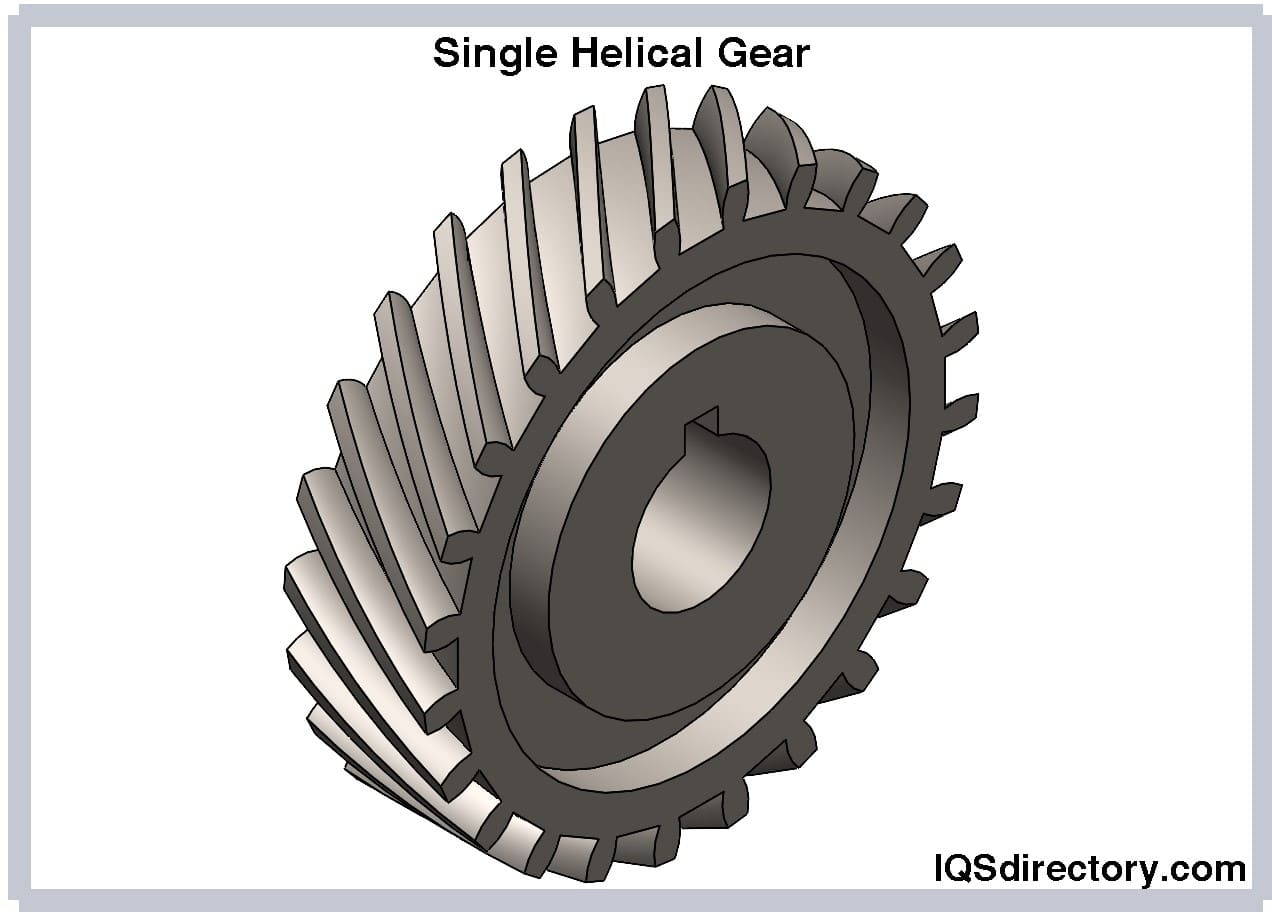

Gears Helical Gears . They are also used in applications that require high. A helical gear is a type of cylindrical gear on which the teeth are helicoid, that has teeth that are cut at an angle to the axis of rotation. Helical gears have similarities with spur gears, but fundamental differences do exist. Helical gears have a smoother operation due to the angle twist creating instant contact with the gear teeth. A helical gear is similar to a spur gear with an applied twist. They are classified into two main types: The main difference between straight cut gears and helical gears is their tooth design and resulting performance. Helical gears are primarily used to enhance torque and reduce speed between rotating shafts. The teeth on a helical gear cut at an angle to the face of the gear. Since the teeth engage more gradually, they have a smoother and quieter operation than spur gears. Helical gears have teeth that are set on an angle to the gear axis. Those that transmit mechanical energy between.

from www.iqsdirectory.com

Helical gears are primarily used to enhance torque and reduce speed between rotating shafts. Helical gears have similarities with spur gears, but fundamental differences do exist. They are also used in applications that require high. They are classified into two main types: Helical gears have teeth that are set on an angle to the gear axis. Since the teeth engage more gradually, they have a smoother and quieter operation than spur gears. Those that transmit mechanical energy between. The teeth on a helical gear cut at an angle to the face of the gear. Helical gears have a smoother operation due to the angle twist creating instant contact with the gear teeth. The main difference between straight cut gears and helical gears is their tooth design and resulting performance.

Types of Gears Design, Types, Applications, and Materials

Gears Helical Gears Helical gears have a smoother operation due to the angle twist creating instant contact with the gear teeth. A helical gear is a type of cylindrical gear on which the teeth are helicoid, that has teeth that are cut at an angle to the axis of rotation. They are also used in applications that require high. Since the teeth engage more gradually, they have a smoother and quieter operation than spur gears. Helical gears have a smoother operation due to the angle twist creating instant contact with the gear teeth. Helical gears have similarities with spur gears, but fundamental differences do exist. They are classified into two main types: Helical gears are primarily used to enhance torque and reduce speed between rotating shafts. A helical gear is similar to a spur gear with an applied twist. Helical gears have teeth that are set on an angle to the gear axis. The main difference between straight cut gears and helical gears is their tooth design and resulting performance. Those that transmit mechanical energy between. The teeth on a helical gear cut at an angle to the face of the gear.

From www.reddit.com

Types of Gears r/coolguides Gears Helical Gears They are classified into two main types: The teeth on a helical gear cut at an angle to the face of the gear. The main difference between straight cut gears and helical gears is their tooth design and resulting performance. Those that transmit mechanical energy between. A helical gear is a type of cylindrical gear on which the teeth are. Gears Helical Gears.

From www.difference.minaprem.com

Difference Between Single Helical Gear and Double Helical Gear Gears Helical Gears Those that transmit mechanical energy between. Helical gears have similarities with spur gears, but fundamental differences do exist. A helical gear is a type of cylindrical gear on which the teeth are helicoid, that has teeth that are cut at an angle to the axis of rotation. They are classified into two main types: The teeth on a helical gear. Gears Helical Gears.

From www.geartechnology.com

Back to Basics Helical Gears Gear Talk With Chuck Gear Technology Gears Helical Gears The main difference between straight cut gears and helical gears is their tooth design and resulting performance. They are classified into two main types: Helical gears have teeth that are set on an angle to the gear axis. They are also used in applications that require high. The teeth on a helical gear cut at an angle to the face. Gears Helical Gears.

From www.iqsdirectory.com

Types of Gears Design, Types, Applications, and Materials Gears Helical Gears Helical gears have teeth that are set on an angle to the gear axis. Since the teeth engage more gradually, they have a smoother and quieter operation than spur gears. The teeth on a helical gear cut at an angle to the face of the gear. Helical gears have a smoother operation due to the angle twist creating instant contact. Gears Helical Gears.

From durston.com

Set of Side Helical Gears for DRM 130, Agile 130 and DRM 150 Durston Gears Helical Gears Helical gears have similarities with spur gears, but fundamental differences do exist. A helical gear is a type of cylindrical gear on which the teeth are helicoid, that has teeth that are cut at an angle to the axis of rotation. Since the teeth engage more gradually, they have a smoother and quieter operation than spur gears. They are also. Gears Helical Gears.

From www.eedtransmission.com

Helical Gear Manufacturers EED Transmission Gears Helical Gears Helical gears have teeth that are set on an angle to the gear axis. Helical gears are primarily used to enhance torque and reduce speed between rotating shafts. The main difference between straight cut gears and helical gears is their tooth design and resulting performance. They are also used in applications that require high. Those that transmit mechanical energy between.. Gears Helical Gears.

From premium-transmission.com

What you need to know about Helical Gearboxes? Premium Transmission Gears Helical Gears Helical gears have similarities with spur gears, but fundamental differences do exist. A helical gear is a type of cylindrical gear on which the teeth are helicoid, that has teeth that are cut at an angle to the axis of rotation. Since the teeth engage more gradually, they have a smoother and quieter operation than spur gears. Those that transmit. Gears Helical Gears.

From ringgears.net

Double Helical Gear Minghua MH GEAR Gears Helical Gears The main difference between straight cut gears and helical gears is their tooth design and resulting performance. Helical gears are primarily used to enhance torque and reduce speed between rotating shafts. They are also used in applications that require high. Helical gears have similarities with spur gears, but fundamental differences do exist. Helical gears have a smoother operation due to. Gears Helical Gears.

From www.iqsdirectory.com

Helical Gear What Are They? Types, Uses & Considerations Gears Helical Gears The main difference between straight cut gears and helical gears is their tooth design and resulting performance. Those that transmit mechanical energy between. A helical gear is similar to a spur gear with an applied twist. They are also used in applications that require high. The teeth on a helical gear cut at an angle to the face of the. Gears Helical Gears.

From www.iqsdirectory.com

Helical Gear What Are They? Types, Uses & Considerations Gears Helical Gears Since the teeth engage more gradually, they have a smoother and quieter operation than spur gears. Helical gears have teeth that are set on an angle to the gear axis. The main difference between straight cut gears and helical gears is their tooth design and resulting performance. The teeth on a helical gear cut at an angle to the face. Gears Helical Gears.

From mtgear.com.my

HELICAL GEAR MT Gear Gears Helical Gears A helical gear is similar to a spur gear with an applied twist. Helical gears have a smoother operation due to the angle twist creating instant contact with the gear teeth. The teeth on a helical gear cut at an angle to the face of the gear. The main difference between straight cut gears and helical gears is their tooth. Gears Helical Gears.

From www.iqsdirectory.com

Types of Gears Design, Types, Applications, and Materials Gears Helical Gears A helical gear is a type of cylindrical gear on which the teeth are helicoid, that has teeth that are cut at an angle to the axis of rotation. Helical gears have teeth that are set on an angle to the gear axis. They are classified into two main types: They are also used in applications that require high. The. Gears Helical Gears.

From news.thomasnet.com

Helical Gears Gears Helical Gears Those that transmit mechanical energy between. They are also used in applications that require high. They are classified into two main types: The teeth on a helical gear cut at an angle to the face of the gear. Helical gears have teeth that are set on an angle to the gear axis. Helical gears are primarily used to enhance torque. Gears Helical Gears.

From www.mrosupply.com

Advantages and Disadvantages of Helical Gears Gears Helical Gears Helical gears are primarily used to enhance torque and reduce speed between rotating shafts. The main difference between straight cut gears and helical gears is their tooth design and resulting performance. Helical gears have a smoother operation due to the angle twist creating instant contact with the gear teeth. Those that transmit mechanical energy between. They are classified into two. Gears Helical Gears.

From www.rempco.com

Helical Gears Rempco Rempco Gears Helical Gears Helical gears have a smoother operation due to the angle twist creating instant contact with the gear teeth. Helical gears are primarily used to enhance torque and reduce speed between rotating shafts. Those that transmit mechanical energy between. Since the teeth engage more gradually, they have a smoother and quieter operation than spur gears. They are classified into two main. Gears Helical Gears.

From mechtecheducation.blogspot.com

Parallel Helical Gear Vs Crossed Helical Gear Gears Helical Gears The main difference between straight cut gears and helical gears is their tooth design and resulting performance. They are classified into two main types: Helical gears have a smoother operation due to the angle twist creating instant contact with the gear teeth. Helical gears have similarities with spur gears, but fundamental differences do exist. Helical gears are primarily used to. Gears Helical Gears.

From www.mechanicalbooster.com

Types of Gears Spur Gear, Helical Gear, Bevel Gear etc. Mechanical Gears Helical Gears Since the teeth engage more gradually, they have a smoother and quieter operation than spur gears. Helical gears are primarily used to enhance torque and reduce speed between rotating shafts. A helical gear is similar to a spur gear with an applied twist. The teeth on a helical gear cut at an angle to the face of the gear. They. Gears Helical Gears.

From www.iqsdirectory.com

Helical Gear What Are They? Types, Uses & Considerations Gears Helical Gears Helical gears have similarities with spur gears, but fundamental differences do exist. Helical gears are primarily used to enhance torque and reduce speed between rotating shafts. A helical gear is similar to a spur gear with an applied twist. Helical gears have teeth that are set on an angle to the gear axis. Those that transmit mechanical energy between. The. Gears Helical Gears.

From www.iqsdirectory.com

Helical Gear What Are They? Types, Uses & Considerations Gears Helical Gears A helical gear is similar to a spur gear with an applied twist. They are also used in applications that require high. Since the teeth engage more gradually, they have a smoother and quieter operation than spur gears. Helical gears have similarities with spur gears, but fundamental differences do exist. Helical gears have a smoother operation due to the angle. Gears Helical Gears.

From www.scribd.com

Helical Gears Gear Kinematics Gears Helical Gears Helical gears have similarities with spur gears, but fundamental differences do exist. Helical gears have a smoother operation due to the angle twist creating instant contact with the gear teeth. The main difference between straight cut gears and helical gears is their tooth design and resulting performance. They are classified into two main types: A helical gear is a type. Gears Helical Gears.

From www.iqsdirectory.com

Helical Gear What Are They? Types, Uses & Considerations Gears Helical Gears Since the teeth engage more gradually, they have a smoother and quieter operation than spur gears. The main difference between straight cut gears and helical gears is their tooth design and resulting performance. Helical gears are primarily used to enhance torque and reduce speed between rotating shafts. Helical gears have a smoother operation due to the angle twist creating instant. Gears Helical Gears.

From www.drivetrainhub.com

Helical Gears Geometry of helical gears and gear meshes Gears Helical Gears A helical gear is a type of cylindrical gear on which the teeth are helicoid, that has teeth that are cut at an angle to the axis of rotation. Helical gears have similarities with spur gears, but fundamental differences do exist. Helical gears have a smoother operation due to the angle twist creating instant contact with the gear teeth. They. Gears Helical Gears.

From www.difference.minaprem.com

Difference Between Spur Gear and Helical Gear Gears Helical Gears Helical gears have teeth that are set on an angle to the gear axis. Helical gears are primarily used to enhance torque and reduce speed between rotating shafts. A helical gear is a type of cylindrical gear on which the teeth are helicoid, that has teeth that are cut at an angle to the axis of rotation. A helical gear. Gears Helical Gears.

From hi-techgears.com

Helical HiTech Gears Gears Helical Gears They are also used in applications that require high. Helical gears have similarities with spur gears, but fundamental differences do exist. A helical gear is a type of cylindrical gear on which the teeth are helicoid, that has teeth that are cut at an angle to the axis of rotation. Helical gears have teeth that are set on an angle. Gears Helical Gears.

From www.iqsdirectory.com

Helical Gear What Are They? Types, Uses & Considerations Gears Helical Gears The main difference between straight cut gears and helical gears is their tooth design and resulting performance. Helical gears have a smoother operation due to the angle twist creating instant contact with the gear teeth. They are also used in applications that require high. A helical gear is a type of cylindrical gear on which the teeth are helicoid, that. Gears Helical Gears.

From www.iqsdirectory.com

Helical Gear What Are They? Types, Uses & Considerations Gears Helical Gears A helical gear is similar to a spur gear with an applied twist. Helical gears have similarities with spur gears, but fundamental differences do exist. A helical gear is a type of cylindrical gear on which the teeth are helicoid, that has teeth that are cut at an angle to the axis of rotation. Helical gears are primarily used to. Gears Helical Gears.

From vestavia.eu

helical gear making Gears Helical Gears The main difference between straight cut gears and helical gears is their tooth design and resulting performance. Helical gears have a smoother operation due to the angle twist creating instant contact with the gear teeth. Helical gears are primarily used to enhance torque and reduce speed between rotating shafts. Those that transmit mechanical energy between. The teeth on a helical. Gears Helical Gears.

From www.youtube.com

Tutorial How to Model Screw (Crossed Helical) Gears in Blender YouTube Gears Helical Gears Since the teeth engage more gradually, they have a smoother and quieter operation than spur gears. Helical gears are primarily used to enhance torque and reduce speed between rotating shafts. Those that transmit mechanical energy between. Helical gears have similarities with spur gears, but fundamental differences do exist. The teeth on a helical gear cut at an angle to the. Gears Helical Gears.

From ycgear.en.made-in-china.com

Customized High Precision Alloy Steel Bevel Gear/Helical Gear Gear Gears Helical Gears They are classified into two main types: Helical gears have similarities with spur gears, but fundamental differences do exist. Since the teeth engage more gradually, they have a smoother and quieter operation than spur gears. Helical gears have a smoother operation due to the angle twist creating instant contact with the gear teeth. The teeth on a helical gear cut. Gears Helical Gears.

From www.iqsdirectory.com

Helical Gear What Are They? Types, Uses & Considerations Gears Helical Gears Helical gears have teeth that are set on an angle to the gear axis. Those that transmit mechanical energy between. Since the teeth engage more gradually, they have a smoother and quieter operation than spur gears. Helical gears are primarily used to enhance torque and reduce speed between rotating shafts. Helical gears have similarities with spur gears, but fundamental differences. Gears Helical Gears.

From www.rapiddirect.com

Gear Manufacturing 101 A Comolete Guide on Gear Production Processes Gears Helical Gears A helical gear is similar to a spur gear with an applied twist. The main difference between straight cut gears and helical gears is their tooth design and resulting performance. The teeth on a helical gear cut at an angle to the face of the gear. Helical gears have teeth that are set on an angle to the gear axis.. Gears Helical Gears.

From www.iqsdirectory.com

Gear Drive What Is It? Types, Uses, Components, Design Gears Helical Gears They are also used in applications that require high. Helical gears have a smoother operation due to the angle twist creating instant contact with the gear teeth. Helical gears are primarily used to enhance torque and reduce speed between rotating shafts. Helical gears have similarities with spur gears, but fundamental differences do exist. Since the teeth engage more gradually, they. Gears Helical Gears.

From www.drivetrainhub.com

Helical Gears Geometry of helical gears and gear meshes Gears Helical Gears Helical gears have similarities with spur gears, but fundamental differences do exist. They are classified into two main types: Helical gears have teeth that are set on an angle to the gear axis. They are also used in applications that require high. A helical gear is similar to a spur gear with an applied twist. Helical gears are primarily used. Gears Helical Gears.

From themechanicalengineering.com

Types of Gear Spur, Helical, Herring Bone, Worm Gear [Notes & PDF] Gears Helical Gears The teeth on a helical gear cut at an angle to the face of the gear. The main difference between straight cut gears and helical gears is their tooth design and resulting performance. Helical gears have a smoother operation due to the angle twist creating instant contact with the gear teeth. Helical gears are primarily used to enhance torque and. Gears Helical Gears.

From www.iqsdirectory.com

Helical Gear What Are They? Types, Uses & Considerations Gears Helical Gears The teeth on a helical gear cut at an angle to the face of the gear. Helical gears have similarities with spur gears, but fundamental differences do exist. Helical gears have teeth that are set on an angle to the gear axis. Helical gears have a smoother operation due to the angle twist creating instant contact with the gear teeth.. Gears Helical Gears.