Filler Metal Used In Stick Welding . Filler metal is the metal or alloy that is added to making a welded, brazed, or soldered joint. The filler metal is melted and drawn into. Choosing the right filler metal for the job and using it properly it supports high weld quality and productivity and helps reduce downtime for rework. This allows the weld pool to fill up the groove almost instantly, enabling the welder to use higher travel speeds. Filler metals for the field stick welding is very common for outdoor structural steel applications, in part due to its familiarity among operators, but also because of its portability — it doesn’t require a separate shielding gas cylinder. Welding filler metals are available in various forms and packaging options to suit different welding processes and applications. These electrodes melt very quickly. To help along the way, here are five.

from weldingpros.net

Filler metals for the field stick welding is very common for outdoor structural steel applications, in part due to its familiarity among operators, but also because of its portability — it doesn’t require a separate shielding gas cylinder. The filler metal is melted and drawn into. These electrodes melt very quickly. Filler metal is the metal or alloy that is added to making a welded, brazed, or soldered joint. Choosing the right filler metal for the job and using it properly it supports high weld quality and productivity and helps reduce downtime for rework. This allows the weld pool to fill up the groove almost instantly, enabling the welder to use higher travel speeds. Welding filler metals are available in various forms and packaging options to suit different welding processes and applications. To help along the way, here are five.

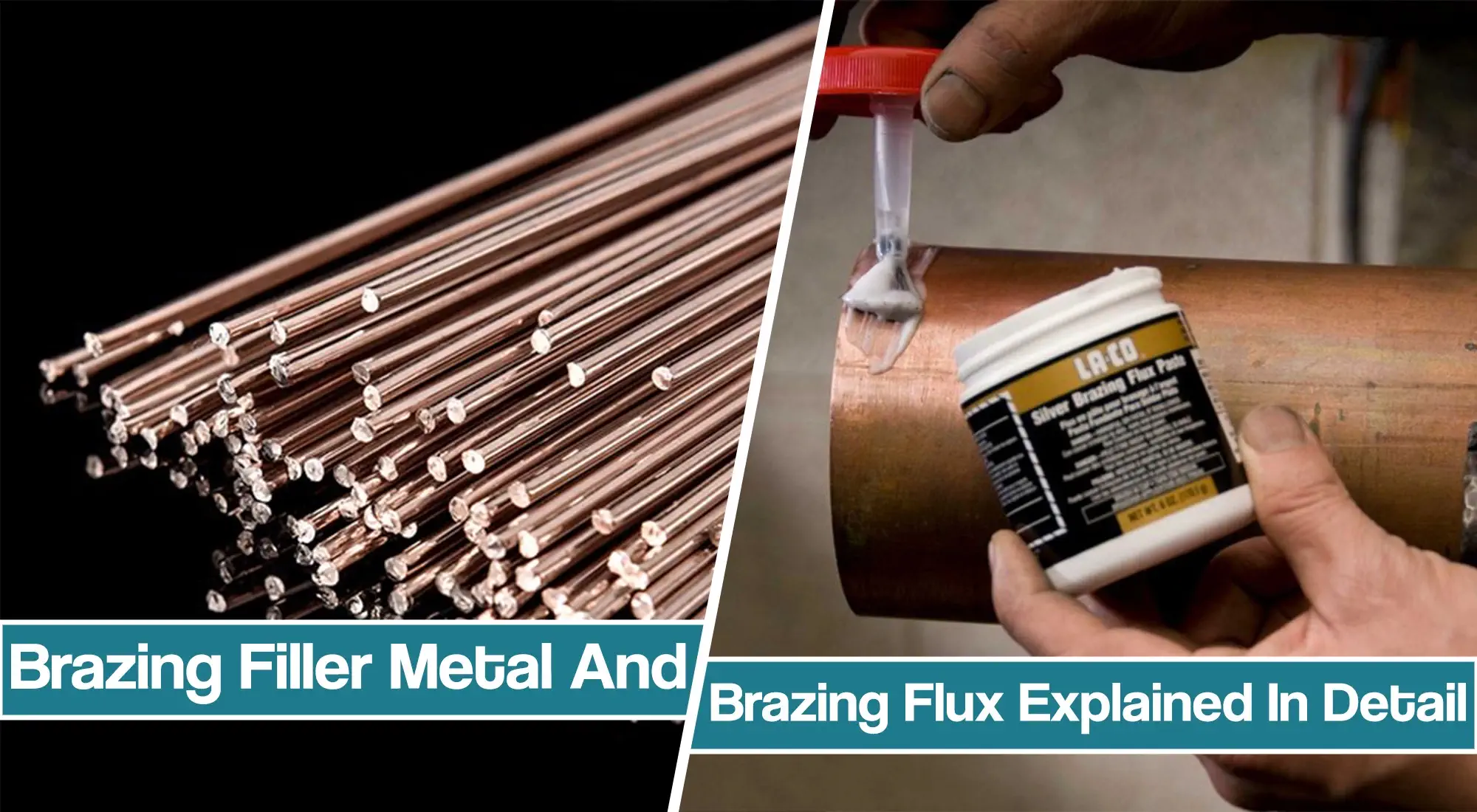

Brazing Filler Metals And Fluxes Explained In Detail

Filler Metal Used In Stick Welding Welding filler metals are available in various forms and packaging options to suit different welding processes and applications. Welding filler metals are available in various forms and packaging options to suit different welding processes and applications. Filler metals for the field stick welding is very common for outdoor structural steel applications, in part due to its familiarity among operators, but also because of its portability — it doesn’t require a separate shielding gas cylinder. Filler metal is the metal or alloy that is added to making a welded, brazed, or soldered joint. The filler metal is melted and drawn into. These electrodes melt very quickly. This allows the weld pool to fill up the groove almost instantly, enabling the welder to use higher travel speeds. Choosing the right filler metal for the job and using it properly it supports high weld quality and productivity and helps reduce downtime for rework. To help along the way, here are five.

From www.thefabricator.com

Weldcote’s ER70S6 coppercoated mild steel filler metal suitable for Filler Metal Used In Stick Welding The filler metal is melted and drawn into. These electrodes melt very quickly. Filler metal is the metal or alloy that is added to making a welded, brazed, or soldered joint. Choosing the right filler metal for the job and using it properly it supports high weld quality and productivity and helps reduce downtime for rework. Welding filler metals are. Filler Metal Used In Stick Welding.

From www.diytrade.com

Phos Copper brazing filler metal welding stick JCuP2 Qixing (China Filler Metal Used In Stick Welding To help along the way, here are five. These electrodes melt very quickly. Choosing the right filler metal for the job and using it properly it supports high weld quality and productivity and helps reduce downtime for rework. Welding filler metals are available in various forms and packaging options to suit different welding processes and applications. Filler metal is the. Filler Metal Used In Stick Welding.

From www.diytrade.com

Phos Copper brazing filler metal welding stick JCuP2 Qixing (China Filler Metal Used In Stick Welding The filler metal is melted and drawn into. Filler metal is the metal or alloy that is added to making a welded, brazed, or soldered joint. Filler metals for the field stick welding is very common for outdoor structural steel applications, in part due to its familiarity among operators, but also because of its portability — it doesn’t require a. Filler Metal Used In Stick Welding.

From shop.puritygas.com

Stick Welding (SMAW) Filler Metal Used In Stick Welding This allows the weld pool to fill up the groove almost instantly, enabling the welder to use higher travel speeds. These electrodes melt very quickly. The filler metal is melted and drawn into. To help along the way, here are five. Filler metal is the metal or alloy that is added to making a welded, brazed, or soldered joint. Welding. Filler Metal Used In Stick Welding.

From weldcotemetals.com

aluminum alloy 1100 filler metals Weldcote Welding For WellBeing Filler Metal Used In Stick Welding Choosing the right filler metal for the job and using it properly it supports high weld quality and productivity and helps reduce downtime for rework. This allows the weld pool to fill up the groove almost instantly, enabling the welder to use higher travel speeds. Filler metals for the field stick welding is very common for outdoor structural steel applications,. Filler Metal Used In Stick Welding.

From materials-welding.blogspot.com

Materials & Welding Aluminum Filler Metals Which Are Right for You? Filler Metal Used In Stick Welding Choosing the right filler metal for the job and using it properly it supports high weld quality and productivity and helps reduce downtime for rework. Filler metal is the metal or alloy that is added to making a welded, brazed, or soldered joint. To help along the way, here are five. These electrodes melt very quickly. The filler metal is. Filler Metal Used In Stick Welding.

From www.hobartbrothers.com

Understanding Deoxidizers in Filler Metals Hobart Brothers Filler Metal Used In Stick Welding This allows the weld pool to fill up the groove almost instantly, enabling the welder to use higher travel speeds. Welding filler metals are available in various forms and packaging options to suit different welding processes and applications. These electrodes melt very quickly. The filler metal is melted and drawn into. To help along the way, here are five. Filler. Filler Metal Used In Stick Welding.

From www.onestopndt.com

Welding with filler wire procedure Filler Metal Used In Stick Welding These electrodes melt very quickly. Choosing the right filler metal for the job and using it properly it supports high weld quality and productivity and helps reduce downtime for rework. To help along the way, here are five. Welding filler metals are available in various forms and packaging options to suit different welding processes and applications. This allows the weld. Filler Metal Used In Stick Welding.

From weldguru.com

TIG Welding Filler Rods Selection Size With Chart Weld Guru Filler Metal Used In Stick Welding This allows the weld pool to fill up the groove almost instantly, enabling the welder to use higher travel speeds. The filler metal is melted and drawn into. These electrodes melt very quickly. Filler metals for the field stick welding is very common for outdoor structural steel applications, in part due to its familiarity among operators, but also because of. Filler Metal Used In Stick Welding.

From www.canadianmetalworking.com

Five welding filler and filler metal mustknows for new welders Filler Metal Used In Stick Welding Choosing the right filler metal for the job and using it properly it supports high weld quality and productivity and helps reduce downtime for rework. Welding filler metals are available in various forms and packaging options to suit different welding processes and applications. These electrodes melt very quickly. To help along the way, here are five. Filler metal is the. Filler Metal Used In Stick Welding.

From www.kingsofwelding.com

The Complete Guide of How to Stick Weld (SMAW) Kings of Welding Filler Metal Used In Stick Welding To help along the way, here are five. These electrodes melt very quickly. Choosing the right filler metal for the job and using it properly it supports high weld quality and productivity and helps reduce downtime for rework. Filler metals for the field stick welding is very common for outdoor structural steel applications, in part due to its familiarity among. Filler Metal Used In Stick Welding.

From www.electroweld.com.au

Why Is Filler Metal Required During Welding? Filler Metal Used In Stick Welding The filler metal is melted and drawn into. To help along the way, here are five. These electrodes melt very quickly. Choosing the right filler metal for the job and using it properly it supports high weld quality and productivity and helps reduce downtime for rework. Welding filler metals are available in various forms and packaging options to suit different. Filler Metal Used In Stick Welding.

From blog.thepipingmart.com

How to Choose the Right Filler Metal? Filler Metal Used In Stick Welding These electrodes melt very quickly. Filler metals for the field stick welding is very common for outdoor structural steel applications, in part due to its familiarity among operators, but also because of its portability — it doesn’t require a separate shielding gas cylinder. This allows the weld pool to fill up the groove almost instantly, enabling the welder to use. Filler Metal Used In Stick Welding.

From www.tinmantech.com

Cast Iron Filler Metals for Gas or TIG welding Filler Metal Used In Stick Welding Filler metal is the metal or alloy that is added to making a welded, brazed, or soldered joint. This allows the weld pool to fill up the groove almost instantly, enabling the welder to use higher travel speeds. These electrodes melt very quickly. Choosing the right filler metal for the job and using it properly it supports high weld quality. Filler Metal Used In Stick Welding.

From weldingpros.net

Brazing Filler Metals And Fluxes Explained In Detail Filler Metal Used In Stick Welding To help along the way, here are five. Choosing the right filler metal for the job and using it properly it supports high weld quality and productivity and helps reduce downtime for rework. The filler metal is melted and drawn into. Welding filler metals are available in various forms and packaging options to suit different welding processes and applications. Filler. Filler Metal Used In Stick Welding.

From steelsupplylp.com

Filler Metals Stick Welding Electrodes, MIG Wire,… Steel Supply LP Filler Metal Used In Stick Welding Choosing the right filler metal for the job and using it properly it supports high weld quality and productivity and helps reduce downtime for rework. The filler metal is melted and drawn into. Filler metal is the metal or alloy that is added to making a welded, brazed, or soldered joint. To help along the way, here are five. Filler. Filler Metal Used In Stick Welding.

From www.northerntool.com

Hobart Filler Metals Stick Welding Electrodes — 6011, 1/16in. Dia. x Filler Metal Used In Stick Welding Welding filler metals are available in various forms and packaging options to suit different welding processes and applications. These electrodes melt very quickly. To help along the way, here are five. Choosing the right filler metal for the job and using it properly it supports high weld quality and productivity and helps reduce downtime for rework. Filler metals for the. Filler Metal Used In Stick Welding.

From bancrofteng.com

Choosing the Right Filler Metal Based on Material Conditions A Welders Filler Metal Used In Stick Welding Welding filler metals are available in various forms and packaging options to suit different welding processes and applications. To help along the way, here are five. Choosing the right filler metal for the job and using it properly it supports high weld quality and productivity and helps reduce downtime for rework. These electrodes melt very quickly. This allows the weld. Filler Metal Used In Stick Welding.

From www.northerntool.com

Hobart Filler Metals Stick Welding Electrodes — Stainless Steel 308L16 Filler Metal Used In Stick Welding Filler metals for the field stick welding is very common for outdoor structural steel applications, in part due to its familiarity among operators, but also because of its portability — it doesn’t require a separate shielding gas cylinder. Welding filler metals are available in various forms and packaging options to suit different welding processes and applications. To help along the. Filler Metal Used In Stick Welding.

From lucygibbons.z13.web.core.windows.net

Weld Filler Metal Selection Chart Filler Metal Used In Stick Welding This allows the weld pool to fill up the groove almost instantly, enabling the welder to use higher travel speeds. To help along the way, here are five. Choosing the right filler metal for the job and using it properly it supports high weld quality and productivity and helps reduce downtime for rework. Filler metals for the field stick welding. Filler Metal Used In Stick Welding.

From weldingplus.com.au

Category Filler Metals Welding Plus Filler Metal Used In Stick Welding Filler metals for the field stick welding is very common for outdoor structural steel applications, in part due to its familiarity among operators, but also because of its portability — it doesn’t require a separate shielding gas cylinder. Filler metal is the metal or alloy that is added to making a welded, brazed, or soldered joint. To help along the. Filler Metal Used In Stick Welding.

From www.youtube.com

TIG Welding Copper Using improvised filler rod YouTube Filler Metal Used In Stick Welding Choosing the right filler metal for the job and using it properly it supports high weld quality and productivity and helps reduce downtime for rework. Filler metals for the field stick welding is very common for outdoor structural steel applications, in part due to its familiarity among operators, but also because of its portability — it doesn’t require a separate. Filler Metal Used In Stick Welding.

From www.northerntool.com

Hobart Filler Metals 6013 Stick Welding Electrodes Northern Tool Filler Metal Used In Stick Welding To help along the way, here are five. These electrodes melt very quickly. This allows the weld pool to fill up the groove almost instantly, enabling the welder to use higher travel speeds. The filler metal is melted and drawn into. Welding filler metals are available in various forms and packaging options to suit different welding processes and applications. Filler. Filler Metal Used In Stick Welding.

From www.steelsupplylp.com

Welding Processes Steel Supply LP Filler Metal Used In Stick Welding Filler metals for the field stick welding is very common for outdoor structural steel applications, in part due to its familiarity among operators, but also because of its portability — it doesn’t require a separate shielding gas cylinder. Welding filler metals are available in various forms and packaging options to suit different welding processes and applications. To help along the. Filler Metal Used In Stick Welding.

From www.weldingcity.com

Filler Metals Stick Welding Electrodes Carbon Steel Electrodes Filler Metal Used In Stick Welding Choosing the right filler metal for the job and using it properly it supports high weld quality and productivity and helps reduce downtime for rework. This allows the weld pool to fill up the groove almost instantly, enabling the welder to use higher travel speeds. To help along the way, here are five. Filler metals for the field stick welding. Filler Metal Used In Stick Welding.

From www.youtube.com

STICK WELDING 101 Getting Started With SMAW YouTube Filler Metal Used In Stick Welding This allows the weld pool to fill up the groove almost instantly, enabling the welder to use higher travel speeds. To help along the way, here are five. The filler metal is melted and drawn into. Welding filler metals are available in various forms and packaging options to suit different welding processes and applications. Choosing the right filler metal for. Filler Metal Used In Stick Welding.

From weldingwatch.com

What Filler Metal is Used in TIG Welding? WeldingWatch Filler Metal Used In Stick Welding Filler metal is the metal or alloy that is added to making a welded, brazed, or soldered joint. The filler metal is melted and drawn into. Welding filler metals are available in various forms and packaging options to suit different welding processes and applications. Filler metals for the field stick welding is very common for outdoor structural steel applications, in. Filler Metal Used In Stick Welding.

From weldguru.com

MIG vs Stick Welding Which is Better? (Pros & Cons) Filler Metal Used In Stick Welding Filler metals for the field stick welding is very common for outdoor structural steel applications, in part due to its familiarity among operators, but also because of its portability — it doesn’t require a separate shielding gas cylinder. Welding filler metals are available in various forms and packaging options to suit different welding processes and applications. The filler metal is. Filler Metal Used In Stick Welding.

From gioausvvj.blob.core.windows.net

Filler Metal Used In Arc Welding at Daniel Skillman blog Filler Metal Used In Stick Welding These electrodes melt very quickly. Choosing the right filler metal for the job and using it properly it supports high weld quality and productivity and helps reduce downtime for rework. The filler metal is melted and drawn into. Filler metal is the metal or alloy that is added to making a welded, brazed, or soldered joint. Filler metals for the. Filler Metal Used In Stick Welding.

From www.diytrade.com

fast delivery Brass filler metal welding stick BCu62Zn Qixing Filler Metal Used In Stick Welding Choosing the right filler metal for the job and using it properly it supports high weld quality and productivity and helps reduce downtime for rework. The filler metal is melted and drawn into. Filler metal is the metal or alloy that is added to making a welded, brazed, or soldered joint. To help along the way, here are five. Filler. Filler Metal Used In Stick Welding.

From www.weldequip.com

316L Stainless Steel TIG Welding Filler Rods Weldequip Filler Metal Used In Stick Welding These electrodes melt very quickly. Welding filler metals are available in various forms and packaging options to suit different welding processes and applications. This allows the weld pool to fill up the groove almost instantly, enabling the welder to use higher travel speeds. Choosing the right filler metal for the job and using it properly it supports high weld quality. Filler Metal Used In Stick Welding.

From www.youtube.com

Weld filler metal selection for carbon Steel & Alloy Steel YouTube Filler Metal Used In Stick Welding These electrodes melt very quickly. Filler metal is the metal or alloy that is added to making a welded, brazed, or soldered joint. Filler metals for the field stick welding is very common for outdoor structural steel applications, in part due to its familiarity among operators, but also because of its portability — it doesn’t require a separate shielding gas. Filler Metal Used In Stick Welding.

From www.northerntool.com

ESAB 70181 Prime Filler Metals Stick Welding Electrodes Northern Tool Filler Metal Used In Stick Welding This allows the weld pool to fill up the groove almost instantly, enabling the welder to use higher travel speeds. Choosing the right filler metal for the job and using it properly it supports high weld quality and productivity and helps reduce downtime for rework. Filler metal is the metal or alloy that is added to making a welded, brazed,. Filler Metal Used In Stick Welding.

From www.weldingcity.com

3/32" x 12" WeldingCity® E309L16 Stainless Steel Stick Welding Filler Metal Used In Stick Welding To help along the way, here are five. Welding filler metals are available in various forms and packaging options to suit different welding processes and applications. Choosing the right filler metal for the job and using it properly it supports high weld quality and productivity and helps reduce downtime for rework. Filler metals for the field stick welding is very. Filler Metal Used In Stick Welding.

From blog.thepipingmart.com

How to Stick Weld Thin Metal An Overview Filler Metal Used In Stick Welding Welding filler metals are available in various forms and packaging options to suit different welding processes and applications. Filler metal is the metal or alloy that is added to making a welded, brazed, or soldered joint. The filler metal is melted and drawn into. To help along the way, here are five. Choosing the right filler metal for the job. Filler Metal Used In Stick Welding.