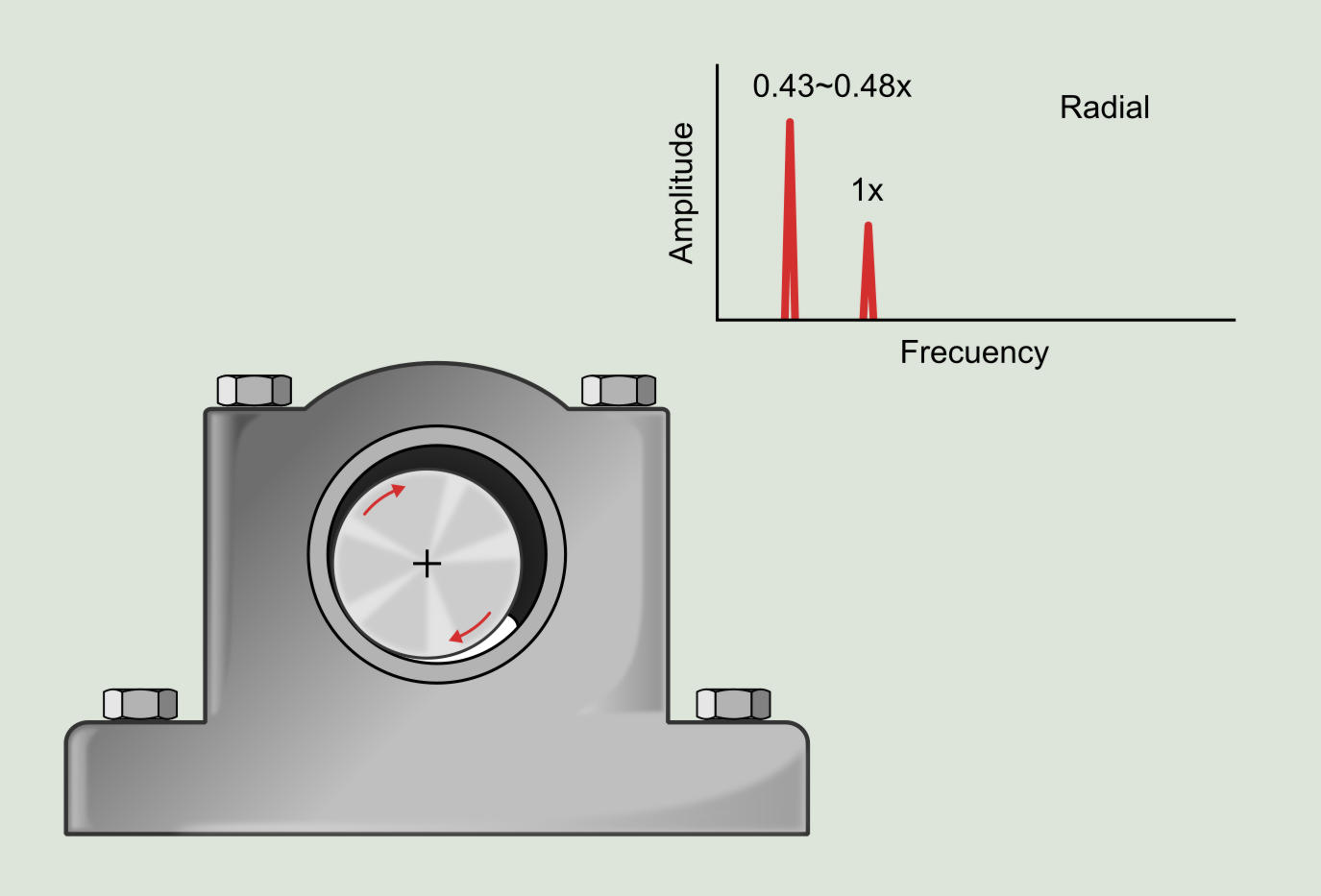

Bearing Oil Wedge . Typically, the oil film itself flows around the journal to lubricate. This lubrication regime condition occurs after a machine has begun to rotate and the speeds and loads are such that a wedge of oil has been formed between the shaft and bearing surfaces. Oil whirl is probably the most common cause of subsynchronous instability in hydrodynamic journal bearings. This difference is called oil. Locating and installing the cam bearing to take advantage of this hydrodynamic wedge will supply the maximum support for the camshaft during engine operation. They ride on a “wedge” of. An engine bearing is not designed to contact the crankshaft journals. The wedge parameters are determined by the difference between the diameters. The journals do not ride on the bearing surface: This wedge of oil lifts the shaft away from the bearing surface so there is little risk of asperity contact. The oil wedge of a bearing with eccentricity is the same as the wedge formed by a bearing with an increased diameter (”effective bearing.

from power-mi.com

This lubrication regime condition occurs after a machine has begun to rotate and the speeds and loads are such that a wedge of oil has been formed between the shaft and bearing surfaces. Typically, the oil film itself flows around the journal to lubricate. Oil whirl is probably the most common cause of subsynchronous instability in hydrodynamic journal bearings. The wedge parameters are determined by the difference between the diameters. Locating and installing the cam bearing to take advantage of this hydrodynamic wedge will supply the maximum support for the camshaft during engine operation. The journals do not ride on the bearing surface: The oil wedge of a bearing with eccentricity is the same as the wedge formed by a bearing with an increased diameter (”effective bearing. This wedge of oil lifts the shaft away from the bearing surface so there is little risk of asperity contact. They ride on a “wedge” of. An engine bearing is not designed to contact the crankshaft journals.

Troubleshooting of plain bearings PowerMI

Bearing Oil Wedge An engine bearing is not designed to contact the crankshaft journals. An engine bearing is not designed to contact the crankshaft journals. This lubrication regime condition occurs after a machine has begun to rotate and the speeds and loads are such that a wedge of oil has been formed between the shaft and bearing surfaces. This difference is called oil. The oil wedge of a bearing with eccentricity is the same as the wedge formed by a bearing with an increased diameter (”effective bearing. Locating and installing the cam bearing to take advantage of this hydrodynamic wedge will supply the maximum support for the camshaft during engine operation. They ride on a “wedge” of. The journals do not ride on the bearing surface: This wedge of oil lifts the shaft away from the bearing surface so there is little risk of asperity contact. Oil whirl is probably the most common cause of subsynchronous instability in hydrodynamic journal bearings. Typically, the oil film itself flows around the journal to lubricate. The wedge parameters are determined by the difference between the diameters.

From allegro.pl

TD03/TD04 Turbo Thrust Bearing High Performance Positive Oil Wedge S Bearing Oil Wedge The oil wedge of a bearing with eccentricity is the same as the wedge formed by a bearing with an increased diameter (”effective bearing. This lubrication regime condition occurs after a machine has begun to rotate and the speeds and loads are such that a wedge of oil has been formed between the shaft and bearing surfaces. They ride on. Bearing Oil Wedge.

From www.slideserve.com

PPT Hydrodynamic lubrication PowerPoint Presentation, free download Bearing Oil Wedge Typically, the oil film itself flows around the journal to lubricate. This lubrication regime condition occurs after a machine has begun to rotate and the speeds and loads are such that a wedge of oil has been formed between the shaft and bearing surfaces. They ride on a “wedge” of. The oil wedge of a bearing with eccentricity is the. Bearing Oil Wedge.

From slidetodoc.com

Hydrodynamic lubrication Also called fluidfilm thickfilm or flooded Bearing Oil Wedge Locating and installing the cam bearing to take advantage of this hydrodynamic wedge will supply the maximum support for the camshaft during engine operation. Typically, the oil film itself flows around the journal to lubricate. The journals do not ride on the bearing surface: An engine bearing is not designed to contact the crankshaft journals. The wedge parameters are determined. Bearing Oil Wedge.

From www.youtube.com

How to Properly Lubricate a Plain Linear Bearing YouTube Bearing Oil Wedge This wedge of oil lifts the shaft away from the bearing surface so there is little risk of asperity contact. This difference is called oil. Typically, the oil film itself flows around the journal to lubricate. They ride on a “wedge” of. The oil wedge of a bearing with eccentricity is the same as the wedge formed by a bearing. Bearing Oil Wedge.

From www.researchgate.net

Structural diagram of spiral oil wedge sleeve bearing. Download Bearing Oil Wedge Oil whirl is probably the most common cause of subsynchronous instability in hydrodynamic journal bearings. This lubrication regime condition occurs after a machine has begun to rotate and the speeds and loads are such that a wedge of oil has been formed between the shaft and bearing surfaces. This difference is called oil. The journals do not ride on the. Bearing Oil Wedge.

From www.slideserve.com

PPT Hydrodynamic lubrication PowerPoint Presentation, free download Bearing Oil Wedge The journals do not ride on the bearing surface: This difference is called oil. Oil whirl is probably the most common cause of subsynchronous instability in hydrodynamic journal bearings. They ride on a “wedge” of. The oil wedge of a bearing with eccentricity is the same as the wedge formed by a bearing with an increased diameter (”effective bearing. The. Bearing Oil Wedge.

From stucki.com

Body Side Bearings (Plate & Wedge) Stucki Co. Bearing Oil Wedge Oil whirl is probably the most common cause of subsynchronous instability in hydrodynamic journal bearings. This difference is called oil. The wedge parameters are determined by the difference between the diameters. They ride on a “wedge” of. The oil wedge of a bearing with eccentricity is the same as the wedge formed by a bearing with an increased diameter (”effective. Bearing Oil Wedge.

From www.youtube.com

Machining a Steam Bearing Wedge YouTube Bearing Oil Wedge An engine bearing is not designed to contact the crankshaft journals. This wedge of oil lifts the shaft away from the bearing surface so there is little risk of asperity contact. They ride on a “wedge” of. This difference is called oil. Oil whirl is probably the most common cause of subsynchronous instability in hydrodynamic journal bearings. Typically, the oil. Bearing Oil Wedge.

From www.pumpsandsystems.com

Back to Basics Pump Bearing Housing LubricationPart 2 Bearing Oil Wedge They ride on a “wedge” of. Locating and installing the cam bearing to take advantage of this hydrodynamic wedge will supply the maximum support for the camshaft during engine operation. The oil wedge of a bearing with eccentricity is the same as the wedge formed by a bearing with an increased diameter (”effective bearing. Typically, the oil film itself flows. Bearing Oil Wedge.

From www.marineengine.com

SBC 5.7 cam bearings Bearing Oil Wedge Locating and installing the cam bearing to take advantage of this hydrodynamic wedge will supply the maximum support for the camshaft during engine operation. This difference is called oil. An engine bearing is not designed to contact the crankshaft journals. The wedge parameters are determined by the difference between the diameters. This lubrication regime condition occurs after a machine has. Bearing Oil Wedge.

From www.turbobuicks.com

Main bearing oil grooves Bearing Oil Wedge Typically, the oil film itself flows around the journal to lubricate. The wedge parameters are determined by the difference between the diameters. Oil whirl is probably the most common cause of subsynchronous instability in hydrodynamic journal bearings. This wedge of oil lifts the shaft away from the bearing surface so there is little risk of asperity contact. They ride on. Bearing Oil Wedge.

From www.slideserve.com

PPT Thrust bearings PowerPoint Presentation, free download ID509077 Bearing Oil Wedge They ride on a “wedge” of. Oil whirl is probably the most common cause of subsynchronous instability in hydrodynamic journal bearings. This lubrication regime condition occurs after a machine has begun to rotate and the speeds and loads are such that a wedge of oil has been formed between the shaft and bearing surfaces. The journals do not ride on. Bearing Oil Wedge.

From www.machinerylubrication.com

Rolling Bearing Lubrication for Critical Running Conditions Bearing Oil Wedge This difference is called oil. This wedge of oil lifts the shaft away from the bearing surface so there is little risk of asperity contact. The journals do not ride on the bearing surface: Locating and installing the cam bearing to take advantage of this hydrodynamic wedge will supply the maximum support for the camshaft during engine operation. They ride. Bearing Oil Wedge.

From gbr.grandado.com

TD03/TD04 Turbo Thrust Bearing High Performance Po... Grandado Bearing Oil Wedge This wedge of oil lifts the shaft away from the bearing surface so there is little risk of asperity contact. An engine bearing is not designed to contact the crankshaft journals. The journals do not ride on the bearing surface: This difference is called oil. Oil whirl is probably the most common cause of subsynchronous instability in hydrodynamic journal bearings.. Bearing Oil Wedge.

From www.researchgate.net

(PDF) Influence of Spiral Angle on the Performance of Spiral Oil Wedge Bearing Oil Wedge They ride on a “wedge” of. The journals do not ride on the bearing surface: The wedge parameters are determined by the difference between the diameters. This lubrication regime condition occurs after a machine has begun to rotate and the speeds and loads are such that a wedge of oil has been formed between the shaft and bearing surfaces. This. Bearing Oil Wedge.

From www.slideserve.com

PPT Hydrodynamic lubrication PowerPoint Presentation, free download Bearing Oil Wedge This lubrication regime condition occurs after a machine has begun to rotate and the speeds and loads are such that a wedge of oil has been formed between the shaft and bearing surfaces. Typically, the oil film itself flows around the journal to lubricate. The oil wedge of a bearing with eccentricity is the same as the wedge formed by. Bearing Oil Wedge.

From proguideroller.com

Bearing Wedge PROGUIDE Bearing Oil Wedge This difference is called oil. Typically, the oil film itself flows around the journal to lubricate. An engine bearing is not designed to contact the crankshaft journals. The oil wedge of a bearing with eccentricity is the same as the wedge formed by a bearing with an increased diameter (”effective bearing. The journals do not ride on the bearing surface:. Bearing Oil Wedge.

From qdfqhongyuan.en.made-in-china.com

Unidirectional Bearing Wedge of Chrome Steel China Bearing Roller and Bearing Oil Wedge This wedge of oil lifts the shaft away from the bearing surface so there is little risk of asperity contact. They ride on a “wedge” of. This difference is called oil. Typically, the oil film itself flows around the journal to lubricate. The oil wedge of a bearing with eccentricity is the same as the wedge formed by a bearing. Bearing Oil Wedge.

From jinfaindustrial.en.made-in-china.com

Marine DN420mm Multi Oil Wedge Gliding Shaft Intermediate Bearing Bearing Oil Wedge They ride on a “wedge” of. The wedge parameters are determined by the difference between the diameters. This wedge of oil lifts the shaft away from the bearing surface so there is little risk of asperity contact. Oil whirl is probably the most common cause of subsynchronous instability in hydrodynamic journal bearings. Locating and installing the cam bearing to take. Bearing Oil Wedge.

From www.slideserve.com

PPT Hydrodynamic lubrication PowerPoint Presentation, free download Bearing Oil Wedge This difference is called oil. This wedge of oil lifts the shaft away from the bearing surface so there is little risk of asperity contact. The wedge parameters are determined by the difference between the diameters. They ride on a “wedge” of. Typically, the oil film itself flows around the journal to lubricate. The journals do not ride on the. Bearing Oil Wedge.

From www.researchgate.net

Structural diagram of spiral oil wedge sleeve bearing. Download Bearing Oil Wedge Locating and installing the cam bearing to take advantage of this hydrodynamic wedge will supply the maximum support for the camshaft during engine operation. An engine bearing is not designed to contact the crankshaft journals. Oil whirl is probably the most common cause of subsynchronous instability in hydrodynamic journal bearings. The wedge parameters are determined by the difference between the. Bearing Oil Wedge.

From bohong-bearing.en.made-in-china.com

Three Oil Wedge Dynamic Pressure Radial Thrust Sliding Bearings China Bearing Oil Wedge This difference is called oil. Oil whirl is probably the most common cause of subsynchronous instability in hydrodynamic journal bearings. The journals do not ride on the bearing surface: They ride on a “wedge” of. The oil wedge of a bearing with eccentricity is the same as the wedge formed by a bearing with an increased diameter (”effective bearing. Locating. Bearing Oil Wedge.

From substech.com

EccentriX™ Optimal Eccentricity for High Performance Bearings [SubsTech] Bearing Oil Wedge They ride on a “wedge” of. Typically, the oil film itself flows around the journal to lubricate. The wedge parameters are determined by the difference between the diameters. This difference is called oil. Locating and installing the cam bearing to take advantage of this hydrodynamic wedge will supply the maximum support for the camshaft during engine operation. This lubrication regime. Bearing Oil Wedge.

From pubs.sciepub.com

Figure 1. Hydrodynamic journal bearing Experimental Analysis of Oil Bearing Oil Wedge The wedge parameters are determined by the difference between the diameters. They ride on a “wedge” of. Locating and installing the cam bearing to take advantage of this hydrodynamic wedge will supply the maximum support for the camshaft during engine operation. Oil whirl is probably the most common cause of subsynchronous instability in hydrodynamic journal bearings. This difference is called. Bearing Oil Wedge.

From www.slideserve.com

PPT Hydrodynamic lubrication PowerPoint Presentation, free download Bearing Oil Wedge Locating and installing the cam bearing to take advantage of this hydrodynamic wedge will supply the maximum support for the camshaft during engine operation. The journals do not ride on the bearing surface: Typically, the oil film itself flows around the journal to lubricate. The wedge parameters are determined by the difference between the diameters. This wedge of oil lifts. Bearing Oil Wedge.

From www.youtube.com

Wedge Film Journal Bearings ‖ Sliding Contact Bearing YouTube Bearing Oil Wedge This wedge of oil lifts the shaft away from the bearing surface so there is little risk of asperity contact. Typically, the oil film itself flows around the journal to lubricate. This difference is called oil. Locating and installing the cam bearing to take advantage of this hydrodynamic wedge will supply the maximum support for the camshaft during engine operation.. Bearing Oil Wedge.

From power-mi.com

Troubleshooting of plain bearings PowerMI Bearing Oil Wedge The oil wedge of a bearing with eccentricity is the same as the wedge formed by a bearing with an increased diameter (”effective bearing. Oil whirl is probably the most common cause of subsynchronous instability in hydrodynamic journal bearings. The journals do not ride on the bearing surface: This lubrication regime condition occurs after a machine has begun to rotate. Bearing Oil Wedge.

From www.tomorrowstechnician.com

Engine Bearings Under Pressure Bearing Oil Wedge The wedge parameters are determined by the difference between the diameters. This wedge of oil lifts the shaft away from the bearing surface so there is little risk of asperity contact. An engine bearing is not designed to contact the crankshaft journals. The journals do not ride on the bearing surface: They ride on a “wedge” of. The oil wedge. Bearing Oil Wedge.

From bohong-bearing.en.made-in-china.com

Four Oil Wedge Dynamic Pressure Radial Thrust Sliding Bearings China Bearing Oil Wedge Typically, the oil film itself flows around the journal to lubricate. The wedge parameters are determined by the difference between the diameters. Oil whirl is probably the most common cause of subsynchronous instability in hydrodynamic journal bearings. Locating and installing the cam bearing to take advantage of this hydrodynamic wedge will supply the maximum support for the camshaft during engine. Bearing Oil Wedge.

From www.indiamart.com

Material Aluminium Oil Wedge Bearing at Rs 20000/piece in Howrah ID Bearing Oil Wedge This wedge of oil lifts the shaft away from the bearing surface so there is little risk of asperity contact. The journals do not ride on the bearing surface: The wedge parameters are determined by the difference between the diameters. This difference is called oil. The oil wedge of a bearing with eccentricity is the same as the wedge formed. Bearing Oil Wedge.

From www.mdpi.com

Lubricants Free FullText Effects of Wear on Lubrication Bearing Oil Wedge An engine bearing is not designed to contact the crankshaft journals. The wedge parameters are determined by the difference between the diameters. Typically, the oil film itself flows around the journal to lubricate. This lubrication regime condition occurs after a machine has begun to rotate and the speeds and loads are such that a wedge of oil has been formed. Bearing Oil Wedge.

From gbr.grandado.com

TD03/TD04 Turbo Thrust Bearing High Performance Positive oil wedge Bearing Oil Wedge An engine bearing is not designed to contact the crankshaft journals. This lubrication regime condition occurs after a machine has begun to rotate and the speeds and loads are such that a wedge of oil has been formed between the shaft and bearing surfaces. This wedge of oil lifts the shaft away from the bearing surface so there is little. Bearing Oil Wedge.

From ijinmarnie.blogspot.com

IJIN MARINE LIMITED Procedure for Cross Head Bearing Removal of Marine Bearing Oil Wedge Oil whirl is probably the most common cause of subsynchronous instability in hydrodynamic journal bearings. The wedge parameters are determined by the difference between the diameters. An engine bearing is not designed to contact the crankshaft journals. The oil wedge of a bearing with eccentricity is the same as the wedge formed by a bearing with an increased diameter (”effective. Bearing Oil Wedge.

From gbr.grandado.com

TD03/TD04 Turbo Thrust Bearing High Performance Po... Grandado Bearing Oil Wedge This lubrication regime condition occurs after a machine has begun to rotate and the speeds and loads are such that a wedge of oil has been formed between the shaft and bearing surfaces. Oil whirl is probably the most common cause of subsynchronous instability in hydrodynamic journal bearings. An engine bearing is not designed to contact the crankshaft journals. The. Bearing Oil Wedge.

From www.machinerylubrication.com

Journal Bearings and Their Lubrication Bearing Oil Wedge They ride on a “wedge” of. An engine bearing is not designed to contact the crankshaft journals. Typically, the oil film itself flows around the journal to lubricate. This difference is called oil. The wedge parameters are determined by the difference between the diameters. This wedge of oil lifts the shaft away from the bearing surface so there is little. Bearing Oil Wedge.