Types Of Blow Molding . They differ according to the method of producing the preform or parison. There are two main types of blow molding: Learn the ins and outs of the blow molding process and the different types of machines used. There are three main types of blow molding: Different assembling or manufacturing plants can utilize extra processes like heating processes and added substances and colorants compounding. Extrusion blow molding, injection blow molding, and injection stretch blow molding. Blow molding is a manufacturing process that shapes hollow plastic parts, including bottles, containers, and automotive components, by inflating a heated plastic tube, known as a parison or preform, inside a mold. Discover its applications and custom design. Blow molding is a fairly straightforward process that includes melting, homogenizing, extruding, molding (blowing), cooling, and ejection. Blow molding is widely used to produce bottles, containers, toys, automotive parts, and other hollow products. To recap, there are three main blow molding processes: Blow molding is a really direct and simple process that consolidates melting or liquefying, homogenizing, extruding, molding, cooling, and ejection. Extrusion and injection blow molding. Air is blown into the tube, causing it to expand and take the shape of the mold.

from chinablowmachine.com

Extrusion blow molding, injection blow molding, and injection stretch blow molding. There are three main types of blow molding: Blow molding is widely used to produce bottles, containers, toys, automotive parts, and other hollow products. There are two main types of blow molding: Extrusion and injection blow molding. Learn the ins and outs of the blow molding process and the different types of machines used. Blow molding is a really direct and simple process that consolidates melting or liquefying, homogenizing, extruding, molding, cooling, and ejection. Discover its applications and custom design. They differ according to the method of producing the preform or parison. Blow molding is a fairly straightforward process that includes melting, homogenizing, extruding, molding (blowing), cooling, and ejection.

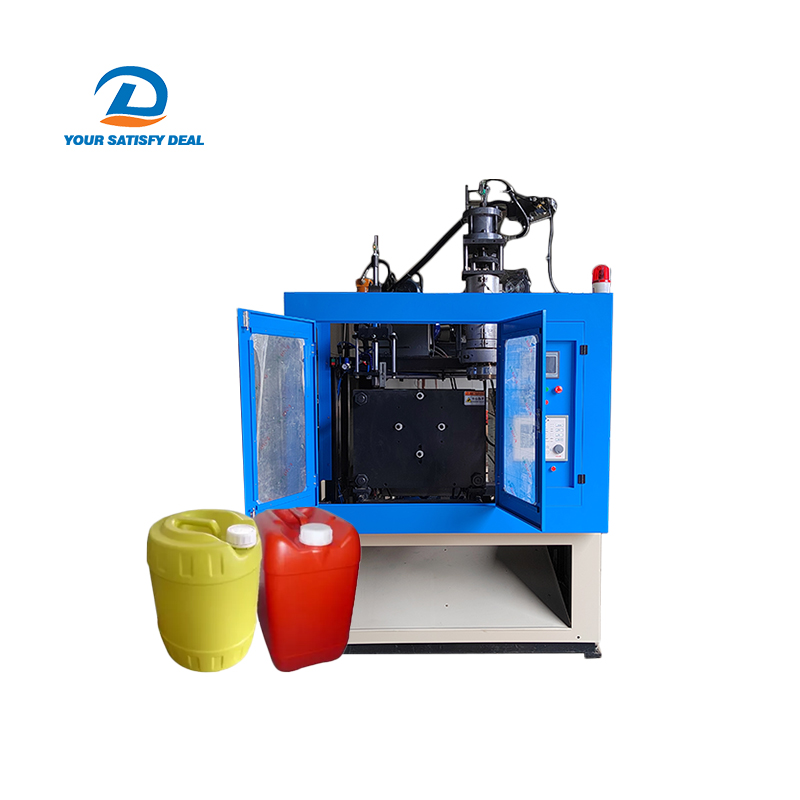

Types of blow molding machine YSD Blow Molding Machine extrusion blow moulding machine

Types Of Blow Molding Discover its applications and custom design. To recap, there are three main blow molding processes: Learn the ins and outs of the blow molding process and the different types of machines used. They differ according to the method of producing the preform or parison. Different assembling or manufacturing plants can utilize extra processes like heating processes and added substances and colorants compounding. Extrusion and injection blow molding. Blow molding is a manufacturing process that shapes hollow plastic parts, including bottles, containers, and automotive components, by inflating a heated plastic tube, known as a parison or preform, inside a mold. There are three main types of blow molding: Discover its applications and custom design. Blow molding is a fairly straightforward process that includes melting, homogenizing, extruding, molding (blowing), cooling, and ejection. Extrusion blow molding, injection blow molding, and injection stretch blow molding. Blow molding is widely used to produce bottles, containers, toys, automotive parts, and other hollow products. There are two main types of blow molding: Air is blown into the tube, causing it to expand and take the shape of the mold. Blow molding is a really direct and simple process that consolidates melting or liquefying, homogenizing, extruding, molding, cooling, and ejection.

From www.hardwareinterviews.fyi

Basics of Blow Molding Consumer Hardware Guide Hardware FYI Types Of Blow Molding Learn the ins and outs of the blow molding process and the different types of machines used. Extrusion blow molding, injection blow molding, and injection stretch blow molding. Discover its applications and custom design. Blow molding is a manufacturing process that shapes hollow plastic parts, including bottles, containers, and automotive components, by inflating a heated plastic tube, known as a. Types Of Blow Molding.

From www.kemalmfg.com

An Insight Into The World of Blow Molding Kemal Types Of Blow Molding Blow molding is a fairly straightforward process that includes melting, homogenizing, extruding, molding (blowing), cooling, and ejection. Blow molding is widely used to produce bottles, containers, toys, automotive parts, and other hollow products. There are three main types of blow molding: Air is blown into the tube, causing it to expand and take the shape of the mold. Extrusion and. Types Of Blow Molding.

From www.ace-mold.com

A Complete Introduction to Blow Molding ACE Group Types Of Blow Molding There are two main types of blow molding: Discover its applications and custom design. Extrusion and injection blow molding. Blow molding is a fairly straightforward process that includes melting, homogenizing, extruding, molding (blowing), cooling, and ejection. There are three main types of blow molding: To recap, there are three main blow molding processes: Air is blown into the tube, causing. Types Of Blow Molding.

From mavink.com

Blow Molding Process Flow Chart Types Of Blow Molding Discover its applications and custom design. Extrusion and injection blow molding. Extrusion blow molding, injection blow molding, and injection stretch blow molding. Blow molding is widely used to produce bottles, containers, toys, automotive parts, and other hollow products. Blow molding is a manufacturing process that shapes hollow plastic parts, including bottles, containers, and automotive components, by inflating a heated plastic. Types Of Blow Molding.

From chinablowmachine.com

Types of blow molding machine YSD Blow Molding Machine extrusion blow moulding machine Types Of Blow Molding Air is blown into the tube, causing it to expand and take the shape of the mold. Blow molding is a manufacturing process that shapes hollow plastic parts, including bottles, containers, and automotive components, by inflating a heated plastic tube, known as a parison or preform, inside a mold. Discover its applications and custom design. Blow molding is a fairly. Types Of Blow Molding.

From sgasealcoating.com

Exploring the Different Types of Blow Molding Machines Sgasealcoating Types Of Blow Molding Extrusion and injection blow molding. Blow molding is a fairly straightforward process that includes melting, homogenizing, extruding, molding (blowing), cooling, and ejection. Different assembling or manufacturing plants can utilize extra processes like heating processes and added substances and colorants compounding. Discover its applications and custom design. They differ according to the method of producing the preform or parison. Blow molding. Types Of Blow Molding.

From www.slideserve.com

PPT Blow Molding PowerPoint Presentation, free download ID323378 Types Of Blow Molding To recap, there are three main blow molding processes: Blow molding is widely used to produce bottles, containers, toys, automotive parts, and other hollow products. Different assembling or manufacturing plants can utilize extra processes like heating processes and added substances and colorants compounding. They differ according to the method of producing the preform or parison. Extrusion and injection blow molding.. Types Of Blow Molding.

From chinablowmachine.com

Types of blow molding machine YSD Blow Molding Machine extrusion blow moulding machine Types Of Blow Molding Learn the ins and outs of the blow molding process and the different types of machines used. There are three main types of blow molding: There are two main types of blow molding: Blow molding is a manufacturing process that shapes hollow plastic parts, including bottles, containers, and automotive components, by inflating a heated plastic tube, known as a parison. Types Of Blow Molding.

From www.jaxtr.com

Blow Molding vs. Injection Molding What's the Difference Jaxtr Types Of Blow Molding Extrusion and injection blow molding. Different assembling or manufacturing plants can utilize extra processes like heating processes and added substances and colorants compounding. Discover its applications and custom design. To recap, there are three main blow molding processes: They differ according to the method of producing the preform or parison. Blow molding is a manufacturing process that shapes hollow plastic. Types Of Blow Molding.

From www.iqsdirectory.com

Blow Molding What Is It? How Does It Work? Materials Types Of Blow Molding Blow molding is widely used to produce bottles, containers, toys, automotive parts, and other hollow products. Extrusion blow molding, injection blow molding, and injection stretch blow molding. Extrusion and injection blow molding. Blow molding is a fairly straightforward process that includes melting, homogenizing, extruding, molding (blowing), cooling, and ejection. There are two main types of blow molding: Blow molding is. Types Of Blow Molding.

From www.youtube.com

Lecture 11 Blow Molding Process & its Classification YouTube Types Of Blow Molding Extrusion and injection blow molding. They differ according to the method of producing the preform or parison. Different assembling or manufacturing plants can utilize extra processes like heating processes and added substances and colorants compounding. Air is blown into the tube, causing it to expand and take the shape of the mold. Extrusion blow molding, injection blow molding, and injection. Types Of Blow Molding.

From www.cm-pet.com

3 Main Types of Blow Molding Process and Examples CHIA MING Blow Molding Mchine Company Types Of Blow Molding Extrusion blow molding, injection blow molding, and injection stretch blow molding. There are three main types of blow molding: Blow molding is a manufacturing process that shapes hollow plastic parts, including bottles, containers, and automotive components, by inflating a heated plastic tube, known as a parison or preform, inside a mold. Blow molding is a fairly straightforward process that includes. Types Of Blow Molding.

From www.westernind.com

FAQ's About Blow Molding Western Industries Plastic Products, LLC Types Of Blow Molding They differ according to the method of producing the preform or parison. Discover its applications and custom design. There are two main types of blow molding: Blow molding is a fairly straightforward process that includes melting, homogenizing, extruding, molding (blowing), cooling, and ejection. Different assembling or manufacturing plants can utilize extra processes like heating processes and added substances and colorants. Types Of Blow Molding.

From www.iqsdirectory.com

Blow Molding What Is It? How Does It Work? Materials Types Of Blow Molding Blow molding is a fairly straightforward process that includes melting, homogenizing, extruding, molding (blowing), cooling, and ejection. Discover its applications and custom design. Blow molding is a manufacturing process that shapes hollow plastic parts, including bottles, containers, and automotive components, by inflating a heated plastic tube, known as a parison or preform, inside a mold. Extrusion blow molding, injection blow. Types Of Blow Molding.

From engineeringlearn.com

16 Types of Moulding [Explained with Complete Details] Engineering Learn Types Of Blow Molding Learn the ins and outs of the blow molding process and the different types of machines used. Discover its applications and custom design. To recap, there are three main blow molding processes: Blow molding is widely used to produce bottles, containers, toys, automotive parts, and other hollow products. Blow molding is a really direct and simple process that consolidates melting. Types Of Blow Molding.

From www.youtube.com

Blow Moulding YouTube Types Of Blow Molding There are three main types of blow molding: Extrusion and injection blow molding. Air is blown into the tube, causing it to expand and take the shape of the mold. Blow molding is a manufacturing process that shapes hollow plastic parts, including bottles, containers, and automotive components, by inflating a heated plastic tube, known as a parison or preform, inside. Types Of Blow Molding.

From www.mullerheads.com

Blow Molding 101 Mullerheads Types Of Blow Molding Air is blown into the tube, causing it to expand and take the shape of the mold. There are two main types of blow molding: To recap, there are three main blow molding processes: Blow molding is a manufacturing process that shapes hollow plastic parts, including bottles, containers, and automotive components, by inflating a heated plastic tube, known as a. Types Of Blow Molding.

From www.iqsdirectory.com

Blow Molding What Is It? How Does It Work? Materials Types Of Blow Molding There are two main types of blow molding: Blow molding is a fairly straightforward process that includes melting, homogenizing, extruding, molding (blowing), cooling, and ejection. Extrusion blow molding, injection blow molding, and injection stretch blow molding. Extrusion and injection blow molding. Different assembling or manufacturing plants can utilize extra processes like heating processes and added substances and colorants compounding. Blow. Types Of Blow Molding.

From www.naplasticsltd.com

Blow Molding Process Overview North American Plastics, Ltd. Types Of Blow Molding Extrusion blow molding, injection blow molding, and injection stretch blow molding. Blow molding is a really direct and simple process that consolidates melting or liquefying, homogenizing, extruding, molding, cooling, and ejection. To recap, there are three main blow molding processes: They differ according to the method of producing the preform or parison. Learn the ins and outs of the blow. Types Of Blow Molding.

From www.iqsdirectory.com

Blow Molding What Is It? How Does It Work? Materials Types Of Blow Molding Blow molding is a really direct and simple process that consolidates melting or liquefying, homogenizing, extruding, molding, cooling, and ejection. Blow molding is a fairly straightforward process that includes melting, homogenizing, extruding, molding (blowing), cooling, and ejection. There are two main types of blow molding: Learn the ins and outs of the blow molding process and the different types of. Types Of Blow Molding.

From www.iqsdirectory.com

Blow Molding What Is It? How Does It Work? Materials Types Of Blow Molding Extrusion and injection blow molding. Learn the ins and outs of the blow molding process and the different types of machines used. There are three main types of blow molding: To recap, there are three main blow molding processes: Blow molding is widely used to produce bottles, containers, toys, automotive parts, and other hollow products. Blow molding is a fairly. Types Of Blow Molding.

From currierplastics.com

Custom Blow Molding Currier Plastics Types Of Blow Molding Blow molding is a really direct and simple process that consolidates melting or liquefying, homogenizing, extruding, molding, cooling, and ejection. Extrusion blow molding, injection blow molding, and injection stretch blow molding. They differ according to the method of producing the preform or parison. There are three main types of blow molding: Discover its applications and custom design. Learn the ins. Types Of Blow Molding.

From engineeringlearn.com

Blow Molding Definition, Types, Process, Advantages & Disadvantages Details Types Of Blow Molding To recap, there are three main blow molding processes: Blow molding is a fairly straightforward process that includes melting, homogenizing, extruding, molding (blowing), cooling, and ejection. Blow molding is widely used to produce bottles, containers, toys, automotive parts, and other hollow products. Discover its applications and custom design. Different assembling or manufacturing plants can utilize extra processes like heating processes. Types Of Blow Molding.

From www.oberk.com

Plastic Bottle Production What is Extrusion Blow Molding (EBM) Types Of Blow Molding Blow molding is a really direct and simple process that consolidates melting or liquefying, homogenizing, extruding, molding, cooling, and ejection. To recap, there are three main blow molding processes: Learn the ins and outs of the blow molding process and the different types of machines used. Extrusion blow molding, injection blow molding, and injection stretch blow molding. They differ according. Types Of Blow Molding.

From www.iqsdirectory.com

Blow Molding What Is It? How Does It Work? Materials Types Of Blow Molding Blow molding is a manufacturing process that shapes hollow plastic parts, including bottles, containers, and automotive components, by inflating a heated plastic tube, known as a parison or preform, inside a mold. There are three main types of blow molding: They differ according to the method of producing the preform or parison. To recap, there are three main blow molding. Types Of Blow Molding.

From en.wikipedia.org

Blow molding Wikipedia Types Of Blow Molding Air is blown into the tube, causing it to expand and take the shape of the mold. Extrusion and injection blow molding. To recap, there are three main blow molding processes: Extrusion blow molding, injection blow molding, and injection stretch blow molding. Blow molding is a manufacturing process that shapes hollow plastic parts, including bottles, containers, and automotive components, by. Types Of Blow Molding.

From www.youtube.com

What Is blow molding process?? Applications, Types, Advantages & Disadvantages YouTube Types Of Blow Molding Different assembling or manufacturing plants can utilize extra processes like heating processes and added substances and colorants compounding. Extrusion blow molding, injection blow molding, and injection stretch blow molding. There are three main types of blow molding: Blow molding is a fairly straightforward process that includes melting, homogenizing, extruding, molding (blowing), cooling, and ejection. Air is blown into the tube,. Types Of Blow Molding.

From packerasia.com

Types of Plastic Blow molding & Injection Molding Types Of Blow Molding Different assembling or manufacturing plants can utilize extra processes like heating processes and added substances and colorants compounding. Blow molding is a really direct and simple process that consolidates melting or liquefying, homogenizing, extruding, molding, cooling, and ejection. Blow molding is a manufacturing process that shapes hollow plastic parts, including bottles, containers, and automotive components, by inflating a heated plastic. Types Of Blow Molding.

From www.tsiproducts.com

Blow Molding TSI Products, Inc. Types Of Blow Molding Air is blown into the tube, causing it to expand and take the shape of the mold. Discover its applications and custom design. Different assembling or manufacturing plants can utilize extra processes like heating processes and added substances and colorants compounding. Blow molding is a really direct and simple process that consolidates melting or liquefying, homogenizing, extruding, molding, cooling, and. Types Of Blow Molding.

From www.hardwareinterviews.fyi

Basics of Blow Molding Consumer Hardware Guide Hardware FYI Types Of Blow Molding Blow molding is a manufacturing process that shapes hollow plastic parts, including bottles, containers, and automotive components, by inflating a heated plastic tube, known as a parison or preform, inside a mold. Extrusion blow molding, injection blow molding, and injection stretch blow molding. Blow molding is widely used to produce bottles, containers, toys, automotive parts, and other hollow products. There. Types Of Blow Molding.

From cmppin.com

What are the 2 types of Extrusion Blow Moulding Machines? Central Machinery & Plastic Products Types Of Blow Molding Blow molding is a manufacturing process that shapes hollow plastic parts, including bottles, containers, and automotive components, by inflating a heated plastic tube, known as a parison or preform, inside a mold. Extrusion and injection blow molding. Different assembling or manufacturing plants can utilize extra processes like heating processes and added substances and colorants compounding. Blow molding is widely used. Types Of Blow Molding.

From fillplas.com

The Comparison Blow Molding and Injection Molding Types Of Blow Molding There are three main types of blow molding: Blow molding is a fairly straightforward process that includes melting, homogenizing, extruding, molding (blowing), cooling, and ejection. They differ according to the method of producing the preform or parison. To recap, there are three main blow molding processes: Blow molding is a really direct and simple process that consolidates melting or liquefying,. Types Of Blow Molding.

From makenica.com

How to get consistent with blow molding? Types Of Blow Molding To recap, there are three main blow molding processes: They differ according to the method of producing the preform or parison. There are three main types of blow molding: Extrusion and injection blow molding. Blow molding is a manufacturing process that shapes hollow plastic parts, including bottles, containers, and automotive components, by inflating a heated plastic tube, known as a. Types Of Blow Molding.

From laiyangpackaging.com

4 Kinds of Blow Molding Process About Medicine Bottles Types Of Blow Molding Different assembling or manufacturing plants can utilize extra processes like heating processes and added substances and colorants compounding. They differ according to the method of producing the preform or parison. There are three main types of blow molding: Learn the ins and outs of the blow molding process and the different types of machines used. Extrusion blow molding, injection blow. Types Of Blow Molding.

From makenica.com

Everything you need to know about blow molding Makenica Types Of Blow Molding There are three main types of blow molding: Blow molding is a manufacturing process that shapes hollow plastic parts, including bottles, containers, and automotive components, by inflating a heated plastic tube, known as a parison or preform, inside a mold. Extrusion blow molding, injection blow molding, and injection stretch blow molding. Blow molding is a fairly straightforward process that includes. Types Of Blow Molding.