Grind Surface Finish . We will explain the different types of machines used for surface grinding, the types of grinding wheels and their applications, and how surface grinding can help achieve a specific surface. Precision cnc production grinding shines when parts require tight geometric tolerances and quality surface finishes. Surface grinding is an abrasive machining process, creating flat, smooth finishes on workpieces using a spinning wheel with rough particles, essential for precision. Surface grinding emerges as a highly effective technique for attaining a smooth, precise, and uniformly polished surface finish on steel and metal components. Typically, surface finishes in the range of 32.

from ssccreinadelapaz.edu.pe

We will explain the different types of machines used for surface grinding, the types of grinding wheels and their applications, and how surface grinding can help achieve a specific surface. Surface grinding is an abrasive machining process, creating flat, smooth finishes on workpieces using a spinning wheel with rough particles, essential for precision. Precision cnc production grinding shines when parts require tight geometric tolerances and quality surface finishes. Surface grinding emerges as a highly effective technique for attaining a smooth, precise, and uniformly polished surface finish on steel and metal components. Typically, surface finishes in the range of 32.

Measuring tool factory surface roughness comparison sample block full

Grind Surface Finish Precision cnc production grinding shines when parts require tight geometric tolerances and quality surface finishes. Typically, surface finishes in the range of 32. Precision cnc production grinding shines when parts require tight geometric tolerances and quality surface finishes. Surface grinding emerges as a highly effective technique for attaining a smooth, precise, and uniformly polished surface finish on steel and metal components. Surface grinding is an abrasive machining process, creating flat, smooth finishes on workpieces using a spinning wheel with rough particles, essential for precision. We will explain the different types of machines used for surface grinding, the types of grinding wheels and their applications, and how surface grinding can help achieve a specific surface.

From www.grindingacademy.com

STUNNING PROCESS OF GRINDING A FLAWLESS SURFACE FINISH Titans of CNC Grind Surface Finish Surface grinding emerges as a highly effective technique for attaining a smooth, precise, and uniformly polished surface finish on steel and metal components. We will explain the different types of machines used for surface grinding, the types of grinding wheels and their applications, and how surface grinding can help achieve a specific surface. Precision cnc production grinding shines when parts. Grind Surface Finish.

From nsmaquinas.com

Surface Deviations No Problem! HeavyDuty Flat Grinding Machine Grind Surface Finish Typically, surface finishes in the range of 32. We will explain the different types of machines used for surface grinding, the types of grinding wheels and their applications, and how surface grinding can help achieve a specific surface. Precision cnc production grinding shines when parts require tight geometric tolerances and quality surface finishes. Surface grinding emerges as a highly effective. Grind Surface Finish.

From www.slideserve.com

PPT Surface Finish PowerPoint Presentation ID3866407 Grind Surface Finish Typically, surface finishes in the range of 32. Surface grinding is an abrasive machining process, creating flat, smooth finishes on workpieces using a spinning wheel with rough particles, essential for precision. We will explain the different types of machines used for surface grinding, the types of grinding wheels and their applications, and how surface grinding can help achieve a specific. Grind Surface Finish.

From www.youtube.com

So You Need A Good Surface Finish YouTube Grind Surface Finish Surface grinding emerges as a highly effective technique for attaining a smooth, precise, and uniformly polished surface finish on steel and metal components. Surface grinding is an abrasive machining process, creating flat, smooth finishes on workpieces using a spinning wheel with rough particles, essential for precision. Typically, surface finishes in the range of 32. Precision cnc production grinding shines when. Grind Surface Finish.

From keywordsuggest.org

Image Gallery Machining Symbols Grind Surface Finish Precision cnc production grinding shines when parts require tight geometric tolerances and quality surface finishes. We will explain the different types of machines used for surface grinding, the types of grinding wheels and their applications, and how surface grinding can help achieve a specific surface. Surface grinding is an abrasive machining process, creating flat, smooth finishes on workpieces using a. Grind Surface Finish.

From mungfali.com

Surface Finish Roughness Chart Grind Surface Finish We will explain the different types of machines used for surface grinding, the types of grinding wheels and their applications, and how surface grinding can help achieve a specific surface. Surface grinding emerges as a highly effective technique for attaining a smooth, precise, and uniformly polished surface finish on steel and metal components. Typically, surface finishes in the range of. Grind Surface Finish.

From etcnmachining.com

A Comprehensive Guide to Surface Finish Symbols in Engineering Drawings Grind Surface Finish Surface grinding is an abrasive machining process, creating flat, smooth finishes on workpieces using a spinning wheel with rough particles, essential for precision. Precision cnc production grinding shines when parts require tight geometric tolerances and quality surface finishes. We will explain the different types of machines used for surface grinding, the types of grinding wheels and their applications, and how. Grind Surface Finish.

From pgisteel.com

Steel Surface Finishes Precision Grinding, Inc. Grind Surface Finish Typically, surface finishes in the range of 32. We will explain the different types of machines used for surface grinding, the types of grinding wheels and their applications, and how surface grinding can help achieve a specific surface. Surface grinding emerges as a highly effective technique for attaining a smooth, precise, and uniformly polished surface finish on steel and metal. Grind Surface Finish.

From ssccreinadelapaz.edu.pe

Measuring tool factory surface roughness comparison sample block full Grind Surface Finish Precision cnc production grinding shines when parts require tight geometric tolerances and quality surface finishes. Typically, surface finishes in the range of 32. Surface grinding is an abrasive machining process, creating flat, smooth finishes on workpieces using a spinning wheel with rough particles, essential for precision. We will explain the different types of machines used for surface grinding, the types. Grind Surface Finish.

From mavink.com

Surface Finish Call Out On Drawings Grind Surface Finish We will explain the different types of machines used for surface grinding, the types of grinding wheels and their applications, and how surface grinding can help achieve a specific surface. Surface grinding emerges as a highly effective technique for attaining a smooth, precise, and uniformly polished surface finish on steel and metal components. Precision cnc production grinding shines when parts. Grind Surface Finish.

From xometry.pro

Selecting Right Surface Roughness for CNC Machining Xometry Pro Grind Surface Finish We will explain the different types of machines used for surface grinding, the types of grinding wheels and their applications, and how surface grinding can help achieve a specific surface. Precision cnc production grinding shines when parts require tight geometric tolerances and quality surface finishes. Surface grinding emerges as a highly effective technique for attaining a smooth, precise, and uniformly. Grind Surface Finish.

From www.multigrind.co.uk

Surface Grinding Services For Surfaces Up To 300mm x 650mm Grind Surface Finish Surface grinding emerges as a highly effective technique for attaining a smooth, precise, and uniformly polished surface finish on steel and metal components. Typically, surface finishes in the range of 32. Precision cnc production grinding shines when parts require tight geometric tolerances and quality surface finishes. We will explain the different types of machines used for surface grinding, the types. Grind Surface Finish.

From www.rapiddirect.com

Surface Roughness Chart Understanding Surface Finishes RapidDirect Grind Surface Finish Typically, surface finishes in the range of 32. Precision cnc production grinding shines when parts require tight geometric tolerances and quality surface finishes. We will explain the different types of machines used for surface grinding, the types of grinding wheels and their applications, and how surface grinding can help achieve a specific surface. Surface grinding emerges as a highly effective. Grind Surface Finish.

From sturgeonshouse.ipbhost.com

Machine Finishes Chart Open Discussion Sturgeon's House Grind Surface Finish Typically, surface finishes in the range of 32. Surface grinding emerges as a highly effective technique for attaining a smooth, precise, and uniformly polished surface finish on steel and metal components. We will explain the different types of machines used for surface grinding, the types of grinding wheels and their applications, and how surface grinding can help achieve a specific. Grind Surface Finish.

From www.thefabricator.com

Three ways to achieve a specific metal finish Grind Surface Finish We will explain the different types of machines used for surface grinding, the types of grinding wheels and their applications, and how surface grinding can help achieve a specific surface. Surface grinding is an abrasive machining process, creating flat, smooth finishes on workpieces using a spinning wheel with rough particles, essential for precision. Surface grinding emerges as a highly effective. Grind Surface Finish.

From www.thefabricator.com

The basics of metal surface finishes Grind Surface Finish Typically, surface finishes in the range of 32. Precision cnc production grinding shines when parts require tight geometric tolerances and quality surface finishes. We will explain the different types of machines used for surface grinding, the types of grinding wheels and their applications, and how surface grinding can help achieve a specific surface. Surface grinding is an abrasive machining process,. Grind Surface Finish.

From mungfali.com

Ra Surface Roughness Chart Grind Surface Finish Surface grinding is an abrasive machining process, creating flat, smooth finishes on workpieces using a spinning wheel with rough particles, essential for precision. We will explain the different types of machines used for surface grinding, the types of grinding wheels and their applications, and how surface grinding can help achieve a specific surface. Typically, surface finishes in the range of. Grind Surface Finish.

From www.nassit.org.sl

Surface Roughness Explained Ra Roughness Chart, 45 OFF Grind Surface Finish Surface grinding is an abrasive machining process, creating flat, smooth finishes on workpieces using a spinning wheel with rough particles, essential for precision. We will explain the different types of machines used for surface grinding, the types of grinding wheels and their applications, and how surface grinding can help achieve a specific surface. Typically, surface finishes in the range of. Grind Surface Finish.

From www.rapiddirect.com

Surface Roughness Chart Understanding Surface Finishes RapidDirect Grind Surface Finish Precision cnc production grinding shines when parts require tight geometric tolerances and quality surface finishes. Typically, surface finishes in the range of 32. Surface grinding is an abrasive machining process, creating flat, smooth finishes on workpieces using a spinning wheel with rough particles, essential for precision. We will explain the different types of machines used for surface grinding, the types. Grind Surface Finish.

From www.pinterest.co.uk

Surface Finish Guide 5.5" x 8.5" Tool Box CNC Shop eBay in Grind Surface Finish Surface grinding is an abrasive machining process, creating flat, smooth finishes on workpieces using a spinning wheel with rough particles, essential for precision. We will explain the different types of machines used for surface grinding, the types of grinding wheels and their applications, and how surface grinding can help achieve a specific surface. Surface grinding emerges as a highly effective. Grind Surface Finish.

From gbu-presnenskij.ru

Understanding Surface Roughness Symbols Introduction To, 40 OFF Grind Surface Finish Surface grinding emerges as a highly effective technique for attaining a smooth, precise, and uniformly polished surface finish on steel and metal components. Precision cnc production grinding shines when parts require tight geometric tolerances and quality surface finishes. We will explain the different types of machines used for surface grinding, the types of grinding wheels and their applications, and how. Grind Surface Finish.

From www.gdandtbasics.com

The Basics of Surface Finish GD&T Basics Grind Surface Finish Surface grinding emerges as a highly effective technique for attaining a smooth, precise, and uniformly polished surface finish on steel and metal components. Surface grinding is an abrasive machining process, creating flat, smooth finishes on workpieces using a spinning wheel with rough particles, essential for precision. Typically, surface finishes in the range of 32. Precision cnc production grinding shines when. Grind Surface Finish.

From technofaq.org

9 Common Surface Finishes In Metal CNC Machining Techno FAQ Grind Surface Finish Surface grinding emerges as a highly effective technique for attaining a smooth, precise, and uniformly polished surface finish on steel and metal components. Precision cnc production grinding shines when parts require tight geometric tolerances and quality surface finishes. Typically, surface finishes in the range of 32. We will explain the different types of machines used for surface grinding, the types. Grind Surface Finish.

From mavink.com

Iso Surface Finish Chart Grind Surface Finish Typically, surface finishes in the range of 32. Surface grinding emerges as a highly effective technique for attaining a smooth, precise, and uniformly polished surface finish on steel and metal components. We will explain the different types of machines used for surface grinding, the types of grinding wheels and their applications, and how surface grinding can help achieve a specific. Grind Surface Finish.

From www.empireabrasives.com

How Can You Reduce Surface Roughness when Milling Metal? Empire Abrasives Grind Surface Finish Precision cnc production grinding shines when parts require tight geometric tolerances and quality surface finishes. Surface grinding emerges as a highly effective technique for attaining a smooth, precise, and uniformly polished surface finish on steel and metal components. Surface grinding is an abrasive machining process, creating flat, smooth finishes on workpieces using a spinning wheel with rough particles, essential for. Grind Surface Finish.

From pgisteel.com

Steel Surface Finishes Precision Grinding, Inc. Grind Surface Finish Surface grinding emerges as a highly effective technique for attaining a smooth, precise, and uniformly polished surface finish on steel and metal components. Precision cnc production grinding shines when parts require tight geometric tolerances and quality surface finishes. We will explain the different types of machines used for surface grinding, the types of grinding wheels and their applications, and how. Grind Surface Finish.

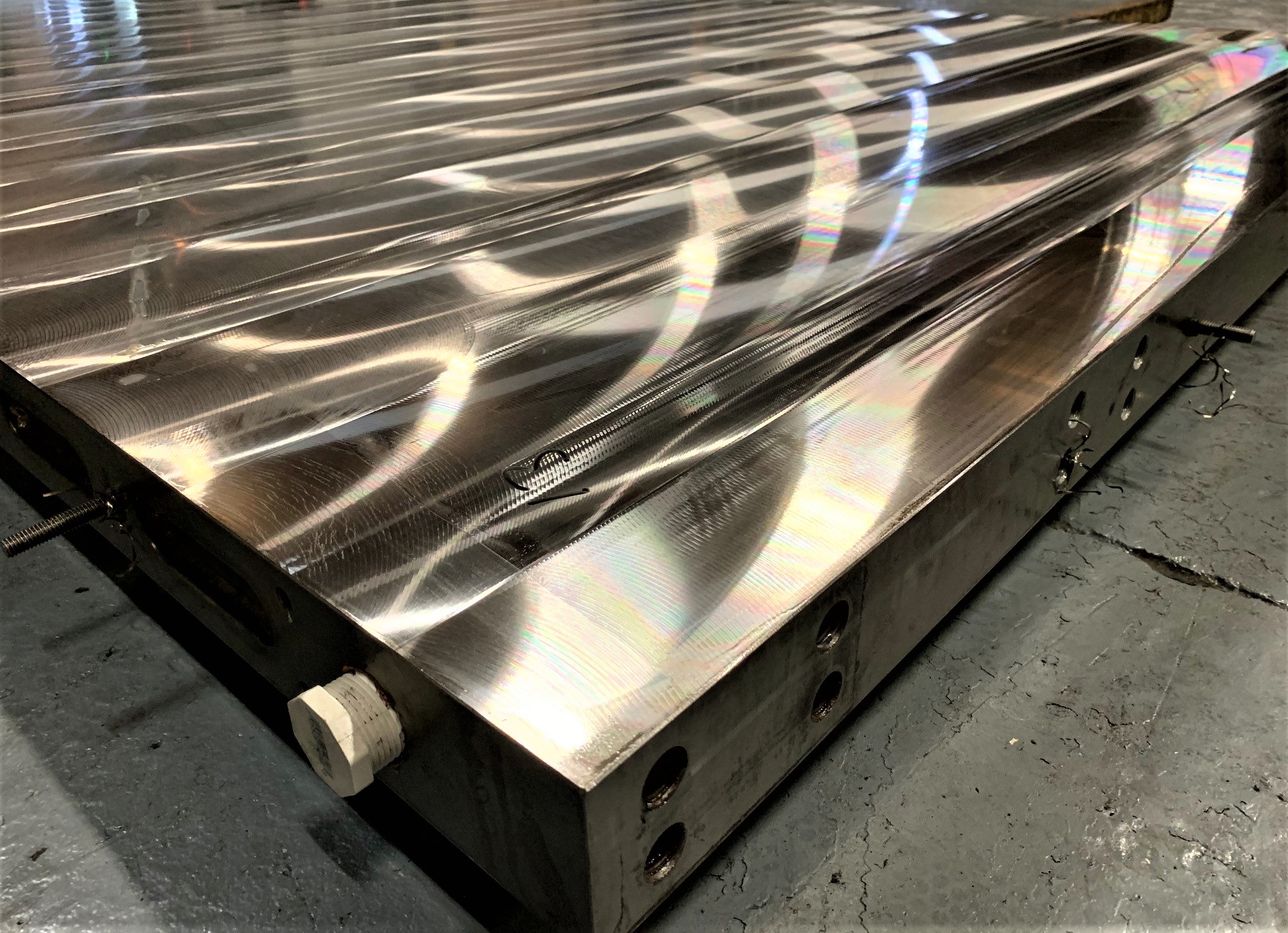

From pgisteel.com

Steel Base Plate Precision Grinding, Inc. Grind Surface Finish We will explain the different types of machines used for surface grinding, the types of grinding wheels and their applications, and how surface grinding can help achieve a specific surface. Precision cnc production grinding shines when parts require tight geometric tolerances and quality surface finishes. Surface grinding emerges as a highly effective technique for attaining a smooth, precise, and uniformly. Grind Surface Finish.

From pgisteel.com

Steel Surface Finishes Precision Grinding, Inc. Grind Surface Finish Typically, surface finishes in the range of 32. Surface grinding emerges as a highly effective technique for attaining a smooth, precise, and uniformly polished surface finish on steel and metal components. We will explain the different types of machines used for surface grinding, the types of grinding wheels and their applications, and how surface grinding can help achieve a specific. Grind Surface Finish.

From www.venangomachine.com

PA CNC Shop with Precision Large Surface & Blanchard Grinding Grind Surface Finish Precision cnc production grinding shines when parts require tight geometric tolerances and quality surface finishes. Typically, surface finishes in the range of 32. Surface grinding is an abrasive machining process, creating flat, smooth finishes on workpieces using a spinning wheel with rough particles, essential for precision. We will explain the different types of machines used for surface grinding, the types. Grind Surface Finish.

From www.precision-surface.com

What is Surface Grinding & Reciprocating grinding? Grind Surface Finish Surface grinding is an abrasive machining process, creating flat, smooth finishes on workpieces using a spinning wheel with rough particles, essential for precision. Typically, surface finishes in the range of 32. Surface grinding emerges as a highly effective technique for attaining a smooth, precise, and uniformly polished surface finish on steel and metal components. We will explain the different types. Grind Surface Finish.

From www.stahliusa.com

Grinding Applications Stahli USA Worldwide Leader Grind Surface Finish Surface grinding is an abrasive machining process, creating flat, smooth finishes on workpieces using a spinning wheel with rough particles, essential for precision. Typically, surface finishes in the range of 32. Surface grinding emerges as a highly effective technique for attaining a smooth, precise, and uniformly polished surface finish on steel and metal components. We will explain the different types. Grind Surface Finish.

From forturetools.com

8 points common knowledge of grinding wheel safety Forture Tools Grind Surface Finish Precision cnc production grinding shines when parts require tight geometric tolerances and quality surface finishes. Surface grinding is an abrasive machining process, creating flat, smooth finishes on workpieces using a spinning wheel with rough particles, essential for precision. We will explain the different types of machines used for surface grinding, the types of grinding wheels and their applications, and how. Grind Surface Finish.

From www.youtube.com

Surface Roughness & Finishing Symbols YouTube Grind Surface Finish Precision cnc production grinding shines when parts require tight geometric tolerances and quality surface finishes. Typically, surface finishes in the range of 32. Surface grinding emerges as a highly effective technique for attaining a smooth, precise, and uniformly polished surface finish on steel and metal components. Surface grinding is an abrasive machining process, creating flat, smooth finishes on workpieces using. Grind Surface Finish.

From pgisteel.com

Steel Surface Finishes Precision Grinding, Inc. Grind Surface Finish Typically, surface finishes in the range of 32. Surface grinding is an abrasive machining process, creating flat, smooth finishes on workpieces using a spinning wheel with rough particles, essential for precision. Surface grinding emerges as a highly effective technique for attaining a smooth, precise, and uniformly polished surface finish on steel and metal components. We will explain the different types. Grind Surface Finish.

From www.precisiongroundbars.com

Surface Grinding The Essential Guide for Precision and Quality Grind Surface Finish Surface grinding is an abrasive machining process, creating flat, smooth finishes on workpieces using a spinning wheel with rough particles, essential for precision. Surface grinding emerges as a highly effective technique for attaining a smooth, precise, and uniformly polished surface finish on steel and metal components. Precision cnc production grinding shines when parts require tight geometric tolerances and quality surface. Grind Surface Finish.