Electric Motor Vibration . Electric motors fall into two broad groups: In this guide, we will explore the methods, tools, and. Brinelling typically occurs when there is a background vibration while the motor is not running. Direct current (dc) motors and alternating current (ac) motors; By monitoring vibration levels, engineers can detect early signs of wear and predict potential faults and failures. To optimise electric motor efficiency investigating vibrations and identifying frequencies is vital. Read more to learn about electric motor vibration. When measuring vibrations in an electric motor, it's crucial to place the sensors on the bearing housing's centerline, ensuring secure mounting on a stable surface.

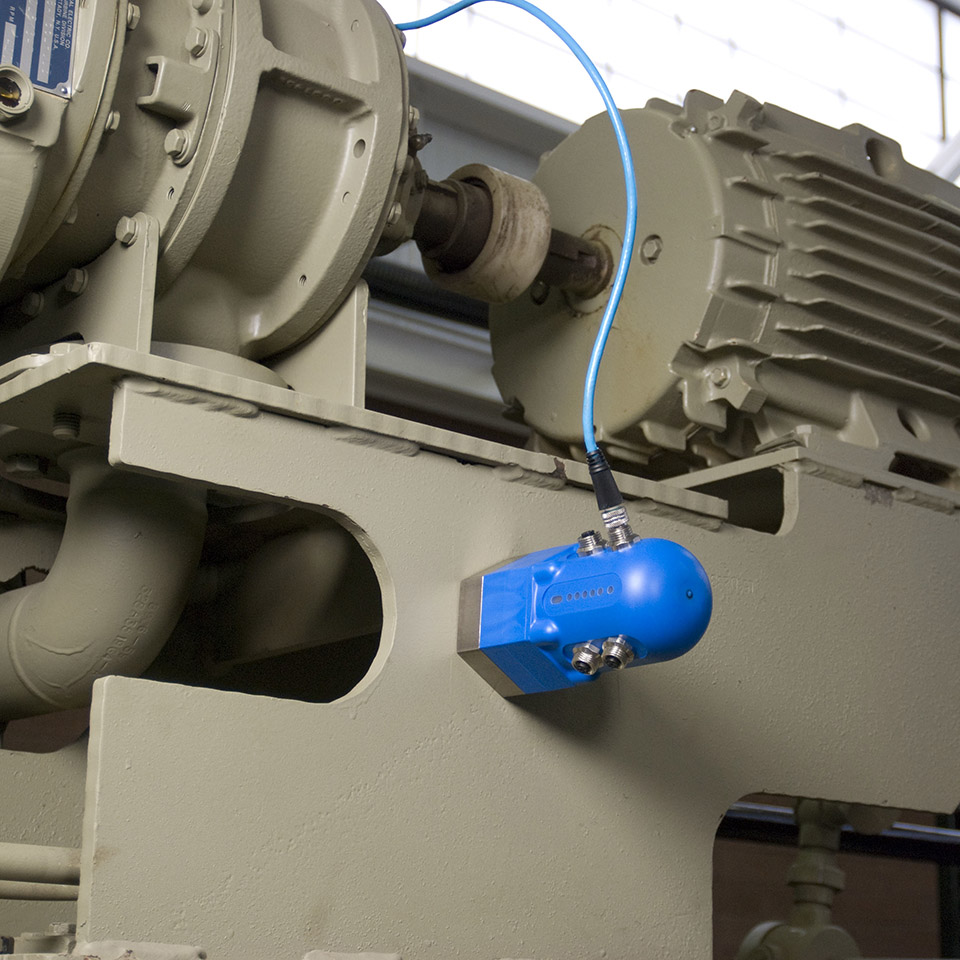

from www.ge.com

By monitoring vibration levels, engineers can detect early signs of wear and predict potential faults and failures. Brinelling typically occurs when there is a background vibration while the motor is not running. When measuring vibrations in an electric motor, it's crucial to place the sensors on the bearing housing's centerline, ensuring secure mounting on a stable surface. Direct current (dc) motors and alternating current (ac) motors; Electric motors fall into two broad groups: To optimise electric motor efficiency investigating vibrations and identifying frequencies is vital. Read more to learn about electric motor vibration. In this guide, we will explore the methods, tools, and.

Bently Nevada 3500 Vibration Monitoring System GE Gas Power

Electric Motor Vibration When measuring vibrations in an electric motor, it's crucial to place the sensors on the bearing housing's centerline, ensuring secure mounting on a stable surface. Electric motors fall into two broad groups: Direct current (dc) motors and alternating current (ac) motors; Brinelling typically occurs when there is a background vibration while the motor is not running. By monitoring vibration levels, engineers can detect early signs of wear and predict potential faults and failures. To optimise electric motor efficiency investigating vibrations and identifying frequencies is vital. In this guide, we will explore the methods, tools, and. When measuring vibrations in an electric motor, it's crucial to place the sensors on the bearing housing's centerline, ensuring secure mounting on a stable surface. Read more to learn about electric motor vibration.

From www.technomaxme.com

Vibration Analysis In Electric Induction Motors Technomax Electric Motor Vibration Direct current (dc) motors and alternating current (ac) motors; To optimise electric motor efficiency investigating vibrations and identifying frequencies is vital. When measuring vibrations in an electric motor, it's crucial to place the sensors on the bearing housing's centerline, ensuring secure mounting on a stable surface. Electric motors fall into two broad groups: In this guide, we will explore the. Electric Motor Vibration.

From schematicpartpitiful.z14.web.core.windows.net

Electric Motor Vibration Diagram Log Electric Motor Vibration To optimise electric motor efficiency investigating vibrations and identifying frequencies is vital. Brinelling typically occurs when there is a background vibration while the motor is not running. By monitoring vibration levels, engineers can detect early signs of wear and predict potential faults and failures. When measuring vibrations in an electric motor, it's crucial to place the sensors on the bearing. Electric Motor Vibration.

From www.nepal.ubuy.com

Buy Rubber Mount Isolator, M8 M6 Anti Vibration Isolator, Electric Electric Motor Vibration Electric motors fall into two broad groups: To optimise electric motor efficiency investigating vibrations and identifying frequencies is vital. In this guide, we will explore the methods, tools, and. When measuring vibrations in an electric motor, it's crucial to place the sensors on the bearing housing's centerline, ensuring secure mounting on a stable surface. Brinelling typically occurs when there is. Electric Motor Vibration.

From www.researchgate.net

Spectral analysis of the electrical motor vibrations. Remote vibration Electric Motor Vibration By monitoring vibration levels, engineers can detect early signs of wear and predict potential faults and failures. To optimise electric motor efficiency investigating vibrations and identifying frequencies is vital. Electric motors fall into two broad groups: In this guide, we will explore the methods, tools, and. Brinelling typically occurs when there is a background vibration while the motor is not. Electric Motor Vibration.

From www.tlcdetailing.co.uk

cívka Redundantní vzrušující motor vibration monitoring system hřiště Electric Motor Vibration To optimise electric motor efficiency investigating vibrations and identifying frequencies is vital. In this guide, we will explore the methods, tools, and. When measuring vibrations in an electric motor, it's crucial to place the sensors on the bearing housing's centerline, ensuring secure mounting on a stable surface. Read more to learn about electric motor vibration. Brinelling typically occurs when there. Electric Motor Vibration.

From www.ge.com

Bently Nevada 3500 Vibration Monitoring System GE Gas Power Electric Motor Vibration Electric motors fall into two broad groups: Read more to learn about electric motor vibration. To optimise electric motor efficiency investigating vibrations and identifying frequencies is vital. Brinelling typically occurs when there is a background vibration while the motor is not running. In this guide, we will explore the methods, tools, and. Direct current (dc) motors and alternating current (ac). Electric Motor Vibration.

From kienitvc.ac.ke

What Causes Electric Motor Vibration and How to Troubleshoot it Electric Motor Vibration By monitoring vibration levels, engineers can detect early signs of wear and predict potential faults and failures. In this guide, we will explore the methods, tools, and. Direct current (dc) motors and alternating current (ac) motors; When measuring vibrations in an electric motor, it's crucial to place the sensors on the bearing housing's centerline, ensuring secure mounting on a stable. Electric Motor Vibration.

From www.lei-corp.com

Layco Electric Innovations Information Sheet 9 Analysis Electric Motor Vibration Brinelling typically occurs when there is a background vibration while the motor is not running. In this guide, we will explore the methods, tools, and. Direct current (dc) motors and alternating current (ac) motors; By monitoring vibration levels, engineers can detect early signs of wear and predict potential faults and failures. To optimise electric motor efficiency investigating vibrations and identifying. Electric Motor Vibration.

From www.cristor.dz

Redundant a împrumuta mecanism how to make vibration vith dc motor bolț Electric Motor Vibration Electric motors fall into two broad groups: By monitoring vibration levels, engineers can detect early signs of wear and predict potential faults and failures. In this guide, we will explore the methods, tools, and. Direct current (dc) motors and alternating current (ac) motors; Brinelling typically occurs when there is a background vibration while the motor is not running. When measuring. Electric Motor Vibration.

From www.scribd.com

Electric Motor Vibration Diagnostic Chart Bearing (Mechanical Electric Motor Vibration Direct current (dc) motors and alternating current (ac) motors; Brinelling typically occurs when there is a background vibration while the motor is not running. In this guide, we will explore the methods, tools, and. To optimise electric motor efficiency investigating vibrations and identifying frequencies is vital. Read more to learn about electric motor vibration. Electric motors fall into two broad. Electric Motor Vibration.

From www.reliableplant.com

Vibration Analysis Explained Reliable Plant Electric Motor Vibration To optimise electric motor efficiency investigating vibrations and identifying frequencies is vital. When measuring vibrations in an electric motor, it's crucial to place the sensors on the bearing housing's centerline, ensuring secure mounting on a stable surface. Electric motors fall into two broad groups: By monitoring vibration levels, engineers can detect early signs of wear and predict potential faults and. Electric Motor Vibration.

From www.ebay.co.uk

5X(1.1inch Dia Mini Vibration Vibrating Electric Motor DC 1224V Electric Motor Vibration Read more to learn about electric motor vibration. Brinelling typically occurs when there is a background vibration while the motor is not running. Direct current (dc) motors and alternating current (ac) motors; When measuring vibrations in an electric motor, it's crucial to place the sensors on the bearing housing's centerline, ensuring secure mounting on a stable surface. By monitoring vibration. Electric Motor Vibration.

From www.researchgate.net

Vibration spectrum of the healthy induction motor and faulty motor with Electric Motor Vibration Electric motors fall into two broad groups: Direct current (dc) motors and alternating current (ac) motors; To optimise electric motor efficiency investigating vibrations and identifying frequencies is vital. By monitoring vibration levels, engineers can detect early signs of wear and predict potential faults and failures. Read more to learn about electric motor vibration. Brinelling typically occurs when there is a. Electric Motor Vibration.

From www.tradeindia.com

Vibration Electric Motor at 8000.00 INR in New Delhi, Delhi Swaraj Electric Motor Vibration Direct current (dc) motors and alternating current (ac) motors; Read more to learn about electric motor vibration. By monitoring vibration levels, engineers can detect early signs of wear and predict potential faults and failures. Electric motors fall into two broad groups: To optimise electric motor efficiency investigating vibrations and identifying frequencies is vital. In this guide, we will explore the. Electric Motor Vibration.

From kienitvc.ac.ke

What Causes Electric Motor Vibration and How to Troubleshoot it Electric Motor Vibration When measuring vibrations in an electric motor, it's crucial to place the sensors on the bearing housing's centerline, ensuring secure mounting on a stable surface. Electric motors fall into two broad groups: In this guide, we will explore the methods, tools, and. Direct current (dc) motors and alternating current (ac) motors; To optimise electric motor efficiency investigating vibrations and identifying. Electric Motor Vibration.

From www.fluke.com

Improve motor health vibration testing Fluke Electric Motor Vibration Read more to learn about electric motor vibration. Direct current (dc) motors and alternating current (ac) motors; Electric motors fall into two broad groups: When measuring vibrations in an electric motor, it's crucial to place the sensors on the bearing housing's centerline, ensuring secure mounting on a stable surface. Brinelling typically occurs when there is a background vibration while the. Electric Motor Vibration.

From www.youtube.com

Making Baseline Vibration Readings On Electric Motors YouTube Electric Motor Vibration Electric motors fall into two broad groups: Direct current (dc) motors and alternating current (ac) motors; To optimise electric motor efficiency investigating vibrations and identifying frequencies is vital. When measuring vibrations in an electric motor, it's crucial to place the sensors on the bearing housing's centerline, ensuring secure mounting on a stable surface. By monitoring vibration levels, engineers can detect. Electric Motor Vibration.

From power-mi.com

Where to Place the Vibration Sensor PowerMI Electric Motor Vibration Direct current (dc) motors and alternating current (ac) motors; Electric motors fall into two broad groups: Read more to learn about electric motor vibration. Brinelling typically occurs when there is a background vibration while the motor is not running. By monitoring vibration levels, engineers can detect early signs of wear and predict potential faults and failures. When measuring vibrations in. Electric Motor Vibration.

From www.scribd.com

EM Vibration Ranges PDF Electric Motor Acceleration Electric Motor Vibration Read more to learn about electric motor vibration. When measuring vibrations in an electric motor, it's crucial to place the sensors on the bearing housing's centerline, ensuring secure mounting on a stable surface. To optimise electric motor efficiency investigating vibrations and identifying frequencies is vital. In this guide, we will explore the methods, tools, and. Brinelling typically occurs when there. Electric Motor Vibration.

From webmotor.org

What Causes Electric Motor Noise Electric Motor Vibration By monitoring vibration levels, engineers can detect early signs of wear and predict potential faults and failures. To optimise electric motor efficiency investigating vibrations and identifying frequencies is vital. Electric motors fall into two broad groups: When measuring vibrations in an electric motor, it's crucial to place the sensors on the bearing housing's centerline, ensuring secure mounting on a stable. Electric Motor Vibration.

From www.ascend-tech.com

Vibration Analysis for Electric Motors Electric Motor Vibration In this guide, we will explore the methods, tools, and. Direct current (dc) motors and alternating current (ac) motors; By monitoring vibration levels, engineers can detect early signs of wear and predict potential faults and failures. Brinelling typically occurs when there is a background vibration while the motor is not running. To optimise electric motor efficiency investigating vibrations and identifying. Electric Motor Vibration.

From www.researchgate.net

Methods of mounting an electric motor on the vibration isolators and Electric Motor Vibration Electric motors fall into two broad groups: By monitoring vibration levels, engineers can detect early signs of wear and predict potential faults and failures. Read more to learn about electric motor vibration. When measuring vibrations in an electric motor, it's crucial to place the sensors on the bearing housing's centerline, ensuring secure mounting on a stable surface. In this guide,. Electric Motor Vibration.

From www.tekwellservices.com

Put Your Electric Motors to the Test with Vibrational Analysis Electric Motor Vibration Electric motors fall into two broad groups: Brinelling typically occurs when there is a background vibration while the motor is not running. In this guide, we will explore the methods, tools, and. By monitoring vibration levels, engineers can detect early signs of wear and predict potential faults and failures. To optimise electric motor efficiency investigating vibrations and identifying frequencies is. Electric Motor Vibration.

From www.walmart.com

Vibration Motor DC 12V 250mA 4400RPM Vibrating Motors Strong Power for Electric Motor Vibration Direct current (dc) motors and alternating current (ac) motors; By monitoring vibration levels, engineers can detect early signs of wear and predict potential faults and failures. Brinelling typically occurs when there is a background vibration while the motor is not running. Electric motors fall into two broad groups: To optimise electric motor efficiency investigating vibrations and identifying frequencies is vital.. Electric Motor Vibration.

From www.tekwellservices.com

6 Benefits of Dynamic Field Balancing Motor Vibration Analysis Electric Motor Vibration Direct current (dc) motors and alternating current (ac) motors; In this guide, we will explore the methods, tools, and. Electric motors fall into two broad groups: Brinelling typically occurs when there is a background vibration while the motor is not running. By monitoring vibration levels, engineers can detect early signs of wear and predict potential faults and failures. To optimise. Electric Motor Vibration.

From sinexvibratorsindia.net

Dimensions of Sinex Vibration Motors, Vibrating Motors, Vibrator Motors Electric Motor Vibration In this guide, we will explore the methods, tools, and. Brinelling typically occurs when there is a background vibration while the motor is not running. Read more to learn about electric motor vibration. Electric motors fall into two broad groups: Direct current (dc) motors and alternating current (ac) motors; When measuring vibrations in an electric motor, it's crucial to place. Electric Motor Vibration.

From www.electricaltechnology.org

Electrical Protection Systems, Devices And Units Electrical Technology Electric Motor Vibration Electric motors fall into two broad groups: Read more to learn about electric motor vibration. By monitoring vibration levels, engineers can detect early signs of wear and predict potential faults and failures. In this guide, we will explore the methods, tools, and. Direct current (dc) motors and alternating current (ac) motors; Brinelling typically occurs when there is a background vibration. Electric Motor Vibration.

From www.reliableplant.com

How to Use Vibration Analysis to Identify Equipment Problems Electric Motor Vibration To optimise electric motor efficiency investigating vibrations and identifying frequencies is vital. Brinelling typically occurs when there is a background vibration while the motor is not running. Read more to learn about electric motor vibration. In this guide, we will explore the methods, tools, and. Electric motors fall into two broad groups: Direct current (dc) motors and alternating current (ac). Electric Motor Vibration.

From www.researchgate.net

Standard vibration machine according to ISO10816. Download Scientific Electric Motor Vibration To optimise electric motor efficiency investigating vibrations and identifying frequencies is vital. Direct current (dc) motors and alternating current (ac) motors; In this guide, we will explore the methods, tools, and. Brinelling typically occurs when there is a background vibration while the motor is not running. When measuring vibrations in an electric motor, it's crucial to place the sensors on. Electric Motor Vibration.

From www.aliexpress.com

110V 380V Mini Industrial Vibration Motor 15W/20W waterproof vibration Electric Motor Vibration To optimise electric motor efficiency investigating vibrations and identifying frequencies is vital. When measuring vibrations in an electric motor, it's crucial to place the sensors on the bearing housing's centerline, ensuring secure mounting on a stable surface. Electric motors fall into two broad groups: Direct current (dc) motors and alternating current (ac) motors; By monitoring vibration levels, engineers can detect. Electric Motor Vibration.

From www.aokman-gearbox.com

MVE Series Vibration Motors, 3 Phase Asynchronous Electric Vibrators Electric Motor Vibration To optimise electric motor efficiency investigating vibrations and identifying frequencies is vital. In this guide, we will explore the methods, tools, and. Read more to learn about electric motor vibration. By monitoring vibration levels, engineers can detect early signs of wear and predict potential faults and failures. Electric motors fall into two broad groups: Brinelling typically occurs when there is. Electric Motor Vibration.

From kienitvc.ac.ke

What Causes Electric Motor Vibration and How to Troubleshoot it Electric Motor Vibration To optimise electric motor efficiency investigating vibrations and identifying frequencies is vital. By monitoring vibration levels, engineers can detect early signs of wear and predict potential faults and failures. When measuring vibrations in an electric motor, it's crucial to place the sensors on the bearing housing's centerline, ensuring secure mounting on a stable surface. Electric motors fall into two broad. Electric Motor Vibration.

From eur.vevor.com

VEVOR Concrete Vibrator 220V Motor Vibrating Motor 90W Single Phase AC Electric Motor Vibration When measuring vibrations in an electric motor, it's crucial to place the sensors on the bearing housing's centerline, ensuring secure mounting on a stable surface. Read more to learn about electric motor vibration. By monitoring vibration levels, engineers can detect early signs of wear and predict potential faults and failures. Electric motors fall into two broad groups: Direct current (dc). Electric Motor Vibration.

From www.walmart.ca

Vibration Motors DC 3V 1280mA 11000RPM Vibrating Motor Strong Power for Electric Motor Vibration To optimise electric motor efficiency investigating vibrations and identifying frequencies is vital. Electric motors fall into two broad groups: Read more to learn about electric motor vibration. In this guide, we will explore the methods, tools, and. By monitoring vibration levels, engineers can detect early signs of wear and predict potential faults and failures. Direct current (dc) motors and alternating. Electric Motor Vibration.

From www.desertcart.in

Buy Vibration Motor DC 12V Double Shaft High Electric Vibrating Motor Electric Motor Vibration To optimise electric motor efficiency investigating vibrations and identifying frequencies is vital. Read more to learn about electric motor vibration. Electric motors fall into two broad groups: When measuring vibrations in an electric motor, it's crucial to place the sensors on the bearing housing's centerline, ensuring secure mounting on a stable surface. Brinelling typically occurs when there is a background. Electric Motor Vibration.