Lead Time Formula In Manufacturing . The amount of time it takes your business to manufacture a product. The basic lead time formula is: However, lead time is applicable in other smaller or more specific situations, too. Your lead time is how much time you need to receive the order, create the product (whether you’re manufacturing it yourself or relying on suppliers), and deliver it to your customer’s doorstep. Lead time equals the time before processing, the processing time, and the time after processing. The general formula for calculating lead time is straightforward: Let’s break down the concept further with two examples: To effectively calculate lead time, businesses track and analyze each of these phases to identify delays or inefficiencies. Making a product from procuring raw resources to ending the final assembly or production run. And how do they relate to one another? In manufacturing, the time before processing is the procurement stage. This varies widely and depends on the industry. Let’s lean into these time concepts and provide. It envelops times like processing, waiting, and. How do we measure and calculate them?

from www.vistable.com

And how do they relate to one another? Let’s break down the concept further with two examples: How do we measure and calculate them? The general formula for calculating lead time is straightforward: Your lead time is how much time you need to receive the order, create the product (whether you’re manufacturing it yourself or relying on suppliers), and deliver it to your customer’s doorstep. This varies widely and depends on the industry. It envelops times like processing, waiting, and. In manufacturing, the time before processing is the procurement stage. The basic lead time formula is: To effectively calculate lead time, businesses track and analyze each of these phases to identify delays or inefficiencies.

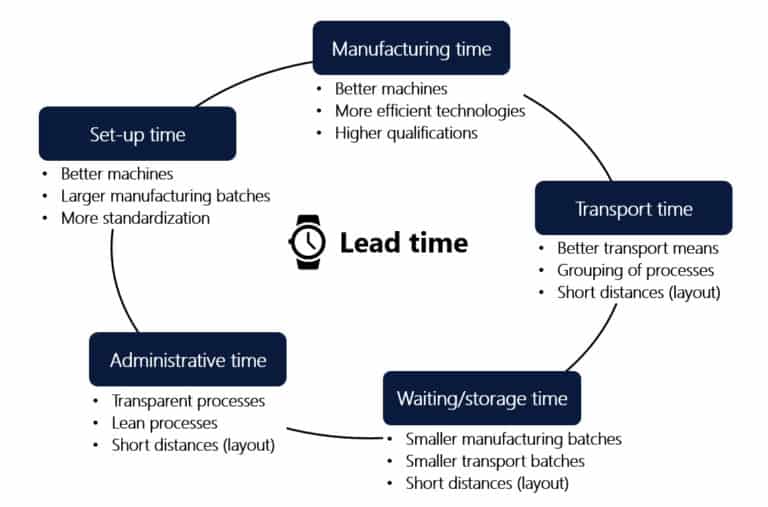

What is the significance of lead time in the factory planning process?

Lead Time Formula In Manufacturing Making a product from procuring raw resources to ending the final assembly or production run. To effectively calculate lead time, businesses track and analyze each of these phases to identify delays or inefficiencies. The general formula for calculating lead time is straightforward: Making a product from procuring raw resources to ending the final assembly or production run. Lead time equals the time before processing, the processing time, and the time after processing. Let’s lean into these time concepts and provide. Let’s break down the concept further with two examples: However, lead time is applicable in other smaller or more specific situations, too. How do we measure and calculate them? The basic lead time formula is: In manufacturing, the time before processing is the procurement stage. Your lead time is how much time you need to receive the order, create the product (whether you’re manufacturing it yourself or relying on suppliers), and deliver it to your customer’s doorstep. It envelops times like processing, waiting, and. And how do they relate to one another? The amount of time it takes your business to manufacture a product. This varies widely and depends on the industry.

From www.machinemetrics.com

Takt Time vs Cycle Time vs Lead Time Definitions and Calculations Lead Time Formula In Manufacturing And how do they relate to one another? The amount of time it takes your business to manufacture a product. Making a product from procuring raw resources to ending the final assembly or production run. It envelops times like processing, waiting, and. In manufacturing, the time before processing is the procurement stage. Let’s lean into these time concepts and provide.. Lead Time Formula In Manufacturing.

From developers.paragon-software.com

Takt Time, Lead Time, and Cycle Time Paragon Developers Portal Lead Time Formula In Manufacturing Your lead time is how much time you need to receive the order, create the product (whether you’re manufacturing it yourself or relying on suppliers), and deliver it to your customer’s doorstep. The general formula for calculating lead time is straightforward: Lead time equals the time before processing, the processing time, and the time after processing. And how do they. Lead Time Formula In Manufacturing.

From addvise.net

Calculating supply chain lead time Addvise Lead Time Formula In Manufacturing The basic lead time formula is: It envelops times like processing, waiting, and. Lead time equals the time before processing, the processing time, and the time after processing. Let’s lean into these time concepts and provide. In manufacturing, the time before processing is the procurement stage. However, lead time is applicable in other smaller or more specific situations, too. Let’s. Lead Time Formula In Manufacturing.

From www.vistable.com

What is the significance of lead time in the factory planning process? Lead Time Formula In Manufacturing How do we measure and calculate them? Let’s lean into these time concepts and provide. The basic lead time formula is: This varies widely and depends on the industry. It envelops times like processing, waiting, and. However, lead time is applicable in other smaller or more specific situations, too. Making a product from procuring raw resources to ending the final. Lead Time Formula In Manufacturing.

From www.gorillaroi.com

Free lead time calculator, formula, and management Gorilla ROI Lead Time Formula In Manufacturing How do we measure and calculate them? In manufacturing, the time before processing is the procurement stage. Your lead time is how much time you need to receive the order, create the product (whether you’re manufacturing it yourself or relying on suppliers), and deliver it to your customer’s doorstep. Making a product from procuring raw resources to ending the final. Lead Time Formula In Manufacturing.

From www.bluecart.com

Lead Time Definition & Formula What Is Lead Time? Lead Time Formula In Manufacturing How do we measure and calculate them? The basic lead time formula is: To effectively calculate lead time, businesses track and analyze each of these phases to identify delays or inefficiencies. This varies widely and depends on the industry. It envelops times like processing, waiting, and. However, lead time is applicable in other smaller or more specific situations, too. The. Lead Time Formula In Manufacturing.

From toggl.com

Takt Time vs Cycle Time vs Lead Time Lead Time Formula In Manufacturing However, lead time is applicable in other smaller or more specific situations, too. In manufacturing, the time before processing is the procurement stage. Let’s lean into these time concepts and provide. This varies widely and depends on the industry. The general formula for calculating lead time is straightforward: To effectively calculate lead time, businesses track and analyze each of these. Lead Time Formula In Manufacturing.

From businessfluency.com.br

A Quick Guide to Understanding Lead Time Business Fluency Lead Time Formula In Manufacturing And how do they relate to one another? Your lead time is how much time you need to receive the order, create the product (whether you’re manufacturing it yourself or relying on suppliers), and deliver it to your customer’s doorstep. Let’s lean into these time concepts and provide. Let’s break down the concept further with two examples: It envelops times. Lead Time Formula In Manufacturing.

From www.youtube.com

Case(iii) Constant Lead Time & Variable Demand YouTube Lead Time Formula In Manufacturing This varies widely and depends on the industry. Let’s lean into these time concepts and provide. How do we measure and calculate them? To effectively calculate lead time, businesses track and analyze each of these phases to identify delays or inefficiencies. However, lead time is applicable in other smaller or more specific situations, too. In manufacturing, the time before processing. Lead Time Formula In Manufacturing.

From www.youtube.com

Manufacturing Leadtime Explained YouTube Lead Time Formula In Manufacturing To effectively calculate lead time, businesses track and analyze each of these phases to identify delays or inefficiencies. And how do they relate to one another? The amount of time it takes your business to manufacture a product. This varies widely and depends on the industry. Lead time equals the time before processing, the processing time, and the time after. Lead Time Formula In Manufacturing.

From www.cecmhs.com

Order Lead Time More Vital Now Than Ever! Lead Time Formula In Manufacturing The general formula for calculating lead time is straightforward: The basic lead time formula is: Making a product from procuring raw resources to ending the final assembly or production run. And how do they relate to one another? However, lead time is applicable in other smaller or more specific situations, too. Let’s break down the concept further with two examples:. Lead Time Formula In Manufacturing.

From www.youtube.com

Lead Time (for Lean Manufacturing) YouTube Lead Time Formula In Manufacturing In manufacturing, the time before processing is the procurement stage. This varies widely and depends on the industry. Making a product from procuring raw resources to ending the final assembly or production run. However, lead time is applicable in other smaller or more specific situations, too. And how do they relate to one another? The basic lead time formula is:. Lead Time Formula In Manufacturing.

From www.cin7test.com

What Is Manufacturing Lead Time? Cin7 Lead Time Formula In Manufacturing Lead time equals the time before processing, the processing time, and the time after processing. This varies widely and depends on the industry. In manufacturing, the time before processing is the procurement stage. Let’s break down the concept further with two examples: Let’s lean into these time concepts and provide. To effectively calculate lead time, businesses track and analyze each. Lead Time Formula In Manufacturing.

From efinancemanagement.com

Lead Time Meaning, Importance, How to Improve and More Lead Time Formula In Manufacturing The basic lead time formula is: Lead time equals the time before processing, the processing time, and the time after processing. The amount of time it takes your business to manufacture a product. And how do they relate to one another? How do we measure and calculate them? However, lead time is applicable in other smaller or more specific situations,. Lead Time Formula In Manufacturing.

From www.deskera.com

What is Manufacturing Lead Time? It's Easier Than You Think! Lead Time Formula In Manufacturing To effectively calculate lead time, businesses track and analyze each of these phases to identify delays or inefficiencies. And how do they relate to one another? The amount of time it takes your business to manufacture a product. Let’s lean into these time concepts and provide. Your lead time is how much time you need to receive the order, create. Lead Time Formula In Manufacturing.

From sheleighezra.blogspot.com

21+ lead time calculator SheleighEzra Lead Time Formula In Manufacturing Lead time equals the time before processing, the processing time, and the time after processing. The general formula for calculating lead time is straightforward: Making a product from procuring raw resources to ending the final assembly or production run. And how do they relate to one another? In manufacturing, the time before processing is the procurement stage. How do we. Lead Time Formula In Manufacturing.

From cin7.com

What Is Manufacturing Lead Time? Cin7 Lead Time Formula In Manufacturing Lead time equals the time before processing, the processing time, and the time after processing. To effectively calculate lead time, businesses track and analyze each of these phases to identify delays or inefficiencies. The amount of time it takes your business to manufacture a product. Let’s break down the concept further with two examples: However, lead time is applicable in. Lead Time Formula In Manufacturing.

From www.youtube.com

Takt Time Calculation, Cycle Time and Bottleneck YouTube Lead Time Formula In Manufacturing How do we measure and calculate them? The amount of time it takes your business to manufacture a product. In manufacturing, the time before processing is the procurement stage. It envelops times like processing, waiting, and. This varies widely and depends on the industry. However, lead time is applicable in other smaller or more specific situations, too. Your lead time. Lead Time Formula In Manufacturing.

From www.theodmgroup.com

Manufacturing Lead Time A Quick Guide to Improve Business Efficiency Lead Time Formula In Manufacturing To effectively calculate lead time, businesses track and analyze each of these phases to identify delays or inefficiencies. In manufacturing, the time before processing is the procurement stage. However, lead time is applicable in other smaller or more specific situations, too. The general formula for calculating lead time is straightforward: How do we measure and calculate them? This varies widely. Lead Time Formula In Manufacturing.

From abcsupplychain.com

Supply Chain Lead Time What Is It And How To Track It Lead Time Formula In Manufacturing It envelops times like processing, waiting, and. In manufacturing, the time before processing is the procurement stage. The general formula for calculating lead time is straightforward: Let’s lean into these time concepts and provide. Making a product from procuring raw resources to ending the final assembly or production run. This varies widely and depends on the industry. However, lead time. Lead Time Formula In Manufacturing.

From cashflowinventory.com

Lead Times Meaning, How It Impacts Your Business, With Example Lead Time Formula In Manufacturing How do we measure and calculate them? The amount of time it takes your business to manufacture a product. However, lead time is applicable in other smaller or more specific situations, too. Your lead time is how much time you need to receive the order, create the product (whether you’re manufacturing it yourself or relying on suppliers), and deliver it. Lead Time Formula In Manufacturing.

From www.interempresas.net

¿Qué es el Lead Time y por qué es importante medirlo? Metalmecánica Lead Time Formula In Manufacturing Making a product from procuring raw resources to ending the final assembly or production run. The amount of time it takes your business to manufacture a product. Your lead time is how much time you need to receive the order, create the product (whether you’re manufacturing it yourself or relying on suppliers), and deliver it to your customer’s doorstep. However,. Lead Time Formula In Manufacturing.

From efex.vn

Lead Time In Inventory Management Definition And Formula Lead Time Formula In Manufacturing Your lead time is how much time you need to receive the order, create the product (whether you’re manufacturing it yourself or relying on suppliers), and deliver it to your customer’s doorstep. The general formula for calculating lead time is straightforward: It envelops times like processing, waiting, and. In manufacturing, the time before processing is the procurement stage. Let’s lean. Lead Time Formula In Manufacturing.

From cin7.com

What Is Manufacturing Lead Time? Cin7 Lead Time Formula In Manufacturing The general formula for calculating lead time is straightforward: This varies widely and depends on the industry. The basic lead time formula is: Lead time equals the time before processing, the processing time, and the time after processing. Let’s lean into these time concepts and provide. It envelops times like processing, waiting, and. Making a product from procuring raw resources. Lead Time Formula In Manufacturing.

From www.slideshare.net

Lead Time vs. Process Time Lead Time Formula In Manufacturing However, lead time is applicable in other smaller or more specific situations, too. The basic lead time formula is: Let’s break down the concept further with two examples: How do we measure and calculate them? Lead time equals the time before processing, the processing time, and the time after processing. Your lead time is how much time you need to. Lead Time Formula In Manufacturing.

From endel.afphila.com

Lead Time Overview, Components, and How to Reduce LT Lead Time Formula In Manufacturing And how do they relate to one another? Let’s break down the concept further with two examples: In manufacturing, the time before processing is the procurement stage. However, lead time is applicable in other smaller or more specific situations, too. Lead time equals the time before processing, the processing time, and the time after processing. Your lead time is how. Lead Time Formula In Manufacturing.

From redstagfulfillment.com

Lead Time Your Complete Guide Red Stag Fulfillment Lead Time Formula In Manufacturing The amount of time it takes your business to manufacture a product. Your lead time is how much time you need to receive the order, create the product (whether you’re manufacturing it yourself or relying on suppliers), and deliver it to your customer’s doorstep. How do we measure and calculate them? And how do they relate to one another? Let’s. Lead Time Formula In Manufacturing.

From news.ewmfg.com

Your Complete Guide to Lead Times Lead Time Formula In Manufacturing It envelops times like processing, waiting, and. The general formula for calculating lead time is straightforward: How do we measure and calculate them? The amount of time it takes your business to manufacture a product. And how do they relate to one another? Your lead time is how much time you need to receive the order, create the product (whether. Lead Time Formula In Manufacturing.

From www.slideserve.com

PPT Unit 2 Manufacturing Operations PowerPoint Presentation, free Lead Time Formula In Manufacturing This varies widely and depends on the industry. The basic lead time formula is: How do we measure and calculate them? It envelops times like processing, waiting, and. However, lead time is applicable in other smaller or more specific situations, too. In manufacturing, the time before processing is the procurement stage. Lead time equals the time before processing, the processing. Lead Time Formula In Manufacturing.

From www.mas-software.com

Apa Itu Lead Time? 5 Komponen dan 7 Jenis Lead Time Lead Time Formula In Manufacturing To effectively calculate lead time, businesses track and analyze each of these phases to identify delays or inefficiencies. Let’s break down the concept further with two examples: The general formula for calculating lead time is straightforward: Making a product from procuring raw resources to ending the final assembly or production run. In manufacturing, the time before processing is the procurement. Lead Time Formula In Manufacturing.

From www.scmdojo.com

Lead Time Definition How to Calculate & Reduce it? SCMDOJO Lead Time Formula In Manufacturing The general formula for calculating lead time is straightforward: It envelops times like processing, waiting, and. The amount of time it takes your business to manufacture a product. And how do they relate to one another? However, lead time is applicable in other smaller or more specific situations, too. Let’s lean into these time concepts and provide. To effectively calculate. Lead Time Formula In Manufacturing.

From buildd.co

Lead Time What it is, How to Calculate it and How to Reduce Lead Time Lead Time Formula In Manufacturing The amount of time it takes your business to manufacture a product. In manufacturing, the time before processing is the procurement stage. It envelops times like processing, waiting, and. Let’s break down the concept further with two examples: Let’s lean into these time concepts and provide. This varies widely and depends on the industry. However, lead time is applicable in. Lead Time Formula In Manufacturing.

From www.deskera.com

What is Manufacturing Lead Time? It's Easier Than You Think! Lead Time Formula In Manufacturing Let’s break down the concept further with two examples: The general formula for calculating lead time is straightforward: It envelops times like processing, waiting, and. However, lead time is applicable in other smaller or more specific situations, too. How do we measure and calculate them? Let’s lean into these time concepts and provide. In manufacturing, the time before processing is. Lead Time Formula In Manufacturing.

From www.quidlo.com

Takt Time vs Cycle Time vs Lead Time (+ Calculators) Quidlo Lead Time Formula In Manufacturing It envelops times like processing, waiting, and. To effectively calculate lead time, businesses track and analyze each of these phases to identify delays or inefficiencies. The general formula for calculating lead time is straightforward: In manufacturing, the time before processing is the procurement stage. Making a product from procuring raw resources to ending the final assembly or production run. The. Lead Time Formula In Manufacturing.

From www.gorillaroi.com

Free lead time calculator, formula, and management Gorilla ROI Lead Time Formula In Manufacturing This varies widely and depends on the industry. In manufacturing, the time before processing is the procurement stage. Let’s lean into these time concepts and provide. The general formula for calculating lead time is straightforward: And how do they relate to one another? Making a product from procuring raw resources to ending the final assembly or production run. How do. Lead Time Formula In Manufacturing.