How To Make A Mold For Casting Iron . If you're casting a single sculpture in bronze or aluminum from a wax base (lost wax casting), use the ceramic mold. To track progress and measure success, i’m starting with the basics: How is cast iron made? Metal casting comes in two main categories: Processes with reusable molds and processes with expendable molds. Here are the basic steps involved in making cast iron: Engineers, designers, jewelers, and hobbyists can capitalize on the speed and flexibility of 3d printing by combining castings processes like indirect investment casting, direct. Foundry pattern making is the process of designing and creating a mold pattern, casting pattern, or sand casting pattern if sand. Cast iron is made by melting iron and adding carbon and other elements to the molten metal, which is then poured into a mold to cool and solidify.

from www.youtube.com

Processes with reusable molds and processes with expendable molds. Foundry pattern making is the process of designing and creating a mold pattern, casting pattern, or sand casting pattern if sand. Here are the basic steps involved in making cast iron: Cast iron is made by melting iron and adding carbon and other elements to the molten metal, which is then poured into a mold to cool and solidify. Engineers, designers, jewelers, and hobbyists can capitalize on the speed and flexibility of 3d printing by combining castings processes like indirect investment casting, direct. If you're casting a single sculpture in bronze or aluminum from a wax base (lost wax casting), use the ceramic mold. To track progress and measure success, i’m starting with the basics: How is cast iron made? Metal casting comes in two main categories:

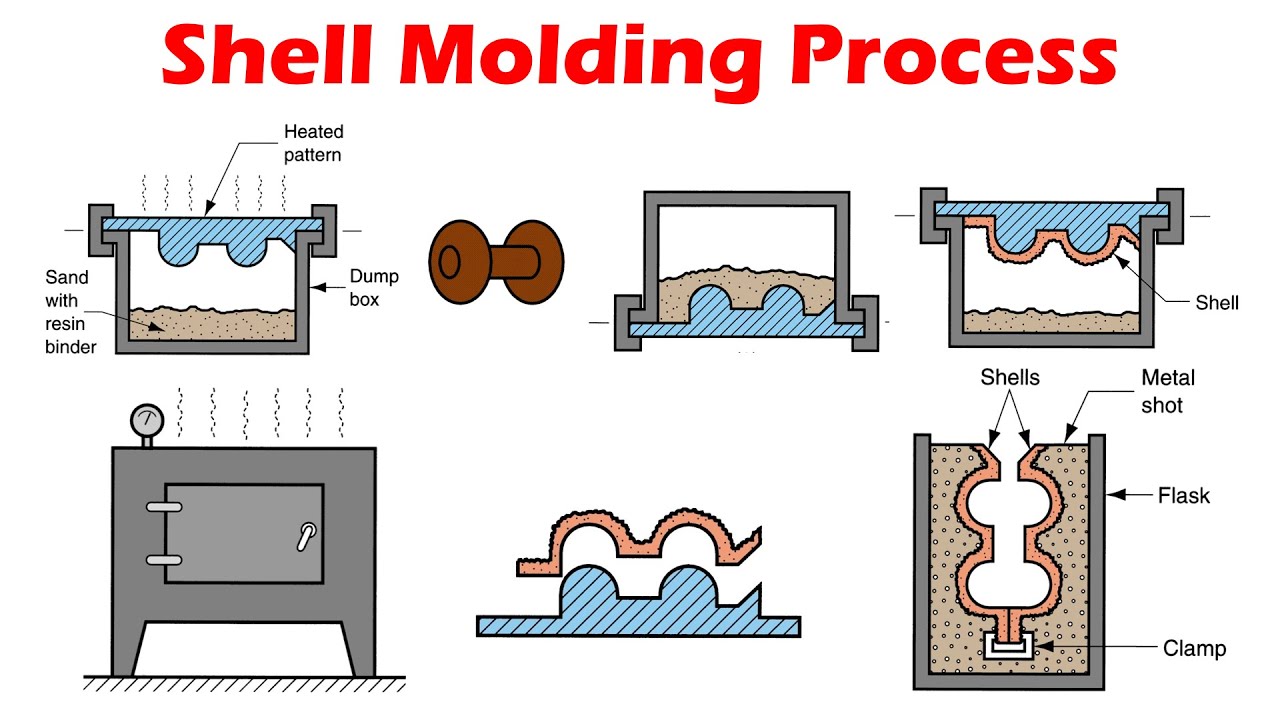

Shell Molding Expandable Mold Casting Processes YouTube

How To Make A Mold For Casting Iron Cast iron is made by melting iron and adding carbon and other elements to the molten metal, which is then poured into a mold to cool and solidify. Foundry pattern making is the process of designing and creating a mold pattern, casting pattern, or sand casting pattern if sand. Processes with reusable molds and processes with expendable molds. Metal casting comes in two main categories: How is cast iron made? Cast iron is made by melting iron and adding carbon and other elements to the molten metal, which is then poured into a mold to cool and solidify. Engineers, designers, jewelers, and hobbyists can capitalize on the speed and flexibility of 3d printing by combining castings processes like indirect investment casting, direct. Here are the basic steps involved in making cast iron: To track progress and measure success, i’m starting with the basics: If you're casting a single sculpture in bronze or aluminum from a wax base (lost wax casting), use the ceramic mold.

From www.pinterest.com.mx

Metal Casting Process Metal casting, Metal casting process, Metal How To Make A Mold For Casting Iron To track progress and measure success, i’m starting with the basics: If you're casting a single sculpture in bronze or aluminum from a wax base (lost wax casting), use the ceramic mold. Here are the basic steps involved in making cast iron: Foundry pattern making is the process of designing and creating a mold pattern, casting pattern, or sand casting. How To Make A Mold For Casting Iron.

From www.intoresin.com

Beginners Guide to Make Resin Molds With Materials Explained IntoResin How To Make A Mold For Casting Iron Metal casting comes in two main categories: If you're casting a single sculpture in bronze or aluminum from a wax base (lost wax casting), use the ceramic mold. Here are the basic steps involved in making cast iron: Engineers, designers, jewelers, and hobbyists can capitalize on the speed and flexibility of 3d printing by combining castings processes like indirect investment. How To Make A Mold For Casting Iron.

From vietnamcastiron.com

Instructions for Making Sand Casting Molds in detail Step by Step How To Make A Mold For Casting Iron If you're casting a single sculpture in bronze or aluminum from a wax base (lost wax casting), use the ceramic mold. Processes with reusable molds and processes with expendable molds. How is cast iron made? Metal casting comes in two main categories: Cast iron is made by melting iron and adding carbon and other elements to the molten metal, which. How To Make A Mold For Casting Iron.

From stonybrookmass.org

Mold Making and Metal Casting Stonybrook Metal Arts & Sculpture School How To Make A Mold For Casting Iron If you're casting a single sculpture in bronze or aluminum from a wax base (lost wax casting), use the ceramic mold. Cast iron is made by melting iron and adding carbon and other elements to the molten metal, which is then poured into a mold to cool and solidify. Processes with reusable molds and processes with expendable molds. To track. How To Make A Mold For Casting Iron.

From www.aniwaa.com

Guide to 3D printing molds for metal casting Aniwaa How To Make A Mold For Casting Iron Here are the basic steps involved in making cast iron: Engineers, designers, jewelers, and hobbyists can capitalize on the speed and flexibility of 3d printing by combining castings processes like indirect investment casting, direct. Foundry pattern making is the process of designing and creating a mold pattern, casting pattern, or sand casting pattern if sand. To track progress and measure. How To Make A Mold For Casting Iron.

From www.thecrucible.org

Metal Casting 101 Learn To Cast Metal [Types & Processes] How To Make A Mold For Casting Iron Engineers, designers, jewelers, and hobbyists can capitalize on the speed and flexibility of 3d printing by combining castings processes like indirect investment casting, direct. Foundry pattern making is the process of designing and creating a mold pattern, casting pattern, or sand casting pattern if sand. Metal casting comes in two main categories: Cast iron is made by melting iron and. How To Make A Mold For Casting Iron.

From www.youtube.com

Make Molds for Resin Casting Beginner's Guide Easy Mold Making How To Make A Mold For Casting Iron How is cast iron made? To track progress and measure success, i’m starting with the basics: Cast iron is made by melting iron and adding carbon and other elements to the molten metal, which is then poured into a mold to cool and solidify. Processes with reusable molds and processes with expendable molds. If you're casting a single sculpture in. How To Make A Mold For Casting Iron.

From www.youtube.com

metal casting machine, perfect molds every time. YouTube How To Make A Mold For Casting Iron Here are the basic steps involved in making cast iron: Processes with reusable molds and processes with expendable molds. Metal casting comes in two main categories: Foundry pattern making is the process of designing and creating a mold pattern, casting pattern, or sand casting pattern if sand. To track progress and measure success, i’m starting with the basics: How is. How To Make A Mold For Casting Iron.

From cejzvipy.blob.core.windows.net

How To Cast A Mold at Mary Monahan blog How To Make A Mold For Casting Iron How is cast iron made? Metal casting comes in two main categories: If you're casting a single sculpture in bronze or aluminum from a wax base (lost wax casting), use the ceramic mold. Here are the basic steps involved in making cast iron: Foundry pattern making is the process of designing and creating a mold pattern, casting pattern, or sand. How To Make A Mold For Casting Iron.

From omnidexcastings.com

Shell Mold Casting Quality Metal Casting Services Omnidex How To Make A Mold For Casting Iron If you're casting a single sculpture in bronze or aluminum from a wax base (lost wax casting), use the ceramic mold. Metal casting comes in two main categories: Processes with reusable molds and processes with expendable molds. Cast iron is made by melting iron and adding carbon and other elements to the molten metal, which is then poured into a. How To Make A Mold For Casting Iron.

From startup-buzz.com

The Beginner’s Guide to Permanent Mold Casting Startup Buzz How To Make A Mold For Casting Iron If you're casting a single sculpture in bronze or aluminum from a wax base (lost wax casting), use the ceramic mold. Foundry pattern making is the process of designing and creating a mold pattern, casting pattern, or sand casting pattern if sand. How is cast iron made? Cast iron is made by melting iron and adding carbon and other elements. How To Make A Mold For Casting Iron.

From www.thecrucible.org

Metal Casting 101 Learn To Cast Metal [Types & Processes] How To Make A Mold For Casting Iron To track progress and measure success, i’m starting with the basics: Metal casting comes in two main categories: Foundry pattern making is the process of designing and creating a mold pattern, casting pattern, or sand casting pattern if sand. If you're casting a single sculpture in bronze or aluminum from a wax base (lost wax casting), use the ceramic mold.. How To Make A Mold For Casting Iron.

From www.omicroncasting.com

5 Different Methods Used in Casting How To Make A Mold For Casting Iron Here are the basic steps involved in making cast iron: If you're casting a single sculpture in bronze or aluminum from a wax base (lost wax casting), use the ceramic mold. Foundry pattern making is the process of designing and creating a mold pattern, casting pattern, or sand casting pattern if sand. Cast iron is made by melting iron and. How To Make A Mold For Casting Iron.

From www.youtube.com

Mold Making and Casting Tutorials From SmoothOn YouTube How To Make A Mold For Casting Iron Metal casting comes in two main categories: Here are the basic steps involved in making cast iron: Cast iron is made by melting iron and adding carbon and other elements to the molten metal, which is then poured into a mold to cool and solidify. How is cast iron made? If you're casting a single sculpture in bronze or aluminum. How To Make A Mold For Casting Iron.

From www.youtube.com

Casting Metal Parts into 3D Printed Molds YouTube How To Make A Mold For Casting Iron If you're casting a single sculpture in bronze or aluminum from a wax base (lost wax casting), use the ceramic mold. Engineers, designers, jewelers, and hobbyists can capitalize on the speed and flexibility of 3d printing by combining castings processes like indirect investment casting, direct. Here are the basic steps involved in making cast iron: Cast iron is made by. How To Make A Mold For Casting Iron.

From www.youtube.com

Casting Iron Mold for Ingots! 2000°+ (MattMakes Mold Part 1/4) YouTube How To Make A Mold For Casting Iron How is cast iron made? Cast iron is made by melting iron and adding carbon and other elements to the molten metal, which is then poured into a mold to cool and solidify. Engineers, designers, jewelers, and hobbyists can capitalize on the speed and flexibility of 3d printing by combining castings processes like indirect investment casting, direct. Foundry pattern making. How To Make A Mold For Casting Iron.

From www.alamy.com

Metal casting process in foundry, liquid metal pouring from container How To Make A Mold For Casting Iron Cast iron is made by melting iron and adding carbon and other elements to the molten metal, which is then poured into a mold to cool and solidify. Foundry pattern making is the process of designing and creating a mold pattern, casting pattern, or sand casting pattern if sand. How is cast iron made? Engineers, designers, jewelers, and hobbyists can. How To Make A Mold For Casting Iron.

From www.open.edu

Ceramic mould casting OpenLearn Open University How To Make A Mold For Casting Iron Here are the basic steps involved in making cast iron: If you're casting a single sculpture in bronze or aluminum from a wax base (lost wax casting), use the ceramic mold. How is cast iron made? Metal casting comes in two main categories: Cast iron is made by melting iron and adding carbon and other elements to the molten metal,. How To Make A Mold For Casting Iron.

From www.thelibraryofmanufacturing.com

Metal Casting Process How To Make A Mold For Casting Iron Engineers, designers, jewelers, and hobbyists can capitalize on the speed and flexibility of 3d printing by combining castings processes like indirect investment casting, direct. Processes with reusable molds and processes with expendable molds. How is cast iron made? To track progress and measure success, i’m starting with the basics: Foundry pattern making is the process of designing and creating a. How To Make A Mold For Casting Iron.

From www.youtube.com

The Basic Permanent Mold Casting Process YouTube How To Make A Mold For Casting Iron If you're casting a single sculpture in bronze or aluminum from a wax base (lost wax casting), use the ceramic mold. Processes with reusable molds and processes with expendable molds. Metal casting comes in two main categories: Here are the basic steps involved in making cast iron: How is cast iron made? Engineers, designers, jewelers, and hobbyists can capitalize on. How To Make A Mold For Casting Iron.

From www.making.unsw.edu.au

Casting and Mould Making UNSW Making How To Make A Mold For Casting Iron To track progress and measure success, i’m starting with the basics: Here are the basic steps involved in making cast iron: Cast iron is made by melting iron and adding carbon and other elements to the molten metal, which is then poured into a mold to cool and solidify. Metal casting comes in two main categories: Foundry pattern making is. How To Make A Mold For Casting Iron.

From goodtuto-rial.blogspot.com

How To Make A Cast Mold For Silver How To Make A Mold For Casting Iron Here are the basic steps involved in making cast iron: If you're casting a single sculpture in bronze or aluminum from a wax base (lost wax casting), use the ceramic mold. Cast iron is made by melting iron and adding carbon and other elements to the molten metal, which is then poured into a mold to cool and solidify. Foundry. How To Make A Mold For Casting Iron.

From www.iqsdirectory.com

Iron Castings Types, Applications, Process, and Benefits How To Make A Mold For Casting Iron How is cast iron made? If you're casting a single sculpture in bronze or aluminum from a wax base (lost wax casting), use the ceramic mold. Foundry pattern making is the process of designing and creating a mold pattern, casting pattern, or sand casting pattern if sand. To track progress and measure success, i’m starting with the basics: Engineers, designers,. How To Make A Mold For Casting Iron.

From www.youtube.com

Casting Metal the Basics YouTube How To Make A Mold For Casting Iron Engineers, designers, jewelers, and hobbyists can capitalize on the speed and flexibility of 3d printing by combining castings processes like indirect investment casting, direct. Here are the basic steps involved in making cast iron: Processes with reusable molds and processes with expendable molds. To track progress and measure success, i’m starting with the basics: If you're casting a single sculpture. How To Make A Mold For Casting Iron.

From www.youtube.com

Easy Metal Casting Pouring Liquid Pewter into a Silicone Mold YouTube How To Make A Mold For Casting Iron Foundry pattern making is the process of designing and creating a mold pattern, casting pattern, or sand casting pattern if sand. How is cast iron made? Processes with reusable molds and processes with expendable molds. Here are the basic steps involved in making cast iron: Metal casting comes in two main categories: Engineers, designers, jewelers, and hobbyists can capitalize on. How To Make A Mold For Casting Iron.

From www.pinterest.co.uk

Aluminum Casting At Home DIY Aluminum Foundry & Molds Timber Ridge How To Make A Mold For Casting Iron If you're casting a single sculpture in bronze or aluminum from a wax base (lost wax casting), use the ceramic mold. Foundry pattern making is the process of designing and creating a mold pattern, casting pattern, or sand casting pattern if sand. How is cast iron made? To track progress and measure success, i’m starting with the basics: Here are. How To Make A Mold For Casting Iron.

From cejzvipy.blob.core.windows.net

How To Cast A Mold at Mary Monahan blog How To Make A Mold For Casting Iron Here are the basic steps involved in making cast iron: To track progress and measure success, i’m starting with the basics: Processes with reusable molds and processes with expendable molds. Metal casting comes in two main categories: Engineers, designers, jewelers, and hobbyists can capitalize on the speed and flexibility of 3d printing by combining castings processes like indirect investment casting,. How To Make A Mold For Casting Iron.

From making-a-mold.blogspot.com

Mold making and Casting products through EnvironMolds, LLC Backdating How To Make A Mold For Casting Iron Cast iron is made by melting iron and adding carbon and other elements to the molten metal, which is then poured into a mold to cool and solidify. Metal casting comes in two main categories: How is cast iron made? Processes with reusable molds and processes with expendable molds. If you're casting a single sculpture in bronze or aluminum from. How To Make A Mold For Casting Iron.

From www.youtube.com

Shell Molding Expandable Mold Casting Processes YouTube How To Make A Mold For Casting Iron If you're casting a single sculpture in bronze or aluminum from a wax base (lost wax casting), use the ceramic mold. Engineers, designers, jewelers, and hobbyists can capitalize on the speed and flexibility of 3d printing by combining castings processes like indirect investment casting, direct. Here are the basic steps involved in making cast iron: Processes with reusable molds and. How To Make A Mold For Casting Iron.

From nl.pinterest.com

SlipCasting 19 Steps (with Pictures) Pottery molds, Ceramic molds How To Make A Mold For Casting Iron Processes with reusable molds and processes with expendable molds. To track progress and measure success, i’m starting with the basics: If you're casting a single sculpture in bronze or aluminum from a wax base (lost wax casting), use the ceramic mold. Metal casting comes in two main categories: How is cast iron made? Here are the basic steps involved in. How To Make A Mold For Casting Iron.

From davidneat.wordpress.com

‘Beginner’s Basics’ mouldmaking and casting explained davidneat How To Make A Mold For Casting Iron Engineers, designers, jewelers, and hobbyists can capitalize on the speed and flexibility of 3d printing by combining castings processes like indirect investment casting, direct. Processes with reusable molds and processes with expendable molds. Cast iron is made by melting iron and adding carbon and other elements to the molten metal, which is then poured into a mold to cool and. How To Make A Mold For Casting Iron.

From veenaengicast.com

Metal Casting Guide for Beginners Veena Enterprise How To Make A Mold For Casting Iron Here are the basic steps involved in making cast iron: Processes with reusable molds and processes with expendable molds. Engineers, designers, jewelers, and hobbyists can capitalize on the speed and flexibility of 3d printing by combining castings processes like indirect investment casting, direct. If you're casting a single sculpture in bronze or aluminum from a wax base (lost wax casting),. How To Make A Mold For Casting Iron.

From www.youtube.com

The beginner's guide to mold making and casting YouTube How To Make A Mold For Casting Iron Processes with reusable molds and processes with expendable molds. If you're casting a single sculpture in bronze or aluminum from a wax base (lost wax casting), use the ceramic mold. Engineers, designers, jewelers, and hobbyists can capitalize on the speed and flexibility of 3d printing by combining castings processes like indirect investment casting, direct. To track progress and measure success,. How To Make A Mold For Casting Iron.

From www.youtube.com

LIVE How To Make Molds For Concrete Casting YouTube How To Make A Mold For Casting Iron If you're casting a single sculpture in bronze or aluminum from a wax base (lost wax casting), use the ceramic mold. To track progress and measure success, i’m starting with the basics: How is cast iron made? Cast iron is made by melting iron and adding carbon and other elements to the molten metal, which is then poured into a. How To Make A Mold For Casting Iron.

From www.youtube.com

How to make a sand mold for casting metal YouTube How To Make A Mold For Casting Iron Metal casting comes in two main categories: Engineers, designers, jewelers, and hobbyists can capitalize on the speed and flexibility of 3d printing by combining castings processes like indirect investment casting, direct. To track progress and measure success, i’m starting with the basics: If you're casting a single sculpture in bronze or aluminum from a wax base (lost wax casting), use. How To Make A Mold For Casting Iron.