Centrifugal Pumps Applications . A centrifugal pump is used to move water and other low viscosity liquids with the assistance of centrifugal force. Centrifugal pumps generate flow by using one of three actions: This energy transfer happens through an impeller installed inside the. The heart of the centrifugal pump, responsible for fluid movement. Radial flow, mixed flow, or axial flow. Slurries such as mud, or high viscosity oils can. Learn about the different types of centrifugal pumps and how they are suited for specific industrial and marine applications. A centrifugal pump converts the mechanical energy of the fluids into hydraulic energy using centrifugal force. The pump uses a motor that converts electric energy into mechanical. Axial flow pumps are characterized by high flow. In general, centrifugal pumps are therefore suited to low pressure, high capacity, pumping applications of liquids with viscosities between 0.1 and 200 cp. Houses the impeller and directs the flow of fluid. Centrifugal pumps have a wide range of applications across several industrial sectors. Key components of a centrifugal pump.

from www.pumpfundamentals.com

Key components of a centrifugal pump. The heart of the centrifugal pump, responsible for fluid movement. Centrifugal pumps generate flow by using one of three actions: Houses the impeller and directs the flow of fluid. Centrifugal pumps have a wide range of applications across several industrial sectors. Slurries such as mud, or high viscosity oils can. Learn about the different types of centrifugal pumps and how they are suited for specific industrial and marine applications. In general, centrifugal pumps are therefore suited to low pressure, high capacity, pumping applications of liquids with viscosities between 0.1 and 200 cp. Axial flow pumps are characterized by high flow. A centrifugal pump converts the mechanical energy of the fluids into hydraulic energy using centrifugal force.

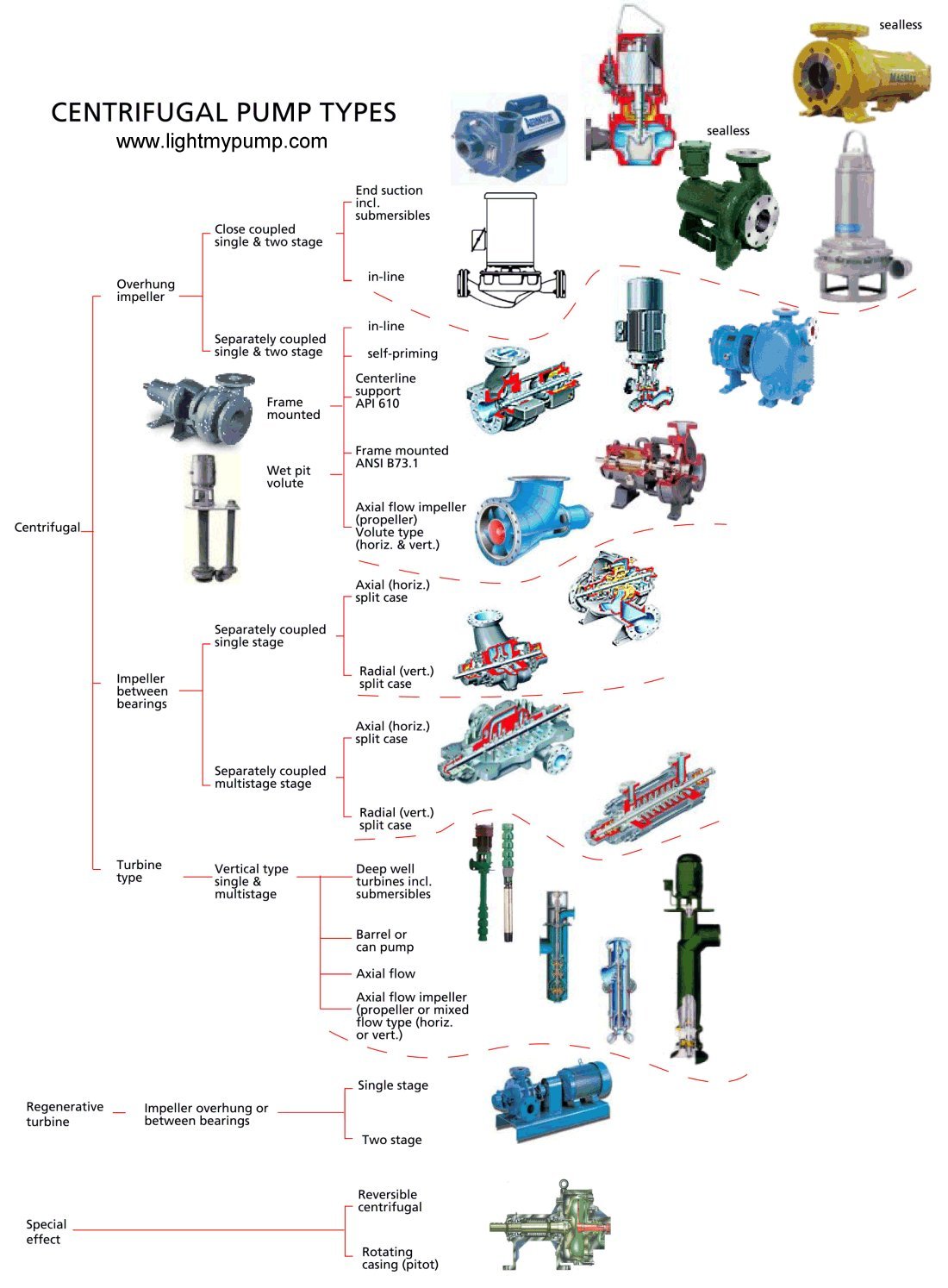

Centrifugal pump type chart

Centrifugal Pumps Applications This energy transfer happens through an impeller installed inside the. The pump uses a motor that converts electric energy into mechanical. The heart of the centrifugal pump, responsible for fluid movement. Key components of a centrifugal pump. Learn about the different types of centrifugal pumps and how they are suited for specific industrial and marine applications. This energy transfer happens through an impeller installed inside the. Centrifugal pumps generate flow by using one of three actions: Radial flow, mixed flow, or axial flow. A centrifugal pump is used to move water and other low viscosity liquids with the assistance of centrifugal force. Centrifugal pumps have a wide range of applications across several industrial sectors. A centrifugal pump converts the mechanical energy of the fluids into hydraulic energy using centrifugal force. Slurries such as mud, or high viscosity oils can. Houses the impeller and directs the flow of fluid. Axial flow pumps are characterized by high flow. In general, centrifugal pumps are therefore suited to low pressure, high capacity, pumping applications of liquids with viscosities between 0.1 and 200 cp.

From blog.thepipingmart.com

Overview of Centrifugal Pumps Centrifugal Pumps Applications Key components of a centrifugal pump. A centrifugal pump converts the mechanical energy of the fluids into hydraulic energy using centrifugal force. This energy transfer happens through an impeller installed inside the. In general, centrifugal pumps are therefore suited to low pressure, high capacity, pumping applications of liquids with viscosities between 0.1 and 200 cp. Axial flow pumps are characterized. Centrifugal Pumps Applications.

From centrifugalpumpsmanufacturer.wordpress.com

Applications of Centrifugal Pump Flowmore Pumps Centrifugal Pumps Applications Slurries such as mud, or high viscosity oils can. Houses the impeller and directs the flow of fluid. A centrifugal pump converts the mechanical energy of the fluids into hydraulic energy using centrifugal force. Key components of a centrifugal pump. The heart of the centrifugal pump, responsible for fluid movement. Centrifugal pumps generate flow by using one of three actions:. Centrifugal Pumps Applications.

From www.elprocus.com

Different Types of Pumps Working & Their Applications Centrifugal Pumps Applications Centrifugal pumps generate flow by using one of three actions: Radial flow, mixed flow, or axial flow. The heart of the centrifugal pump, responsible for fluid movement. A centrifugal pump converts the mechanical energy of the fluids into hydraulic energy using centrifugal force. In general, centrifugal pumps are therefore suited to low pressure, high capacity, pumping applications of liquids with. Centrifugal Pumps Applications.

From blog.hayespump.com

Centrifugal Pumps Explained Principles, Applications & More Centrifugal Pumps Applications The pump uses a motor that converts electric energy into mechanical. This energy transfer happens through an impeller installed inside the. Houses the impeller and directs the flow of fluid. Slurries such as mud, or high viscosity oils can. Axial flow pumps are characterized by high flow. The heart of the centrifugal pump, responsible for fluid movement. Key components of. Centrifugal Pumps Applications.

From www.pumpfundamentals.com

Centrifugal pump type chart Centrifugal Pumps Applications Slurries such as mud, or high viscosity oils can. Radial flow, mixed flow, or axial flow. Key components of a centrifugal pump. A centrifugal pump is used to move water and other low viscosity liquids with the assistance of centrifugal force. A centrifugal pump converts the mechanical energy of the fluids into hydraulic energy using centrifugal force. The pump uses. Centrifugal Pumps Applications.

From centrifugalpumpsmanufacturer.wordpress.com

Types and Applications of Centrifugal Pumps Flowmore Pumps Centrifugal Pumps Applications Centrifugal pumps have a wide range of applications across several industrial sectors. Slurries such as mud, or high viscosity oils can. Houses the impeller and directs the flow of fluid. In general, centrifugal pumps are therefore suited to low pressure, high capacity, pumping applications of liquids with viscosities between 0.1 and 200 cp. Learn about the different types of centrifugal. Centrifugal Pumps Applications.

From www.eduaspirant.com

TYPES OF CENTRIFUGAL PUMPS Centrifugal Pumps Applications Centrifugal pumps generate flow by using one of three actions: In general, centrifugal pumps are therefore suited to low pressure, high capacity, pumping applications of liquids with viscosities between 0.1 and 200 cp. Key components of a centrifugal pump. The heart of the centrifugal pump, responsible for fluid movement. This energy transfer happens through an impeller installed inside the. Learn. Centrifugal Pumps Applications.

From www.tapflopumps.co.uk

Benefits And Uses Of A Centrifugal Pump Tapflo Pumps UK Centrifugal Pumps Applications Key components of a centrifugal pump. Centrifugal pumps have a wide range of applications across several industrial sectors. Houses the impeller and directs the flow of fluid. Axial flow pumps are characterized by high flow. The pump uses a motor that converts electric energy into mechanical. A centrifugal pump converts the mechanical energy of the fluids into hydraulic energy using. Centrifugal Pumps Applications.

From technologywire.net

Centrifugal Pumps Applications and Limitations TechnologyWire Centrifugal Pumps Applications The heart of the centrifugal pump, responsible for fluid movement. Houses the impeller and directs the flow of fluid. Centrifugal pumps generate flow by using one of three actions: This energy transfer happens through an impeller installed inside the. Slurries such as mud, or high viscosity oils can. Axial flow pumps are characterized by high flow. A centrifugal pump is. Centrifugal Pumps Applications.

From www.theengineersperspectives.com

What Is A Centrifugal Pump? The Engineer's Perspective Centrifugal Pumps Applications Axial flow pumps are characterized by high flow. Centrifugal pumps have a wide range of applications across several industrial sectors. Houses the impeller and directs the flow of fluid. A centrifugal pump is used to move water and other low viscosity liquids with the assistance of centrifugal force. Radial flow, mixed flow, or axial flow. The heart of the centrifugal. Centrifugal Pumps Applications.

From www.mechanical-knowledge.com

Types Of Pumps And Its Applications Pdf Centrifugal Pumps Applications Slurries such as mud, or high viscosity oils can. Learn about the different types of centrifugal pumps and how they are suited for specific industrial and marine applications. Axial flow pumps are characterized by high flow. Centrifugal pumps have a wide range of applications across several industrial sectors. A centrifugal pump is used to move water and other low viscosity. Centrifugal Pumps Applications.

From www.engineeringchoice.com

What is Centrifugal Pump? Parts, Working, and Uses Engineering Choice Centrifugal Pumps Applications The pump uses a motor that converts electric energy into mechanical. Radial flow, mixed flow, or axial flow. Centrifugal pumps generate flow by using one of three actions: Slurries such as mud, or high viscosity oils can. In general, centrifugal pumps are therefore suited to low pressure, high capacity, pumping applications of liquids with viscosities between 0.1 and 200 cp.. Centrifugal Pumps Applications.

From www.shenghuipump.com

Different Types of Centrifugal Pumps and Their Applications Centrifugal Pumps Applications This energy transfer happens through an impeller installed inside the. Centrifugal pumps generate flow by using one of three actions: Key components of a centrifugal pump. Slurries such as mud, or high viscosity oils can. The heart of the centrifugal pump, responsible for fluid movement. Radial flow, mixed flow, or axial flow. The pump uses a motor that converts electric. Centrifugal Pumps Applications.

From www.sintechpumps.com

Common Applications of Centrifugal Pumps Sintech Blog Centrifugal Pumps Applications In general, centrifugal pumps are therefore suited to low pressure, high capacity, pumping applications of liquids with viscosities between 0.1 and 200 cp. This energy transfer happens through an impeller installed inside the. A centrifugal pump is used to move water and other low viscosity liquids with the assistance of centrifugal force. The pump uses a motor that converts electric. Centrifugal Pumps Applications.

From www.growmechanical.com

Centrifugal pumps and their applications Grow Mechanical Centrifugal Pumps Applications The heart of the centrifugal pump, responsible for fluid movement. Key components of a centrifugal pump. This energy transfer happens through an impeller installed inside the. Centrifugal pumps generate flow by using one of three actions: Radial flow, mixed flow, or axial flow. In general, centrifugal pumps are therefore suited to low pressure, high capacity, pumping applications of liquids with. Centrifugal Pumps Applications.

From www.inverter.com

What is a Centrifugal Pump? Centrifugal Pumps Applications Slurries such as mud, or high viscosity oils can. Axial flow pumps are characterized by high flow. This energy transfer happens through an impeller installed inside the. The pump uses a motor that converts electric energy into mechanical. Centrifugal pumps have a wide range of applications across several industrial sectors. Centrifugal pumps generate flow by using one of three actions:. Centrifugal Pumps Applications.

From www.pumpindustry.com.au

Centrifugal pumps Pump Industry Magazine Centrifugal Pumps Applications The pump uses a motor that converts electric energy into mechanical. This energy transfer happens through an impeller installed inside the. The heart of the centrifugal pump, responsible for fluid movement. In general, centrifugal pumps are therefore suited to low pressure, high capacity, pumping applications of liquids with viscosities between 0.1 and 200 cp. A centrifugal pump converts the mechanical. Centrifugal Pumps Applications.

From www.tec-science.com

How does a centrifugal pump work? tecscience Centrifugal Pumps Applications Houses the impeller and directs the flow of fluid. The pump uses a motor that converts electric energy into mechanical. A centrifugal pump is used to move water and other low viscosity liquids with the assistance of centrifugal force. Key components of a centrifugal pump. Centrifugal pumps have a wide range of applications across several industrial sectors. Axial flow pumps. Centrifugal Pumps Applications.

From engineeringexploration.com

Centrifugal Pump Components, Types, and Applications Engineering Centrifugal Pumps Applications Centrifugal pumps generate flow by using one of three actions: Houses the impeller and directs the flow of fluid. Radial flow, mixed flow, or axial flow. In general, centrifugal pumps are therefore suited to low pressure, high capacity, pumping applications of liquids with viscosities between 0.1 and 200 cp. Centrifugal pumps have a wide range of applications across several industrial. Centrifugal Pumps Applications.

From www.mechanicaltutorial.com

Centrifugal Pump Different Types And Application Of Centrifugal Pump Centrifugal Pumps Applications A centrifugal pump is used to move water and other low viscosity liquids with the assistance of centrifugal force. Slurries such as mud, or high viscosity oils can. A centrifugal pump converts the mechanical energy of the fluids into hydraulic energy using centrifugal force. In general, centrifugal pumps are therefore suited to low pressure, high capacity, pumping applications of liquids. Centrifugal Pumps Applications.

From www.mechanicaltutorial.com

Centrifugal Pump Different Types And Application Of Centrifugal Pump Centrifugal Pumps Applications Houses the impeller and directs the flow of fluid. Radial flow, mixed flow, or axial flow. A centrifugal pump converts the mechanical energy of the fluids into hydraulic energy using centrifugal force. Learn about the different types of centrifugal pumps and how they are suited for specific industrial and marine applications. Key components of a centrifugal pump. The heart of. Centrifugal Pumps Applications.

From www.iqsdirectory.com

Centrifugal Pumps Types, Applications, Benefits, and Maintenance Centrifugal Pumps Applications In general, centrifugal pumps are therefore suited to low pressure, high capacity, pumping applications of liquids with viscosities between 0.1 and 200 cp. Houses the impeller and directs the flow of fluid. Centrifugal pumps generate flow by using one of three actions: This energy transfer happens through an impeller installed inside the. A centrifugal pump converts the mechanical energy of. Centrifugal Pumps Applications.

From www.mechanicalbooster.com

Centrifugal Pump Working Principle, Main Parts with Application Centrifugal Pumps Applications Learn about the different types of centrifugal pumps and how they are suited for specific industrial and marine applications. Radial flow, mixed flow, or axial flow. Slurries such as mud, or high viscosity oils can. Centrifugal pumps generate flow by using one of three actions: The heart of the centrifugal pump, responsible for fluid movement. This energy transfer happens through. Centrifugal Pumps Applications.

From www.iqsdirectory.com

Centrifugal Pumps Types, Applications, Benefits, and Maintenance Centrifugal Pumps Applications A centrifugal pump converts the mechanical energy of the fluids into hydraulic energy using centrifugal force. This energy transfer happens through an impeller installed inside the. Key components of a centrifugal pump. Houses the impeller and directs the flow of fluid. The heart of the centrifugal pump, responsible for fluid movement. Slurries such as mud, or high viscosity oils can.. Centrifugal Pumps Applications.

From www.rotechpumps.com

What is a Centrifugal Pump? Understanding Its Mechanism, Types, and Centrifugal Pumps Applications The heart of the centrifugal pump, responsible for fluid movement. Centrifugal pumps generate flow by using one of three actions: Axial flow pumps are characterized by high flow. A centrifugal pump converts the mechanical energy of the fluids into hydraulic energy using centrifugal force. Centrifugal pumps have a wide range of applications across several industrial sectors. The pump uses a. Centrifugal Pumps Applications.

From www.ny-engineers.com

Main Types of Pumps Centrifugal and Positive Displacement Centrifugal Pumps Applications The pump uses a motor that converts electric energy into mechanical. In general, centrifugal pumps are therefore suited to low pressure, high capacity, pumping applications of liquids with viscosities between 0.1 and 200 cp. A centrifugal pump converts the mechanical energy of the fluids into hydraulic energy using centrifugal force. Key components of a centrifugal pump. Centrifugal pumps have a. Centrifugal Pumps Applications.

From www.mechanical-knowledge.com

TYPES OF CENTRIFUGAL PUMPS Centrifugal Pumps Applications Centrifugal pumps generate flow by using one of three actions: Houses the impeller and directs the flow of fluid. Radial flow, mixed flow, or axial flow. Axial flow pumps are characterized by high flow. The heart of the centrifugal pump, responsible for fluid movement. The pump uses a motor that converts electric energy into mechanical. Centrifugal pumps have a wide. Centrifugal Pumps Applications.

From www.airmac.org

The Beginner's Guide To Centrifugal Pumps airmac Centrifugal Pumps Applications Key components of a centrifugal pump. Centrifugal pumps have a wide range of applications across several industrial sectors. Houses the impeller and directs the flow of fluid. Slurries such as mud, or high viscosity oils can. A centrifugal pump is used to move water and other low viscosity liquids with the assistance of centrifugal force. In general, centrifugal pumps are. Centrifugal Pumps Applications.

From theconstructor.org

Centrifugal Pump Components, Working, Types and Application Centrifugal Pumps Applications Houses the impeller and directs the flow of fluid. Centrifugal pumps generate flow by using one of three actions: Learn about the different types of centrifugal pumps and how they are suited for specific industrial and marine applications. Centrifugal pumps have a wide range of applications across several industrial sectors. Key components of a centrifugal pump. Radial flow, mixed flow,. Centrifugal Pumps Applications.

From engineeringlearner.com

Working of a Centrifugal Pump Engineering Learner Centrifugal Pumps Applications Centrifugal pumps generate flow by using one of three actions: The heart of the centrifugal pump, responsible for fluid movement. Slurries such as mud, or high viscosity oils can. Axial flow pumps are characterized by high flow. A centrifugal pump converts the mechanical energy of the fluids into hydraulic energy using centrifugal force. The pump uses a motor that converts. Centrifugal Pumps Applications.

From waterpumpcn.com

what is the centrifugal pump? An Pump Machinery Pumps System Centrifugal Pumps Applications Slurries such as mud, or high viscosity oils can. The heart of the centrifugal pump, responsible for fluid movement. Houses the impeller and directs the flow of fluid. Radial flow, mixed flow, or axial flow. This energy transfer happens through an impeller installed inside the. Key components of a centrifugal pump. The pump uses a motor that converts electric energy. Centrifugal Pumps Applications.

From www.youtube.com

Centrifugal Pumps for Different Applications Toolkwip Pumps YouTube Centrifugal Pumps Applications Slurries such as mud, or high viscosity oils can. Key components of a centrifugal pump. A centrifugal pump is used to move water and other low viscosity liquids with the assistance of centrifugal force. In general, centrifugal pumps are therefore suited to low pressure, high capacity, pumping applications of liquids with viscosities between 0.1 and 200 cp. A centrifugal pump. Centrifugal Pumps Applications.

From www.researchgate.net

1. Main components of a centrifugal pump (Taken from [47]) Download Centrifugal Pumps Applications Key components of a centrifugal pump. Slurries such as mud, or high viscosity oils can. Learn about the different types of centrifugal pumps and how they are suited for specific industrial and marine applications. Centrifugal pumps have a wide range of applications across several industrial sectors. A centrifugal pump is used to move water and other low viscosity liquids with. Centrifugal Pumps Applications.

From www.sintechpumps.com

Common Applications of Centrifugal Pumps Sintech Blog Centrifugal Pumps Applications Learn about the different types of centrifugal pumps and how they are suited for specific industrial and marine applications. The pump uses a motor that converts electric energy into mechanical. A centrifugal pump converts the mechanical energy of the fluids into hydraulic energy using centrifugal force. In general, centrifugal pumps are therefore suited to low pressure, high capacity, pumping applications. Centrifugal Pumps Applications.

From www.sujalpumps.com

Centrifugal Pumps Components, Working, Types & Applications A Centrifugal Pumps Applications A centrifugal pump converts the mechanical energy of the fluids into hydraulic energy using centrifugal force. In general, centrifugal pumps are therefore suited to low pressure, high capacity, pumping applications of liquids with viscosities between 0.1 and 200 cp. Radial flow, mixed flow, or axial flow. Axial flow pumps are characterized by high flow. The heart of the centrifugal pump,. Centrifugal Pumps Applications.