Fillet Weld Joint Design . The design of a fillet weld depends on the thickness of the metal being welded, the strength of the weld required, and the type of weld being used. Fillet welds are probably the most common type of weld, particularly in structural steelwork applications, so this first section will look at. Fillet welded joints such as 't', lap and corner joints are the most common connection in welded fabrication. Fillet welds are always designed on the basis of shear stress on the throat (a). The joint design determines what type of weld the operator will need to produce to meet the acceptable quality standard. A general approach for the design of welded joints that combine welds in various directions that reflects the individual segments’ load versus. In total they probably account for around 80% of all joints made by arc welding. A weld joint of the type that will require the minimum amount of weld metal shall be selected.

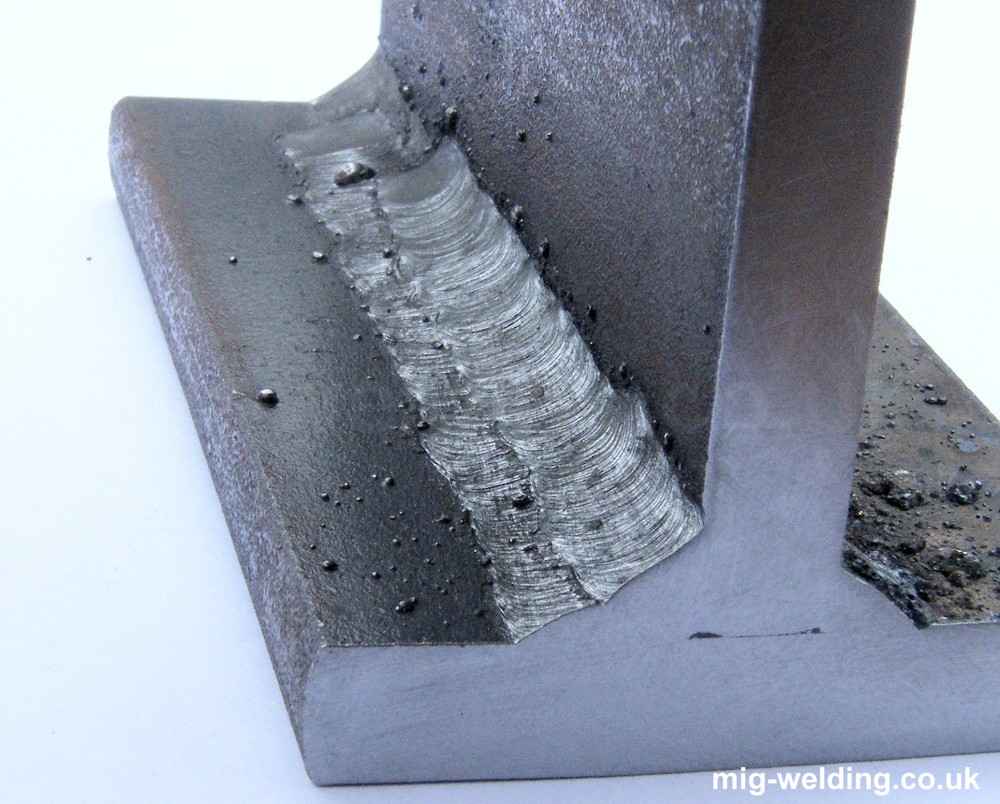

from www.mig-welding.co.uk

The joint design determines what type of weld the operator will need to produce to meet the acceptable quality standard. A general approach for the design of welded joints that combine welds in various directions that reflects the individual segments’ load versus. A weld joint of the type that will require the minimum amount of weld metal shall be selected. In total they probably account for around 80% of all joints made by arc welding. Fillet welds are probably the most common type of weld, particularly in structural steelwork applications, so this first section will look at. The design of a fillet weld depends on the thickness of the metal being welded, the strength of the weld required, and the type of weld being used. Fillet welds are always designed on the basis of shear stress on the throat (a). Fillet welded joints such as 't', lap and corner joints are the most common connection in welded fabrication.

Arc (MMA) Welding Fillet Joints

Fillet Weld Joint Design A general approach for the design of welded joints that combine welds in various directions that reflects the individual segments’ load versus. A weld joint of the type that will require the minimum amount of weld metal shall be selected. Fillet welds are probably the most common type of weld, particularly in structural steelwork applications, so this first section will look at. In total they probably account for around 80% of all joints made by arc welding. Fillet welds are always designed on the basis of shear stress on the throat (a). Fillet welded joints such as 't', lap and corner joints are the most common connection in welded fabrication. The design of a fillet weld depends on the thickness of the metal being welded, the strength of the weld required, and the type of weld being used. A general approach for the design of welded joints that combine welds in various directions that reflects the individual segments’ load versus. The joint design determines what type of weld the operator will need to produce to meet the acceptable quality standard.

From www.mig-welding.co.uk

Arc (MMA) Welding Fillet Joints Fillet Weld Joint Design The joint design determines what type of weld the operator will need to produce to meet the acceptable quality standard. Fillet welded joints such as 't', lap and corner joints are the most common connection in welded fabrication. In total they probably account for around 80% of all joints made by arc welding. A weld joint of the type that. Fillet Weld Joint Design.

From www.youtube.com

Fillet Welds YouTube Fillet Weld Joint Design Fillet welds are always designed on the basis of shear stress on the throat (a). Fillet welds are probably the most common type of weld, particularly in structural steelwork applications, so this first section will look at. In total they probably account for around 80% of all joints made by arc welding. A weld joint of the type that will. Fillet Weld Joint Design.

From www.weldingis.com

Types Of Welding Joints Design and Welding Symbols Fillet Weld Joint Design Fillet welds are always designed on the basis of shear stress on the throat (a). The joint design determines what type of weld the operator will need to produce to meet the acceptable quality standard. A weld joint of the type that will require the minimum amount of weld metal shall be selected. A general approach for the design of. Fillet Weld Joint Design.

From inchbyinch.de

INCH Technical English weld types Fillet Weld Joint Design The design of a fillet weld depends on the thickness of the metal being welded, the strength of the weld required, and the type of weld being used. A general approach for the design of welded joints that combine welds in various directions that reflects the individual segments’ load versus. In total they probably account for around 80% of all. Fillet Weld Joint Design.

From www.engineersgallery.com

Welding joints Engineers Gallery Fillet Weld Joint Design Fillet welds are always designed on the basis of shear stress on the throat (a). The design of a fillet weld depends on the thickness of the metal being welded, the strength of the weld required, and the type of weld being used. The joint design determines what type of weld the operator will need to produce to meet the. Fillet Weld Joint Design.

From www.onestopndt.com

fillet weld Fillet Weld Joint Design Fillet welds are always designed on the basis of shear stress on the throat (a). A general approach for the design of welded joints that combine welds in various directions that reflects the individual segments’ load versus. A weld joint of the type that will require the minimum amount of weld metal shall be selected. The joint design determines what. Fillet Weld Joint Design.

From www.rapiddirect.com

Fillet vs Chamfers What a Fillet is and How It Differs from Chamfers Fillet Weld Joint Design The joint design determines what type of weld the operator will need to produce to meet the acceptable quality standard. Fillet welds are probably the most common type of weld, particularly in structural steelwork applications, so this first section will look at. Fillet welded joints such as 't', lap and corner joints are the most common connection in welded fabrication.. Fillet Weld Joint Design.

From thenavalarch.com

Designing Fillet Welds for Symmetrical Joint Sections TheNavalArch Fillet Weld Joint Design The design of a fillet weld depends on the thickness of the metal being welded, the strength of the weld required, and the type of weld being used. In total they probably account for around 80% of all joints made by arc welding. Fillet welds are always designed on the basis of shear stress on the throat (a). The joint. Fillet Weld Joint Design.

From www.weldingis.com

Types Of Welding Joints Design and Welding Symbols Fillet Weld Joint Design Fillet welded joints such as 't', lap and corner joints are the most common connection in welded fabrication. A weld joint of the type that will require the minimum amount of weld metal shall be selected. The design of a fillet weld depends on the thickness of the metal being welded, the strength of the weld required, and the type. Fillet Weld Joint Design.

From openoregon.pressbooks.pub

Fillet Weld Symbols Interpretation of Metal Fab Drawings Fillet Weld Joint Design A weld joint of the type that will require the minimum amount of weld metal shall be selected. The joint design determines what type of weld the operator will need to produce to meet the acceptable quality standard. The design of a fillet weld depends on the thickness of the metal being welded, the strength of the weld required, and. Fillet Weld Joint Design.

From www.btr-albuquerque.org

Welding Butt Joints Shemale Fingering Fillet Weld Joint Design In total they probably account for around 80% of all joints made by arc welding. The design of a fillet weld depends on the thickness of the metal being welded, the strength of the weld required, and the type of weld being used. Fillet welds are probably the most common type of weld, particularly in structural steelwork applications, so this. Fillet Weld Joint Design.

From fsuweldprof.weebly.com

Basics FSU Weld Prof Fillet Weld Joint Design The joint design determines what type of weld the operator will need to produce to meet the acceptable quality standard. A general approach for the design of welded joints that combine welds in various directions that reflects the individual segments’ load versus. In total they probably account for around 80% of all joints made by arc welding. Fillet welded joints. Fillet Weld Joint Design.

From thenavalarch.com

Designing Fillet Welds for Symmetrical Joint Sections TheNavalArch Fillet Weld Joint Design In total they probably account for around 80% of all joints made by arc welding. The design of a fillet weld depends on the thickness of the metal being welded, the strength of the weld required, and the type of weld being used. The joint design determines what type of weld the operator will need to produce to meet the. Fillet Weld Joint Design.

From engineersblog.net

What is Convex Fillet Joint? Explain in details step by step procedure to make a Convex Fillet Fillet Weld Joint Design Fillet welds are probably the most common type of weld, particularly in structural steelwork applications, so this first section will look at. In total they probably account for around 80% of all joints made by arc welding. A general approach for the design of welded joints that combine welds in various directions that reflects the individual segments’ load versus. Fillet. Fillet Weld Joint Design.

From www.ideastatica.com

Fillet weld in angle plate joint IDEA StatiCa Fillet Weld Joint Design A weld joint of the type that will require the minimum amount of weld metal shall be selected. Fillet welds are always designed on the basis of shear stress on the throat (a). The design of a fillet weld depends on the thickness of the metal being welded, the strength of the weld required, and the type of weld being. Fillet Weld Joint Design.

From www.youtube.com

Principles of Engineering Design 74 Special Cases of Fillet Welded Joints YouTube Fillet Weld Joint Design The design of a fillet weld depends on the thickness of the metal being welded, the strength of the weld required, and the type of weld being used. In total they probably account for around 80% of all joints made by arc welding. A general approach for the design of welded joints that combine welds in various directions that reflects. Fillet Weld Joint Design.

From www.youtube.com

Features of Complete Weld Butt Weld Fillet Weld YouTube Fillet Weld Joint Design The design of a fillet weld depends on the thickness of the metal being welded, the strength of the weld required, and the type of weld being used. A general approach for the design of welded joints that combine welds in various directions that reflects the individual segments’ load versus. The joint design determines what type of weld the operator. Fillet Weld Joint Design.

From www.youtube.com

Design a Lap joint Design of fillet weld Design and details of joint Numerical Problem 1 Fillet Weld Joint Design The joint design determines what type of weld the operator will need to produce to meet the acceptable quality standard. The design of a fillet weld depends on the thickness of the metal being welded, the strength of the weld required, and the type of weld being used. Fillet welds are probably the most common type of weld, particularly in. Fillet Weld Joint Design.

From engineeringlearn.com

Type of Welding Joints Applications, Advantages & Disadvantages Engineering Learn Fillet Weld Joint Design A general approach for the design of welded joints that combine welds in various directions that reflects the individual segments’ load versus. Fillet welded joints such as 't', lap and corner joints are the most common connection in welded fabrication. A weld joint of the type that will require the minimum amount of weld metal shall be selected. Fillet welds. Fillet Weld Joint Design.

From www.steelconn.uk

Fillet weld design two methods Fillet Weld Joint Design Fillet welds are probably the most common type of weld, particularly in structural steelwork applications, so this first section will look at. In total they probably account for around 80% of all joints made by arc welding. A weld joint of the type that will require the minimum amount of weld metal shall be selected. A general approach for the. Fillet Weld Joint Design.

From welderslab.com

What Are the 5 Basic Types of Welding Joints A Beginner's Guide Welders Lab Fillet Weld Joint Design Fillet welds are always designed on the basis of shear stress on the throat (a). In total they probably account for around 80% of all joints made by arc welding. A weld joint of the type that will require the minimum amount of weld metal shall be selected. Fillet welded joints such as 't', lap and corner joints are the. Fillet Weld Joint Design.

From engineersfield.com

Weld Type and Weld Joint Configuration Engineersfield Fillet Weld Joint Design In total they probably account for around 80% of all joints made by arc welding. Fillet welds are probably the most common type of weld, particularly in structural steelwork applications, so this first section will look at. A general approach for the design of welded joints that combine welds in various directions that reflects the individual segments’ load versus. Fillet. Fillet Weld Joint Design.

From www.onestopndt.com

An ultimate Guide to Weld Joints OnestopNDT Fillet Weld Joint Design The joint design determines what type of weld the operator will need to produce to meet the acceptable quality standard. The design of a fillet weld depends on the thickness of the metal being welded, the strength of the weld required, and the type of weld being used. Fillet welded joints such as 't', lap and corner joints are the. Fillet Weld Joint Design.

From www.mem50212.com

Weld Design Fillet Weld Joint Design The joint design determines what type of weld the operator will need to produce to meet the acceptable quality standard. A general approach for the design of welded joints that combine welds in various directions that reflects the individual segments’ load versus. A weld joint of the type that will require the minimum amount of weld metal shall be selected.. Fillet Weld Joint Design.

From ecoursesonline.iasri.res.in

Design of Structures LESSON 7. Welded Connection Fillet Weld Joint Design The joint design determines what type of weld the operator will need to produce to meet the acceptable quality standard. In total they probably account for around 80% of all joints made by arc welding. A general approach for the design of welded joints that combine welds in various directions that reflects the individual segments’ load versus. Fillet welded joints. Fillet Weld Joint Design.

From mewelding.com

OxyFuel Fillet Welding Fillet Weld Joint Design A weld joint of the type that will require the minimum amount of weld metal shall be selected. Fillet welded joints such as 't', lap and corner joints are the most common connection in welded fabrication. The joint design determines what type of weld the operator will need to produce to meet the acceptable quality standard. A general approach for. Fillet Weld Joint Design.

From www.youtube.com

Strength of Transverse Fillet Weld Design of Welded Joints Design of Machine YouTube Fillet Weld Joint Design The design of a fillet weld depends on the thickness of the metal being welded, the strength of the weld required, and the type of weld being used. Fillet welded joints such as 't', lap and corner joints are the most common connection in welded fabrication. Fillet welds are always designed on the basis of shear stress on the throat. Fillet Weld Joint Design.

From www.youtube.com

Type of Joints butt welding Fillet welding YouTube Fillet Weld Joint Design A weld joint of the type that will require the minimum amount of weld metal shall be selected. Fillet welds are probably the most common type of weld, particularly in structural steelwork applications, so this first section will look at. A general approach for the design of welded joints that combine welds in various directions that reflects the individual segments’. Fillet Weld Joint Design.

From ecoursesonline.iasri.res.in

Design of Structures LESSON 7. Welded Connection Fillet Weld Joint Design A general approach for the design of welded joints that combine welds in various directions that reflects the individual segments’ load versus. The design of a fillet weld depends on the thickness of the metal being welded, the strength of the weld required, and the type of weld being used. Fillet welds are always designed on the basis of shear. Fillet Weld Joint Design.

From mungfali.com

Fillet Weld Cross Section Fillet Weld Joint Design Fillet welds are always designed on the basis of shear stress on the throat (a). In total they probably account for around 80% of all joints made by arc welding. A weld joint of the type that will require the minimum amount of weld metal shall be selected. Fillet welded joints such as 't', lap and corner joints are the. Fillet Weld Joint Design.

From slidetodoc.com

WELD JOINT GEOMETERY AND WELDING SYMBOLS Terminology Definitions Fillet Weld Joint Design In total they probably account for around 80% of all joints made by arc welding. The design of a fillet weld depends on the thickness of the metal being welded, the strength of the weld required, and the type of weld being used. Fillet welds are always designed on the basis of shear stress on the throat (a). A general. Fillet Weld Joint Design.

From welditu.com

Guide to Welding Joint Types and Parts WelditU Fillet Weld Joint Design Fillet welds are always designed on the basis of shear stress on the throat (a). A general approach for the design of welded joints that combine welds in various directions that reflects the individual segments’ load versus. The joint design determines what type of weld the operator will need to produce to meet the acceptable quality standard. Fillet welds are. Fillet Weld Joint Design.

From mungfali.com

Fillet Weld Detail Fillet Weld Joint Design Fillet welds are always designed on the basis of shear stress on the throat (a). In total they probably account for around 80% of all joints made by arc welding. A general approach for the design of welded joints that combine welds in various directions that reflects the individual segments’ load versus. The joint design determines what type of weld. Fillet Weld Joint Design.

From www.mig-welding.co.uk

Arc (MMA) Welding Fillet Joints Fillet Weld Joint Design A weld joint of the type that will require the minimum amount of weld metal shall be selected. The joint design determines what type of weld the operator will need to produce to meet the acceptable quality standard. Fillet welded joints such as 't', lap and corner joints are the most common connection in welded fabrication. Fillet welds are always. Fillet Weld Joint Design.

From www.mig-welding.co.uk

Arc (MMA) Welding Fillet Joints Fillet Weld Joint Design Fillet welds are probably the most common type of weld, particularly in structural steelwork applications, so this first section will look at. Fillet welded joints such as 't', lap and corner joints are the most common connection in welded fabrication. Fillet welds are always designed on the basis of shear stress on the throat (a). A general approach for the. Fillet Weld Joint Design.