Copper Tube Roughness . Figure 14.6 melting temperature ranges for copper and copper alloys, brazing filler metals, brazing flux and solders. Dimensions and physical characteristics of copper tube: The roughness considered for this comparison is equivalent roughness of 10 micrometers for both the rough blades, which is ~3.1 times the rms roughness as reported by adams et al. Water velocity in copper tubes should not exceed 8 ft/s (2.4 m/s) for cold water and 5 ft/s (1.5 m/s) for hot water (up to approximately 140of, 60oc). The manning's roughness coefficient is used in the manning's equation to calculate flow in open channels. Surface coefficients that can be used to calculate friction and major pressure loss for fluid flow with surfaces like concrete, galvanized steel,.

from www.engineeringtoolbox.com

Dimensions and physical characteristics of copper tube: The roughness considered for this comparison is equivalent roughness of 10 micrometers for both the rough blades, which is ~3.1 times the rms roughness as reported by adams et al. The manning's roughness coefficient is used in the manning's equation to calculate flow in open channels. Water velocity in copper tubes should not exceed 8 ft/s (2.4 m/s) for cold water and 5 ft/s (1.5 m/s) for hot water (up to approximately 140of, 60oc). Figure 14.6 melting temperature ranges for copper and copper alloys, brazing filler metals, brazing flux and solders. Surface coefficients that can be used to calculate friction and major pressure loss for fluid flow with surfaces like concrete, galvanized steel,.

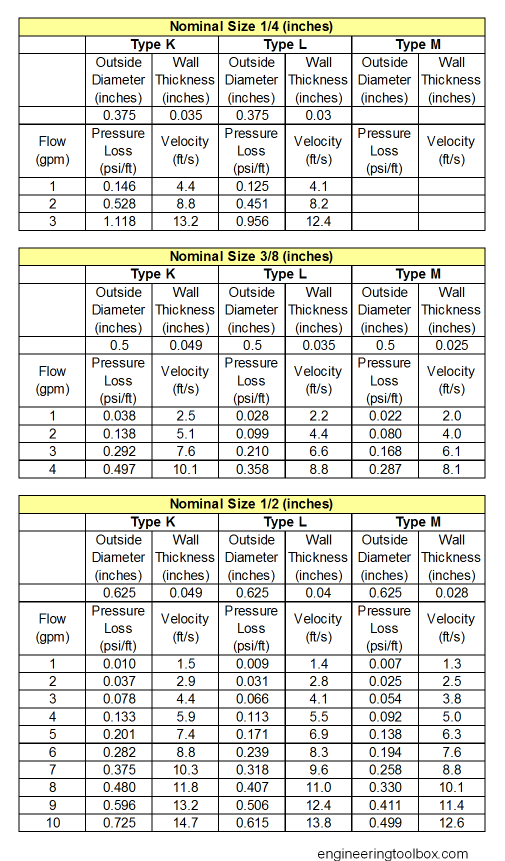

Copper Tubes Pressure Loss vs. Water Flow

Copper Tube Roughness Figure 14.6 melting temperature ranges for copper and copper alloys, brazing filler metals, brazing flux and solders. Surface coefficients that can be used to calculate friction and major pressure loss for fluid flow with surfaces like concrete, galvanized steel,. The manning's roughness coefficient is used in the manning's equation to calculate flow in open channels. Dimensions and physical characteristics of copper tube: The roughness considered for this comparison is equivalent roughness of 10 micrometers for both the rough blades, which is ~3.1 times the rms roughness as reported by adams et al. Figure 14.6 melting temperature ranges for copper and copper alloys, brazing filler metals, brazing flux and solders. Water velocity in copper tubes should not exceed 8 ft/s (2.4 m/s) for cold water and 5 ft/s (1.5 m/s) for hot water (up to approximately 140of, 60oc).

From blog.thepipingmart.com

All You Need to Know About Copper Pipe Insulation Copper Tube Roughness Figure 14.6 melting temperature ranges for copper and copper alloys, brazing filler metals, brazing flux and solders. Water velocity in copper tubes should not exceed 8 ft/s (2.4 m/s) for cold water and 5 ft/s (1.5 m/s) for hot water (up to approximately 140of, 60oc). The roughness considered for this comparison is equivalent roughness of 10 micrometers for both the. Copper Tube Roughness.

From www.vrogue.co

Pipe Roughness Chart vrogue.co Copper Tube Roughness The roughness considered for this comparison is equivalent roughness of 10 micrometers for both the rough blades, which is ~3.1 times the rms roughness as reported by adams et al. Water velocity in copper tubes should not exceed 8 ft/s (2.4 m/s) for cold water and 5 ft/s (1.5 m/s) for hot water (up to approximately 140of, 60oc). The manning's. Copper Tube Roughness.

From forum.heatinghelp.com

Conflicting Copper Pipe Sizing Info? — Heating Help The Wall Copper Tube Roughness The roughness considered for this comparison is equivalent roughness of 10 micrometers for both the rough blades, which is ~3.1 times the rms roughness as reported by adams et al. The manning's roughness coefficient is used in the manning's equation to calculate flow in open channels. Surface coefficients that can be used to calculate friction and major pressure loss for. Copper Tube Roughness.

From www.researchgate.net

a Surface roughness measurement of cast iron (spindle housing) and b Copper Tube Roughness Surface coefficients that can be used to calculate friction and major pressure loss for fluid flow with surfaces like concrete, galvanized steel,. The roughness considered for this comparison is equivalent roughness of 10 micrometers for both the rough blades, which is ~3.1 times the rms roughness as reported by adams et al. The manning's roughness coefficient is used in the. Copper Tube Roughness.

From www.researchgate.net

Principle scheme of a change in the copper surface roughness during Copper Tube Roughness Surface coefficients that can be used to calculate friction and major pressure loss for fluid flow with surfaces like concrete, galvanized steel,. The roughness considered for this comparison is equivalent roughness of 10 micrometers for both the rough blades, which is ~3.1 times the rms roughness as reported by adams et al. Dimensions and physical characteristics of copper tube: Water. Copper Tube Roughness.

From www.engineeringtoolbox.com

Copper Tubes Pressure Loss vs. Water Flow Copper Tube Roughness Surface coefficients that can be used to calculate friction and major pressure loss for fluid flow with surfaces like concrete, galvanized steel,. The roughness considered for this comparison is equivalent roughness of 10 micrometers for both the rough blades, which is ~3.1 times the rms roughness as reported by adams et al. Dimensions and physical characteristics of copper tube: Figure. Copper Tube Roughness.

From www.researchgate.net

Isometric view of the surface roughness of the fabricated copper Copper Tube Roughness Water velocity in copper tubes should not exceed 8 ft/s (2.4 m/s) for cold water and 5 ft/s (1.5 m/s) for hot water (up to approximately 140of, 60oc). The roughness considered for this comparison is equivalent roughness of 10 micrometers for both the rough blades, which is ~3.1 times the rms roughness as reported by adams et al. Surface coefficients. Copper Tube Roughness.

From mavink.com

Copper Tubing Wall Thickness Chart Copper Tube Roughness Figure 14.6 melting temperature ranges for copper and copper alloys, brazing filler metals, brazing flux and solders. Water velocity in copper tubes should not exceed 8 ft/s (2.4 m/s) for cold water and 5 ft/s (1.5 m/s) for hot water (up to approximately 140of, 60oc). The roughness considered for this comparison is equivalent roughness of 10 micrometers for both the. Copper Tube Roughness.

From www.heritagesteamsupplies.co.uk

6mm OD Copper Tube (10mtrs) Copper Tube Roughness Figure 14.6 melting temperature ranges for copper and copper alloys, brazing filler metals, brazing flux and solders. Dimensions and physical characteristics of copper tube: The manning's roughness coefficient is used in the manning's equation to calculate flow in open channels. Surface coefficients that can be used to calculate friction and major pressure loss for fluid flow with surfaces like concrete,. Copper Tube Roughness.

From www.maximaxsystems.com

EVERSTRONG COPPER TUBE Copper Tube Roughness The manning's roughness coefficient is used in the manning's equation to calculate flow in open channels. Water velocity in copper tubes should not exceed 8 ft/s (2.4 m/s) for cold water and 5 ft/s (1.5 m/s) for hot water (up to approximately 140of, 60oc). The roughness considered for this comparison is equivalent roughness of 10 micrometers for both the rough. Copper Tube Roughness.

From www.researchgate.net

(PDF) ScienceDirect ScienceDirect Surface roughness improvement of the Copper Tube Roughness The roughness considered for this comparison is equivalent roughness of 10 micrometers for both the rough blades, which is ~3.1 times the rms roughness as reported by adams et al. Dimensions and physical characteristics of copper tube: Figure 14.6 melting temperature ranges for copper and copper alloys, brazing filler metals, brazing flux and solders. Water velocity in copper tubes should. Copper Tube Roughness.

From mungfali.com

Pipe Roughness Chart Copper Tube Roughness Figure 14.6 melting temperature ranges for copper and copper alloys, brazing filler metals, brazing flux and solders. The roughness considered for this comparison is equivalent roughness of 10 micrometers for both the rough blades, which is ~3.1 times the rms roughness as reported by adams et al. Dimensions and physical characteristics of copper tube: Surface coefficients that can be used. Copper Tube Roughness.

From mungfali.com

Pipe Roughness Chart Copper Tube Roughness Figure 14.6 melting temperature ranges for copper and copper alloys, brazing filler metals, brazing flux and solders. The roughness considered for this comparison is equivalent roughness of 10 micrometers for both the rough blades, which is ~3.1 times the rms roughness as reported by adams et al. Dimensions and physical characteristics of copper tube: Water velocity in copper tubes should. Copper Tube Roughness.

From www.researchgate.net

(PDF) ScienceDirect ScienceDirect Surface roughness improvement of the Copper Tube Roughness The roughness considered for this comparison is equivalent roughness of 10 micrometers for both the rough blades, which is ~3.1 times the rms roughness as reported by adams et al. Surface coefficients that can be used to calculate friction and major pressure loss for fluid flow with surfaces like concrete, galvanized steel,. Water velocity in copper tubes should not exceed. Copper Tube Roughness.

From yorkshirecopper.com

Copper Tube Products Yorkshire Copper Tube Made In Britain Copper Tube Roughness Figure 14.6 melting temperature ranges for copper and copper alloys, brazing filler metals, brazing flux and solders. The roughness considered for this comparison is equivalent roughness of 10 micrometers for both the rough blades, which is ~3.1 times the rms roughness as reported by adams et al. Dimensions and physical characteristics of copper tube: Water velocity in copper tubes should. Copper Tube Roughness.

From www.researchgate.net

Surface roughness of copper substrates a EPCu substrate, b Cu Copper Tube Roughness The roughness considered for this comparison is equivalent roughness of 10 micrometers for both the rough blades, which is ~3.1 times the rms roughness as reported by adams et al. Surface coefficients that can be used to calculate friction and major pressure loss for fluid flow with surfaces like concrete, galvanized steel,. Water velocity in copper tubes should not exceed. Copper Tube Roughness.

From www.maximaxsystems.com

EVERSTRONG COPPER TUBE Copper Tube Roughness Dimensions and physical characteristics of copper tube: Figure 14.6 melting temperature ranges for copper and copper alloys, brazing filler metals, brazing flux and solders. Surface coefficients that can be used to calculate friction and major pressure loss for fluid flow with surfaces like concrete, galvanized steel,. Water velocity in copper tubes should not exceed 8 ft/s (2.4 m/s) for cold. Copper Tube Roughness.

From warret.weebly.com

Copper tube bending radius chart warret Copper Tube Roughness Dimensions and physical characteristics of copper tube: The roughness considered for this comparison is equivalent roughness of 10 micrometers for both the rough blades, which is ~3.1 times the rms roughness as reported by adams et al. Figure 14.6 melting temperature ranges for copper and copper alloys, brazing filler metals, brazing flux and solders. The manning's roughness coefficient is used. Copper Tube Roughness.

From mungfali.com

Roughness Coefficient PVC Pipe Copper Tube Roughness Surface coefficients that can be used to calculate friction and major pressure loss for fluid flow with surfaces like concrete, galvanized steel,. The roughness considered for this comparison is equivalent roughness of 10 micrometers for both the rough blades, which is ~3.1 times the rms roughness as reported by adams et al. The manning's roughness coefficient is used in the. Copper Tube Roughness.

From beryllium-copper.com

The Difference Between Hard State And Soft State Of Copper Tube Copper Tube Roughness The manning's roughness coefficient is used in the manning's equation to calculate flow in open channels. Dimensions and physical characteristics of copper tube: Water velocity in copper tubes should not exceed 8 ft/s (2.4 m/s) for cold water and 5 ft/s (1.5 m/s) for hot water (up to approximately 140of, 60oc). Surface coefficients that can be used to calculate friction. Copper Tube Roughness.

From www.youtube.com

Copper Tube bending,How to Bend Copper Tube a Tutorial by Kevin Ging Copper Tube Roughness Dimensions and physical characteristics of copper tube: The roughness considered for this comparison is equivalent roughness of 10 micrometers for both the rough blades, which is ~3.1 times the rms roughness as reported by adams et al. The manning's roughness coefficient is used in the manning's equation to calculate flow in open channels. Figure 14.6 melting temperature ranges for copper. Copper Tube Roughness.

From www.grandsteeltube.com

Copper Tube High Precision Tube Experts Copper Tube Roughness Figure 14.6 melting temperature ranges for copper and copper alloys, brazing filler metals, brazing flux and solders. The roughness considered for this comparison is equivalent roughness of 10 micrometers for both the rough blades, which is ~3.1 times the rms roughness as reported by adams et al. Surface coefficients that can be used to calculate friction and major pressure loss. Copper Tube Roughness.

From engineerexcel.com

Pipe Roughness A Complete Guide EngineerExcel Copper Tube Roughness The manning's roughness coefficient is used in the manning's equation to calculate flow in open channels. Water velocity in copper tubes should not exceed 8 ft/s (2.4 m/s) for cold water and 5 ft/s (1.5 m/s) for hot water (up to approximately 140of, 60oc). The roughness considered for this comparison is equivalent roughness of 10 micrometers for both the rough. Copper Tube Roughness.

From www.reece.com.au

Kembla Annealed Copper Tube 25mm x 1.22mm x 18mtr Plain (B) from Reece Copper Tube Roughness The roughness considered for this comparison is equivalent roughness of 10 micrometers for both the rough blades, which is ~3.1 times the rms roughness as reported by adams et al. Figure 14.6 melting temperature ranges for copper and copper alloys, brazing filler metals, brazing flux and solders. Water velocity in copper tubes should not exceed 8 ft/s (2.4 m/s) for. Copper Tube Roughness.

From blog.thepipingmart.com

Copper Tube Welding An Overview Copper Tube Roughness The roughness considered for this comparison is equivalent roughness of 10 micrometers for both the rough blades, which is ~3.1 times the rms roughness as reported by adams et al. The manning's roughness coefficient is used in the manning's equation to calculate flow in open channels. Figure 14.6 melting temperature ranges for copper and copper alloys, brazing filler metals, brazing. Copper Tube Roughness.

From mavink.com

Copper Pipe Sizes Chart Metric Copper Tube Roughness Dimensions and physical characteristics of copper tube: Water velocity in copper tubes should not exceed 8 ft/s (2.4 m/s) for cold water and 5 ft/s (1.5 m/s) for hot water (up to approximately 140of, 60oc). The roughness considered for this comparison is equivalent roughness of 10 micrometers for both the rough blades, which is ~3.1 times the rms roughness as. Copper Tube Roughness.

From www.pipsisland.com

10 Simple Steps to Braze Copper Pipe (Extended Tips) Copper Tube Roughness Water velocity in copper tubes should not exceed 8 ft/s (2.4 m/s) for cold water and 5 ft/s (1.5 m/s) for hot water (up to approximately 140of, 60oc). The manning's roughness coefficient is used in the manning's equation to calculate flow in open channels. The roughness considered for this comparison is equivalent roughness of 10 micrometers for both the rough. Copper Tube Roughness.

From tubingchina.com

ASME SB 111 SB 466 C71500 Copper Nickel Tubes Tubing HH Copper Nickel Copper Tube Roughness The roughness considered for this comparison is equivalent roughness of 10 micrometers for both the rough blades, which is ~3.1 times the rms roughness as reported by adams et al. Surface coefficients that can be used to calculate friction and major pressure loss for fluid flow with surfaces like concrete, galvanized steel,. Dimensions and physical characteristics of copper tube: Water. Copper Tube Roughness.

From garagehunter99.netlify.app

Roughness Of Copper Pipe Copper Tube Roughness Dimensions and physical characteristics of copper tube: Surface coefficients that can be used to calculate friction and major pressure loss for fluid flow with surfaces like concrete, galvanized steel,. Figure 14.6 melting temperature ranges for copper and copper alloys, brazing filler metals, brazing flux and solders. Water velocity in copper tubes should not exceed 8 ft/s (2.4 m/s) for cold. Copper Tube Roughness.

From www.slideserve.com

PPT Pipe Sizing Basics PowerPoint Presentation, free download ID760528 Copper Tube Roughness Water velocity in copper tubes should not exceed 8 ft/s (2.4 m/s) for cold water and 5 ft/s (1.5 m/s) for hot water (up to approximately 140of, 60oc). Dimensions and physical characteristics of copper tube: The manning's roughness coefficient is used in the manning's equation to calculate flow in open channels. Surface coefficients that can be used to calculate friction. Copper Tube Roughness.

From www.engineeringtoolbox.com

Copper Tubes Pressure Loss vs. Water Flow Copper Tube Roughness Figure 14.6 melting temperature ranges for copper and copper alloys, brazing filler metals, brazing flux and solders. The roughness considered for this comparison is equivalent roughness of 10 micrometers for both the rough blades, which is ~3.1 times the rms roughness as reported by adams et al. The manning's roughness coefficient is used in the manning's equation to calculate flow. Copper Tube Roughness.

From www.engineeringtoolbox.com

Copper Tubes Pressure Loss vs. Water Flow Copper Tube Roughness Figure 14.6 melting temperature ranges for copper and copper alloys, brazing filler metals, brazing flux and solders. Water velocity in copper tubes should not exceed 8 ft/s (2.4 m/s) for cold water and 5 ft/s (1.5 m/s) for hot water (up to approximately 140of, 60oc). Surface coefficients that can be used to calculate friction and major pressure loss for fluid. Copper Tube Roughness.

From www.walmart.com

Copper Round Tube 19mm OD 1mm Wall Thickness 100mm Length Straight Copper Tube Roughness The roughness considered for this comparison is equivalent roughness of 10 micrometers for both the rough blades, which is ~3.1 times the rms roughness as reported by adams et al. Surface coefficients that can be used to calculate friction and major pressure loss for fluid flow with surfaces like concrete, galvanized steel,. Figure 14.6 melting temperature ranges for copper and. Copper Tube Roughness.

From maksal.com

Maksal Tubes Copper Tube Roughness Water velocity in copper tubes should not exceed 8 ft/s (2.4 m/s) for cold water and 5 ft/s (1.5 m/s) for hot water (up to approximately 140of, 60oc). Figure 14.6 melting temperature ranges for copper and copper alloys, brazing filler metals, brazing flux and solders. The roughness considered for this comparison is equivalent roughness of 10 micrometers for both the. Copper Tube Roughness.

From mungfali.com

Pipe Roughness Chart Copper Tube Roughness Surface coefficients that can be used to calculate friction and major pressure loss for fluid flow with surfaces like concrete, galvanized steel,. The roughness considered for this comparison is equivalent roughness of 10 micrometers for both the rough blades, which is ~3.1 times the rms roughness as reported by adams et al. The manning's roughness coefficient is used in the. Copper Tube Roughness.