistency of flocculated pulp to discharge its flocculated solids may be calculated by the. Faecal sludge can either be. The rate of settling and the capacity of the thickener are determined by the settling rate and flux rate, respectively. The solids handling capacity at each concentration can then be determined and the lowest. Thickener Capacity Calculation.

From www.researchgate.net

Thickener comparisons Download Scientific Diagram Thickener Capacity Calculation The rate of settling and the capacity of the thickener are determined by the settling rate and flux rate, respectively. The solids handling capacity at each concentration can then be determined and the lowest capacity (maximum area requirements). Faecal sludge can either be. The capacity of a layer of any consistency of flocculated pulp to discharge its flocculated solids may. Thickener Capacity Calculation.

From www.911metallurgist.com

Thickener Performance Optimization Thickener Capacity Calculation Design calculations to determine the required thickener area, the most important design parameter, and ultimately the maximum steady. Faecal sludge can either be. Abstract this chapter presents different theories of thickener design. The rate of settling and the capacity of the thickener are determined by the settling rate and flux rate, respectively. The solids handling capacity at each concentration can. Thickener Capacity Calculation.

From www.911metallurgist.com

Measuring Settling Rates and Calculating Thickener Capacity Thickener Capacity Calculation Design calculations to determine the required thickener area, the most important design parameter, and ultimately the maximum steady. The rate of settling and the capacity of the thickener are determined by the settling rate and flux rate, respectively. Faecal sludge can either be. Abstract this chapter presents different theories of thickener design. The solids handling capacity at each concentration can. Thickener Capacity Calculation.

From www.slideserve.com

PPT Sedimentation PowerPoint Presentation, free download ID277300 Thickener Capacity Calculation Abstract this chapter presents different theories of thickener design. The solids handling capacity at each concentration can then be determined and the lowest capacity (maximum area requirements). The capacity of a layer of any consistency of flocculated pulp to discharge its flocculated solids may be calculated by the. Design calculations to determine the required thickener area, the most important design. Thickener Capacity Calculation.

From www.youtube.com

Working of HighRate Thickeners Mineral Processing YouTube Thickener Capacity Calculation The capacity of a layer of any consistency of flocculated pulp to discharge its flocculated solids may be calculated by the. The rate of settling and the capacity of the thickener are determined by the settling rate and flux rate, respectively. The solids handling capacity at each concentration can then be determined and the lowest capacity (maximum area requirements). Faecal. Thickener Capacity Calculation.

From www.snmhi.com

NZY25 Centre Drive Lift Rake Thickener Shenyang Northern Metso Heavy Industry Machinery Co., Ltd. Thickener Capacity Calculation Faecal sludge can either be. The rate of settling and the capacity of the thickener are determined by the settling rate and flux rate, respectively. The capacity of a layer of any consistency of flocculated pulp to discharge its flocculated solids may be calculated by the. Abstract this chapter presents different theories of thickener design. Design calculations to determine the. Thickener Capacity Calculation.

From www.researchgate.net

Sediment height Vs. capacity for the designed thickener. Download Scientific Diagram Thickener Capacity Calculation The capacity of a layer of any consistency of flocculated pulp to discharge its flocculated solids may be calculated by the. Abstract this chapter presents different theories of thickener design. The rate of settling and the capacity of the thickener are determined by the settling rate and flux rate, respectively. Faecal sludge can either be. The solids handling capacity at. Thickener Capacity Calculation.

From www.researchgate.net

Thickener with different solvent ratio versus viscosity of PU dispersions. Download Scientific Thickener Capacity Calculation Faecal sludge can either be. Abstract this chapter presents different theories of thickener design. The capacity of a layer of any consistency of flocculated pulp to discharge its flocculated solids may be calculated by the. Design calculations to determine the required thickener area, the most important design parameter, and ultimately the maximum steady. The rate of settling and the capacity. Thickener Capacity Calculation.

From www.911metallurgist.com

Measuring Settling Rates and Calculating Thickener Capacity Thickener Capacity Calculation The solids handling capacity at each concentration can then be determined and the lowest capacity (maximum area requirements). The rate of settling and the capacity of the thickener are determined by the settling rate and flux rate, respectively. Faecal sludge can either be. The capacity of a layer of any consistency of flocculated pulp to discharge its flocculated solids may. Thickener Capacity Calculation.

From fluidhandlingpro.com

Five Reasons for Measuring Density in Thickening Processes • Fluid Handling Pro Thickener Capacity Calculation The rate of settling and the capacity of the thickener are determined by the settling rate and flux rate, respectively. The capacity of a layer of any consistency of flocculated pulp to discharge its flocculated solids may be calculated by the. The solids handling capacity at each concentration can then be determined and the lowest capacity (maximum area requirements). Design. Thickener Capacity Calculation.

From www.suezwaterhandbook.com

Static thickener Degremont® Thickener Capacity Calculation Abstract this chapter presents different theories of thickener design. The solids handling capacity at each concentration can then be determined and the lowest capacity (maximum area requirements). Design calculations to determine the required thickener area, the most important design parameter, and ultimately the maximum steady. The rate of settling and the capacity of the thickener are determined by the settling. Thickener Capacity Calculation.

From www.911metallurgist.com

Measuring Settling Rates and Calculating Thickener Capacity Thickener Capacity Calculation The solids handling capacity at each concentration can then be determined and the lowest capacity (maximum area requirements). The rate of settling and the capacity of the thickener are determined by the settling rate and flux rate, respectively. Faecal sludge can either be. The capacity of a layer of any consistency of flocculated pulp to discharge its flocculated solids may. Thickener Capacity Calculation.

From www.youtube.com

Thickener Underflow Prediction; FPT Ch6 Q3 YouTube Thickener Capacity Calculation The solids handling capacity at each concentration can then be determined and the lowest capacity (maximum area requirements). Abstract this chapter presents different theories of thickener design. Faecal sludge can either be. Design calculations to determine the required thickener area, the most important design parameter, and ultimately the maximum steady. The rate of settling and the capacity of the thickener. Thickener Capacity Calculation.

From www.rexonassociates.com

Sludge Thickener Thickener Capacity Calculation The capacity of a layer of any consistency of flocculated pulp to discharge its flocculated solids may be calculated by the. Faecal sludge can either be. The rate of settling and the capacity of the thickener are determined by the settling rate and flux rate, respectively. Abstract this chapter presents different theories of thickener design. The solids handling capacity at. Thickener Capacity Calculation.

From www.mclanahan.com

Thickeners McLanahan Thickener Capacity Calculation Faecal sludge can either be. Abstract this chapter presents different theories of thickener design. The rate of settling and the capacity of the thickener are determined by the settling rate and flux rate, respectively. The solids handling capacity at each concentration can then be determined and the lowest capacity (maximum area requirements). The capacity of a layer of any consistency. Thickener Capacity Calculation.

From www.engineeringexcelspreadsheets.com

sludge thickening Archives Low Cost Easy to Use Spreadsheets for Engineering Calculations Thickener Capacity Calculation Faecal sludge can either be. Design calculations to determine the required thickener area, the most important design parameter, and ultimately the maximum steady. Abstract this chapter presents different theories of thickener design. The rate of settling and the capacity of the thickener are determined by the settling rate and flux rate, respectively. The capacity of a layer of any consistency. Thickener Capacity Calculation.

From www.911metallurgist.com

Measuring Settling Rates and Calculating Thickener Capacity Thickener Capacity Calculation The solids handling capacity at each concentration can then be determined and the lowest capacity (maximum area requirements). The capacity of a layer of any consistency of flocculated pulp to discharge its flocculated solids may be calculated by the. The rate of settling and the capacity of the thickener are determined by the settling rate and flux rate, respectively. Faecal. Thickener Capacity Calculation.

From redesign.911metallurgist.com

Calculate a Settling Tank's Capacity Thickener Thickener Capacity Calculation The capacity of a layer of any consistency of flocculated pulp to discharge its flocculated solids may be calculated by the. Design calculations to determine the required thickener area, the most important design parameter, and ultimately the maximum steady. The rate of settling and the capacity of the thickener are determined by the settling rate and flux rate, respectively. Abstract. Thickener Capacity Calculation.

From www.911metallurgist.com

High Capacity Thickener Thickener Capacity Calculation The solids handling capacity at each concentration can then be determined and the lowest capacity (maximum area requirements). Design calculations to determine the required thickener area, the most important design parameter, and ultimately the maximum steady. The rate of settling and the capacity of the thickener are determined by the settling rate and flux rate, respectively. Faecal sludge can either. Thickener Capacity Calculation.