What Is Tool Nose Radius Compensation . Tool nose radius compensation, represented by the g40 code, is a powerful feature that allows cnc machinists to account for the shape of a tool’s cutting edge. This compensation ensures precise machining by offsetting the programmed tool path based on the tool’s nose radius. It is a much misused concept on shop floors. Tnrc, or tool nose radius compensation, is a must turning contoured parts. Just as cutter radius compensation allows the programmer to program work surface coordinates, so does tool nose radius compensation. Tool radius compensation is practically mandatory with a machining centre, as that's the only convenient means of regulating. G41 and g42 are cnc programming codes that pertain specifically to tool nose radius compensation. Since no tool has a. When we talk about cutter compensation on a lathe or machining centre, we refer to it as tool nose radius compensation. They allow machinists to adjust. When you use tool nose radius compensation on a cnc lathe (that means we are using g41 and g42) you have to tell the machine where the cutting point of the turning tool is so that the correct tool path is produced. Tool nose radius compensation provides a way to perform precise cutting with a tool that doesn't end in a perfect point.

from gcodetutor.com

Tool nose radius compensation provides a way to perform precise cutting with a tool that doesn't end in a perfect point. Since no tool has a. This compensation ensures precise machining by offsetting the programmed tool path based on the tool’s nose radius. They allow machinists to adjust. When we talk about cutter compensation on a lathe or machining centre, we refer to it as tool nose radius compensation. Tool radius compensation is practically mandatory with a machining centre, as that's the only convenient means of regulating. Tnrc, or tool nose radius compensation, is a must turning contoured parts. Tool nose radius compensation, represented by the g40 code, is a powerful feature that allows cnc machinists to account for the shape of a tool’s cutting edge. When you use tool nose radius compensation on a cnc lathe (that means we are using g41 and g42) you have to tell the machine where the cutting point of the turning tool is so that the correct tool path is produced. G41 and g42 are cnc programming codes that pertain specifically to tool nose radius compensation.

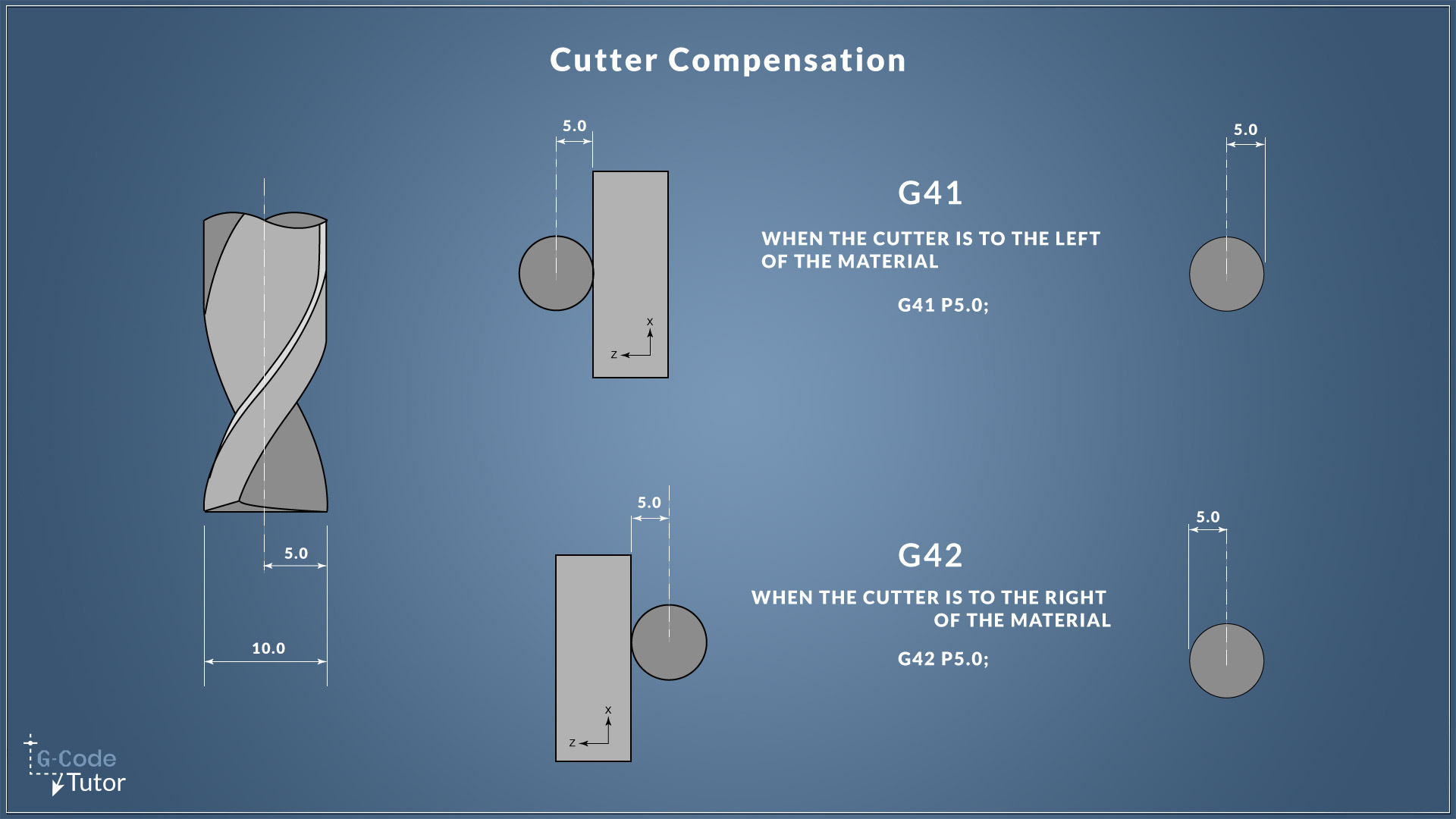

G41 and G42 Cutter Compensation

What Is Tool Nose Radius Compensation Just as cutter radius compensation allows the programmer to program work surface coordinates, so does tool nose radius compensation. Just as cutter radius compensation allows the programmer to program work surface coordinates, so does tool nose radius compensation. When we talk about cutter compensation on a lathe or machining centre, we refer to it as tool nose radius compensation. They allow machinists to adjust. Since no tool has a. When you use tool nose radius compensation on a cnc lathe (that means we are using g41 and g42) you have to tell the machine where the cutting point of the turning tool is so that the correct tool path is produced. Tool nose radius compensation, represented by the g40 code, is a powerful feature that allows cnc machinists to account for the shape of a tool’s cutting edge. This compensation ensures precise machining by offsetting the programmed tool path based on the tool’s nose radius. Tnrc, or tool nose radius compensation, is a must turning contoured parts. Tool radius compensation is practically mandatory with a machining centre, as that's the only convenient means of regulating. G41 and g42 are cnc programming codes that pertain specifically to tool nose radius compensation. It is a much misused concept on shop floors. Tool nose radius compensation provides a way to perform precise cutting with a tool that doesn't end in a perfect point.

From www.cnctrainingcentre.com

CNC Lathe Tool Nose Radius Compensation CNC Training Centre What Is Tool Nose Radius Compensation It is a much misused concept on shop floors. This compensation ensures precise machining by offsetting the programmed tool path based on the tool’s nose radius. When we talk about cutter compensation on a lathe or machining centre, we refer to it as tool nose radius compensation. G41 and g42 are cnc programming codes that pertain specifically to tool nose. What Is Tool Nose Radius Compensation.

From cimco.com

Tool Nose Radius Compensation What Is Tool Nose Radius Compensation G41 and g42 are cnc programming codes that pertain specifically to tool nose radius compensation. Just as cutter radius compensation allows the programmer to program work surface coordinates, so does tool nose radius compensation. Tool radius compensation is practically mandatory with a machining centre, as that's the only convenient means of regulating. This compensation ensures precise machining by offsetting the. What Is Tool Nose Radius Compensation.

From www.scribd.com

Tool Nose Radius Compensation in CNC Turning PDF Machining Radius What Is Tool Nose Radius Compensation This compensation ensures precise machining by offsetting the programmed tool path based on the tool’s nose radius. When you use tool nose radius compensation on a cnc lathe (that means we are using g41 and g42) you have to tell the machine where the cutting point of the turning tool is so that the correct tool path is produced. They. What Is Tool Nose Radius Compensation.

From www.researchgate.net

Critical tool nose radius calculation Download Scientific Diagram What Is Tool Nose Radius Compensation They allow machinists to adjust. G41 and g42 are cnc programming codes that pertain specifically to tool nose radius compensation. When we talk about cutter compensation on a lathe or machining centre, we refer to it as tool nose radius compensation. This compensation ensures precise machining by offsetting the programmed tool path based on the tool’s nose radius. It is. What Is Tool Nose Radius Compensation.

From support.machmotion.com

Lathe Tool Nose Radius... MachMotion What Is Tool Nose Radius Compensation They allow machinists to adjust. G41 and g42 are cnc programming codes that pertain specifically to tool nose radius compensation. Tnrc, or tool nose radius compensation, is a must turning contoured parts. It is a much misused concept on shop floors. Tool nose radius compensation provides a way to perform precise cutting with a tool that doesn't end in a. What Is Tool Nose Radius Compensation.

From toolnotes.com

Cutting Parameters for Turning ToolNotes What Is Tool Nose Radius Compensation When you use tool nose radius compensation on a cnc lathe (that means we are using g41 and g42) you have to tell the machine where the cutting point of the turning tool is so that the correct tool path is produced. Tnrc, or tool nose radius compensation, is a must turning contoured parts. When we talk about cutter compensation. What Is Tool Nose Radius Compensation.

From www.slideserve.com

PPT G40, G41, & G42 cutter radius and tool nose radius compensation What Is Tool Nose Radius Compensation They allow machinists to adjust. Tool nose radius compensation provides a way to perform precise cutting with a tool that doesn't end in a perfect point. Just as cutter radius compensation allows the programmer to program work surface coordinates, so does tool nose radius compensation. When we talk about cutter compensation on a lathe or machining centre, we refer to. What Is Tool Nose Radius Compensation.

From www.practicalmachinist.com

Tool Nose Radius Compensation What Is Tool Nose Radius Compensation It is a much misused concept on shop floors. Tool nose radius compensation provides a way to perform precise cutting with a tool that doesn't end in a perfect point. When we talk about cutter compensation on a lathe or machining centre, we refer to it as tool nose radius compensation. This compensation ensures precise machining by offsetting the programmed. What Is Tool Nose Radius Compensation.

From okumacnc.blogspot.ca

Tool Nose Radius Compensation G40, G41, G42 Online Education What Is Tool Nose Radius Compensation This compensation ensures precise machining by offsetting the programmed tool path based on the tool’s nose radius. When we talk about cutter compensation on a lathe or machining centre, we refer to it as tool nose radius compensation. Tool nose radius compensation provides a way to perform precise cutting with a tool that doesn't end in a perfect point. Tool. What Is Tool Nose Radius Compensation.

From www.numerical.minaprem.com

Surface roughness calculation in turning for sharp and nose radius tool What Is Tool Nose Radius Compensation They allow machinists to adjust. This compensation ensures precise machining by offsetting the programmed tool path based on the tool’s nose radius. When we talk about cutter compensation on a lathe or machining centre, we refer to it as tool nose radius compensation. When you use tool nose radius compensation on a cnc lathe (that means we are using g41. What Is Tool Nose Radius Compensation.

From support.machmotion.com

Lathe Tool Nose Radius... MachMotion What Is Tool Nose Radius Compensation Tool radius compensation is practically mandatory with a machining centre, as that's the only convenient means of regulating. Tool nose radius compensation, represented by the g40 code, is a powerful feature that allows cnc machinists to account for the shape of a tool’s cutting edge. This compensation ensures precise machining by offsetting the programmed tool path based on the tool’s. What Is Tool Nose Radius Compensation.

From mungfali.com

CNC Lathe Tool Nose Radius Compensation Chart What Is Tool Nose Radius Compensation G41 and g42 are cnc programming codes that pertain specifically to tool nose radius compensation. Tnrc, or tool nose radius compensation, is a must turning contoured parts. Tool nose radius compensation, represented by the g40 code, is a powerful feature that allows cnc machinists to account for the shape of a tool’s cutting edge. When we talk about cutter compensation. What Is Tool Nose Radius Compensation.

From www.youtube.com

Tool Nose Radius Compensation_Radial Cutting Passes YouTube What Is Tool Nose Radius Compensation G41 and g42 are cnc programming codes that pertain specifically to tool nose radius compensation. This compensation ensures precise machining by offsetting the programmed tool path based on the tool’s nose radius. When we talk about cutter compensation on a lathe or machining centre, we refer to it as tool nose radius compensation. When you use tool nose radius compensation. What Is Tool Nose Radius Compensation.

From www.youtube.com

How to Use G41 and G42 ! What is Tool Nose Radius Compensation What Is Tool Nose Radius Compensation Just as cutter radius compensation allows the programmer to program work surface coordinates, so does tool nose radius compensation. Tool nose radius compensation, represented by the g40 code, is a powerful feature that allows cnc machinists to account for the shape of a tool’s cutting edge. This compensation ensures precise machining by offsetting the programmed tool path based on the. What Is Tool Nose Radius Compensation.

From www.slideserve.com

PPT Tool Nose Radius = TNR PowerPoint Presentation, free download What Is Tool Nose Radius Compensation Tool nose radius compensation, represented by the g40 code, is a powerful feature that allows cnc machinists to account for the shape of a tool’s cutting edge. They allow machinists to adjust. When you use tool nose radius compensation on a cnc lathe (that means we are using g41 and g42) you have to tell the machine where the cutting. What Is Tool Nose Radius Compensation.

From mungfali.com

Tool Nose Radius Sizes Chart What Is Tool Nose Radius Compensation G41 and g42 are cnc programming codes that pertain specifically to tool nose radius compensation. It is a much misused concept on shop floors. When we talk about cutter compensation on a lathe or machining centre, we refer to it as tool nose radius compensation. Just as cutter radius compensation allows the programmer to program work surface coordinates, so does. What Is Tool Nose Radius Compensation.

From www.researchgate.net

Schematic illustration of tool nose radius compensation Download What Is Tool Nose Radius Compensation Tnrc, or tool nose radius compensation, is a must turning contoured parts. Tool nose radius compensation provides a way to perform precise cutting with a tool that doesn't end in a perfect point. This compensation ensures precise machining by offsetting the programmed tool path based on the tool’s nose radius. Since no tool has a. When we talk about cutter. What Is Tool Nose Radius Compensation.

From www.researchgate.net

Model of tool nose radius compensation. Fig. 3. Model of clearance What Is Tool Nose Radius Compensation It is a much misused concept on shop floors. Tool radius compensation is practically mandatory with a machining centre, as that's the only convenient means of regulating. Tool nose radius compensation, represented by the g40 code, is a powerful feature that allows cnc machinists to account for the shape of a tool’s cutting edge. G41 and g42 are cnc programming. What Is Tool Nose Radius Compensation.

From ponasa.condesan-ecoandes.org

Tool Radius Compensation Chart Ponasa What Is Tool Nose Radius Compensation When we talk about cutter compensation on a lathe or machining centre, we refer to it as tool nose radius compensation. Tool nose radius compensation provides a way to perform precise cutting with a tool that doesn't end in a perfect point. They allow machinists to adjust. This compensation ensures precise machining by offsetting the programmed tool path based on. What Is Tool Nose Radius Compensation.

From www.slideserve.com

PPT G40, G41, & G42 cutter radius and tool nose radius compensation What Is Tool Nose Radius Compensation When you use tool nose radius compensation on a cnc lathe (that means we are using g41 and g42) you have to tell the machine where the cutting point of the turning tool is so that the correct tool path is produced. This compensation ensures precise machining by offsetting the programmed tool path based on the tool’s nose radius. Since. What Is Tool Nose Radius Compensation.

From www.cnctrainingcentre.com

CNC Lathe Tool Nose Radius Compensation CNC Training Centre What Is Tool Nose Radius Compensation Since no tool has a. G41 and g42 are cnc programming codes that pertain specifically to tool nose radius compensation. They allow machinists to adjust. When you use tool nose radius compensation on a cnc lathe (that means we are using g41 and g42) you have to tell the machine where the cutting point of the turning tool is so. What Is Tool Nose Radius Compensation.

From gcodetutor.com

G41 and G42 Cutter Compensation What Is Tool Nose Radius Compensation Tool nose radius compensation, represented by the g40 code, is a powerful feature that allows cnc machinists to account for the shape of a tool’s cutting edge. Since no tool has a. Tnrc, or tool nose radius compensation, is a must turning contoured parts. When we talk about cutter compensation on a lathe or machining centre, we refer to it. What Is Tool Nose Radius Compensation.

From cimco.com

Tool Nose Radius Compensation What Is Tool Nose Radius Compensation Tool nose radius compensation provides a way to perform precise cutting with a tool that doesn't end in a perfect point. When you use tool nose radius compensation on a cnc lathe (that means we are using g41 and g42) you have to tell the machine where the cutting point of the turning tool is so that the correct tool. What Is Tool Nose Radius Compensation.

From mungfali.com

Nose Radius Of Cutting Tool What Is Tool Nose Radius Compensation Tnrc, or tool nose radius compensation, is a must turning contoured parts. G41 and g42 are cnc programming codes that pertain specifically to tool nose radius compensation. Tool nose radius compensation, represented by the g40 code, is a powerful feature that allows cnc machinists to account for the shape of a tool’s cutting edge. Tool radius compensation is practically mandatory. What Is Tool Nose Radius Compensation.

From support.machmotion.com

Lathe Tool Nose Radius... MachMotion What Is Tool Nose Radius Compensation Tnrc, or tool nose radius compensation, is a must turning contoured parts. G41 and g42 are cnc programming codes that pertain specifically to tool nose radius compensation. They allow machinists to adjust. Just as cutter radius compensation allows the programmer to program work surface coordinates, so does tool nose radius compensation. When we talk about cutter compensation on a lathe. What Is Tool Nose Radius Compensation.

From www.youtube.com

TNRC [Tool Nose Radius Compensation] G41 G42 CNCLearning Rajeev What Is Tool Nose Radius Compensation Tool nose radius compensation, represented by the g40 code, is a powerful feature that allows cnc machinists to account for the shape of a tool’s cutting edge. Just as cutter radius compensation allows the programmer to program work surface coordinates, so does tool nose radius compensation. When we talk about cutter compensation on a lathe or machining centre, we refer. What Is Tool Nose Radius Compensation.

From www.youtube.com

G40 G41 G42 TOOL NOSE RADIUS COMPENSATION IN FULL DETAILS YouTube What Is Tool Nose Radius Compensation Since no tool has a. Tool nose radius compensation provides a way to perform precise cutting with a tool that doesn't end in a perfect point. Tool radius compensation is practically mandatory with a machining centre, as that's the only convenient means of regulating. Tool nose radius compensation, represented by the g40 code, is a powerful feature that allows cnc. What Is Tool Nose Radius Compensation.

From www.practicalmachinist.com

Tool Nose Radius Compensation What Is Tool Nose Radius Compensation It is a much misused concept on shop floors. Tool radius compensation is practically mandatory with a machining centre, as that's the only convenient means of regulating. Since no tool has a. When you use tool nose radius compensation on a cnc lathe (that means we are using g41 and g42) you have to tell the machine where the cutting. What Is Tool Nose Radius Compensation.

From www.youtube.com

Tool Nose Radius Compensation YouTube What Is Tool Nose Radius Compensation Since no tool has a. Tool nose radius compensation provides a way to perform precise cutting with a tool that doesn't end in a perfect point. Tool radius compensation is practically mandatory with a machining centre, as that's the only convenient means of regulating. Tool nose radius compensation, represented by the g40 code, is a powerful feature that allows cnc. What Is Tool Nose Radius Compensation.

From www.youtube.com

TurningPrimeTurning™ Tool Nose Radius Compensation YouTube What Is Tool Nose Radius Compensation When you use tool nose radius compensation on a cnc lathe (that means we are using g41 and g42) you have to tell the machine where the cutting point of the turning tool is so that the correct tool path is produced. Tool nose radius compensation provides a way to perform precise cutting with a tool that doesn't end in. What Is Tool Nose Radius Compensation.

From www.youtube.com

CNC Lathe Tool Nose Radius Compensation YouTube What Is Tool Nose Radius Compensation Since no tool has a. Tool nose radius compensation, represented by the g40 code, is a powerful feature that allows cnc machinists to account for the shape of a tool’s cutting edge. Tool radius compensation is practically mandatory with a machining centre, as that's the only convenient means of regulating. When we talk about cutter compensation on a lathe or. What Is Tool Nose Radius Compensation.

From support.machmotion.com

Lathe Tool Nose Radius... MachMotion What Is Tool Nose Radius Compensation Tool nose radius compensation provides a way to perform precise cutting with a tool that doesn't end in a perfect point. G41 and g42 are cnc programming codes that pertain specifically to tool nose radius compensation. Since no tool has a. It is a much misused concept on shop floors. Just as cutter radius compensation allows the programmer to program. What Is Tool Nose Radius Compensation.

From in.pinterest.com

Tool nose radius compensation (TNRC) in CNC turning Cadem Torno What Is Tool Nose Radius Compensation Since no tool has a. This compensation ensures precise machining by offsetting the programmed tool path based on the tool’s nose radius. Tnrc, or tool nose radius compensation, is a must turning contoured parts. Tool nose radius compensation, represented by the g40 code, is a powerful feature that allows cnc machinists to account for the shape of a tool’s cutting. What Is Tool Nose Radius Compensation.

From www.youtube.com

Tool Nose Radius Compensation (Manual) A look at what is required to What Is Tool Nose Radius Compensation G41 and g42 are cnc programming codes that pertain specifically to tool nose radius compensation. Just as cutter radius compensation allows the programmer to program work surface coordinates, so does tool nose radius compensation. When you use tool nose radius compensation on a cnc lathe (that means we are using g41 and g42) you have to tell the machine where. What Is Tool Nose Radius Compensation.

From www.slideserve.com

PPT BMFS 3373 CNC TECHNOLOGY Lecture 10 PowerPoint Presentation, free What Is Tool Nose Radius Compensation When we talk about cutter compensation on a lathe or machining centre, we refer to it as tool nose radius compensation. It is a much misused concept on shop floors. Tnrc, or tool nose radius compensation, is a must turning contoured parts. This compensation ensures precise machining by offsetting the programmed tool path based on the tool’s nose radius. Tool. What Is Tool Nose Radius Compensation.