Weld Quality Quizlet . Welding defects are defined as weld surface irregularities, discontinuities, imperfections, or inconsistencies that occur in welded parts. The most common defects found by a liquid penetrant test are. Study with quizlet and memorise flashcards containing terms like defect, discontinuity, embrittled and others. Study with quizlet and memorize flashcards containing terms like defect, discontinuity, embrittled and more. Looking for a comprehensive resource to test your. Study with quizlet and memorize flashcards containing terms like. From the methods used to test welds to the analysis techniques used to. These standards need to be communicated to. Defects can result in rejection of parts and. Test your knowledge on weld quality assurance with this quiz! Welding quizzes offer an interactive and educational way to test your knowledge and understanding of the art and. A welding quality control system starts with clearly defined quality standards.

from weldingofwelders.com

Welding quizzes offer an interactive and educational way to test your knowledge and understanding of the art and. A welding quality control system starts with clearly defined quality standards. Study with quizlet and memorize flashcards containing terms like defect, discontinuity, embrittled and more. Looking for a comprehensive resource to test your. Welding defects are defined as weld surface irregularities, discontinuities, imperfections, or inconsistencies that occur in welded parts. From the methods used to test welds to the analysis techniques used to. Study with quizlet and memorize flashcards containing terms like. Defects can result in rejection of parts and. Test your knowledge on weld quality assurance with this quiz! Study with quizlet and memorise flashcards containing terms like defect, discontinuity, embrittled and others.

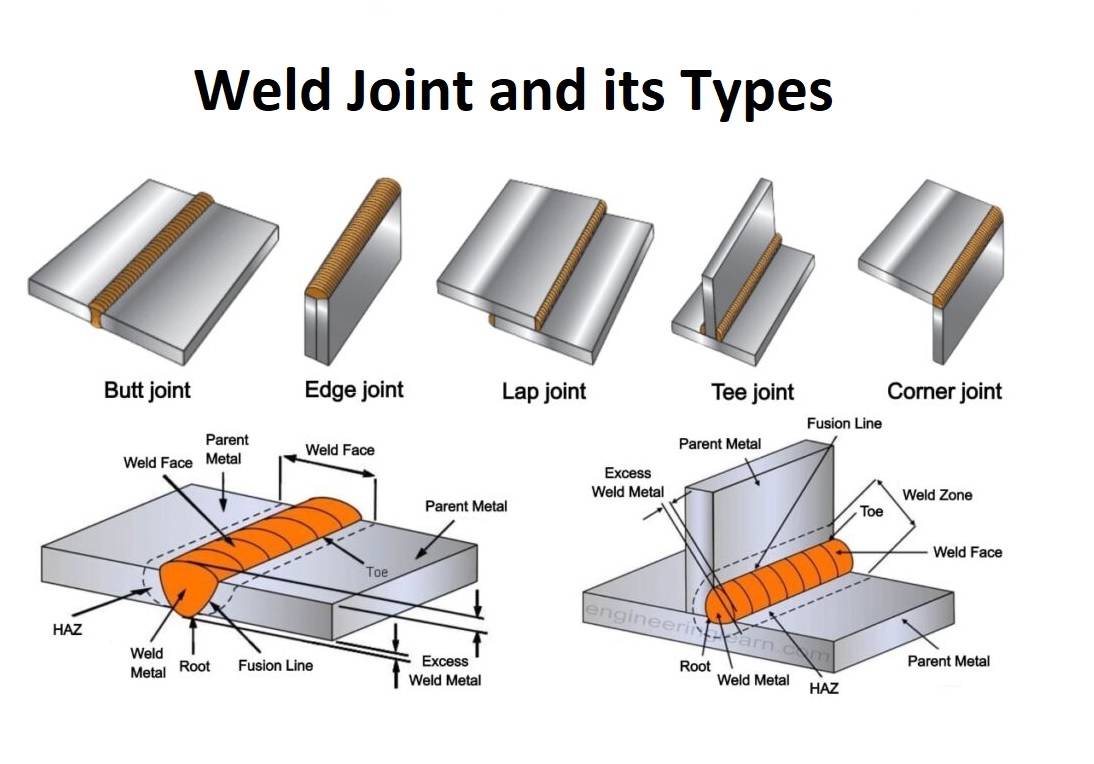

Welding Joints and their Types Welding Basics

Weld Quality Quizlet Welding defects are defined as weld surface irregularities, discontinuities, imperfections, or inconsistencies that occur in welded parts. Test your knowledge on weld quality assurance with this quiz! A welding quality control system starts with clearly defined quality standards. Study with quizlet and memorize flashcards containing terms like defect, discontinuity, embrittled and more. From the methods used to test welds to the analysis techniques used to. Looking for a comprehensive resource to test your. Study with quizlet and memorise flashcards containing terms like defect, discontinuity, embrittled and others. These standards need to be communicated to. Study with quizlet and memorize flashcards containing terms like. Welding quizzes offer an interactive and educational way to test your knowledge and understanding of the art and. The most common defects found by a liquid penetrant test are. Defects can result in rejection of parts and. Welding defects are defined as weld surface irregularities, discontinuities, imperfections, or inconsistencies that occur in welded parts.

From www.hotzxgirl.com

Backing Bar Weld Symbol Hot Sex Picture Weld Quality Quizlet Study with quizlet and memorize flashcards containing terms like. From the methods used to test welds to the analysis techniques used to. Study with quizlet and memorise flashcards containing terms like defect, discontinuity, embrittled and others. Defects can result in rejection of parts and. Looking for a comprehensive resource to test your. A welding quality control system starts with clearly. Weld Quality Quizlet.

From quizlet.com

Parts of a Weld Diagram Quizlet Weld Quality Quizlet From the methods used to test welds to the analysis techniques used to. Test your knowledge on weld quality assurance with this quiz! Welding defects are defined as weld surface irregularities, discontinuities, imperfections, or inconsistencies that occur in welded parts. Welding quizzes offer an interactive and educational way to test your knowledge and understanding of the art and. Defects can. Weld Quality Quizlet.

From www.studypool.com

SOLUTION Quality standard for arc welding Studypool Weld Quality Quizlet Looking for a comprehensive resource to test your. These standards need to be communicated to. Defects can result in rejection of parts and. Welding defects are defined as weld surface irregularities, discontinuities, imperfections, or inconsistencies that occur in welded parts. A welding quality control system starts with clearly defined quality standards. From the methods used to test welds to the. Weld Quality Quizlet.

From www.vrogue.co

Parts Of A Weld Diagram Quizlet vrogue.co Weld Quality Quizlet A welding quality control system starts with clearly defined quality standards. These standards need to be communicated to. Study with quizlet and memorize flashcards containing terms like. The most common defects found by a liquid penetrant test are. Looking for a comprehensive resource to test your. Test your knowledge on weld quality assurance with this quiz! Welding defects are defined. Weld Quality Quizlet.

From www.fabtechexpo.com

Out of This World Weld Quality FABTECH Weld Quality Quizlet From the methods used to test welds to the analysis techniques used to. Study with quizlet and memorize flashcards containing terms like defect, discontinuity, embrittled and more. Test your knowledge on weld quality assurance with this quiz! Welding quizzes offer an interactive and educational way to test your knowledge and understanding of the art and. These standards need to be. Weld Quality Quizlet.

From www.researchgate.net

4Weld Quality Requirements for Discontinuities Occurring in Cyclically Weld Quality Quizlet A welding quality control system starts with clearly defined quality standards. Study with quizlet and memorize flashcards containing terms like. Welding quizzes offer an interactive and educational way to test your knowledge and understanding of the art and. Looking for a comprehensive resource to test your. Defects can result in rejection of parts and. Study with quizlet and memorize flashcards. Weld Quality Quizlet.

From quizlet.com

Welding blueprints Diagram Quizlet Weld Quality Quizlet The most common defects found by a liquid penetrant test are. Defects can result in rejection of parts and. Welding defects are defined as weld surface irregularities, discontinuities, imperfections, or inconsistencies that occur in welded parts. Test your knowledge on weld quality assurance with this quiz! A welding quality control system starts with clearly defined quality standards. Study with quizlet. Weld Quality Quizlet.

From terapiayrehabilitacionfisica.com

Innovation in Metalworking Welding Metal Foam Without Melting Its Bubbles Weld Quality Quizlet The most common defects found by a liquid penetrant test are. A welding quality control system starts with clearly defined quality standards. Study with quizlet and memorize flashcards containing terms like defect, discontinuity, embrittled and more. Study with quizlet and memorise flashcards containing terms like defect, discontinuity, embrittled and others. Study with quizlet and memorize flashcards containing terms like. Test. Weld Quality Quizlet.

From dokumen.tips

(PDF) Relation Between Weld Parameters And Weld Quality In AC DOKUMEN Weld Quality Quizlet The most common defects found by a liquid penetrant test are. Welding defects are defined as weld surface irregularities, discontinuities, imperfections, or inconsistencies that occur in welded parts. Test your knowledge on weld quality assurance with this quiz! A welding quality control system starts with clearly defined quality standards. Study with quizlet and memorize flashcards containing terms like. Welding quizzes. Weld Quality Quizlet.

From mavink.com

Weld Defect Types Weld Quality Quizlet Test your knowledge on weld quality assurance with this quiz! Defects can result in rejection of parts and. Study with quizlet and memorise flashcards containing terms like defect, discontinuity, embrittled and others. The most common defects found by a liquid penetrant test are. Study with quizlet and memorize flashcards containing terms like defect, discontinuity, embrittled and more. Welding quizzes offer. Weld Quality Quizlet.

From abagy.com

What is Robotic Welding How it Works, Advantages, Welding Robots ABAGY Weld Quality Quizlet Study with quizlet and memorize flashcards containing terms like defect, discontinuity, embrittled and more. These standards need to be communicated to. Defects can result in rejection of parts and. A welding quality control system starts with clearly defined quality standards. Study with quizlet and memorize flashcards containing terms like. Looking for a comprehensive resource to test your. Welding defects are. Weld Quality Quizlet.

From www.studocu.com

Learning Unit 3 Weld Quality Notes MANUFACTURING METALLURGY 2 Weld Quality Quizlet Study with quizlet and memorise flashcards containing terms like defect, discontinuity, embrittled and others. Test your knowledge on weld quality assurance with this quiz! From the methods used to test welds to the analysis techniques used to. Welding quizzes offer an interactive and educational way to test your knowledge and understanding of the art and. Defects can result in rejection. Weld Quality Quizlet.

From www.mdpi.com

Effect of Process Parameters on Weld Quality in Vortex Friction Stir Weld Quality Quizlet Study with quizlet and memorise flashcards containing terms like defect, discontinuity, embrittled and others. Test your knowledge on weld quality assurance with this quiz! From the methods used to test welds to the analysis techniques used to. Defects can result in rejection of parts and. Welding quizzes offer an interactive and educational way to test your knowledge and understanding of. Weld Quality Quizlet.

From tupuy.com

Insert Weld Symbol Autocad Printable Online Weld Quality Quizlet From the methods used to test welds to the analysis techniques used to. Defects can result in rejection of parts and. Welding defects are defined as weld surface irregularities, discontinuities, imperfections, or inconsistencies that occur in welded parts. These standards need to be communicated to. Study with quizlet and memorize flashcards containing terms like. Study with quizlet and memorize flashcards. Weld Quality Quizlet.

From www.mdpi.com

Materials Free FullText Comparative Study on the Behavior of Weld Quality Quizlet Study with quizlet and memorize flashcards containing terms like defect, discontinuity, embrittled and more. From the methods used to test welds to the analysis techniques used to. These standards need to be communicated to. Study with quizlet and memorise flashcards containing terms like defect, discontinuity, embrittled and others. Welding defects are defined as weld surface irregularities, discontinuities, imperfections, or inconsistencies. Weld Quality Quizlet.

From makemoneywelding.com

MIG Welding Wire Essentials A Guide to Types & Uses Weld Quality Quizlet Welding defects are defined as weld surface irregularities, discontinuities, imperfections, or inconsistencies that occur in welded parts. From the methods used to test welds to the analysis techniques used to. The most common defects found by a liquid penetrant test are. Test your knowledge on weld quality assurance with this quiz! Study with quizlet and memorize flashcards containing terms like.. Weld Quality Quizlet.

From www.agerawelder.com

News The Impact of Electrode Tip on Nut Spot Welding Machines Weld Quality Quizlet Welding defects are defined as weld surface irregularities, discontinuities, imperfections, or inconsistencies that occur in welded parts. The most common defects found by a liquid penetrant test are. Welding quizzes offer an interactive and educational way to test your knowledge and understanding of the art and. These standards need to be communicated to. Defects can result in rejection of parts. Weld Quality Quizlet.

From mdme.atspace.com

Weld Design Weld Quality Quizlet Defects can result in rejection of parts and. The most common defects found by a liquid penetrant test are. Study with quizlet and memorise flashcards containing terms like defect, discontinuity, embrittled and others. Looking for a comprehensive resource to test your. From the methods used to test welds to the analysis techniques used to. Welding quizzes offer an interactive and. Weld Quality Quizlet.

From weldingofwelders.com

Welding Joints and their Types Welding Basics Weld Quality Quizlet From the methods used to test welds to the analysis techniques used to. These standards need to be communicated to. Test your knowledge on weld quality assurance with this quiz! A welding quality control system starts with clearly defined quality standards. Welding quizzes offer an interactive and educational way to test your knowledge and understanding of the art and. Study. Weld Quality Quizlet.

From www.researchgate.net

(PDF) Welding Quality Detection for Variable Groove Weldments Based on Weld Quality Quizlet Study with quizlet and memorise flashcards containing terms like defect, discontinuity, embrittled and others. The most common defects found by a liquid penetrant test are. Welding defects are defined as weld surface irregularities, discontinuities, imperfections, or inconsistencies that occur in welded parts. Test your knowledge on weld quality assurance with this quiz! Welding quizzes offer an interactive and educational way. Weld Quality Quizlet.

From universe.roboflow.com

Weld Object Detection Dataset by Adam Truong Weld Quality Quizlet Study with quizlet and memorise flashcards containing terms like defect, discontinuity, embrittled and others. Welding quizzes offer an interactive and educational way to test your knowledge and understanding of the art and. Defects can result in rejection of parts and. These standards need to be communicated to. From the methods used to test welds to the analysis techniques used to.. Weld Quality Quizlet.

From ar.pinterest.com

Types Of Welding, Tig Welding, Welders, Welding Projects, Symbols Weld Quality Quizlet A welding quality control system starts with clearly defined quality standards. Study with quizlet and memorise flashcards containing terms like defect, discontinuity, embrittled and others. Defects can result in rejection of parts and. Study with quizlet and memorize flashcards containing terms like defect, discontinuity, embrittled and more. From the methods used to test welds to the analysis techniques used to.. Weld Quality Quizlet.

From www.mdpi.com

Materials Free FullText A Study of the Essential Parameters of Weld Quality Quizlet Test your knowledge on weld quality assurance with this quiz! A welding quality control system starts with clearly defined quality standards. Study with quizlet and memorise flashcards containing terms like defect, discontinuity, embrittled and others. From the methods used to test welds to the analysis techniques used to. Defects can result in rejection of parts and. Study with quizlet and. Weld Quality Quizlet.

From www.studocu.com

Welding quality manual sample Pat [Pick the date] Welding QA/QC Weld Quality Quizlet The most common defects found by a liquid penetrant test are. Defects can result in rejection of parts and. From the methods used to test welds to the analysis techniques used to. Study with quizlet and memorize flashcards containing terms like defect, discontinuity, embrittled and more. A welding quality control system starts with clearly defined quality standards. These standards need. Weld Quality Quizlet.

From blog.thepipingmart.com

Welding Stainless Steel vs Mild Steel What's the Difference Weld Quality Quizlet Test your knowledge on weld quality assurance with this quiz! Looking for a comprehensive resource to test your. Defects can result in rejection of parts and. Welding quizzes offer an interactive and educational way to test your knowledge and understanding of the art and. These standards need to be communicated to. Study with quizlet and memorize flashcards containing terms like.. Weld Quality Quizlet.

From www.tyueweld.com

China D132 (B83) Hardfacing Welding Electrode, Surfacing Welding Rod Weld Quality Quizlet From the methods used to test welds to the analysis techniques used to. Study with quizlet and memorize flashcards containing terms like defect, discontinuity, embrittled and more. Welding defects are defined as weld surface irregularities, discontinuities, imperfections, or inconsistencies that occur in welded parts. Test your knowledge on weld quality assurance with this quiz! A welding quality control system starts. Weld Quality Quizlet.

From eziil.com

Good vs Bad Welds InDepth Examples and Images Weld Quality Quizlet These standards need to be communicated to. Study with quizlet and memorize flashcards containing terms like. Study with quizlet and memorise flashcards containing terms like defect, discontinuity, embrittled and others. Study with quizlet and memorize flashcards containing terms like defect, discontinuity, embrittled and more. A welding quality control system starts with clearly defined quality standards. Test your knowledge on weld. Weld Quality Quizlet.

From quizlet.com

Repeat previous problem with weld size =3 / 8\ \text{in.} Quizlet Weld Quality Quizlet The most common defects found by a liquid penetrant test are. From the methods used to test welds to the analysis techniques used to. Looking for a comprehensive resource to test your. Welding defects are defined as weld surface irregularities, discontinuities, imperfections, or inconsistencies that occur in welded parts. A welding quality control system starts with clearly defined quality standards.. Weld Quality Quizlet.

From www.sexizpix.com

Weld Positions Joints Welding Table Welding Welding Projects Sexiz Pix Weld Quality Quizlet Study with quizlet and memorize flashcards containing terms like defect, discontinuity, embrittled and more. The most common defects found by a liquid penetrant test are. These standards need to be communicated to. Study with quizlet and memorize flashcards containing terms like. Test your knowledge on weld quality assurance with this quiz! Study with quizlet and memorise flashcards containing terms like. Weld Quality Quizlet.

From www.newswire.com

Intertest, Inc. and Cavitar Ltd. Partner in Weld Inspection Divisions Weld Quality Quizlet From the methods used to test welds to the analysis techniques used to. The most common defects found by a liquid penetrant test are. Defects can result in rejection of parts and. These standards need to be communicated to. Study with quizlet and memorise flashcards containing terms like defect, discontinuity, embrittled and others. Study with quizlet and memorize flashcards containing. Weld Quality Quizlet.

From quizlet.com

Weld Bead Anatomy Diagram Quizlet Weld Quality Quizlet Study with quizlet and memorise flashcards containing terms like defect, discontinuity, embrittled and others. Looking for a comprehensive resource to test your. Study with quizlet and memorize flashcards containing terms like. Study with quizlet and memorize flashcards containing terms like defect, discontinuity, embrittled and more. The most common defects found by a liquid penetrant test are. From the methods used. Weld Quality Quizlet.

From www.mdpi.com

Applied Sciences Free FullText Quality Prediction and Parameter Weld Quality Quizlet These standards need to be communicated to. Test your knowledge on weld quality assurance with this quiz! Welding defects are defined as weld surface irregularities, discontinuities, imperfections, or inconsistencies that occur in welded parts. Study with quizlet and memorize flashcards containing terms like. Defects can result in rejection of parts and. Study with quizlet and memorise flashcards containing terms like. Weld Quality Quizlet.

From www.fabtechexpo.com

Out of This World Weld Quality FABTECH Weld Quality Quizlet A welding quality control system starts with clearly defined quality standards. Study with quizlet and memorize flashcards containing terms like defect, discontinuity, embrittled and more. Welding quizzes offer an interactive and educational way to test your knowledge and understanding of the art and. Looking for a comprehensive resource to test your. The most common defects found by a liquid penetrant. Weld Quality Quizlet.

From quizlet.com

Sketch the welding symbols to indicate the following welds. Quizlet Weld Quality Quizlet Welding quizzes offer an interactive and educational way to test your knowledge and understanding of the art and. The most common defects found by a liquid penetrant test are. A welding quality control system starts with clearly defined quality standards. Study with quizlet and memorize flashcards containing terms like defect, discontinuity, embrittled and more. These standards need to be communicated. Weld Quality Quizlet.

From allaboutweldingjobs.com

How Does Stick Welding Work Best Guide & Pros Cons Weld Quality Quizlet Welding defects are defined as weld surface irregularities, discontinuities, imperfections, or inconsistencies that occur in welded parts. A welding quality control system starts with clearly defined quality standards. Study with quizlet and memorise flashcards containing terms like defect, discontinuity, embrittled and others. Study with quizlet and memorize flashcards containing terms like defect, discontinuity, embrittled and more. These standards need to. Weld Quality Quizlet.