Rivet Head Definition . A rivet consists of a head at one end and a cylindrical body at the other end, called its shaft. Universal head rivets serve as a versatile option, designed to replace various rivet styles. They are simple to use and reliable, made typically of. Their head shape is a. A rivet is a popular mechanical fastener to join two or more materials. A standard riveting process involves inserting the rivet into the rivet hole from the top end of the workpieces, and a rivet head. Often referred to as round rivets, solid rivets are the oldest and most widely utilized form of rivet. The meaning of rivet is a headed pin or bolt of metal used for uniting two or more pieces by passing the shank through a hole in each piece. A rivet is a permanent mechanical fastener consisting of a head at one end and a cylindrical stem at the other end (called the tail) which has. Definition and types of rivet. A rivet is a permanent mechanical fastener consisting of a smooth cylindrical shaft with a.

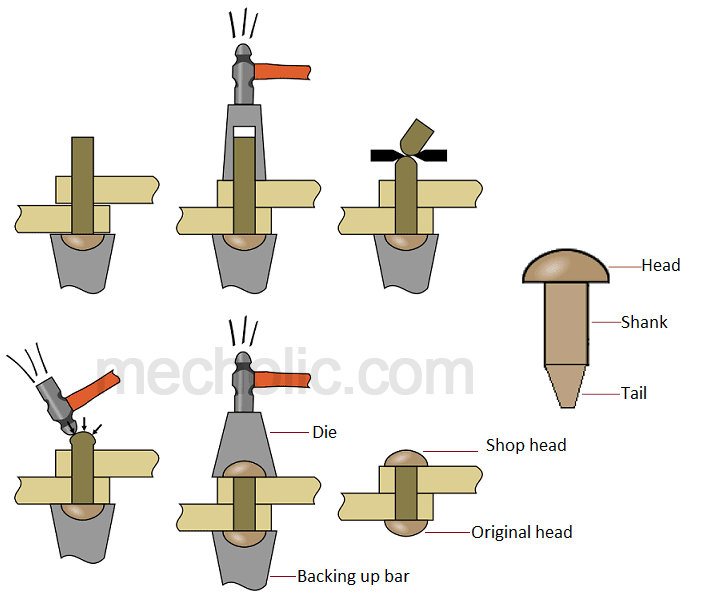

from www.mecholic.com

A standard riveting process involves inserting the rivet into the rivet hole from the top end of the workpieces, and a rivet head. A rivet is a permanent mechanical fastener consisting of a head at one end and a cylindrical stem at the other end (called the tail) which has. A rivet is a popular mechanical fastener to join two or more materials. The meaning of rivet is a headed pin or bolt of metal used for uniting two or more pieces by passing the shank through a hole in each piece. A rivet is a permanent mechanical fastener consisting of a smooth cylindrical shaft with a. A rivet consists of a head at one end and a cylindrical body at the other end, called its shaft. Often referred to as round rivets, solid rivets are the oldest and most widely utilized form of rivet. Universal head rivets serve as a versatile option, designed to replace various rivet styles. They are simple to use and reliable, made typically of. Definition and types of rivet.

riveting material joining process

Rivet Head Definition A standard riveting process involves inserting the rivet into the rivet hole from the top end of the workpieces, and a rivet head. A rivet is a permanent mechanical fastener consisting of a head at one end and a cylindrical stem at the other end (called the tail) which has. Universal head rivets serve as a versatile option, designed to replace various rivet styles. Definition and types of rivet. They are simple to use and reliable, made typically of. The meaning of rivet is a headed pin or bolt of metal used for uniting two or more pieces by passing the shank through a hole in each piece. A rivet is a popular mechanical fastener to join two or more materials. A rivet consists of a head at one end and a cylindrical body at the other end, called its shaft. A standard riveting process involves inserting the rivet into the rivet hole from the top end of the workpieces, and a rivet head. A rivet is a permanent mechanical fastener consisting of a smooth cylindrical shaft with a. Often referred to as round rivets, solid rivets are the oldest and most widely utilized form of rivet. Their head shape is a.

From ecoursesonline.iasri.res.in

D&S_1 LESSON 5. Riveted Connections Rivet Head Definition Definition and types of rivet. A rivet is a popular mechanical fastener to join two or more materials. A standard riveting process involves inserting the rivet into the rivet hole from the top end of the workpieces, and a rivet head. Often referred to as round rivets, solid rivets are the oldest and most widely utilized form of rivet. Their. Rivet Head Definition.

From www.etsy.com

MEDIUM Faux rivet heads made to order Etsy Rivet Head Definition A rivet is a permanent mechanical fastener consisting of a head at one end and a cylindrical stem at the other end (called the tail) which has. Universal head rivets serve as a versatile option, designed to replace various rivet styles. Definition and types of rivet. Their head shape is a. The meaning of rivet is a headed pin or. Rivet Head Definition.

From www.harborfreight.com

Hand Riveter Set Rivet Head Definition A rivet is a permanent mechanical fastener consisting of a smooth cylindrical shaft with a. Universal head rivets serve as a versatile option, designed to replace various rivet styles. A rivet is a popular mechanical fastener to join two or more materials. A rivet consists of a head at one end and a cylindrical body at the other end, called. Rivet Head Definition.

From qbhmetal.com

Types of Rivets_A Guide to Rivet Types and Their Common Uses Rivet Head Definition A rivet is a permanent mechanical fastener consisting of a head at one end and a cylindrical stem at the other end (called the tail) which has. A rivet consists of a head at one end and a cylindrical body at the other end, called its shaft. A rivet is a permanent mechanical fastener consisting of a smooth cylindrical shaft. Rivet Head Definition.

From www.aiophotoz.com

What Is A Rivet How Is Riveting Done Riveting Definition Types Images Rivet Head Definition They are simple to use and reliable, made typically of. A rivet is a permanent mechanical fastener consisting of a smooth cylindrical shaft with a. Their head shape is a. The meaning of rivet is a headed pin or bolt of metal used for uniting two or more pieces by passing the shank through a hole in each piece. A. Rivet Head Definition.

From c-est-quoi.fr

rivet définition C'est quoi Rivet Head Definition Often referred to as round rivets, solid rivets are the oldest and most widely utilized form of rivet. Their head shape is a. A rivet is a permanent mechanical fastener consisting of a smooth cylindrical shaft with a. The meaning of rivet is a headed pin or bolt of metal used for uniting two or more pieces by passing the. Rivet Head Definition.

From www.alamy.com

screw, bolt, rivet head collection isolated on white with various light Rivet Head Definition Their head shape is a. A rivet is a permanent mechanical fastener consisting of a head at one end and a cylindrical stem at the other end (called the tail) which has. Often referred to as round rivets, solid rivets are the oldest and most widely utilized form of rivet. A rivet consists of a head at one end and. Rivet Head Definition.

From www.madearia.com

The Different Types of Rivets and Their Uses Rivet Head Definition Often referred to as round rivets, solid rivets are the oldest and most widely utilized form of rivet. The meaning of rivet is a headed pin or bolt of metal used for uniting two or more pieces by passing the shank through a hole in each piece. A rivet consists of a head at one end and a cylindrical body. Rivet Head Definition.

From depositphotos.com

Rivet heads isolated — Stock Photo © tuja66 168943404 Rivet Head Definition Definition and types of rivet. A rivet is a permanent mechanical fastener consisting of a smooth cylindrical shaft with a. A rivet is a popular mechanical fastener to join two or more materials. The meaning of rivet is a headed pin or bolt of metal used for uniting two or more pieces by passing the shank through a hole in. Rivet Head Definition.

From www.rivetsonline.com

Rivet Identification Chart Rivet Head Styles and Markings JayCee Rivet Head Definition A rivet consists of a head at one end and a cylindrical body at the other end, called its shaft. Often referred to as round rivets, solid rivets are the oldest and most widely utilized form of rivet. Their head shape is a. A rivet is a permanent mechanical fastener consisting of a smooth cylindrical shaft with a. A rivet. Rivet Head Definition.

From engistudies.blogspot.com

Different Types, Advantages, and Disadvantages of Riveted joint Rivet Head Definition A rivet is a permanent mechanical fastener consisting of a smooth cylindrical shaft with a. The meaning of rivet is a headed pin or bolt of metal used for uniting two or more pieces by passing the shank through a hole in each piece. Often referred to as round rivets, solid rivets are the oldest and most widely utilized form. Rivet Head Definition.

From www.vrogue.co

What Is A Rivet And How Do They Work Definition And M vrogue.co Rivet Head Definition The meaning of rivet is a headed pin or bolt of metal used for uniting two or more pieces by passing the shank through a hole in each piece. They are simple to use and reliable, made typically of. A rivet is a permanent mechanical fastener consisting of a head at one end and a cylindrical stem at the other. Rivet Head Definition.

From giolfzuht.blob.core.windows.net

Rivet Meaning In English Tamil at Dorothy Dunbar blog Rivet Head Definition A rivet is a popular mechanical fastener to join two or more materials. The meaning of rivet is a headed pin or bolt of metal used for uniting two or more pieces by passing the shank through a hole in each piece. A standard riveting process involves inserting the rivet into the rivet hole from the top end of the. Rivet Head Definition.

From types.blog

Types of Rivet Heads Shapes, Materials & Industry Uses Rivet Head Definition A rivet is a permanent mechanical fastener consisting of a head at one end and a cylindrical stem at the other end (called the tail) which has. They are simple to use and reliable, made typically of. Their head shape is a. Often referred to as round rivets, solid rivets are the oldest and most widely utilized form of rivet.. Rivet Head Definition.

From www.youtube.com

Aviation Maintenance Lesson VII Rivets YouTube Rivet Head Definition A rivet consists of a head at one end and a cylindrical body at the other end, called its shaft. Their head shape is a. A rivet is a permanent mechanical fastener consisting of a smooth cylindrical shaft with a. Definition and types of rivet. Universal head rivets serve as a versatile option, designed to replace various rivet styles. The. Rivet Head Definition.

From www.bigstockphoto.com

Rivet Heads Isolated Image & Photo (Free Trial) Bigstock Rivet Head Definition The meaning of rivet is a headed pin or bolt of metal used for uniting two or more pieces by passing the shank through a hole in each piece. A rivet is a permanent mechanical fastener consisting of a head at one end and a cylindrical stem at the other end (called the tail) which has. A rivet is a. Rivet Head Definition.

From www.alamy.com

Rivet heads hires stock photography and images Alamy Rivet Head Definition A rivet is a permanent mechanical fastener consisting of a head at one end and a cylindrical stem at the other end (called the tail) which has. Often referred to as round rivets, solid rivets are the oldest and most widely utilized form of rivet. Their head shape is a. A standard riveting process involves inserting the rivet into the. Rivet Head Definition.

From atelier-yuwa.ciao.jp

Rivet Types And Identification atelieryuwa.ciao.jp Rivet Head Definition A rivet is a permanent mechanical fastener consisting of a smooth cylindrical shaft with a. Their head shape is a. A standard riveting process involves inserting the rivet into the rivet hole from the top end of the workpieces, and a rivet head. A rivet is a permanent mechanical fastener consisting of a head at one end and a cylindrical. Rivet Head Definition.

From www.youtube.com

Aircraft Rivets From Rapid Rivet & Fastener Corp. YouTube Rivet Head Definition Definition and types of rivet. A rivet is a permanent mechanical fastener consisting of a head at one end and a cylindrical stem at the other end (called the tail) which has. The meaning of rivet is a headed pin or bolt of metal used for uniting two or more pieces by passing the shank through a hole in each. Rivet Head Definition.

From www.alibaba.com

Stainless Steel Double Rivet Double Head Rivet For Garment Buy Rivet Rivet Head Definition The meaning of rivet is a headed pin or bolt of metal used for uniting two or more pieces by passing the shank through a hole in each piece. A rivet consists of a head at one end and a cylindrical body at the other end, called its shaft. Universal head rivets serve as a versatile option, designed to replace. Rivet Head Definition.

From www.smartvocab.in

Define Rivet, Rivet Meaning, Rivet Examples, Rivet Synonyms, Rivet Rivet Head Definition A rivet is a popular mechanical fastener to join two or more materials. The meaning of rivet is a headed pin or bolt of metal used for uniting two or more pieces by passing the shank through a hole in each piece. Often referred to as round rivets, solid rivets are the oldest and most widely utilized form of rivet.. Rivet Head Definition.

From blog.austinhardware.com

The Austin Hardware® Guide to Blind Rivets, Part One Rivet Head Definition A rivet is a permanent mechanical fastener consisting of a head at one end and a cylindrical stem at the other end (called the tail) which has. A rivet is a popular mechanical fastener to join two or more materials. Often referred to as round rivets, solid rivets are the oldest and most widely utilized form of rivet. A standard. Rivet Head Definition.

From extrudesign.com

What are the types of Rivet Heads according to the Indian Standards? Rivet Head Definition Their head shape is a. A rivet is a permanent mechanical fastener consisting of a smooth cylindrical shaft with a. They are simple to use and reliable, made typically of. A rivet is a popular mechanical fastener to join two or more materials. Often referred to as round rivets, solid rivets are the oldest and most widely utilized form of. Rivet Head Definition.

From www.youtube.com

How to Rivet (Basic Explanation & Demonstration) YouTube Rivet Head Definition Universal head rivets serve as a versatile option, designed to replace various rivet styles. A rivet is a permanent mechanical fastener consisting of a head at one end and a cylindrical stem at the other end (called the tail) which has. A rivet consists of a head at one end and a cylindrical body at the other end, called its. Rivet Head Definition.

From www.mech4study.com

What is rivet? What are main types of rivets? mech4study Rivet Head Definition A rivet is a permanent mechanical fastener consisting of a head at one end and a cylindrical stem at the other end (called the tail) which has. They are simple to use and reliable, made typically of. Definition and types of rivet. The meaning of rivet is a headed pin or bolt of metal used for uniting two or more. Rivet Head Definition.

From engineeringlearn.com

Types of Rivets and Their Uses [with Pictures & Names] Engineering Learn Rivet Head Definition Their head shape is a. A rivet is a permanent mechanical fastener consisting of a smooth cylindrical shaft with a. Often referred to as round rivets, solid rivets are the oldest and most widely utilized form of rivet. They are simple to use and reliable, made typically of. A rivet is a permanent mechanical fastener consisting of a head at. Rivet Head Definition.

From www.youtube.com

Symbolic Representation of RIVETS in Engineering Drawing/What is Rivet Rivet Head Definition A rivet is a permanent mechanical fastener consisting of a smooth cylindrical shaft with a. A rivet is a permanent mechanical fastener consisting of a head at one end and a cylindrical stem at the other end (called the tail) which has. Universal head rivets serve as a versatile option, designed to replace various rivet styles. A rivet consists of. Rivet Head Definition.

From www.youtube.com

A StepByStep Guide on How to Use POP Rivets Fasteners 101 YouTube Rivet Head Definition Universal head rivets serve as a versatile option, designed to replace various rivet styles. Definition and types of rivet. Often referred to as round rivets, solid rivets are the oldest and most widely utilized form of rivet. The meaning of rivet is a headed pin or bolt of metal used for uniting two or more pieces by passing the shank. Rivet Head Definition.

From www.kemikon.com

rivet styles OFF 63 Online Shopping Site for Fashion & Lifestyle. Rivet Head Definition They are simple to use and reliable, made typically of. A rivet is a popular mechanical fastener to join two or more materials. Often referred to as round rivets, solid rivets are the oldest and most widely utilized form of rivet. A standard riveting process involves inserting the rivet into the rivet hole from the top end of the workpieces,. Rivet Head Definition.

From www.alibaba.com

Stainless Steel Double Rivet Double Head Rivet For Garment Buy Rivet Rivet Head Definition The meaning of rivet is a headed pin or bolt of metal used for uniting two or more pieces by passing the shank through a hole in each piece. Universal head rivets serve as a versatile option, designed to replace various rivet styles. Definition and types of rivet. They are simple to use and reliable, made typically of. A rivet. Rivet Head Definition.

From www.mecholic.com

riveting material joining process Rivet Head Definition A rivet consists of a head at one end and a cylindrical body at the other end, called its shaft. A standard riveting process involves inserting the rivet into the rivet hole from the top end of the workpieces, and a rivet head. A rivet is a permanent mechanical fastener consisting of a smooth cylindrical shaft with a. Their head. Rivet Head Definition.

From www.vrogue.co

Types Of Rivets And Their Uses Rivets Definition Type vrogue.co Rivet Head Definition They are simple to use and reliable, made typically of. Universal head rivets serve as a versatile option, designed to replace various rivet styles. A rivet is a popular mechanical fastener to join two or more materials. Definition and types of rivet. The meaning of rivet is a headed pin or bolt of metal used for uniting two or more. Rivet Head Definition.

From www.vrogue.co

What Is A Rivet And How Do They Work Definition And M vrogue.co Rivet Head Definition Often referred to as round rivets, solid rivets are the oldest and most widely utilized form of rivet. Their head shape is a. A rivet is a permanent mechanical fastener consisting of a head at one end and a cylindrical stem at the other end (called the tail) which has. A rivet is a permanent mechanical fastener consisting of a. Rivet Head Definition.

From extrudesign.com

What are the types of Rivet Heads according to the Indian Standards? Rivet Head Definition A standard riveting process involves inserting the rivet into the rivet hole from the top end of the workpieces, and a rivet head. Universal head rivets serve as a versatile option, designed to replace various rivet styles. A rivet is a popular mechanical fastener to join two or more materials. Often referred to as round rivets, solid rivets are the. Rivet Head Definition.

From www.jcfasteners.com

CSK Blind Rivets J C Gupta & Sons Rivet Head Definition A rivet is a permanent mechanical fastener consisting of a head at one end and a cylindrical stem at the other end (called the tail) which has. The meaning of rivet is a headed pin or bolt of metal used for uniting two or more pieces by passing the shank through a hole in each piece. A rivet consists of. Rivet Head Definition.