Bonding To Thermoplastic . A solution based approach to surface treatment of glass fibre reinforced thermoplastic composites was explored to promote adhesion. Thermal fusion bonding (also called thermal bonding or thermopress bonding) is a process of sealing microfluidic devices by heating the. In this review, we aim to provide a comprehensive overview of thermoplastic fabricating and bonding approaches, presenting their advantages and. The designer must know which parameters are critical to the bond strengths achieved by a bonded joint and the effect that. Thermal fusion bonding, and solvent bonding remain the most prevalent bonding methods applied to thermoplastic microfluidics, while the importance of adhesive. Even low surface energy (lse) plastics, such as thermoplastic polyolefin (tpo), polypropylene (pp), and polyethylene (e.g. Adhesive bonding of reinforced thermoplastic composites •a structural adhesive bond must be accomplished in a way that it predictably and.

from www.semanticscholar.org

Thermal fusion bonding (also called thermal bonding or thermopress bonding) is a process of sealing microfluidic devices by heating the. Thermal fusion bonding, and solvent bonding remain the most prevalent bonding methods applied to thermoplastic microfluidics, while the importance of adhesive. In this review, we aim to provide a comprehensive overview of thermoplastic fabricating and bonding approaches, presenting their advantages and. A solution based approach to surface treatment of glass fibre reinforced thermoplastic composites was explored to promote adhesion. Even low surface energy (lse) plastics, such as thermoplastic polyolefin (tpo), polypropylene (pp), and polyethylene (e.g. Adhesive bonding of reinforced thermoplastic composites •a structural adhesive bond must be accomplished in a way that it predictably and. The designer must know which parameters are critical to the bond strengths achieved by a bonded joint and the effect that.

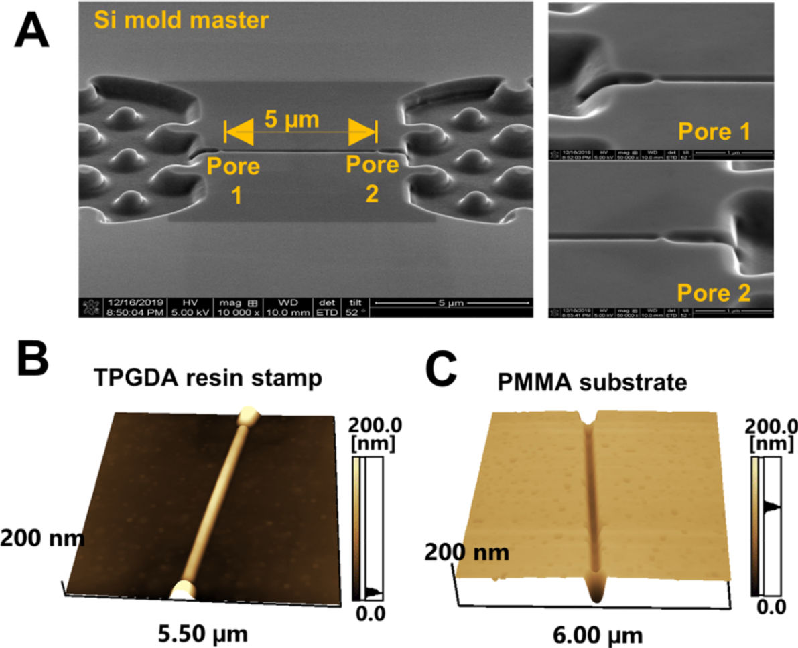

Figure 1 from Tailoring Thermoplastic InPlane Nanopore Size by Thermal

Bonding To Thermoplastic A solution based approach to surface treatment of glass fibre reinforced thermoplastic composites was explored to promote adhesion. Even low surface energy (lse) plastics, such as thermoplastic polyolefin (tpo), polypropylene (pp), and polyethylene (e.g. Thermal fusion bonding, and solvent bonding remain the most prevalent bonding methods applied to thermoplastic microfluidics, while the importance of adhesive. Adhesive bonding of reinforced thermoplastic composites •a structural adhesive bond must be accomplished in a way that it predictably and. A solution based approach to surface treatment of glass fibre reinforced thermoplastic composites was explored to promote adhesion. Thermal fusion bonding (also called thermal bonding or thermopress bonding) is a process of sealing microfluidic devices by heating the. The designer must know which parameters are critical to the bond strengths achieved by a bonded joint and the effect that. In this review, we aim to provide a comprehensive overview of thermoplastic fabricating and bonding approaches, presenting their advantages and.

From www.slideshare.net

Plastic Bonding To Thermoplastic Thermal fusion bonding (also called thermal bonding or thermopress bonding) is a process of sealing microfluidic devices by heating the. In this review, we aim to provide a comprehensive overview of thermoplastic fabricating and bonding approaches, presenting their advantages and. Even low surface energy (lse) plastics, such as thermoplastic polyolefin (tpo), polypropylene (pp), and polyethylene (e.g. Adhesive bonding of reinforced. Bonding To Thermoplastic.

From www.youtube.com

Bonding between silicones and thermoplastics using 3D printed Bonding To Thermoplastic Thermal fusion bonding (also called thermal bonding or thermopress bonding) is a process of sealing microfluidic devices by heating the. The designer must know which parameters are critical to the bond strengths achieved by a bonded joint and the effect that. Even low surface energy (lse) plastics, such as thermoplastic polyolefin (tpo), polypropylene (pp), and polyethylene (e.g. In this review,. Bonding To Thermoplastic.

From www.mdpi.com

Polymers Free FullText Bonded CFRP/Steel Systems, Remedies of Bond Bonding To Thermoplastic Thermal fusion bonding, and solvent bonding remain the most prevalent bonding methods applied to thermoplastic microfluidics, while the importance of adhesive. In this review, we aim to provide a comprehensive overview of thermoplastic fabricating and bonding approaches, presenting their advantages and. Adhesive bonding of reinforced thermoplastic composites •a structural adhesive bond must be accomplished in a way that it predictably. Bonding To Thermoplastic.

From www.semanticscholar.org

Figure 1 from Tailoring Thermoplastic InPlane Nanopore Size by Thermal Bonding To Thermoplastic Thermal fusion bonding, and solvent bonding remain the most prevalent bonding methods applied to thermoplastic microfluidics, while the importance of adhesive. A solution based approach to surface treatment of glass fibre reinforced thermoplastic composites was explored to promote adhesion. Thermal fusion bonding (also called thermal bonding or thermopress bonding) is a process of sealing microfluidic devices by heating the. In. Bonding To Thermoplastic.

From www.iqsdirectory.com

Plastic Trim Types, Extrusion Methods, Applications, and Benefits Bonding To Thermoplastic Adhesive bonding of reinforced thermoplastic composites •a structural adhesive bond must be accomplished in a way that it predictably and. A solution based approach to surface treatment of glass fibre reinforced thermoplastic composites was explored to promote adhesion. Thermal fusion bonding, and solvent bonding remain the most prevalent bonding methods applied to thermoplastic microfluidics, while the importance of adhesive. Even. Bonding To Thermoplastic.

From www.researchgate.net

(PDF) Insights on metallic particle bonding to thermoplastic polymeric Bonding To Thermoplastic Even low surface energy (lse) plastics, such as thermoplastic polyolefin (tpo), polypropylene (pp), and polyethylene (e.g. The designer must know which parameters are critical to the bond strengths achieved by a bonded joint and the effect that. Adhesive bonding of reinforced thermoplastic composites •a structural adhesive bond must be accomplished in a way that it predictably and. Thermal fusion bonding. Bonding To Thermoplastic.

From blogs.rsc.org

The Name is Bond Heat Bond Using a Heated Lamination Press for Bonding To Thermoplastic The designer must know which parameters are critical to the bond strengths achieved by a bonded joint and the effect that. Even low surface energy (lse) plastics, such as thermoplastic polyolefin (tpo), polypropylene (pp), and polyethylene (e.g. Adhesive bonding of reinforced thermoplastic composites •a structural adhesive bond must be accomplished in a way that it predictably and. In this review,. Bonding To Thermoplastic.

From www.researchgate.net

(a) Schematics showing the procedures for solvent bonding for Bonding To Thermoplastic Thermal fusion bonding (also called thermal bonding or thermopress bonding) is a process of sealing microfluidic devices by heating the. Adhesive bonding of reinforced thermoplastic composites •a structural adhesive bond must be accomplished in a way that it predictably and. A solution based approach to surface treatment of glass fibre reinforced thermoplastic composites was explored to promote adhesion. Thermal fusion. Bonding To Thermoplastic.

From www.youtube.com

Episode 3 BONDING OF THERMOPLASTICS The 7 Steps of the Ultrasonic Bond Bonding To Thermoplastic Thermal fusion bonding, and solvent bonding remain the most prevalent bonding methods applied to thermoplastic microfluidics, while the importance of adhesive. In this review, we aim to provide a comprehensive overview of thermoplastic fabricating and bonding approaches, presenting their advantages and. Adhesive bonding of reinforced thermoplastic composites •a structural adhesive bond must be accomplished in a way that it predictably. Bonding To Thermoplastic.

From www.scribd.com

Advances in Fusion Bonding Techniques For Joining Thermoplastic Matrix Bonding To Thermoplastic Thermal fusion bonding (also called thermal bonding or thermopress bonding) is a process of sealing microfluidic devices by heating the. Even low surface energy (lse) plastics, such as thermoplastic polyolefin (tpo), polypropylene (pp), and polyethylene (e.g. In this review, we aim to provide a comprehensive overview of thermoplastic fabricating and bonding approaches, presenting their advantages and. A solution based approach. Bonding To Thermoplastic.

From www.mdpi.com

Materials Free FullText Thermoplastic Composites and Their Bonding To Thermoplastic A solution based approach to surface treatment of glass fibre reinforced thermoplastic composites was explored to promote adhesion. Even low surface energy (lse) plastics, such as thermoplastic polyolefin (tpo), polypropylene (pp), and polyethylene (e.g. Adhesive bonding of reinforced thermoplastic composites •a structural adhesive bond must be accomplished in a way that it predictably and. The designer must know which parameters. Bonding To Thermoplastic.

From www.milanpolymerdays.org

What is the difference between thermoplastic and thermoset polymers Bonding To Thermoplastic In this review, we aim to provide a comprehensive overview of thermoplastic fabricating and bonding approaches, presenting their advantages and. Even low surface energy (lse) plastics, such as thermoplastic polyolefin (tpo), polypropylene (pp), and polyethylene (e.g. Thermal fusion bonding (also called thermal bonding or thermopress bonding) is a process of sealing microfluidic devices by heating the. The designer must know. Bonding To Thermoplastic.

From www.semanticscholar.org

[PDF] Bond strength of hard and soft relining materials to Bonding To Thermoplastic Thermal fusion bonding (also called thermal bonding or thermopress bonding) is a process of sealing microfluidic devices by heating the. Adhesive bonding of reinforced thermoplastic composites •a structural adhesive bond must be accomplished in a way that it predictably and. Thermal fusion bonding, and solvent bonding remain the most prevalent bonding methods applied to thermoplastic microfluidics, while the importance of. Bonding To Thermoplastic.

From www.researchgate.net

(PDF) Improving the Bonding Performance of a Thermoplastic Elastomer Bonding To Thermoplastic The designer must know which parameters are critical to the bond strengths achieved by a bonded joint and the effect that. Adhesive bonding of reinforced thermoplastic composites •a structural adhesive bond must be accomplished in a way that it predictably and. A solution based approach to surface treatment of glass fibre reinforced thermoplastic composites was explored to promote adhesion. Thermal. Bonding To Thermoplastic.

From www.researchgate.net

Manufacturing toughened thermoplastic tapes and bonding DCB samples Bonding To Thermoplastic In this review, we aim to provide a comprehensive overview of thermoplastic fabricating and bonding approaches, presenting their advantages and. Even low surface energy (lse) plastics, such as thermoplastic polyolefin (tpo), polypropylene (pp), and polyethylene (e.g. The designer must know which parameters are critical to the bond strengths achieved by a bonded joint and the effect that. Adhesive bonding of. Bonding To Thermoplastic.

From www.veryst.com

FTIR microscopy analysis of thermoplastic solvent bonding Veryst Bonding To Thermoplastic Even low surface energy (lse) plastics, such as thermoplastic polyolefin (tpo), polypropylene (pp), and polyethylene (e.g. Thermal fusion bonding (also called thermal bonding or thermopress bonding) is a process of sealing microfluidic devices by heating the. Thermal fusion bonding, and solvent bonding remain the most prevalent bonding methods applied to thermoplastic microfluidics, while the importance of adhesive. Adhesive bonding of. Bonding To Thermoplastic.

From www.mdpi.com

Micromachines Free FullText Bonding Strategies for Thermoplastics Bonding To Thermoplastic In this review, we aim to provide a comprehensive overview of thermoplastic fabricating and bonding approaches, presenting their advantages and. The designer must know which parameters are critical to the bond strengths achieved by a bonded joint and the effect that. Adhesive bonding of reinforced thermoplastic composites •a structural adhesive bond must be accomplished in a way that it predictably. Bonding To Thermoplastic.

From www.youtube.com

Thermoplastics and Thermosetting plastics Polymer Chemistry YouTube Bonding To Thermoplastic In this review, we aim to provide a comprehensive overview of thermoplastic fabricating and bonding approaches, presenting their advantages and. Even low surface energy (lse) plastics, such as thermoplastic polyolefin (tpo), polypropylene (pp), and polyethylene (e.g. The designer must know which parameters are critical to the bond strengths achieved by a bonded joint and the effect that. Adhesive bonding of. Bonding To Thermoplastic.

From www.mdpi.com

Polymers Free FullText Effect of Injection Overmolding Parameters Bonding To Thermoplastic Adhesive bonding of reinforced thermoplastic composites •a structural adhesive bond must be accomplished in a way that it predictably and. In this review, we aim to provide a comprehensive overview of thermoplastic fabricating and bonding approaches, presenting their advantages and. Thermal fusion bonding, and solvent bonding remain the most prevalent bonding methods applied to thermoplastic microfluidics, while the importance of. Bonding To Thermoplastic.

From www.researchgate.net

llustration of the thermoplastic infused metal foam as an intermediary Bonding To Thermoplastic Even low surface energy (lse) plastics, such as thermoplastic polyolefin (tpo), polypropylene (pp), and polyethylene (e.g. In this review, we aim to provide a comprehensive overview of thermoplastic fabricating and bonding approaches, presenting their advantages and. Thermal fusion bonding (also called thermal bonding or thermopress bonding) is a process of sealing microfluidic devices by heating the. Thermal fusion bonding, and. Bonding To Thermoplastic.

From www.linkedin.com

More sustainable Adhesive Bonding of Thermoplastic Composites Bonding To Thermoplastic Thermal fusion bonding, and solvent bonding remain the most prevalent bonding methods applied to thermoplastic microfluidics, while the importance of adhesive. Adhesive bonding of reinforced thermoplastic composites •a structural adhesive bond must be accomplished in a way that it predictably and. Thermal fusion bonding (also called thermal bonding or thermopress bonding) is a process of sealing microfluidic devices by heating. Bonding To Thermoplastic.

From www.adhesivespecialities.co.in

Thermosetting Rubber Adhesive Adhesive Specialities Bonding To Thermoplastic The designer must know which parameters are critical to the bond strengths achieved by a bonded joint and the effect that. A solution based approach to surface treatment of glass fibre reinforced thermoplastic composites was explored to promote adhesion. Even low surface energy (lse) plastics, such as thermoplastic polyolefin (tpo), polypropylene (pp), and polyethylene (e.g. Thermal fusion bonding (also called. Bonding To Thermoplastic.

From www.pinterest.com

Design Guide for Bonding Rubber & Thermoplastic Elastomers Design Bonding To Thermoplastic Even low surface energy (lse) plastics, such as thermoplastic polyolefin (tpo), polypropylene (pp), and polyethylene (e.g. In this review, we aim to provide a comprehensive overview of thermoplastic fabricating and bonding approaches, presenting their advantages and. A solution based approach to surface treatment of glass fibre reinforced thermoplastic composites was explored to promote adhesion. Adhesive bonding of reinforced thermoplastic composites. Bonding To Thermoplastic.

From www.slideshare.net

Plastic Bonding To Thermoplastic Even low surface energy (lse) plastics, such as thermoplastic polyolefin (tpo), polypropylene (pp), and polyethylene (e.g. A solution based approach to surface treatment of glass fibre reinforced thermoplastic composites was explored to promote adhesion. Adhesive bonding of reinforced thermoplastic composites •a structural adhesive bond must be accomplished in a way that it predictably and. Thermal fusion bonding, and solvent bonding. Bonding To Thermoplastic.

From www.researchgate.net

SEM micrographs showing bonding of thermoplastic polymer (up Bonding To Thermoplastic Thermal fusion bonding (also called thermal bonding or thermopress bonding) is a process of sealing microfluidic devices by heating the. Thermal fusion bonding, and solvent bonding remain the most prevalent bonding methods applied to thermoplastic microfluidics, while the importance of adhesive. A solution based approach to surface treatment of glass fibre reinforced thermoplastic composites was explored to promote adhesion. In. Bonding To Thermoplastic.

From www.semanticscholar.org

Figure 1 from Facile Patterning of Thermoplastic Elastomers and Robust Bonding To Thermoplastic Thermal fusion bonding, and solvent bonding remain the most prevalent bonding methods applied to thermoplastic microfluidics, while the importance of adhesive. The designer must know which parameters are critical to the bond strengths achieved by a bonded joint and the effect that. Adhesive bonding of reinforced thermoplastic composites •a structural adhesive bond must be accomplished in a way that it. Bonding To Thermoplastic.

From www.semanticscholar.org

Figure 1 from Chemicalassisted bonding of thermoplastics/elastomer for Bonding To Thermoplastic Adhesive bonding of reinforced thermoplastic composites •a structural adhesive bond must be accomplished in a way that it predictably and. A solution based approach to surface treatment of glass fibre reinforced thermoplastic composites was explored to promote adhesion. Thermal fusion bonding, and solvent bonding remain the most prevalent bonding methods applied to thermoplastic microfluidics, while the importance of adhesive. Thermal. Bonding To Thermoplastic.

From blogs.rsc.org

The Name is Bond Heat Bond Using a Heated Lamination Press for Bonding To Thermoplastic Thermal fusion bonding (also called thermal bonding or thermopress bonding) is a process of sealing microfluidic devices by heating the. In this review, we aim to provide a comprehensive overview of thermoplastic fabricating and bonding approaches, presenting their advantages and. The designer must know which parameters are critical to the bond strengths achieved by a bonded joint and the effect. Bonding To Thermoplastic.

From www.protechnic.fr

What are the adhesive solutions for shoe bonding ? Sustainable dry Bonding To Thermoplastic The designer must know which parameters are critical to the bond strengths achieved by a bonded joint and the effect that. Thermal fusion bonding, and solvent bonding remain the most prevalent bonding methods applied to thermoplastic microfluidics, while the importance of adhesive. Thermal fusion bonding (also called thermal bonding or thermopress bonding) is a process of sealing microfluidic devices by. Bonding To Thermoplastic.

From www.mdpi.com

Micromachines Free FullText Recent Advances in Thermoplastic Bonding To Thermoplastic Even low surface energy (lse) plastics, such as thermoplastic polyolefin (tpo), polypropylene (pp), and polyethylene (e.g. In this review, we aim to provide a comprehensive overview of thermoplastic fabricating and bonding approaches, presenting their advantages and. Adhesive bonding of reinforced thermoplastic composites •a structural adhesive bond must be accomplished in a way that it predictably and. The designer must know. Bonding To Thermoplastic.

From www.starthermoplastics.com

Bonding TPE to Polyamides Star Thermoplastics Bonding To Thermoplastic In this review, we aim to provide a comprehensive overview of thermoplastic fabricating and bonding approaches, presenting their advantages and. Thermal fusion bonding (also called thermal bonding or thermopress bonding) is a process of sealing microfluidic devices by heating the. A solution based approach to surface treatment of glass fibre reinforced thermoplastic composites was explored to promote adhesion. Even low. Bonding To Thermoplastic.

From www.mdpi.com

Micromachines Free FullText Rapid Fabrication of Membrane Bonding To Thermoplastic Thermal fusion bonding, and solvent bonding remain the most prevalent bonding methods applied to thermoplastic microfluidics, while the importance of adhesive. The designer must know which parameters are critical to the bond strengths achieved by a bonded joint and the effect that. Thermal fusion bonding (also called thermal bonding or thermopress bonding) is a process of sealing microfluidic devices by. Bonding To Thermoplastic.

From www.vem-tooling.com

Thermoplastics vs. Thermosets Bonding To Thermoplastic A solution based approach to surface treatment of glass fibre reinforced thermoplastic composites was explored to promote adhesion. Adhesive bonding of reinforced thermoplastic composites •a structural adhesive bond must be accomplished in a way that it predictably and. In this review, we aim to provide a comprehensive overview of thermoplastic fabricating and bonding approaches, presenting their advantages and. Thermal fusion. Bonding To Thermoplastic.

From www.researchgate.net

Manufacturing toughened thermoplastic tapes and bonding DCB samples Bonding To Thermoplastic In this review, we aim to provide a comprehensive overview of thermoplastic fabricating and bonding approaches, presenting their advantages and. Thermal fusion bonding (also called thermal bonding or thermopress bonding) is a process of sealing microfluidic devices by heating the. Adhesive bonding of reinforced thermoplastic composites •a structural adhesive bond must be accomplished in a way that it predictably and.. Bonding To Thermoplastic.

From www.veryst.com

FTIR microscopy analysis of thermoplastic solvent bonding Veryst Bonding To Thermoplastic Adhesive bonding of reinforced thermoplastic composites •a structural adhesive bond must be accomplished in a way that it predictably and. In this review, we aim to provide a comprehensive overview of thermoplastic fabricating and bonding approaches, presenting their advantages and. A solution based approach to surface treatment of glass fibre reinforced thermoplastic composites was explored to promote adhesion. Thermal fusion. Bonding To Thermoplastic.