Welding Gas Temperature Chart . Choosing your welding gas primarily depends on the metal you weld. Understand the gas pressure settings for mig welding, helping you find the perfect flow rate for your welding application. There are also indicators that can help guide. Maybe when things are still, 5 cfm is enough to shield the. But as already discussed, you can also tailor the mixture to improve penetration and arc. Gas is metered in cubic feet per minute (cfm), and drafts, breezes, or cylinder temperatures affect the results. Therefore, the control of heat input is very important in welding in terms of quality control. There are several ways of calculating the.

from qaqctips.blogspot.com

Maybe when things are still, 5 cfm is enough to shield the. But as already discussed, you can also tailor the mixture to improve penetration and arc. Understand the gas pressure settings for mig welding, helping you find the perfect flow rate for your welding application. Therefore, the control of heat input is very important in welding in terms of quality control. There are several ways of calculating the. Gas is metered in cubic feet per minute (cfm), and drafts, breezes, or cylinder temperatures affect the results. There are also indicators that can help guide. Choosing your welding gas primarily depends on the metal you weld.

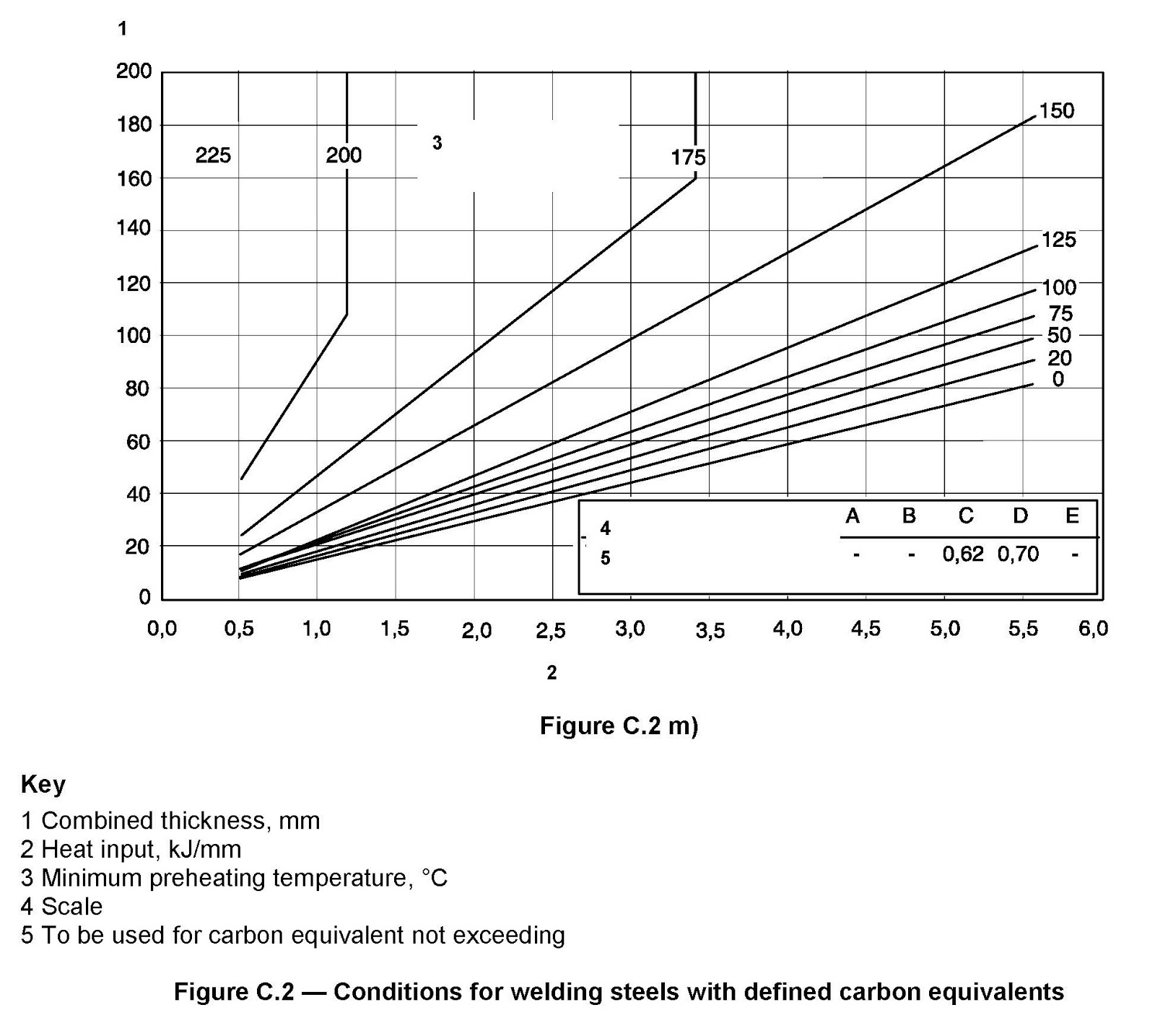

What is the preheat temperature for carbon steel as per BS EN 10112? QA/QC Tips & Guides

Welding Gas Temperature Chart Maybe when things are still, 5 cfm is enough to shield the. There are also indicators that can help guide. Gas is metered in cubic feet per minute (cfm), and drafts, breezes, or cylinder temperatures affect the results. There are several ways of calculating the. Understand the gas pressure settings for mig welding, helping you find the perfect flow rate for your welding application. Choosing your welding gas primarily depends on the metal you weld. Maybe when things are still, 5 cfm is enough to shield the. But as already discussed, you can also tailor the mixture to improve penetration and arc. Therefore, the control of heat input is very important in welding in terms of quality control.

From www.researchgate.net

Temperature field distribution 50 s after welding completion Download Scientific Diagram Welding Gas Temperature Chart Understand the gas pressure settings for mig welding, helping you find the perfect flow rate for your welding application. But as already discussed, you can also tailor the mixture to improve penetration and arc. Choosing your welding gas primarily depends on the metal you weld. Gas is metered in cubic feet per minute (cfm), and drafts, breezes, or cylinder temperatures. Welding Gas Temperature Chart.

From www.researchgate.net

Welding temperatures (maximum temperatures measured during the welding)... Download Scientific Welding Gas Temperature Chart Choosing your welding gas primarily depends on the metal you weld. Therefore, the control of heat input is very important in welding in terms of quality control. There are several ways of calculating the. There are also indicators that can help guide. Understand the gas pressure settings for mig welding, helping you find the perfect flow rate for your welding. Welding Gas Temperature Chart.

From www.researchgate.net

Temperature welding cycle for TIG welding with different preheating... Download Scientific Diagram Welding Gas Temperature Chart Understand the gas pressure settings for mig welding, helping you find the perfect flow rate for your welding application. But as already discussed, you can also tailor the mixture to improve penetration and arc. There are several ways of calculating the. Therefore, the control of heat input is very important in welding in terms of quality control. Choosing your welding. Welding Gas Temperature Chart.

From learnmechanical.com

Different Types of Gas Welding Flames Neutral, Carburizing, and Oxidizing [Notes with PDF Welding Gas Temperature Chart Gas is metered in cubic feet per minute (cfm), and drafts, breezes, or cylinder temperatures affect the results. There are also indicators that can help guide. Understand the gas pressure settings for mig welding, helping you find the perfect flow rate for your welding application. Choosing your welding gas primarily depends on the metal you weld. There are several ways. Welding Gas Temperature Chart.

From mungfali.com

Mig Welder Settings Explained (with Chart) Weld Guru A46 Welding Gas Temperature Chart There are several ways of calculating the. Understand the gas pressure settings for mig welding, helping you find the perfect flow rate for your welding application. Choosing your welding gas primarily depends on the metal you weld. Therefore, the control of heat input is very important in welding in terms of quality control. But as already discussed, you can also. Welding Gas Temperature Chart.

From vacaero.com

800°F, 840°F, 450°C Which temperature defines brazing? Welding Gas Temperature Chart But as already discussed, you can also tailor the mixture to improve penetration and arc. There are several ways of calculating the. Maybe when things are still, 5 cfm is enough to shield the. Gas is metered in cubic feet per minute (cfm), and drafts, breezes, or cylinder temperatures affect the results. Understand the gas pressure settings for mig welding,. Welding Gas Temperature Chart.

From blog.huntingdonfusion.com

Heat Tint Charts Huntingdon Fusion Techniques HFT Weld Purging Specialists Welding Gas Temperature Chart But as already discussed, you can also tailor the mixture to improve penetration and arc. Maybe when things are still, 5 cfm is enough to shield the. Understand the gas pressure settings for mig welding, helping you find the perfect flow rate for your welding application. Gas is metered in cubic feet per minute (cfm), and drafts, breezes, or cylinder. Welding Gas Temperature Chart.

From www.scribd.com

Welding Preheat Chart Welding Gas Temperature Chart Gas is metered in cubic feet per minute (cfm), and drafts, breezes, or cylinder temperatures affect the results. Maybe when things are still, 5 cfm is enough to shield the. Therefore, the control of heat input is very important in welding in terms of quality control. There are several ways of calculating the. Choosing your welding gas primarily depends on. Welding Gas Temperature Chart.

From digitaledition.industrialheating.com

Brazing vs Welding Welding Gas Temperature Chart But as already discussed, you can also tailor the mixture to improve penetration and arc. Understand the gas pressure settings for mig welding, helping you find the perfect flow rate for your welding application. There are also indicators that can help guide. Choosing your welding gas primarily depends on the metal you weld. Maybe when things are still, 5 cfm. Welding Gas Temperature Chart.

From www.damatech.com

Hardox Welding Damatech Welding Gas Temperature Chart Understand the gas pressure settings for mig welding, helping you find the perfect flow rate for your welding application. There are several ways of calculating the. Maybe when things are still, 5 cfm is enough to shield the. But as already discussed, you can also tailor the mixture to improve penetration and arc. Choosing your welding gas primarily depends on. Welding Gas Temperature Chart.

From joshuawest.z13.web.core.windows.net

Metal Temperature Color Chart Welding Gas Temperature Chart There are also indicators that can help guide. But as already discussed, you can also tailor the mixture to improve penetration and arc. There are several ways of calculating the. Choosing your welding gas primarily depends on the metal you weld. Therefore, the control of heat input is very important in welding in terms of quality control. Maybe when things. Welding Gas Temperature Chart.

From mavink.com

Stainless Steel Weld Color Chart Welding Gas Temperature Chart Gas is metered in cubic feet per minute (cfm), and drafts, breezes, or cylinder temperatures affect the results. There are also indicators that can help guide. Understand the gas pressure settings for mig welding, helping you find the perfect flow rate for your welding application. There are several ways of calculating the. Therefore, the control of heat input is very. Welding Gas Temperature Chart.

From weldingwet.netlify.app

Welding Rod Temperature Welding Gas Temperature Chart Understand the gas pressure settings for mig welding, helping you find the perfect flow rate for your welding application. Gas is metered in cubic feet per minute (cfm), and drafts, breezes, or cylinder temperatures affect the results. Choosing your welding gas primarily depends on the metal you weld. Maybe when things are still, 5 cfm is enough to shield the.. Welding Gas Temperature Chart.

From bakersgas.com

Electrode Amperage Chart Baker's Gas & Welding Supplies, Inc. Welding Gas Temperature Chart Choosing your welding gas primarily depends on the metal you weld. But as already discussed, you can also tailor the mixture to improve penetration and arc. Understand the gas pressure settings for mig welding, helping you find the perfect flow rate for your welding application. Gas is metered in cubic feet per minute (cfm), and drafts, breezes, or cylinder temperatures. Welding Gas Temperature Chart.

From weldingtrends.com

JB Weld Cure Time Vs Temperature JB Weld Dry Time Welding Gas Temperature Chart But as already discussed, you can also tailor the mixture to improve penetration and arc. Maybe when things are still, 5 cfm is enough to shield the. There are several ways of calculating the. Therefore, the control of heat input is very important in welding in terms of quality control. Understand the gas pressure settings for mig welding, helping you. Welding Gas Temperature Chart.

From www.scribd.com

Determination of the Preheating Temperature for High Welding Materials Science Welding Gas Temperature Chart Maybe when things are still, 5 cfm is enough to shield the. There are also indicators that can help guide. Gas is metered in cubic feet per minute (cfm), and drafts, breezes, or cylinder temperatures affect the results. But as already discussed, you can also tailor the mixture to improve penetration and arc. There are several ways of calculating the.. Welding Gas Temperature Chart.

From www.electronicshub.org

Welding Flame Types Choose the Right One for Your Project Welding Gas Temperature Chart There are also indicators that can help guide. Therefore, the control of heat input is very important in welding in terms of quality control. Gas is metered in cubic feet per minute (cfm), and drafts, breezes, or cylinder temperatures affect the results. Understand the gas pressure settings for mig welding, helping you find the perfect flow rate for your welding. Welding Gas Temperature Chart.

From www.pinterest.com

Welding rod chart, Welding rods, Welding and fabrication Welding Gas Temperature Chart Therefore, the control of heat input is very important in welding in terms of quality control. Understand the gas pressure settings for mig welding, helping you find the perfect flow rate for your welding application. There are also indicators that can help guide. Maybe when things are still, 5 cfm is enough to shield the. There are several ways of. Welding Gas Temperature Chart.

From saychrome.weebly.com

Temperature conversion chart saychrome Welding Gas Temperature Chart But as already discussed, you can also tailor the mixture to improve penetration and arc. Therefore, the control of heat input is very important in welding in terms of quality control. Maybe when things are still, 5 cfm is enough to shield the. Understand the gas pressure settings for mig welding, helping you find the perfect flow rate for your. Welding Gas Temperature Chart.

From roundrockweldingsupplyroundrocktdozoc.blogspot.com

Round Rock Welding Supply Round Rock T Tig Welding Temperature Chart Welding Gas Temperature Chart Therefore, the control of heat input is very important in welding in terms of quality control. Choosing your welding gas primarily depends on the metal you weld. But as already discussed, you can also tailor the mixture to improve penetration and arc. There are several ways of calculating the. Maybe when things are still, 5 cfm is enough to shield. Welding Gas Temperature Chart.

From qaqctips.blogspot.com

What is the preheat temperature for carbon steel as per BS EN 10112? QA/QC Tips & Guides Welding Gas Temperature Chart Understand the gas pressure settings for mig welding, helping you find the perfect flow rate for your welding application. Choosing your welding gas primarily depends on the metal you weld. But as already discussed, you can also tailor the mixture to improve penetration and arc. There are several ways of calculating the. Therefore, the control of heat input is very. Welding Gas Temperature Chart.

From www.mechanicalclasses.com

Types of gas welding flames MechanicalMaster Welding Gas Temperature Chart Gas is metered in cubic feet per minute (cfm), and drafts, breezes, or cylinder temperatures affect the results. But as already discussed, you can also tailor the mixture to improve penetration and arc. Understand the gas pressure settings for mig welding, helping you find the perfect flow rate for your welding application. Maybe when things are still, 5 cfm is. Welding Gas Temperature Chart.

From pt.scribd.com

Preheat Temperature Table For Different Materials in Welding Steel Transition Metals Welding Gas Temperature Chart Choosing your welding gas primarily depends on the metal you weld. But as already discussed, you can also tailor the mixture to improve penetration and arc. There are also indicators that can help guide. Maybe when things are still, 5 cfm is enough to shield the. Understand the gas pressure settings for mig welding, helping you find the perfect flow. Welding Gas Temperature Chart.

From mavink.com

Welding Chart For Mig Welding Welding Gas Temperature Chart But as already discussed, you can also tailor the mixture to improve penetration and arc. Maybe when things are still, 5 cfm is enough to shield the. Gas is metered in cubic feet per minute (cfm), and drafts, breezes, or cylinder temperatures affect the results. There are several ways of calculating the. Choosing your welding gas primarily depends on the. Welding Gas Temperature Chart.

From www.inspiredtaste.net

Oven Temperature Conversion Fahrenheit & Celsius Welding Gas Temperature Chart Choosing your welding gas primarily depends on the metal you weld. Understand the gas pressure settings for mig welding, helping you find the perfect flow rate for your welding application. Therefore, the control of heat input is very important in welding in terms of quality control. There are several ways of calculating the. There are also indicators that can help. Welding Gas Temperature Chart.

From www.researchgate.net

Temperature distribution during welding process at different times Download Scientific Diagram Welding Gas Temperature Chart But as already discussed, you can also tailor the mixture to improve penetration and arc. There are also indicators that can help guide. Gas is metered in cubic feet per minute (cfm), and drafts, breezes, or cylinder temperatures affect the results. Understand the gas pressure settings for mig welding, helping you find the perfect flow rate for your welding application.. Welding Gas Temperature Chart.

From orbi-tech.de

Welding temperatures OrbiTech Welding Gas Temperature Chart Therefore, the control of heat input is very important in welding in terms of quality control. Understand the gas pressure settings for mig welding, helping you find the perfect flow rate for your welding application. There are also indicators that can help guide. Gas is metered in cubic feet per minute (cfm), and drafts, breezes, or cylinder temperatures affect the. Welding Gas Temperature Chart.

From roundrockweldingsupplyroundrocktdozoc.blogspot.com

Round Rock Welding Supply Round Rock T Tig Welding Temperature Chart Welding Gas Temperature Chart Choosing your welding gas primarily depends on the metal you weld. But as already discussed, you can also tailor the mixture to improve penetration and arc. Gas is metered in cubic feet per minute (cfm), and drafts, breezes, or cylinder temperatures affect the results. There are also indicators that can help guide. Therefore, the control of heat input is very. Welding Gas Temperature Chart.

From weldguru.com

How to Weld Stainless Steel A Complete Guide Welding Gas Temperature Chart Maybe when things are still, 5 cfm is enough to shield the. Gas is metered in cubic feet per minute (cfm), and drafts, breezes, or cylinder temperatures affect the results. Understand the gas pressure settings for mig welding, helping you find the perfect flow rate for your welding application. But as already discussed, you can also tailor the mixture to. Welding Gas Temperature Chart.

From ilmoproducts.com

TIG Welding Charts ILMO Products Company Welding Gas Temperature Chart Gas is metered in cubic feet per minute (cfm), and drafts, breezes, or cylinder temperatures affect the results. Therefore, the control of heat input is very important in welding in terms of quality control. But as already discussed, you can also tailor the mixture to improve penetration and arc. Understand the gas pressure settings for mig welding, helping you find. Welding Gas Temperature Chart.

From www.myxxgirl.com

Mig Welding Temperature Chart My XXX Hot Girl Welding Gas Temperature Chart There are several ways of calculating the. There are also indicators that can help guide. Choosing your welding gas primarily depends on the metal you weld. But as already discussed, you can also tailor the mixture to improve penetration and arc. Maybe when things are still, 5 cfm is enough to shield the. Gas is metered in cubic feet per. Welding Gas Temperature Chart.

From www.researchgate.net

Temperatures of welding processes performed at the speed of 40 and 70... Download Scientific Welding Gas Temperature Chart But as already discussed, you can also tailor the mixture to improve penetration and arc. There are also indicators that can help guide. Understand the gas pressure settings for mig welding, helping you find the perfect flow rate for your welding application. Choosing your welding gas primarily depends on the metal you weld. Gas is metered in cubic feet per. Welding Gas Temperature Chart.

From www.pinterest.com.au

Search Results temperature Contenti Metal working, Welding, Welding and fabrication Welding Gas Temperature Chart There are several ways of calculating the. But as already discussed, you can also tailor the mixture to improve penetration and arc. There are also indicators that can help guide. Gas is metered in cubic feet per minute (cfm), and drafts, breezes, or cylinder temperatures affect the results. Understand the gas pressure settings for mig welding, helping you find the. Welding Gas Temperature Chart.

From www.youtube.com

PREHEAT TEMPERATURE MEASUREMENTS IN WELDING WHERE & WHEN TO MEASURE ? YouTube Welding Gas Temperature Chart Understand the gas pressure settings for mig welding, helping you find the perfect flow rate for your welding application. But as already discussed, you can also tailor the mixture to improve penetration and arc. Gas is metered in cubic feet per minute (cfm), and drafts, breezes, or cylinder temperatures affect the results. There are also indicators that can help guide.. Welding Gas Temperature Chart.

From www.pinterest.com

Steel temperature chart Metal working, Blacksmithing, metal Welding Gas Temperature Chart Therefore, the control of heat input is very important in welding in terms of quality control. But as already discussed, you can also tailor the mixture to improve penetration and arc. Understand the gas pressure settings for mig welding, helping you find the perfect flow rate for your welding application. There are several ways of calculating the. Choosing your welding. Welding Gas Temperature Chart.