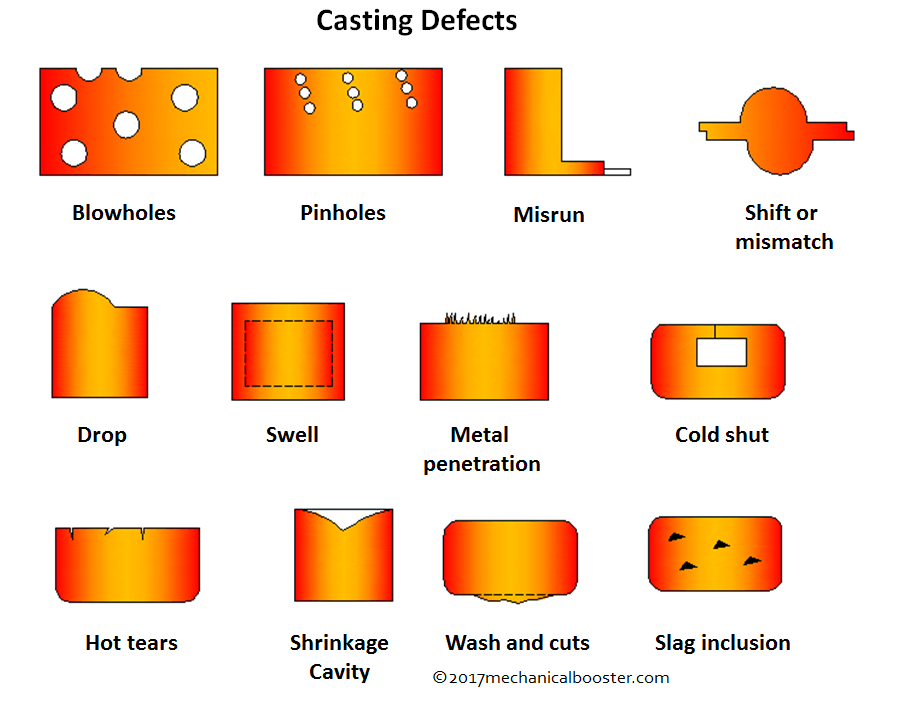

Mold Material Casting Defects . Learn about the common casting defects and their causes, such as porosity, shrinkage, inclusions, cold shut, hot tear,. Find out how to avoid them with proper mold design, pouring techniques and quality control. Below is a breakdown of different casting defects, categorized into metallurgical defects, defects due to heat, mold material. Find out the causes and solutions for each defect and how to prevent them in the casting process. Learn about the common types of casting defects in metal parts, such as porosity, shrinkage, and mold material defects. Learn about 11 common casting defects in metal, such as porosity, shrinkage, fusion, run out and more. The most common causes of casting defects include improper cooling rates, uneven solidification, gas entrapment, and inadequate.

from www.mechanicalbooster.com

Find out how to avoid them with proper mold design, pouring techniques and quality control. Find out the causes and solutions for each defect and how to prevent them in the casting process. Learn about the common types of casting defects in metal parts, such as porosity, shrinkage, and mold material defects. The most common causes of casting defects include improper cooling rates, uneven solidification, gas entrapment, and inadequate. Learn about the common casting defects and their causes, such as porosity, shrinkage, inclusions, cold shut, hot tear,. Learn about 11 common casting defects in metal, such as porosity, shrinkage, fusion, run out and more. Below is a breakdown of different casting defects, categorized into metallurgical defects, defects due to heat, mold material.

What is Casting Defects Types, Causes and Remedies? Mechanical Booster

Mold Material Casting Defects The most common causes of casting defects include improper cooling rates, uneven solidification, gas entrapment, and inadequate. Find out the causes and solutions for each defect and how to prevent them in the casting process. Find out how to avoid them with proper mold design, pouring techniques and quality control. The most common causes of casting defects include improper cooling rates, uneven solidification, gas entrapment, and inadequate. Learn about the common casting defects and their causes, such as porosity, shrinkage, inclusions, cold shut, hot tear,. Learn about the common types of casting defects in metal parts, such as porosity, shrinkage, and mold material defects. Below is a breakdown of different casting defects, categorized into metallurgical defects, defects due to heat, mold material. Learn about 11 common casting defects in metal, such as porosity, shrinkage, fusion, run out and more.

From www.diecastingcompany.com

The Concrete Measures To Solve The Sticky Mold Defects Of Die Casting Mold Material Casting Defects Below is a breakdown of different casting defects, categorized into metallurgical defects, defects due to heat, mold material. Learn about the common types of casting defects in metal parts, such as porosity, shrinkage, and mold material defects. Learn about the common casting defects and their causes, such as porosity, shrinkage, inclusions, cold shut, hot tear,. Find out how to avoid. Mold Material Casting Defects.

From ermak.com

Metal Casting Defects Ermak Foundry & Machining, Inc. Mold Material Casting Defects Find out the causes and solutions for each defect and how to prevent them in the casting process. Find out how to avoid them with proper mold design, pouring techniques and quality control. Learn about the common types of casting defects in metal parts, such as porosity, shrinkage, and mold material defects. The most common causes of casting defects include. Mold Material Casting Defects.

From cejdwyrc.blob.core.windows.net

Typical Casting Defects at Jene Holub blog Mold Material Casting Defects Find out how to avoid them with proper mold design, pouring techniques and quality control. Below is a breakdown of different casting defects, categorized into metallurgical defects, defects due to heat, mold material. Learn about 11 common casting defects in metal, such as porosity, shrinkage, fusion, run out and more. The most common causes of casting defects include improper cooling. Mold Material Casting Defects.

From www.pioneerplastics.com

Injection Molding Defects and How to Avoid Them Mold Material Casting Defects Find out the causes and solutions for each defect and how to prevent them in the casting process. Learn about the common casting defects and their causes, such as porosity, shrinkage, inclusions, cold shut, hot tear,. Learn about the common types of casting defects in metal parts, such as porosity, shrinkage, and mold material defects. Find out how to avoid. Mold Material Casting Defects.

From present5.com

IE 337 Materials Manufacturing Processes Lecture 9 Mold Material Casting Defects Find out how to avoid them with proper mold design, pouring techniques and quality control. The most common causes of casting defects include improper cooling rates, uneven solidification, gas entrapment, and inadequate. Find out the causes and solutions for each defect and how to prevent them in the casting process. Learn about the common casting defects and their causes, such. Mold Material Casting Defects.

From blog.eaglegroupmanufacturers.com

Understanding Casting Defects When Is a Casting Returnable? Mold Material Casting Defects The most common causes of casting defects include improper cooling rates, uneven solidification, gas entrapment, and inadequate. Below is a breakdown of different casting defects, categorized into metallurgical defects, defects due to heat, mold material. Learn about the common casting defects and their causes, such as porosity, shrinkage, inclusions, cold shut, hot tear,. Find out how to avoid them with. Mold Material Casting Defects.

From www.steel-foundry.com

Description, Reasons and Remedies of Common Sand Casting Defects Mold Material Casting Defects The most common causes of casting defects include improper cooling rates, uneven solidification, gas entrapment, and inadequate. Below is a breakdown of different casting defects, categorized into metallurgical defects, defects due to heat, mold material. Find out the causes and solutions for each defect and how to prevent them in the casting process. Learn about 11 common casting defects in. Mold Material Casting Defects.

From www.semanticscholar.org

Figure 1 from Transient FluidFlow Phenomena in the Continuous Steel Mold Material Casting Defects Find out the causes and solutions for each defect and how to prevent them in the casting process. Learn about the common types of casting defects in metal parts, such as porosity, shrinkage, and mold material defects. The most common causes of casting defects include improper cooling rates, uneven solidification, gas entrapment, and inadequate. Learn about the common casting defects. Mold Material Casting Defects.

From vietnamcastiron.com

5 types of Sand casting defects and how to prevent to improve cast quality Mold Material Casting Defects Find out how to avoid them with proper mold design, pouring techniques and quality control. Below is a breakdown of different casting defects, categorized into metallurgical defects, defects due to heat, mold material. Learn about the common types of casting defects in metal parts, such as porosity, shrinkage, and mold material defects. The most common causes of casting defects include. Mold Material Casting Defects.

From www.numerade.com

SOLVED Casting defects The main reasons for casting defects are Mold Material Casting Defects Find out how to avoid them with proper mold design, pouring techniques and quality control. The most common causes of casting defects include improper cooling rates, uneven solidification, gas entrapment, and inadequate. Find out the causes and solutions for each defect and how to prevent them in the casting process. Learn about 11 common casting defects in metal, such as. Mold Material Casting Defects.

From sealectplastics.com

The Top 5 Plastic Injection Molding Defects (and How to Solve Them) Mold Material Casting Defects Learn about 11 common casting defects in metal, such as porosity, shrinkage, fusion, run out and more. The most common causes of casting defects include improper cooling rates, uneven solidification, gas entrapment, and inadequate. Find out how to avoid them with proper mold design, pouring techniques and quality control. Learn about the common types of casting defects in metal parts,. Mold Material Casting Defects.

From precision-casting.co.id

What is Casting Defects? Gas Porosity and Shrinkage Zenith Allmart Mold Material Casting Defects The most common causes of casting defects include improper cooling rates, uneven solidification, gas entrapment, and inadequate. Learn about 11 common casting defects in metal, such as porosity, shrinkage, fusion, run out and more. Learn about the common types of casting defects in metal parts, such as porosity, shrinkage, and mold material defects. Below is a breakdown of different casting. Mold Material Casting Defects.

From www.fastradius.com

7 Injection Molding Defects and How to Avoid Mold Material Casting Defects The most common causes of casting defects include improper cooling rates, uneven solidification, gas entrapment, and inadequate. Learn about the common casting defects and their causes, such as porosity, shrinkage, inclusions, cold shut, hot tear,. Learn about the common types of casting defects in metal parts, such as porosity, shrinkage, and mold material defects. Below is a breakdown of different. Mold Material Casting Defects.

From justinfozone.blogspot.com

Sand Casting Defects Informational Encyclopedia Mold Material Casting Defects Learn about 11 common casting defects in metal, such as porosity, shrinkage, fusion, run out and more. Find out how to avoid them with proper mold design, pouring techniques and quality control. The most common causes of casting defects include improper cooling rates, uneven solidification, gas entrapment, and inadequate. Learn about the common types of casting defects in metal parts,. Mold Material Casting Defects.

From www.omnidexcn.com

Defectfree Metal Casting Process 1 Quality Metal Castings Mold Material Casting Defects The most common causes of casting defects include improper cooling rates, uneven solidification, gas entrapment, and inadequate. Below is a breakdown of different casting defects, categorized into metallurgical defects, defects due to heat, mold material. Learn about the common types of casting defects in metal parts, such as porosity, shrinkage, and mold material defects. Find out how to avoid them. Mold Material Casting Defects.

From www.dongruncasting.com

Metal Casting DefectsDongrun Casting Mold Material Casting Defects Below is a breakdown of different casting defects, categorized into metallurgical defects, defects due to heat, mold material. The most common causes of casting defects include improper cooling rates, uneven solidification, gas entrapment, and inadequate. Learn about the common types of casting defects in metal parts, such as porosity, shrinkage, and mold material defects. Find out the causes and solutions. Mold Material Casting Defects.

From www.mechanicalbooster.com

What is Casting Defects Types, Causes and Remedies? Mechanical Booster Mold Material Casting Defects Learn about the common types of casting defects in metal parts, such as porosity, shrinkage, and mold material defects. The most common causes of casting defects include improper cooling rates, uneven solidification, gas entrapment, and inadequate. Below is a breakdown of different casting defects, categorized into metallurgical defects, defects due to heat, mold material. Learn about 11 common casting defects. Mold Material Casting Defects.

From www.youtube.com

Molding DefectsFlow marksProduct Review & Design YouTube Mold Material Casting Defects Learn about the common casting defects and their causes, such as porosity, shrinkage, inclusions, cold shut, hot tear,. The most common causes of casting defects include improper cooling rates, uneven solidification, gas entrapment, and inadequate. Learn about 11 common casting defects in metal, such as porosity, shrinkage, fusion, run out and more. Find out the causes and solutions for each. Mold Material Casting Defects.

From in.pinterest.com

Different Types of Casting Defects Their Causes and Remedies It cast Mold Material Casting Defects Learn about 11 common casting defects in metal, such as porosity, shrinkage, fusion, run out and more. Find out the causes and solutions for each defect and how to prevent them in the casting process. Learn about the common casting defects and their causes, such as porosity, shrinkage, inclusions, cold shut, hot tear,. Learn about the common types of casting. Mold Material Casting Defects.

From www.zhycasting.com

Nitrogen porosity casting defects in iron mold sand covered gray cast Mold Material Casting Defects Below is a breakdown of different casting defects, categorized into metallurgical defects, defects due to heat, mold material. Learn about 11 common casting defects in metal, such as porosity, shrinkage, fusion, run out and more. Find out the causes and solutions for each defect and how to prevent them in the casting process. The most common causes of casting defects. Mold Material Casting Defects.

From studylib.net

casting defects Mold Material Casting Defects Below is a breakdown of different casting defects, categorized into metallurgical defects, defects due to heat, mold material. Find out how to avoid them with proper mold design, pouring techniques and quality control. Find out the causes and solutions for each defect and how to prevent them in the casting process. Learn about the common casting defects and their causes,. Mold Material Casting Defects.

From www.youtube.com

Defects in casting YouTube Mold Material Casting Defects Learn about the common types of casting defects in metal parts, such as porosity, shrinkage, and mold material defects. Learn about 11 common casting defects in metal, such as porosity, shrinkage, fusion, run out and more. Below is a breakdown of different casting defects, categorized into metallurgical defects, defects due to heat, mold material. Find out how to avoid them. Mold Material Casting Defects.

From www.slideserve.com

PPT Metal Casting I PowerPoint Presentation, free download ID597235 Mold Material Casting Defects Find out the causes and solutions for each defect and how to prevent them in the casting process. Learn about the common casting defects and their causes, such as porosity, shrinkage, inclusions, cold shut, hot tear,. The most common causes of casting defects include improper cooling rates, uneven solidification, gas entrapment, and inadequate. Below is a breakdown of different casting. Mold Material Casting Defects.

From www.slideserve.com

PPT CASTING DEFECTS PowerPoint Presentation, free download ID9600903 Mold Material Casting Defects Find out the causes and solutions for each defect and how to prevent them in the casting process. Learn about 11 common casting defects in metal, such as porosity, shrinkage, fusion, run out and more. Learn about the common casting defects and their causes, such as porosity, shrinkage, inclusions, cold shut, hot tear,. Learn about the common types of casting. Mold Material Casting Defects.

From www.foundrymag.com

Understanding the Science Behind Defects Foundry Mold Material Casting Defects Learn about the common types of casting defects in metal parts, such as porosity, shrinkage, and mold material defects. Find out how to avoid them with proper mold design, pouring techniques and quality control. Below is a breakdown of different casting defects, categorized into metallurgical defects, defects due to heat, mold material. The most common causes of casting defects include. Mold Material Casting Defects.

From www.mdpi.com

Metals Free FullText The Impact of Process Factors on Creating Mold Material Casting Defects Learn about the common casting defects and their causes, such as porosity, shrinkage, inclusions, cold shut, hot tear,. Learn about 11 common casting defects in metal, such as porosity, shrinkage, fusion, run out and more. Find out how to avoid them with proper mold design, pouring techniques and quality control. Learn about the common types of casting defects in metal. Mold Material Casting Defects.

From www.prodiecasting.com

Defect Analysis for Die Casting Crack WEIHENG Mold Material Casting Defects Learn about 11 common casting defects in metal, such as porosity, shrinkage, fusion, run out and more. Find out the causes and solutions for each defect and how to prevent them in the casting process. Learn about the common types of casting defects in metal parts, such as porosity, shrinkage, and mold material defects. Find out how to avoid them. Mold Material Casting Defects.

From www.mdpi.com

Metals Free FullText Casting Defects in SandMold Cast Irons—An Mold Material Casting Defects The most common causes of casting defects include improper cooling rates, uneven solidification, gas entrapment, and inadequate. Learn about 11 common casting defects in metal, such as porosity, shrinkage, fusion, run out and more. Find out how to avoid them with proper mold design, pouring techniques and quality control. Find out the causes and solutions for each defect and how. Mold Material Casting Defects.

From www.magmasoft.cn

MoldFilling Defects in Gray and Ductile Iron Mold Material Casting Defects Learn about the common types of casting defects in metal parts, such as porosity, shrinkage, and mold material defects. Learn about 11 common casting defects in metal, such as porosity, shrinkage, fusion, run out and more. The most common causes of casting defects include improper cooling rates, uneven solidification, gas entrapment, and inadequate. Find out the causes and solutions for. Mold Material Casting Defects.

From www.linkedin.com

Understanding Defects in Continuous Casting Billets Mold Material Casting Defects Find out how to avoid them with proper mold design, pouring techniques and quality control. Below is a breakdown of different casting defects, categorized into metallurgical defects, defects due to heat, mold material. Learn about the common casting defects and their causes, such as porosity, shrinkage, inclusions, cold shut, hot tear,. The most common causes of casting defects include improper. Mold Material Casting Defects.

From www.slideserve.com

PPT Fundamentals of Casting PowerPoint Presentation, free download Mold Material Casting Defects Learn about the common casting defects and their causes, such as porosity, shrinkage, inclusions, cold shut, hot tear,. Learn about the common types of casting defects in metal parts, such as porosity, shrinkage, and mold material defects. Find out how to avoid them with proper mold design, pouring techniques and quality control. Find out the causes and solutions for each. Mold Material Casting Defects.

From www.iqsdirectory.com

Iron Castings Types, Applications, Process, and Benefits Mold Material Casting Defects The most common causes of casting defects include improper cooling rates, uneven solidification, gas entrapment, and inadequate. Learn about the common types of casting defects in metal parts, such as porosity, shrinkage, and mold material defects. Find out how to avoid them with proper mold design, pouring techniques and quality control. Learn about 11 common casting defects in metal, such. Mold Material Casting Defects.

From www.mdpi.com

Metals Free FullText Casting Defects in SandMold Cast Irons—An Mold Material Casting Defects The most common causes of casting defects include improper cooling rates, uneven solidification, gas entrapment, and inadequate. Learn about the common casting defects and their causes, such as porosity, shrinkage, inclusions, cold shut, hot tear,. Learn about the common types of casting defects in metal parts, such as porosity, shrinkage, and mold material defects. Find out how to avoid them. Mold Material Casting Defects.

From www.rapiddirect.com

17 Types of Casting Defects Understanding Their Causes and Remidies Mold Material Casting Defects Learn about the common casting defects and their causes, such as porosity, shrinkage, inclusions, cold shut, hot tear,. Find out the causes and solutions for each defect and how to prevent them in the casting process. Below is a breakdown of different casting defects, categorized into metallurgical defects, defects due to heat, mold material. Learn about 11 common casting defects. Mold Material Casting Defects.

From www.mdpi.com

Metals Free FullText Casting Defects in SandMold Cast Irons—An Mold Material Casting Defects Learn about the common types of casting defects in metal parts, such as porosity, shrinkage, and mold material defects. Find out how to avoid them with proper mold design, pouring techniques and quality control. Find out the causes and solutions for each defect and how to prevent them in the casting process. Below is a breakdown of different casting defects,. Mold Material Casting Defects.