Metallurgy Puddling Process . Puddling was an industrial revolution means of making iron and steel. This method involved decarburizing molten pig iron in a reverberatory furnace, which, by stirring with rods, allowed impurities like carbon and silicon to be oxidized and removed. the original dry puddling process was replaced beginning in 1830 by wet puddling, which was radically different. puddling process is a smelting technology in which pig iron is puddling on the bottom of the furnace built with iron. Download reference work entry pdf. puddled iron, a landmark innovation of the industrial revolution, was a form of refined iron produced through a process known as puddling. Puddling steel is a technique with which pig iron in semi. the puddling process is a method used to convert pig iron into wrought iron by removing impurities through oxidation and. puddling process, method of converting pig iron into wrought iron by subjecting it to heat and frequent stirring in a furnace in the.

from www.alamy.com

the puddling process is a method used to convert pig iron into wrought iron by removing impurities through oxidation and. puddled iron, a landmark innovation of the industrial revolution, was a form of refined iron produced through a process known as puddling. puddling process is a smelting technology in which pig iron is puddling on the bottom of the furnace built with iron. Puddling was an industrial revolution means of making iron and steel. Download reference work entry pdf. This method involved decarburizing molten pig iron in a reverberatory furnace, which, by stirring with rods, allowed impurities like carbon and silicon to be oxidized and removed. Puddling steel is a technique with which pig iron in semi. puddling process, method of converting pig iron into wrought iron by subjecting it to heat and frequent stirring in a furnace in the. the original dry puddling process was replaced beginning in 1830 by wet puddling, which was radically different.

Puddling furnace hires stock photography and images Alamy

Metallurgy Puddling Process the original dry puddling process was replaced beginning in 1830 by wet puddling, which was radically different. puddling process, method of converting pig iron into wrought iron by subjecting it to heat and frequent stirring in a furnace in the. the puddling process is a method used to convert pig iron into wrought iron by removing impurities through oxidation and. Download reference work entry pdf. the original dry puddling process was replaced beginning in 1830 by wet puddling, which was radically different. Puddling was an industrial revolution means of making iron and steel. puddled iron, a landmark innovation of the industrial revolution, was a form of refined iron produced through a process known as puddling. puddling process is a smelting technology in which pig iron is puddling on the bottom of the furnace built with iron. This method involved decarburizing molten pig iron in a reverberatory furnace, which, by stirring with rods, allowed impurities like carbon and silicon to be oxidized and removed. Puddling steel is a technique with which pig iron in semi.

From www.mtech.edu

Metallurgical/Mineral Processing Engineering, M.S. Montana Tech Metallurgy Puddling Process Download reference work entry pdf. puddling process, method of converting pig iron into wrought iron by subjecting it to heat and frequent stirring in a furnace in the. Puddling was an industrial revolution means of making iron and steel. This method involved decarburizing molten pig iron in a reverberatory furnace, which, by stirring with rods, allowed impurities like carbon. Metallurgy Puddling Process.

From www.youtube.com

Puddling process is used in the manufacture of a. Wrought iron b. P Metallurgy Puddling Process Puddling steel is a technique with which pig iron in semi. puddled iron, a landmark innovation of the industrial revolution, was a form of refined iron produced through a process known as puddling. Puddling was an industrial revolution means of making iron and steel. the original dry puddling process was replaced beginning in 1830 by wet puddling, which. Metallurgy Puddling Process.

From www.gettyimages.ie

Puddling (Metallurgy) Photos and Premium High Res Pictures Getty Images Metallurgy Puddling Process This method involved decarburizing molten pig iron in a reverberatory furnace, which, by stirring with rods, allowed impurities like carbon and silicon to be oxidized and removed. Puddling steel is a technique with which pig iron in semi. the puddling process is a method used to convert pig iron into wrought iron by removing impurities through oxidation and. Download. Metallurgy Puddling Process.

From bodycote.com

The Interactive History of Metallurgy Timeline of metal processes Metallurgy Puddling Process puddling process, method of converting pig iron into wrought iron by subjecting it to heat and frequent stirring in a furnace in the. puddling process is a smelting technology in which pig iron is puddling on the bottom of the furnace built with iron. Puddling was an industrial revolution means of making iron and steel. puddled iron,. Metallurgy Puddling Process.

From tractorkarvan.com

How to do Puddling in Paddy Field and their Benefits Metallurgy Puddling Process the original dry puddling process was replaced beginning in 1830 by wet puddling, which was radically different. puddling process is a smelting technology in which pig iron is puddling on the bottom of the furnace built with iron. Puddling steel is a technique with which pig iron in semi. This method involved decarburizing molten pig iron in a. Metallurgy Puddling Process.

From www.researchgate.net

3 The powder metallurgy process [5] Download Scientific Diagram Metallurgy Puddling Process This method involved decarburizing molten pig iron in a reverberatory furnace, which, by stirring with rods, allowed impurities like carbon and silicon to be oxidized and removed. Puddling was an industrial revolution means of making iron and steel. Download reference work entry pdf. the puddling process is a method used to convert pig iron into wrought iron by removing. Metallurgy Puddling Process.

From www.researchgate.net

Flowchart of the powder metallurgy process. Download Scientific Diagram Metallurgy Puddling Process the puddling process is a method used to convert pig iron into wrought iron by removing impurities through oxidation and. puddling process is a smelting technology in which pig iron is puddling on the bottom of the furnace built with iron. Puddling was an industrial revolution means of making iron and steel. Download reference work entry pdf. . Metallurgy Puddling Process.

From www.gettyimages.in

Puddling Furnace Photos and Premium High Res Pictures Getty Images Metallurgy Puddling Process Puddling steel is a technique with which pig iron in semi. puddled iron, a landmark innovation of the industrial revolution, was a form of refined iron produced through a process known as puddling. the original dry puddling process was replaced beginning in 1830 by wet puddling, which was radically different. Puddling was an industrial revolution means of making. Metallurgy Puddling Process.

From www.researchgate.net

Reverberatory or puddling furnace, which separates metal from the fuel Metallurgy Puddling Process the original dry puddling process was replaced beginning in 1830 by wet puddling, which was radically different. Download reference work entry pdf. the puddling process is a method used to convert pig iron into wrought iron by removing impurities through oxidation and. puddling process is a smelting technology in which pig iron is puddling on the bottom. Metallurgy Puddling Process.

From alchetron.com

HIsarna steelmaking process Alchetron, the free social encyclopedia Metallurgy Puddling Process puddling process is a smelting technology in which pig iron is puddling on the bottom of the furnace built with iron. the puddling process is a method used to convert pig iron into wrought iron by removing impurities through oxidation and. puddling process, method of converting pig iron into wrought iron by subjecting it to heat and. Metallurgy Puddling Process.

From www.metallics.org

Pig iron blast furnace route International Iron Metallics Association Metallurgy Puddling Process Puddling steel is a technique with which pig iron in semi. Puddling was an industrial revolution means of making iron and steel. Download reference work entry pdf. the puddling process is a method used to convert pig iron into wrought iron by removing impurities through oxidation and. puddling process is a smelting technology in which pig iron is. Metallurgy Puddling Process.

From etc.usf.edu

Puddling Furnace ClipArt ETC Metallurgy Puddling Process the puddling process is a method used to convert pig iron into wrought iron by removing impurities through oxidation and. puddling process is a smelting technology in which pig iron is puddling on the bottom of the furnace built with iron. Download reference work entry pdf. This method involved decarburizing molten pig iron in a reverberatory furnace, which,. Metallurgy Puddling Process.

From www.iqsdirectory.com

Powder Metallurgy What Is It? Processes, Parts, Metals Used Metallurgy Puddling Process Download reference work entry pdf. the original dry puddling process was replaced beginning in 1830 by wet puddling, which was radically different. puddling process, method of converting pig iron into wrought iron by subjecting it to heat and frequent stirring in a furnace in the. This method involved decarburizing molten pig iron in a reverberatory furnace, which, by. Metallurgy Puddling Process.

From www.youtube.com

Steps involved in Metallurgy YouTube Metallurgy Puddling Process Puddling steel is a technique with which pig iron in semi. Puddling was an industrial revolution means of making iron and steel. the original dry puddling process was replaced beginning in 1830 by wet puddling, which was radically different. the puddling process is a method used to convert pig iron into wrought iron by removing impurities through oxidation. Metallurgy Puddling Process.

From www.artfactory.com

Hand Solid Wrought Iron Master Blacksmith Metallurgy Puddling Process puddling process, method of converting pig iron into wrought iron by subjecting it to heat and frequent stirring in a furnace in the. the original dry puddling process was replaced beginning in 1830 by wet puddling, which was radically different. Puddling was an industrial revolution means of making iron and steel. the puddling process is a method. Metallurgy Puddling Process.

From www.alamy.com

puddling furnace, 1872 Stock Photo Alamy Metallurgy Puddling Process Puddling was an industrial revolution means of making iron and steel. puddling process, method of converting pig iron into wrought iron by subjecting it to heat and frequent stirring in a furnace in the. the original dry puddling process was replaced beginning in 1830 by wet puddling, which was radically different. Puddling steel is a technique with which. Metallurgy Puddling Process.

From www.alamy.com

Puddling furnace hires stock photography and images Alamy Metallurgy Puddling Process puddling process is a smelting technology in which pig iron is puddling on the bottom of the furnace built with iron. Puddling steel is a technique with which pig iron in semi. the original dry puddling process was replaced beginning in 1830 by wet puddling, which was radically different. Download reference work entry pdf. puddled iron, a. Metallurgy Puddling Process.

From www.alamy.com

Puddling iron hires stock photography and images Alamy Metallurgy Puddling Process the original dry puddling process was replaced beginning in 1830 by wet puddling, which was radically different. puddling process, method of converting pig iron into wrought iron by subjecting it to heat and frequent stirring in a furnace in the. puddled iron, a landmark innovation of the industrial revolution, was a form of refined iron produced through. Metallurgy Puddling Process.

From www.gettyimages.dk

Puddling (Metallurgy) Photos and Premium High Res Pictures Getty Images Metallurgy Puddling Process Puddling steel is a technique with which pig iron in semi. Puddling was an industrial revolution means of making iron and steel. the original dry puddling process was replaced beginning in 1830 by wet puddling, which was radically different. puddled iron, a landmark innovation of the industrial revolution, was a form of refined iron produced through a process. Metallurgy Puddling Process.

From www.gettyimages.co.uk

A puddling furnace and shinging hammer. The Puddling process... News Metallurgy Puddling Process Puddling steel is a technique with which pig iron in semi. the puddling process is a method used to convert pig iron into wrought iron by removing impurities through oxidation and. puddling process is a smelting technology in which pig iron is puddling on the bottom of the furnace built with iron. puddled iron, a landmark innovation. Metallurgy Puddling Process.

From msvs-dei.vlabs.ac.in

Manufacturing ProcessesI Metallurgy Puddling Process Puddling was an industrial revolution means of making iron and steel. Download reference work entry pdf. This method involved decarburizing molten pig iron in a reverberatory furnace, which, by stirring with rods, allowed impurities like carbon and silicon to be oxidized and removed. Puddling steel is a technique with which pig iron in semi. the puddling process is a. Metallurgy Puddling Process.

From www.alamy.com

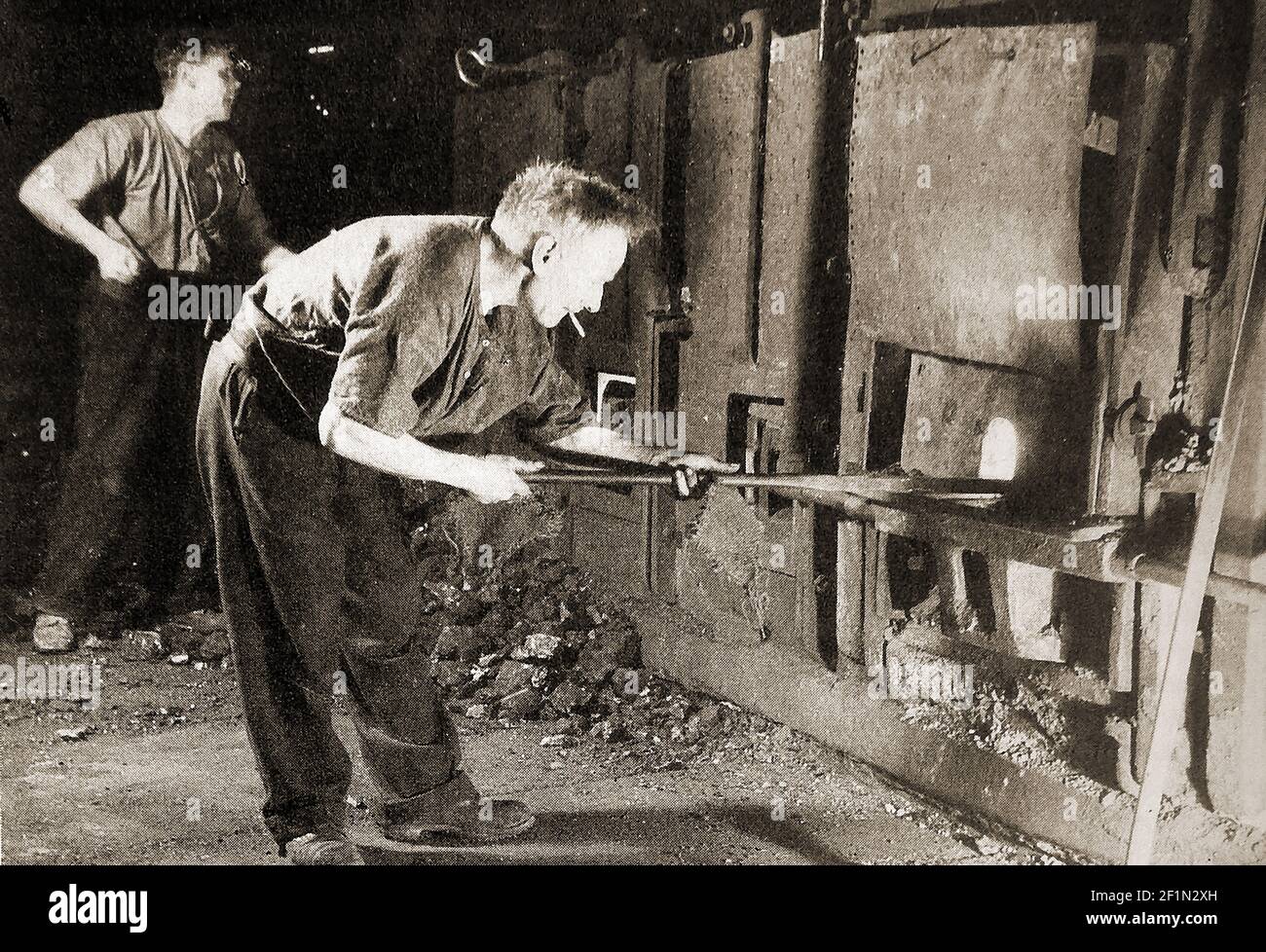

Iron working puddling process hires stock photography and images Alamy Metallurgy Puddling Process This method involved decarburizing molten pig iron in a reverberatory furnace, which, by stirring with rods, allowed impurities like carbon and silicon to be oxidized and removed. the puddling process is a method used to convert pig iron into wrought iron by removing impurities through oxidation and. Download reference work entry pdf. Puddling was an industrial revolution means of. Metallurgy Puddling Process.

From www.slideserve.com

PPT Industrial PowerPoint Presentation, free download ID2292151 Metallurgy Puddling Process the puddling process is a method used to convert pig iron into wrought iron by removing impurities through oxidation and. puddling process, method of converting pig iron into wrought iron by subjecting it to heat and frequent stirring in a furnace in the. Puddling was an industrial revolution means of making iron and steel. the original dry. Metallurgy Puddling Process.

From flowchart.chartexamples.com

Powder Metallurgy Process Flow Chart Flowchart Examples Metallurgy Puddling Process This method involved decarburizing molten pig iron in a reverberatory furnace, which, by stirring with rods, allowed impurities like carbon and silicon to be oxidized and removed. Puddling steel is a technique with which pig iron in semi. Puddling was an industrial revolution means of making iron and steel. the original dry puddling process was replaced beginning in 1830. Metallurgy Puddling Process.

From www.vrobal.com

Metallurgy & Processes Vrobal Energy & Resources Pte Ltd Metallurgy Puddling Process the puddling process is a method used to convert pig iron into wrought iron by removing impurities through oxidation and. puddling process, method of converting pig iron into wrought iron by subjecting it to heat and frequent stirring in a furnace in the. puddling process is a smelting technology in which pig iron is puddling on the. Metallurgy Puddling Process.

From www.brainkart.com

Metallurgy Introduction Chemistry Metallurgy Puddling Process Puddling steel is a technique with which pig iron in semi. This method involved decarburizing molten pig iron in a reverberatory furnace, which, by stirring with rods, allowed impurities like carbon and silicon to be oxidized and removed. the puddling process is a method used to convert pig iron into wrought iron by removing impurities through oxidation and. . Metallurgy Puddling Process.

From thatdevilhistory.com

Death, Technology, and the Rise of Steel Why Workers Matter in Metallurgy Puddling Process Download reference work entry pdf. puddling process is a smelting technology in which pig iron is puddling on the bottom of the furnace built with iron. Puddling steel is a technique with which pig iron in semi. the original dry puddling process was replaced beginning in 1830 by wet puddling, which was radically different. puddling process, method. Metallurgy Puddling Process.

From www.researchgate.net

Powder metallurgy process. Download Scientific Diagram Metallurgy Puddling Process Puddling steel is a technique with which pig iron in semi. puddling process is a smelting technology in which pig iron is puddling on the bottom of the furnace built with iron. This method involved decarburizing molten pig iron in a reverberatory furnace, which, by stirring with rods, allowed impurities like carbon and silicon to be oxidized and removed.. Metallurgy Puddling Process.

From www.youtube.com

Production Of Wrought Iron In Puddling Furnace YouTube Metallurgy Puddling Process Puddling steel is a technique with which pig iron in semi. puddling process, method of converting pig iron into wrought iron by subjecting it to heat and frequent stirring in a furnace in the. This method involved decarburizing molten pig iron in a reverberatory furnace, which, by stirring with rods, allowed impurities like carbon and silicon to be oxidized. Metallurgy Puddling Process.

From brainly.in

Basic Metallurgical Processes with diagram Brainly.in Metallurgy Puddling Process Download reference work entry pdf. the puddling process is a method used to convert pig iron into wrought iron by removing impurities through oxidation and. This method involved decarburizing molten pig iron in a reverberatory furnace, which, by stirring with rods, allowed impurities like carbon and silicon to be oxidized and removed. puddling process, method of converting pig. Metallurgy Puddling Process.

From www.youtube.com

What is Physical Metallurgy Lecture 1 Part 1 [Level 1 Course] YouTube Metallurgy Puddling Process the puddling process is a method used to convert pig iron into wrought iron by removing impurities through oxidation and. puddled iron, a landmark innovation of the industrial revolution, was a form of refined iron produced through a process known as puddling. Puddling was an industrial revolution means of making iron and steel. puddling process, method of. Metallurgy Puddling Process.

From www.culturenlmuseums.co.uk

Puddlers, Shinglers & Rollers the Story of Malleable Iron CultureNL Metallurgy Puddling Process This method involved decarburizing molten pig iron in a reverberatory furnace, which, by stirring with rods, allowed impurities like carbon and silicon to be oxidized and removed. puddling process, method of converting pig iron into wrought iron by subjecting it to heat and frequent stirring in a furnace in the. Puddling was an industrial revolution means of making iron. Metallurgy Puddling Process.

From www.culturenlmuseums.co.uk

Puddlers, Shinglers & Rollers the Story of Malleable Iron CultureNL Metallurgy Puddling Process puddling process, method of converting pig iron into wrought iron by subjecting it to heat and frequent stirring in a furnace in the. the original dry puddling process was replaced beginning in 1830 by wet puddling, which was radically different. Download reference work entry pdf. Puddling was an industrial revolution means of making iron and steel. the. Metallurgy Puddling Process.

From www.culturenlmuseums.co.uk

Puddlers, Shinglers & Rollers the Story of Malleable Iron CultureNL Metallurgy Puddling Process Puddling steel is a technique with which pig iron in semi. puddling process is a smelting technology in which pig iron is puddling on the bottom of the furnace built with iron. the original dry puddling process was replaced beginning in 1830 by wet puddling, which was radically different. puddling process, method of converting pig iron into. Metallurgy Puddling Process.

From www.alamy.com

Puddling (metallurgy) DMK Stock Photo Alamy Metallurgy Puddling Process the original dry puddling process was replaced beginning in 1830 by wet puddling, which was radically different. puddled iron, a landmark innovation of the industrial revolution, was a form of refined iron produced through a process known as puddling. Download reference work entry pdf. puddling process, method of converting pig iron into wrought iron by subjecting it. Metallurgy Puddling Process.