Belt Drive Tension Relationship . proper belt tension is a critical step when installing a belt. to control the initial tension of the transmission belt and ensure the operational capability of the belt drive, an appropriate tensioning. You can change the belt tensions and the moment will adjust to maintain equilibrium, or. The friction is multiplied by the mechanical advantage of the wedging. belt manufacturers recommend that the tension ratio for a system with 180° of contact on each sheave should be no. this interactive shows fbds of a belt and pulley system, and the isolated belt. in practice, a belt drive can be designed such that the desired slack side tension, t2, is equal to 10% to 30% of the effective.

from studylib.net

to control the initial tension of the transmission belt and ensure the operational capability of the belt drive, an appropriate tensioning. this interactive shows fbds of a belt and pulley system, and the isolated belt. belt manufacturers recommend that the tension ratio for a system with 180° of contact on each sheave should be no. The friction is multiplied by the mechanical advantage of the wedging. You can change the belt tensions and the moment will adjust to maintain equilibrium, or. proper belt tension is a critical step when installing a belt. in practice, a belt drive can be designed such that the desired slack side tension, t2, is equal to 10% to 30% of the effective.

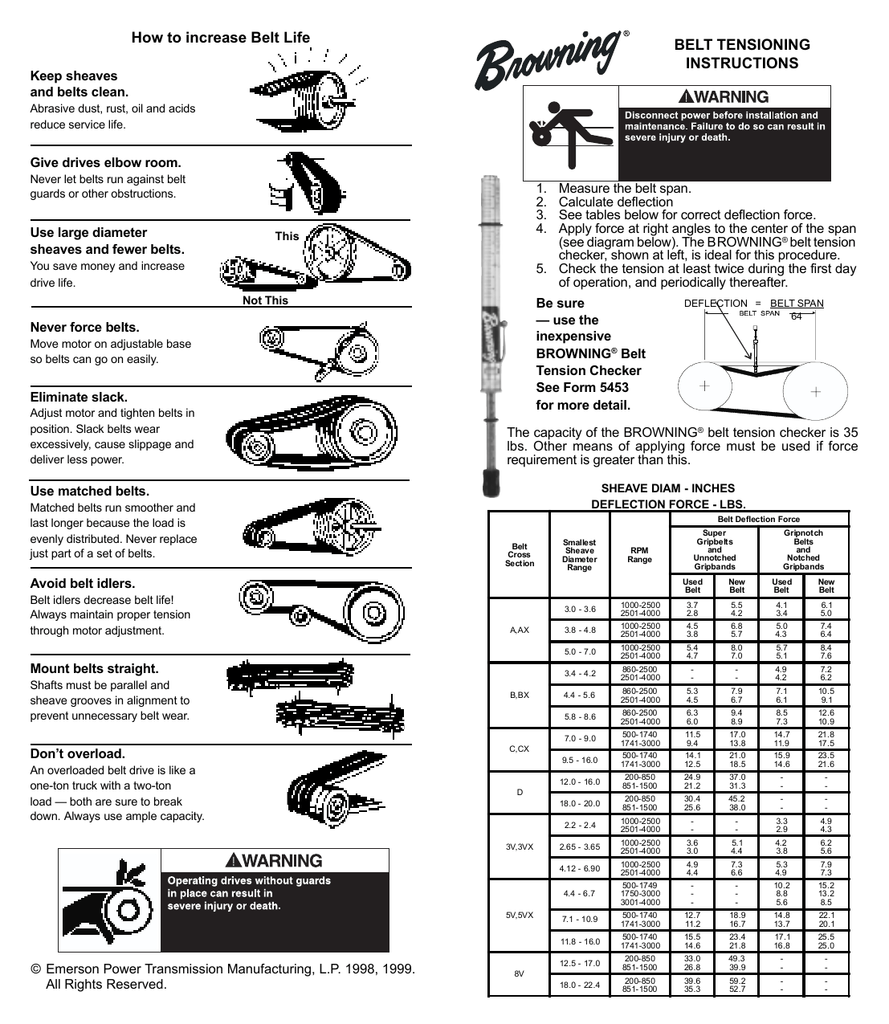

Browning Belt Tensioning InstructionsForm 8082

Belt Drive Tension Relationship proper belt tension is a critical step when installing a belt. this interactive shows fbds of a belt and pulley system, and the isolated belt. proper belt tension is a critical step when installing a belt. to control the initial tension of the transmission belt and ensure the operational capability of the belt drive, an appropriate tensioning. belt manufacturers recommend that the tension ratio for a system with 180° of contact on each sheave should be no. in practice, a belt drive can be designed such that the desired slack side tension, t2, is equal to 10% to 30% of the effective. You can change the belt tensions and the moment will adjust to maintain equilibrium, or. The friction is multiplied by the mechanical advantage of the wedging.

From studylib.net

Browning Belt Tensioning InstructionsForm 8082 Belt Drive Tension Relationship belt manufacturers recommend that the tension ratio for a system with 180° of contact on each sheave should be no. in practice, a belt drive can be designed such that the desired slack side tension, t2, is equal to 10% to 30% of the effective. this interactive shows fbds of a belt and pulley system, and the. Belt Drive Tension Relationship.

From www.tec-science.com

Maximum belt stress in belt drives tecscience Belt Drive Tension Relationship proper belt tension is a critical step when installing a belt. You can change the belt tensions and the moment will adjust to maintain equilibrium, or. in practice, a belt drive can be designed such that the desired slack side tension, t2, is equal to 10% to 30% of the effective. this interactive shows fbds of a. Belt Drive Tension Relationship.

From www.iqsdirectory.com

VBelt What Is It? How Does It Work? Types Of, Uses Belt Drive Tension Relationship this interactive shows fbds of a belt and pulley system, and the isolated belt. belt manufacturers recommend that the tension ratio for a system with 180° of contact on each sheave should be no. in practice, a belt drive can be designed such that the desired slack side tension, t2, is equal to 10% to 30% of. Belt Drive Tension Relationship.

From ricksfreeautorepairadvice.com

How to adjust a manual belt tensioner — Ricks Free Auto Repair Advice Belt Drive Tension Relationship in practice, a belt drive can be designed such that the desired slack side tension, t2, is equal to 10% to 30% of the effective. to control the initial tension of the transmission belt and ensure the operational capability of the belt drive, an appropriate tensioning. The friction is multiplied by the mechanical advantage of the wedging. . Belt Drive Tension Relationship.

From www.yourmechanic.com

How Belt Tensioners Work YourMechanic Advice Belt Drive Tension Relationship You can change the belt tensions and the moment will adjust to maintain equilibrium, or. The friction is multiplied by the mechanical advantage of the wedging. this interactive shows fbds of a belt and pulley system, and the isolated belt. belt manufacturers recommend that the tension ratio for a system with 180° of contact on each sheave should. Belt Drive Tension Relationship.

From www.tec-science.com

Power transmission of a belt drive tecscience Belt Drive Tension Relationship belt manufacturers recommend that the tension ratio for a system with 180° of contact on each sheave should be no. to control the initial tension of the transmission belt and ensure the operational capability of the belt drive, an appropriate tensioning. You can change the belt tensions and the moment will adjust to maintain equilibrium, or. this. Belt Drive Tension Relationship.

From www.parktool.com

BDT2 Belt Drive Tension and Alignment Tool Park Tool Belt Drive Tension Relationship The friction is multiplied by the mechanical advantage of the wedging. belt manufacturers recommend that the tension ratio for a system with 180° of contact on each sheave should be no. proper belt tension is a critical step when installing a belt. to control the initial tension of the transmission belt and ensure the operational capability of. Belt Drive Tension Relationship.

From www.tec-science.com

Types of belts for belt drives tecscience Belt Drive Tension Relationship proper belt tension is a critical step when installing a belt. belt manufacturers recommend that the tension ratio for a system with 180° of contact on each sheave should be no. The friction is multiplied by the mechanical advantage of the wedging. to control the initial tension of the transmission belt and ensure the operational capability of. Belt Drive Tension Relationship.

From www.youtube.com

Initial tension in the belt drive YouTube Belt Drive Tension Relationship in practice, a belt drive can be designed such that the desired slack side tension, t2, is equal to 10% to 30% of the effective. to control the initial tension of the transmission belt and ensure the operational capability of the belt drive, an appropriate tensioning. belt manufacturers recommend that the tension ratio for a system with. Belt Drive Tension Relationship.

From www.tec-science.com

Belt tensioner systems for belt drives tecscience Belt Drive Tension Relationship in practice, a belt drive can be designed such that the desired slack side tension, t2, is equal to 10% to 30% of the effective. You can change the belt tensions and the moment will adjust to maintain equilibrium, or. to control the initial tension of the transmission belt and ensure the operational capability of the belt drive,. Belt Drive Tension Relationship.

From www.len.com.ng

Belt and Pulley Drives Types of belt in belt drives Belt Drive Tension Relationship this interactive shows fbds of a belt and pulley system, and the isolated belt. in practice, a belt drive can be designed such that the desired slack side tension, t2, is equal to 10% to 30% of the effective. to control the initial tension of the transmission belt and ensure the operational capability of the belt drive,. Belt Drive Tension Relationship.

From www.justanswer.com

How do I adjust the belt tension on my Dixon ZTR 4516? Belt Drive Tension Relationship this interactive shows fbds of a belt and pulley system, and the isolated belt. The friction is multiplied by the mechanical advantage of the wedging. You can change the belt tensions and the moment will adjust to maintain equilibrium, or. to control the initial tension of the transmission belt and ensure the operational capability of the belt drive,. Belt Drive Tension Relationship.

From ubicaciondepersonas.cdmx.gob.mx

Belt Deflection Belt Tension Chart ubicaciondepersonas.cdmx.gob.mx Belt Drive Tension Relationship in practice, a belt drive can be designed such that the desired slack side tension, t2, is equal to 10% to 30% of the effective. to control the initial tension of the transmission belt and ensure the operational capability of the belt drive, an appropriate tensioning. You can change the belt tensions and the moment will adjust to. Belt Drive Tension Relationship.

From userdataleominster.z21.web.core.windows.net

Diagram Of A Belt Drive Belt Drive Tension Relationship You can change the belt tensions and the moment will adjust to maintain equilibrium, or. The friction is multiplied by the mechanical advantage of the wedging. this interactive shows fbds of a belt and pulley system, and the isolated belt. belt manufacturers recommend that the tension ratio for a system with 180° of contact on each sheave should. Belt Drive Tension Relationship.

From www.tec-science.com

Belt tensioner systems for belt drives tecscience Belt Drive Tension Relationship belt manufacturers recommend that the tension ratio for a system with 180° of contact on each sheave should be no. proper belt tension is a critical step when installing a belt. in practice, a belt drive can be designed such that the desired slack side tension, t2, is equal to 10% to 30% of the effective. The. Belt Drive Tension Relationship.

From www.linearmotiontips.com

How to measue synchronous (toothed) belt tension Belt Drive Tension Relationship proper belt tension is a critical step when installing a belt. this interactive shows fbds of a belt and pulley system, and the isolated belt. to control the initial tension of the transmission belt and ensure the operational capability of the belt drive, an appropriate tensioning. You can change the belt tensions and the moment will adjust. Belt Drive Tension Relationship.

From www.tec-science.com

Calculation of the bearing force for belt drives tecscience Belt Drive Tension Relationship this interactive shows fbds of a belt and pulley system, and the isolated belt. proper belt tension is a critical step when installing a belt. The friction is multiplied by the mechanical advantage of the wedging. You can change the belt tensions and the moment will adjust to maintain equilibrium, or. in practice, a belt drive can. Belt Drive Tension Relationship.

From charliewyatt.z13.web.core.windows.net

Gates V Belt Tension Chart Belt Drive Tension Relationship belt manufacturers recommend that the tension ratio for a system with 180° of contact on each sheave should be no. to control the initial tension of the transmission belt and ensure the operational capability of the belt drive, an appropriate tensioning. The friction is multiplied by the mechanical advantage of the wedging. this interactive shows fbds of. Belt Drive Tension Relationship.

From www.justanswer.com

The drive belt came off of my Cub Cadet ZT1 42" and I can't find a Belt Drive Tension Relationship to control the initial tension of the transmission belt and ensure the operational capability of the belt drive, an appropriate tensioning. You can change the belt tensions and the moment will adjust to maintain equilibrium, or. this interactive shows fbds of a belt and pulley system, and the isolated belt. proper belt tension is a critical step. Belt Drive Tension Relationship.

From www.mech4study.com

Belt Drive and its Types mech4study Belt Drive Tension Relationship in practice, a belt drive can be designed such that the desired slack side tension, t2, is equal to 10% to 30% of the effective. You can change the belt tensions and the moment will adjust to maintain equilibrium, or. The friction is multiplied by the mechanical advantage of the wedging. belt manufacturers recommend that the tension ratio. Belt Drive Tension Relationship.

From www.tec-science.com

Belt tensioner systems for belt drives tecscience Belt Drive Tension Relationship this interactive shows fbds of a belt and pulley system, and the isolated belt. The friction is multiplied by the mechanical advantage of the wedging. You can change the belt tensions and the moment will adjust to maintain equilibrium, or. to control the initial tension of the transmission belt and ensure the operational capability of the belt drive,. Belt Drive Tension Relationship.

From www.tec-science.com

Centrifugal forces in the belt of a belt drive tecscience Belt Drive Tension Relationship this interactive shows fbds of a belt and pulley system, and the isolated belt. The friction is multiplied by the mechanical advantage of the wedging. You can change the belt tensions and the moment will adjust to maintain equilibrium, or. belt manufacturers recommend that the tension ratio for a system with 180° of contact on each sheave should. Belt Drive Tension Relationship.

From eureka.patsnap.com

Belt drive tension device Eureka Patsnap Belt Drive Tension Relationship The friction is multiplied by the mechanical advantage of the wedging. proper belt tension is a critical step when installing a belt. belt manufacturers recommend that the tension ratio for a system with 180° of contact on each sheave should be no. in practice, a belt drive can be designed such that the desired slack side tension,. Belt Drive Tension Relationship.

From stock.adobe.com

Belt drive with automatic belt tensioning mechanism. Fragment of a Belt Drive Tension Relationship to control the initial tension of the transmission belt and ensure the operational capability of the belt drive, an appropriate tensioning. this interactive shows fbds of a belt and pulley system, and the isolated belt. in practice, a belt drive can be designed such that the desired slack side tension, t2, is equal to 10% to 30%. Belt Drive Tension Relationship.

From www.youtube.com

7.7 Belt Friction Video Lecture JPM YouTube Belt Drive Tension Relationship You can change the belt tensions and the moment will adjust to maintain equilibrium, or. belt manufacturers recommend that the tension ratio for a system with 180° of contact on each sheave should be no. in practice, a belt drive can be designed such that the desired slack side tension, t2, is equal to 10% to 30% of. Belt Drive Tension Relationship.

From precor-articulate.s3.amazonaws.com

Drive Belt Tension and Tracking Adjustment Belt Drive Tension Relationship The friction is multiplied by the mechanical advantage of the wedging. proper belt tension is a critical step when installing a belt. to control the initial tension of the transmission belt and ensure the operational capability of the belt drive, an appropriate tensioning. in practice, a belt drive can be designed such that the desired slack side. Belt Drive Tension Relationship.

From www.doubtnut.com

What is Vbelt. Drive the expression of Ratio in belt tension for Belt Drive Tension Relationship You can change the belt tensions and the moment will adjust to maintain equilibrium, or. The friction is multiplied by the mechanical advantage of the wedging. to control the initial tension of the transmission belt and ensure the operational capability of the belt drive, an appropriate tensioning. belt manufacturers recommend that the tension ratio for a system with. Belt Drive Tension Relationship.

From www.youtube.com

Description of Ratio of Driving Tension for Belt Drive Description of Belt Drive Tension Relationship in practice, a belt drive can be designed such that the desired slack side tension, t2, is equal to 10% to 30% of the effective. belt manufacturers recommend that the tension ratio for a system with 180° of contact on each sheave should be no. this interactive shows fbds of a belt and pulley system, and the. Belt Drive Tension Relationship.

From www.youtube.com

Relation Between Tension on Tight Side and Tension on Slack Side Belt Drive Tension Relationship to control the initial tension of the transmission belt and ensure the operational capability of the belt drive, an appropriate tensioning. in practice, a belt drive can be designed such that the desired slack side tension, t2, is equal to 10% to 30% of the effective. proper belt tension is a critical step when installing a belt.. Belt Drive Tension Relationship.

From dxozrkcpn.blob.core.windows.net

How To Tension A Belt Drive at Bryon Bergman blog Belt Drive Tension Relationship in practice, a belt drive can be designed such that the desired slack side tension, t2, is equal to 10% to 30% of the effective. You can change the belt tensions and the moment will adjust to maintain equilibrium, or. to control the initial tension of the transmission belt and ensure the operational capability of the belt drive,. Belt Drive Tension Relationship.

From www.samarins.com

Serpentine belt, tensioner problems, signs of wear, when to replace Belt Drive Tension Relationship proper belt tension is a critical step when installing a belt. The friction is multiplied by the mechanical advantage of the wedging. this interactive shows fbds of a belt and pulley system, and the isolated belt. in practice, a belt drive can be designed such that the desired slack side tension, t2, is equal to 10% to. Belt Drive Tension Relationship.

From armychemicaloperations.tpub.com

Figure 15. Checking tension of drive belts. Belt Drive Tension Relationship this interactive shows fbds of a belt and pulley system, and the isolated belt. You can change the belt tensions and the moment will adjust to maintain equilibrium, or. The friction is multiplied by the mechanical advantage of the wedging. to control the initial tension of the transmission belt and ensure the operational capability of the belt drive,. Belt Drive Tension Relationship.

From www.scribd.com

Belt Tension Required Belt (Mechanical) Manufactured Goods Belt Drive Tension Relationship to control the initial tension of the transmission belt and ensure the operational capability of the belt drive, an appropriate tensioning. belt manufacturers recommend that the tension ratio for a system with 180° of contact on each sheave should be no. You can change the belt tensions and the moment will adjust to maintain equilibrium, or. in. Belt Drive Tension Relationship.

From www.youtube.com

Belt Tension Tutorial YouTube Belt Drive Tension Relationship The friction is multiplied by the mechanical advantage of the wedging. in practice, a belt drive can be designed such that the desired slack side tension, t2, is equal to 10% to 30% of the effective. to control the initial tension of the transmission belt and ensure the operational capability of the belt drive, an appropriate tensioning. You. Belt Drive Tension Relationship.

From hofm.com.pk

Belt Drive Tensioning Elements House Of Machines Belt Drive Tension Relationship You can change the belt tensions and the moment will adjust to maintain equilibrium, or. this interactive shows fbds of a belt and pulley system, and the isolated belt. The friction is multiplied by the mechanical advantage of the wedging. in practice, a belt drive can be designed such that the desired slack side tension, t2, is equal. Belt Drive Tension Relationship.